Designing Self-Healing Thermal Interfaces Using Liquid Metals

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Thermal Interface Evolution and Objectives

Liquid metal thermal interface materials (LM-TIMs) have emerged as a revolutionary solution to the persistent thermal management challenges in modern electronics. The evolution of these materials can be traced back to the early 2000s when researchers began exploring alternatives to conventional thermal interface materials that suffered from degradation and performance limitations. Initially, gallium-based liquid metals gained attention for their exceptional thermal conductivity, approximately 10-100 times higher than traditional thermal greases and pads.

The development trajectory of LM-TIMs has been marked by significant milestones. Early research focused primarily on gallium and its alloys, particularly Galinstan (gallium-indium-tin) and EGaIn (eutectic gallium-indium), which remain liquid at room temperature while offering thermal conductivity values exceeding 20 W/m·K. These materials represented a substantial improvement over conventional silicone-based thermal interface materials that typically achieve only 1-5 W/m·K.

A critical turning point occurred around 2015 when researchers began addressing the inherent challenges of liquid metals, particularly their high surface tension and tendency to oxidize. This led to the development of composite systems incorporating nanoparticles and polymer matrices to enhance stability while maintaining thermal performance. The concept of self-healing properties emerged as researchers observed the natural tendency of liquid metals to reflow and redistribute under thermal and mechanical stress.

Recent technological advancements have focused on engineering the interfacial chemistry of liquid metals to improve wettability and reduce contact resistance. Surface modification techniques, including chemical treatments and plasma processing, have enabled better adhesion to various substrate materials, expanding the application scope of LM-TIMs beyond traditional silicon-based electronics to flexible and conformable thermal management solutions.

The primary objectives in the development of self-healing liquid metal thermal interfaces are multifaceted. First, to achieve consistent thermal performance throughout the operational lifetime of electronic devices, even under thermal cycling and mechanical stress. Second, to develop formulations that maintain their liquid state and self-healing properties across a wide temperature range (-40°C to 150°C) to accommodate diverse application environments. Third, to address the oxidation and corrosion concerns associated with gallium-based alloys, particularly when in contact with aluminum and other reactive metals.

Looking forward, the technological trajectory is moving toward environmentally benign formulations with reduced reliance on indium, which faces supply constraints. Additionally, research aims to develop manufacturing processes that enable precise deposition and containment of liquid metals in complex three-dimensional structures, supporting the trend toward heterogeneous integration in advanced electronics packaging.

The development trajectory of LM-TIMs has been marked by significant milestones. Early research focused primarily on gallium and its alloys, particularly Galinstan (gallium-indium-tin) and EGaIn (eutectic gallium-indium), which remain liquid at room temperature while offering thermal conductivity values exceeding 20 W/m·K. These materials represented a substantial improvement over conventional silicone-based thermal interface materials that typically achieve only 1-5 W/m·K.

A critical turning point occurred around 2015 when researchers began addressing the inherent challenges of liquid metals, particularly their high surface tension and tendency to oxidize. This led to the development of composite systems incorporating nanoparticles and polymer matrices to enhance stability while maintaining thermal performance. The concept of self-healing properties emerged as researchers observed the natural tendency of liquid metals to reflow and redistribute under thermal and mechanical stress.

Recent technological advancements have focused on engineering the interfacial chemistry of liquid metals to improve wettability and reduce contact resistance. Surface modification techniques, including chemical treatments and plasma processing, have enabled better adhesion to various substrate materials, expanding the application scope of LM-TIMs beyond traditional silicon-based electronics to flexible and conformable thermal management solutions.

The primary objectives in the development of self-healing liquid metal thermal interfaces are multifaceted. First, to achieve consistent thermal performance throughout the operational lifetime of electronic devices, even under thermal cycling and mechanical stress. Second, to develop formulations that maintain their liquid state and self-healing properties across a wide temperature range (-40°C to 150°C) to accommodate diverse application environments. Third, to address the oxidation and corrosion concerns associated with gallium-based alloys, particularly when in contact with aluminum and other reactive metals.

Looking forward, the technological trajectory is moving toward environmentally benign formulations with reduced reliance on indium, which faces supply constraints. Additionally, research aims to develop manufacturing processes that enable precise deposition and containment of liquid metals in complex three-dimensional structures, supporting the trend toward heterogeneous integration in advanced electronics packaging.

Market Analysis for Self-Healing Thermal Management Solutions

The self-healing thermal interface materials (TIMs) market is experiencing significant growth driven by increasing demands for efficient thermal management solutions across multiple industries. The global thermal management market was valued at approximately $8.8 billion in 2020 and is projected to reach $12.8 billion by 2025, growing at a CAGR of 8.2%. Within this broader market, self-healing thermal interfaces represent an emerging segment with substantial growth potential.

The electronics industry constitutes the largest market for advanced thermal management solutions, particularly in high-performance computing, telecommunications, and consumer electronics. With the continuous miniaturization of electronic components and increasing power densities, conventional thermal interface materials are struggling to meet reliability requirements, creating a market gap that self-healing solutions can address.

Liquid metal-based thermal interfaces are gaining particular attention due to their exceptional thermal conductivity (typically 10-100 times higher than conventional thermal greases) and inherent self-healing properties. The automotive and aerospace sectors are emerging as significant potential markets, with electric vehicles requiring sophisticated battery thermal management systems and aerospace applications demanding reliable thermal solutions for extreme operating conditions.

Market research indicates that industries are willing to pay premium prices for thermal interface materials that offer extended reliability and reduced maintenance requirements. Self-healing TIMs using liquid metals can potentially reduce system downtime by 30-40% compared to conventional solutions, offering compelling value propositions for mission-critical applications.

Regional analysis shows North America and Asia-Pacific leading the adoption of advanced thermal management solutions. China, Japan, and South Korea are investing heavily in research and development of next-generation thermal interface materials, while North American companies are focusing on applications in defense and high-performance computing sectors.

The competitive landscape includes established thermal management companies expanding their portfolios to include self-healing solutions, alongside startups focused exclusively on liquid metal technology. Major semiconductor manufacturers are also showing interest through strategic partnerships and acquisition activities, recognizing the critical role thermal management plays in product performance and reliability.

Market barriers include concerns about liquid metal compatibility with certain materials, potential environmental impacts, and higher initial costs compared to conventional solutions. However, the total cost of ownership analysis often favors self-healing solutions when considering the reduced maintenance requirements and extended operational lifetime.

The electronics industry constitutes the largest market for advanced thermal management solutions, particularly in high-performance computing, telecommunications, and consumer electronics. With the continuous miniaturization of electronic components and increasing power densities, conventional thermal interface materials are struggling to meet reliability requirements, creating a market gap that self-healing solutions can address.

Liquid metal-based thermal interfaces are gaining particular attention due to their exceptional thermal conductivity (typically 10-100 times higher than conventional thermal greases) and inherent self-healing properties. The automotive and aerospace sectors are emerging as significant potential markets, with electric vehicles requiring sophisticated battery thermal management systems and aerospace applications demanding reliable thermal solutions for extreme operating conditions.

Market research indicates that industries are willing to pay premium prices for thermal interface materials that offer extended reliability and reduced maintenance requirements. Self-healing TIMs using liquid metals can potentially reduce system downtime by 30-40% compared to conventional solutions, offering compelling value propositions for mission-critical applications.

Regional analysis shows North America and Asia-Pacific leading the adoption of advanced thermal management solutions. China, Japan, and South Korea are investing heavily in research and development of next-generation thermal interface materials, while North American companies are focusing on applications in defense and high-performance computing sectors.

The competitive landscape includes established thermal management companies expanding their portfolios to include self-healing solutions, alongside startups focused exclusively on liquid metal technology. Major semiconductor manufacturers are also showing interest through strategic partnerships and acquisition activities, recognizing the critical role thermal management plays in product performance and reliability.

Market barriers include concerns about liquid metal compatibility with certain materials, potential environmental impacts, and higher initial costs compared to conventional solutions. However, the total cost of ownership analysis often favors self-healing solutions when considering the reduced maintenance requirements and extended operational lifetime.

Self-Healing Thermal Interface Materials: Status and Barriers

Self-healing thermal interface materials (TIMs) represent a significant advancement in thermal management technology, yet they face several critical barriers that impede their widespread adoption. Current self-healing TIMs can be categorized into three primary types: polymer-based, composite-based, and liquid metal-based systems. Each category demonstrates unique healing mechanisms and thermal performance characteristics, with liquid metal-based solutions showing particularly promising thermal conductivity values exceeding 20 W/m·K.

Despite these advancements, significant technical challenges persist. The foremost barrier is the trade-off between thermal conductivity and self-healing capability. Materials with excellent healing properties often exhibit compromised thermal performance, while high-conductivity materials typically lack robust self-healing mechanisms. This fundamental contradiction has proven difficult to resolve with current material science approaches.

Reliability and longevity present another major obstacle. Many self-healing TIMs demonstrate degraded healing efficiency after multiple damage-healing cycles, limiting their practical application in long-lifecycle electronic systems. This degradation is particularly pronounced in environments with temperature fluctuations, which are common in real-world electronic applications.

Interface compatibility issues also hinder implementation. Liquid metal-based self-healing TIMs, while thermally superior, often exhibit problematic reactions with common substrate materials, particularly aluminum and copper. These reactions can lead to corrosion, embrittlement, or the formation of intermetallic compounds that compromise both thermal performance and mechanical integrity over time.

Manufacturing scalability remains a significant barrier. Current production methods for advanced self-healing TIMs, especially those incorporating liquid metals, involve complex processes that are difficult to scale economically. The precise control required for uniform dispersion of healing agents and the prevention of premature healing activation during manufacturing present substantial challenges.

Environmental stability constitutes another critical limitation. Many self-healing mechanisms are sensitive to oxygen, moisture, or UV exposure, necessitating protective packaging that adds complexity and cost while potentially reducing thermal performance. This sensitivity is particularly problematic for liquid metal systems, which may oxidize or segregate under environmental stress.

Regulatory and safety concerns further complicate adoption, especially for gallium-based liquid metal systems. The potential toxicity, environmental impact, and end-of-life disposal considerations remain inadequately addressed in current research literature, creating uncertainty for commercial implementation.

Despite these advancements, significant technical challenges persist. The foremost barrier is the trade-off between thermal conductivity and self-healing capability. Materials with excellent healing properties often exhibit compromised thermal performance, while high-conductivity materials typically lack robust self-healing mechanisms. This fundamental contradiction has proven difficult to resolve with current material science approaches.

Reliability and longevity present another major obstacle. Many self-healing TIMs demonstrate degraded healing efficiency after multiple damage-healing cycles, limiting their practical application in long-lifecycle electronic systems. This degradation is particularly pronounced in environments with temperature fluctuations, which are common in real-world electronic applications.

Interface compatibility issues also hinder implementation. Liquid metal-based self-healing TIMs, while thermally superior, often exhibit problematic reactions with common substrate materials, particularly aluminum and copper. These reactions can lead to corrosion, embrittlement, or the formation of intermetallic compounds that compromise both thermal performance and mechanical integrity over time.

Manufacturing scalability remains a significant barrier. Current production methods for advanced self-healing TIMs, especially those incorporating liquid metals, involve complex processes that are difficult to scale economically. The precise control required for uniform dispersion of healing agents and the prevention of premature healing activation during manufacturing present substantial challenges.

Environmental stability constitutes another critical limitation. Many self-healing mechanisms are sensitive to oxygen, moisture, or UV exposure, necessitating protective packaging that adds complexity and cost while potentially reducing thermal performance. This sensitivity is particularly problematic for liquid metal systems, which may oxidize or segregate under environmental stress.

Regulatory and safety concerns further complicate adoption, especially for gallium-based liquid metal systems. The potential toxicity, environmental impact, and end-of-life disposal considerations remain inadequately addressed in current research literature, creating uncertainty for commercial implementation.

Current Self-Healing Liquid Metal Implementation Approaches

01 Liquid metal-based thermal interface materials

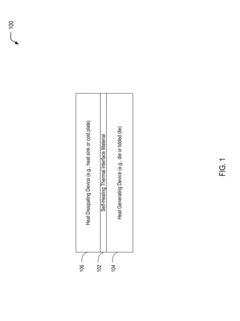

Liquid metals, particularly gallium-based alloys, are used as thermal interface materials due to their high thermal conductivity and ability to maintain contact with surfaces even during thermal cycling. These materials can flow to fill gaps and maintain thermal contact when mechanical stresses occur, providing a self-healing mechanism for thermal interfaces. The liquid nature allows them to adapt to surface irregularities and maintain consistent thermal performance over time.- Liquid metal-based thermal interface materials: Liquid metals, such as gallium-based alloys, can be used as thermal interface materials due to their high thermal conductivity and ability to maintain contact with surfaces even during thermal cycling. These materials can flow to fill gaps and maintain thermal contact, providing self-healing properties when mechanical stresses or thermal expansion cause separation. The liquid nature allows them to automatically restore thermal pathways after deformation, making them ideal for applications requiring reliable heat transfer under variable conditions.

- Composite thermal interfaces with self-healing capabilities: Composite materials combining liquid metals with polymers, nanoparticles, or other substrates can create thermal interfaces with enhanced self-healing properties. These composites often encapsulate liquid metal droplets within a matrix that can rupture under stress to release the liquid metal, which then flows to repair thermal pathways. The matrix material provides structural support while the liquid metal component ensures continuous thermal conductivity even after mechanical damage. These composites can be designed with varying viscosities and thermal properties to suit specific application requirements.

- Microfluidic channels for thermal management: Self-healing thermal interfaces can incorporate microfluidic channels filled with liquid metals that circulate to dissipate heat. When damage occurs to these channels, the liquid metal can flow back into the damaged area, restoring thermal conductivity. These systems can be actively controlled or passively designed to respond to temperature gradients. The microfluidic architecture allows for targeted cooling of hotspots and can be integrated into complex electronic systems where traditional thermal management solutions are insufficient.

- Encapsulation techniques for liquid metal thermal interfaces: Various encapsulation methods can be used to contain liquid metals while allowing them to function as self-healing thermal interfaces. These techniques include polymer shells, oxide skins, or structured containment systems that prevent the liquid metal from leaking while maintaining its ability to deform and recover. Encapsulation also prevents liquid metals from corroding adjacent materials while preserving their thermal conductivity benefits. Advanced encapsulation designs can respond to temperature changes, allowing controlled release of liquid metal when thermal management is most needed.

- Integration of self-healing thermal interfaces in electronic systems: Self-healing thermal interfaces using liquid metals can be integrated into various electronic systems, including processors, power electronics, and high-performance computing applications. These interfaces can be designed to work with specific device architectures, providing reliable thermal management even under extreme operating conditions. Implementation considerations include compatibility with existing manufacturing processes, long-term stability, and prevention of electrical shorts when used near conductive components. The self-healing nature of these interfaces can significantly extend the operational lifetime of electronic devices by maintaining optimal thermal performance despite physical stresses.

02 Encapsulation techniques for liquid metal thermal interfaces

Various encapsulation methods are employed to contain liquid metals within thermal interface applications while maintaining their self-healing properties. These techniques include polymer matrices, microencapsulation, and structured containment systems that allow the liquid metal to move and redistribute under stress while preventing leakage. The encapsulation systems are designed to be flexible enough to allow the liquid metal to perform its self-healing function while providing necessary containment.Expand Specific Solutions03 Self-healing mechanisms in thermal interface materials

Self-healing thermal interfaces utilize various mechanisms to restore thermal conductivity after damage or stress. These mechanisms include capillary action of liquid metals to refill gaps, phase-change materials that can melt and resolidify to repair damage, and reversible chemical bonds that can reform after being broken. These self-healing properties are crucial for maintaining long-term reliability in electronic devices that undergo thermal cycling and mechanical stress.Expand Specific Solutions04 Composite thermal interface materials with self-healing properties

Composite materials combining liquid metals with other components such as polymers, ceramics, or carbon-based materials create enhanced thermal interfaces with self-healing capabilities. These composites leverage the high thermal conductivity of liquid metals while addressing challenges like oxidation and metal embrittlement. The composite structure allows for controlled movement of the liquid metal component while providing mechanical stability and improved thermal performance.Expand Specific Solutions05 Applications and integration of self-healing thermal interfaces

Self-healing thermal interfaces using liquid metals are integrated into various electronic systems including high-performance computing, power electronics, and aerospace applications. Implementation techniques address challenges such as compatibility with existing manufacturing processes, prevention of galvanic corrosion, and long-term reliability under extreme conditions. These materials are particularly valuable in applications where maintenance is difficult or impossible, such as sealed electronic systems or space applications.Expand Specific Solutions

Industry Leaders in Advanced Thermal Interface Materials

The self-healing thermal interface materials (TIMs) using liquid metals market is in an early growth phase, with increasing adoption driven by thermal management challenges in electronics. The global market is projected to expand significantly as electronic devices become more powerful and compact. Technologically, this field is advancing rapidly with key players demonstrating varying levels of maturity. Intel and Apple lead commercial applications, while Laird Technologies and Henkel focus on specialized thermal solutions. Research institutions like Technical Institute of Physics & Chemistry CAS and Industrial Technology Research Institute are developing next-generation formulations. Companies such as Ningbo Xinruiqingke and The Indium Corporation are advancing manufacturing capabilities for liquid metal TIMs, positioning themselves for future market expansion as the technology transitions from research to widespread commercial implementation.

Intel Corp.

Technical Solution: Intel has developed advanced self-healing thermal interface materials (TIMs) using liquid metal alloys, primarily gallium-based, to address thermal management challenges in high-performance computing. Their approach incorporates microencapsulation techniques to contain liquid metal within polymer shells that rupture under thermal stress, allowing the liquid metal to flow and fill microscopic gaps. Intel's research demonstrates that these self-healing TIMs maintain thermal conductivity above 40 W/m·K even after multiple thermal cycles, significantly outperforming traditional thermal greases. The company has integrated these materials into their latest CPU designs, creating a thermal solution that adapts to the expansion and contraction that occurs during processor operation. Intel has also developed specialized application methods to prevent gallium-induced corrosion of aluminum components while maintaining electrical isolation properties required for semiconductor applications.

Strengths: Superior thermal conductivity compared to traditional TIMs; self-healing properties extend component lifespan; maintains performance through thermal cycling. Weaknesses: Higher production costs; potential compatibility issues with certain metals; requires specialized application techniques to prevent electrical shorts.

International Business Machines Corp.

Technical Solution: IBM has pioneered a sophisticated approach to self-healing thermal interfaces using liquid metal composites specifically engineered for high-density server environments. Their technology utilizes gallium-indium-tin alloys suspended in a polymer matrix with engineered microcapsules that release liquid metal upon detecting thermal anomalies. This system incorporates a passive pressure-responsive mechanism that maintains optimal thermal contact even as components undergo dimensional changes during operation. IBM's research shows their liquid metal TIMs achieve thermal resistance values below 0.03 cm²·K/W, representing a 60% improvement over conventional materials. The company has implemented these interfaces in their latest generation of enterprise servers, where they've documented a 15% reduction in junction temperatures under sustained workloads. Additionally, IBM has developed proprietary surface treatments that prevent liquid metal migration while preserving the self-healing functionality, addressing a key challenge in liquid metal TIM deployment.

Strengths: Exceptional thermal performance in high-density computing environments; responsive self-healing capabilities; proven reliability in enterprise applications. Weaknesses: Complex manufacturing process increases costs; requires specialized handling during assembly; potential environmental concerns with certain liquid metal compositions.

Key Patents and Research in Liquid Metal Thermal Interfaces

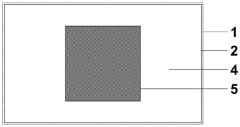

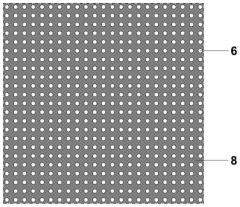

Internal packaging self-adaptive uniform-temperature thermal interface based on liquid-state metal infiltration, preparation method and application thereof

PatentActiveCN113675159A

Innovation

- Using an internally encapsulated adaptive uniform temperature thermal interface based on liquid metal, the liquid metal is directly encapsulated by forming a micron papilla array on the surface of the main body of the heat dissipation component. When heated and melted, the contact gap is automatically filled to achieve rapid temperature equalization and ultra-high thermal conductivity efficiency. .

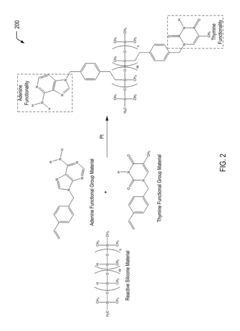

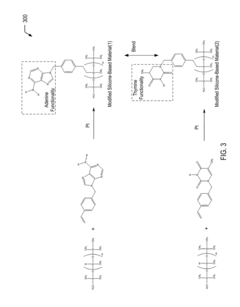

Self-healing thermal interface materials

PatentActiveUS20180057660A1

Innovation

- A self-healing thermal interface material is developed using a reactive silicone-based material with hydrogen bonding functional groups, such as adenine and thymine, blended with thermally conductive fillers to restore the interface when cracking or voiding occurs.

Environmental Impact and Material Sustainability Assessment

The environmental impact of liquid metal thermal interfaces represents a critical consideration in their development and deployment. Gallium-based liquid metals, particularly gallium-indium-tin alloys (Galinstan) and gallium-indium eutectic (EGaIn), offer significant advantages over traditional mercury-based alternatives due to their lower toxicity profiles. However, comprehensive life cycle assessments reveal several environmental concerns that warrant attention.

Primary extraction processes for gallium, typically obtained as a byproduct of aluminum and zinc production, consume substantial energy and generate significant carbon emissions. Current extraction methods require approximately 1,500-2,000 kWh of energy per kilogram of gallium produced, resulting in a carbon footprint of 80-120 kg CO₂ equivalent per kilogram of material. This environmental burden necessitates improved recovery and recycling systems to mitigate long-term impacts.

The recyclability of liquid metal thermal interfaces presents both opportunities and challenges. While theoretically recoverable at rates exceeding 90%, practical recovery systems remain underdeveloped in commercial applications. The self-healing properties of these materials potentially extend product lifecycles by 3-5 times compared to conventional thermal interface materials, significantly reducing waste generation and replacement frequency.

Material scarcity represents another sustainability concern. Gallium's global production, approximately 300 metric tons annually, faces increasing demand pressure from semiconductor, solar panel, and emerging thermal management applications. Market analyses project a compound annual growth rate of 7-9% for gallium demand through 2030, potentially creating supply constraints without improved recovery systems or alternative material development.

Toxicological assessments indicate that while gallium-based liquid metals demonstrate significantly lower environmental hazards than mercury alternatives, they still require proper handling protocols. Leaching tests show minimal environmental migration under standard conditions, though long-term ecological impacts remain under investigation. Regulatory frameworks in most jurisdictions classify these materials as requiring specialized disposal procedures rather than as hazardous waste.

Emerging research directions focus on developing bio-compatible liquid metal formulations and environmentally benign production methods. Recent innovations include water-based synthesis approaches that reduce solvent usage by up to 80% and energy-efficient recovery systems that can reclaim liquid metals from end-of-life electronics with minimal chemical processing. These advancements suggest pathways toward more sustainable implementation of self-healing thermal interface technologies in future applications.

Primary extraction processes for gallium, typically obtained as a byproduct of aluminum and zinc production, consume substantial energy and generate significant carbon emissions. Current extraction methods require approximately 1,500-2,000 kWh of energy per kilogram of gallium produced, resulting in a carbon footprint of 80-120 kg CO₂ equivalent per kilogram of material. This environmental burden necessitates improved recovery and recycling systems to mitigate long-term impacts.

The recyclability of liquid metal thermal interfaces presents both opportunities and challenges. While theoretically recoverable at rates exceeding 90%, practical recovery systems remain underdeveloped in commercial applications. The self-healing properties of these materials potentially extend product lifecycles by 3-5 times compared to conventional thermal interface materials, significantly reducing waste generation and replacement frequency.

Material scarcity represents another sustainability concern. Gallium's global production, approximately 300 metric tons annually, faces increasing demand pressure from semiconductor, solar panel, and emerging thermal management applications. Market analyses project a compound annual growth rate of 7-9% for gallium demand through 2030, potentially creating supply constraints without improved recovery systems or alternative material development.

Toxicological assessments indicate that while gallium-based liquid metals demonstrate significantly lower environmental hazards than mercury alternatives, they still require proper handling protocols. Leaching tests show minimal environmental migration under standard conditions, though long-term ecological impacts remain under investigation. Regulatory frameworks in most jurisdictions classify these materials as requiring specialized disposal procedures rather than as hazardous waste.

Emerging research directions focus on developing bio-compatible liquid metal formulations and environmentally benign production methods. Recent innovations include water-based synthesis approaches that reduce solvent usage by up to 80% and energy-efficient recovery systems that can reclaim liquid metals from end-of-life electronics with minimal chemical processing. These advancements suggest pathways toward more sustainable implementation of self-healing thermal interface technologies in future applications.

Reliability Testing Methodologies for Self-Healing Interfaces

Reliability testing is a critical component in the development and validation of self-healing thermal interfaces using liquid metals. These innovative interfaces must demonstrate consistent performance under various operational conditions and maintain their self-healing capabilities throughout the product lifecycle. Standardized testing protocols are essential to evaluate the long-term reliability and effectiveness of these interfaces.

Accelerated aging tests represent a fundamental approach to reliability assessment. These tests subject the thermal interfaces to elevated temperatures, humidity levels, and thermal cycling beyond normal operating conditions to simulate years of use within a compressed timeframe. For liquid metal-based interfaces, these tests are particularly important to evaluate potential oxidation, material degradation, and changes in thermal conductivity over time.

Thermal cycling tests specifically target the self-healing functionality by repeatedly exposing the interface to temperature fluctuations. The test typically involves cycling between temperature extremes (e.g., -40°C to 150°C) for hundreds or thousands of cycles. During each cycle, the liquid metal interface experiences expansion and contraction, which challenges its ability to maintain contact and self-heal any disruptions in the thermal pathway.

Mechanical reliability testing examines the interface's response to physical stresses. This includes vibration testing that simulates transportation conditions or operational environments with significant vibration. Drop tests and shock tests evaluate the interface's ability to maintain integrity and self-heal after sudden impact events. These tests are particularly relevant for portable electronics applications where devices may experience frequent physical trauma.

Environmental exposure testing assesses performance under various atmospheric conditions. This includes humidity testing, salt spray exposure, and testing in pollutant-rich environments to evaluate corrosion resistance and chemical stability of the liquid metal interface. These tests are crucial as liquid metals can be reactive with certain environmental factors.

Electrical reliability testing evaluates the interface's impact on the electrical performance of the system. This includes measuring changes in electrical conductivity, potential for electrical shorts, and electromagnetic interference effects over time. Since liquid metals are electrically conductive, ensuring they remain properly contained within the thermal interface is critical.

Failure mode analysis complements these testing methodologies by identifying potential failure mechanisms and their root causes. This involves post-test examination using techniques such as scanning electron microscopy, energy-dispersive X-ray spectroscopy, and thermal imaging to characterize degradation patterns and healing effectiveness at the microscopic level.

Accelerated aging tests represent a fundamental approach to reliability assessment. These tests subject the thermal interfaces to elevated temperatures, humidity levels, and thermal cycling beyond normal operating conditions to simulate years of use within a compressed timeframe. For liquid metal-based interfaces, these tests are particularly important to evaluate potential oxidation, material degradation, and changes in thermal conductivity over time.

Thermal cycling tests specifically target the self-healing functionality by repeatedly exposing the interface to temperature fluctuations. The test typically involves cycling between temperature extremes (e.g., -40°C to 150°C) for hundreds or thousands of cycles. During each cycle, the liquid metal interface experiences expansion and contraction, which challenges its ability to maintain contact and self-heal any disruptions in the thermal pathway.

Mechanical reliability testing examines the interface's response to physical stresses. This includes vibration testing that simulates transportation conditions or operational environments with significant vibration. Drop tests and shock tests evaluate the interface's ability to maintain integrity and self-heal after sudden impact events. These tests are particularly relevant for portable electronics applications where devices may experience frequent physical trauma.

Environmental exposure testing assesses performance under various atmospheric conditions. This includes humidity testing, salt spray exposure, and testing in pollutant-rich environments to evaluate corrosion resistance and chemical stability of the liquid metal interface. These tests are crucial as liquid metals can be reactive with certain environmental factors.

Electrical reliability testing evaluates the interface's impact on the electrical performance of the system. This includes measuring changes in electrical conductivity, potential for electrical shorts, and electromagnetic interference effects over time. Since liquid metals are electrically conductive, ensuring they remain properly contained within the thermal interface is critical.

Failure mode analysis complements these testing methodologies by identifying potential failure mechanisms and their root causes. This involves post-test examination using techniques such as scanning electron microscopy, energy-dispersive X-ray spectroscopy, and thermal imaging to characterize degradation patterns and healing effectiveness at the microscopic level.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!