Microchannel Liquid Metal Heat Spreaders: Fabrication And Performance

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Heat Spreader Technology Background and Objectives

Liquid metal heat spreaders represent a significant advancement in thermal management technology, evolving from traditional copper and aluminum heat dissipation solutions. The development of these innovative thermal management devices began in the early 2000s, with research intensifying over the past decade as electronic components have become increasingly powerful and compact, generating unprecedented thermal challenges.

The evolution of liquid metal heat spreaders has been marked by several key milestones. Initially, mercury was considered for its excellent thermal conductivity, but its toxicity prompted researchers to explore safer alternatives such as gallium-based alloys. Gallium and its alloys (particularly Ga-In-Sn eutectic alloys) have emerged as the primary materials of choice due to their low melting points, high thermal conductivity, and relatively low toxicity compared to mercury.

Microchannel architectures represent the latest advancement in this field, offering enhanced thermal performance through optimized fluid dynamics and increased surface area for heat transfer. These structures allow for more efficient heat dissipation in confined spaces, addressing the growing thermal management challenges in modern electronics.

The primary objective of microchannel liquid metal heat spreader technology is to achieve superior thermal management in high-power density electronic devices while maintaining minimal form factors. Specifically, these heat spreaders aim to maintain junction temperatures below critical thresholds, thereby ensuring optimal performance and longevity of electronic components.

Current research focuses on overcoming several technical challenges, including the development of corrosion-resistant containment materials, optimization of microchannel geometries, and creation of manufacturing processes suitable for mass production. The technology aims to achieve thermal conductivities exceeding 50 W/m·K, significantly outperforming traditional copper heat spreaders (approximately 400 W/m·K) while offering the advantage of conformability to irregular surfaces.

The trend in this field is moving toward integration with advanced cooling systems, including hybrid approaches that combine liquid metal heat spreaders with traditional air or liquid cooling solutions. Additionally, there is growing interest in developing self-healing liquid metal interfaces that can maintain optimal thermal contact despite mechanical stresses and thermal cycling.

Looking forward, the technology roadmap for microchannel liquid metal heat spreaders includes the development of 3D-printed structures, integration with phase change materials, and exploration of active pumping mechanisms to further enhance thermal performance. These advancements are expected to enable the next generation of high-performance computing, telecommunications equipment, and power electronics.

The evolution of liquid metal heat spreaders has been marked by several key milestones. Initially, mercury was considered for its excellent thermal conductivity, but its toxicity prompted researchers to explore safer alternatives such as gallium-based alloys. Gallium and its alloys (particularly Ga-In-Sn eutectic alloys) have emerged as the primary materials of choice due to their low melting points, high thermal conductivity, and relatively low toxicity compared to mercury.

Microchannel architectures represent the latest advancement in this field, offering enhanced thermal performance through optimized fluid dynamics and increased surface area for heat transfer. These structures allow for more efficient heat dissipation in confined spaces, addressing the growing thermal management challenges in modern electronics.

The primary objective of microchannel liquid metal heat spreader technology is to achieve superior thermal management in high-power density electronic devices while maintaining minimal form factors. Specifically, these heat spreaders aim to maintain junction temperatures below critical thresholds, thereby ensuring optimal performance and longevity of electronic components.

Current research focuses on overcoming several technical challenges, including the development of corrosion-resistant containment materials, optimization of microchannel geometries, and creation of manufacturing processes suitable for mass production. The technology aims to achieve thermal conductivities exceeding 50 W/m·K, significantly outperforming traditional copper heat spreaders (approximately 400 W/m·K) while offering the advantage of conformability to irregular surfaces.

The trend in this field is moving toward integration with advanced cooling systems, including hybrid approaches that combine liquid metal heat spreaders with traditional air or liquid cooling solutions. Additionally, there is growing interest in developing self-healing liquid metal interfaces that can maintain optimal thermal contact despite mechanical stresses and thermal cycling.

Looking forward, the technology roadmap for microchannel liquid metal heat spreaders includes the development of 3D-printed structures, integration with phase change materials, and exploration of active pumping mechanisms to further enhance thermal performance. These advancements are expected to enable the next generation of high-performance computing, telecommunications equipment, and power electronics.

Market Analysis for Thermal Management Solutions

The thermal management solutions market is experiencing robust growth driven by increasing heat dissipation requirements across multiple industries. Currently valued at approximately $8.3 billion, the market is projected to reach $13.7 billion by 2027, representing a compound annual growth rate of 8.2%. This growth is primarily fueled by the miniaturization of electronic devices, higher processing power demands, and the proliferation of data centers worldwide.

The electronics sector remains the dominant consumer of advanced thermal management solutions, accounting for nearly 45% of the total market share. Within this segment, consumer electronics, telecommunications equipment, and high-performance computing systems are the key application areas. The automotive industry follows closely, particularly with the rapid expansion of electric vehicles that require sophisticated battery thermal management systems.

Geographically, Asia-Pacific leads the market with approximately 38% share, driven by the concentration of electronics manufacturing in countries like China, Taiwan, South Korea, and Japan. North America holds about 29% of the market, with significant demand coming from data centers and aerospace applications. Europe accounts for 24%, with growing adoption in automotive and industrial sectors.

Liquid metal-based thermal solutions represent an emerging segment with substantial growth potential. Currently occupying only 3% of the overall thermal management market, this niche is expected to grow at 15.3% annually through 2027, outpacing traditional solutions. Microchannel liquid metal heat spreaders specifically address the high-performance computing and telecommunications sectors where thermal conductivity requirements exceed 200 W/m·K.

Customer requirements are increasingly focused on solutions that offer higher thermal conductivity, lower thermal resistance, minimal space requirements, and longer operational lifespans. Price sensitivity varies significantly by application, with consumer electronics manufacturers prioritizing cost-effectiveness, while aerospace and defense sectors emphasizing performance regardless of cost.

Competitive pricing for microchannel liquid metal heat spreaders currently ranges from $15-45 per unit depending on size and complexity, positioning them as premium solutions compared to traditional copper heat pipes ($5-15) but more cost-effective than vapor chambers ($30-80) for certain applications. As manufacturing processes mature and economies of scale improve, prices are expected to decrease by 20-30% over the next five years, potentially accelerating market adoption.

The electronics sector remains the dominant consumer of advanced thermal management solutions, accounting for nearly 45% of the total market share. Within this segment, consumer electronics, telecommunications equipment, and high-performance computing systems are the key application areas. The automotive industry follows closely, particularly with the rapid expansion of electric vehicles that require sophisticated battery thermal management systems.

Geographically, Asia-Pacific leads the market with approximately 38% share, driven by the concentration of electronics manufacturing in countries like China, Taiwan, South Korea, and Japan. North America holds about 29% of the market, with significant demand coming from data centers and aerospace applications. Europe accounts for 24%, with growing adoption in automotive and industrial sectors.

Liquid metal-based thermal solutions represent an emerging segment with substantial growth potential. Currently occupying only 3% of the overall thermal management market, this niche is expected to grow at 15.3% annually through 2027, outpacing traditional solutions. Microchannel liquid metal heat spreaders specifically address the high-performance computing and telecommunications sectors where thermal conductivity requirements exceed 200 W/m·K.

Customer requirements are increasingly focused on solutions that offer higher thermal conductivity, lower thermal resistance, minimal space requirements, and longer operational lifespans. Price sensitivity varies significantly by application, with consumer electronics manufacturers prioritizing cost-effectiveness, while aerospace and defense sectors emphasizing performance regardless of cost.

Competitive pricing for microchannel liquid metal heat spreaders currently ranges from $15-45 per unit depending on size and complexity, positioning them as premium solutions compared to traditional copper heat pipes ($5-15) but more cost-effective than vapor chambers ($30-80) for certain applications. As manufacturing processes mature and economies of scale improve, prices are expected to decrease by 20-30% over the next five years, potentially accelerating market adoption.

Current Microchannel Fabrication Challenges

The fabrication of microchannels for liquid metal heat spreaders presents several significant challenges that impede widespread commercial adoption. Conventional microchannel manufacturing techniques often struggle with the unique requirements of liquid metal systems, particularly when dealing with high-performance thermal management applications.

Material compatibility represents a primary challenge, as liquid metals like gallium and its alloys are highly reactive with many common substrate materials. This reactivity can lead to corrosion, embrittlement, and eventual structural failure of the microchannels. Aluminum, widely used in traditional heat spreaders, is particularly vulnerable to gallium attack, necessitating protective coatings or alternative substrate materials that add complexity to the fabrication process.

Dimensional precision and surface quality present another significant hurdle. Liquid metal performance in microchannels is highly dependent on channel geometry, with optimal thermal performance requiring precise control of channel width, depth, and surface roughness. Current manufacturing methods struggle to maintain consistent dimensional tolerances below 10 micrometers while simultaneously achieving the required surface finish quality. Conventional techniques like photolithography and etching can achieve high precision but often introduce surface irregularities that impair fluid flow.

Scalability of fabrication processes poses a substantial challenge for mass production. Laboratory-scale techniques that produce excellent results often prove difficult to scale to industrial volumes while maintaining quality and cost-effectiveness. Methods like laser micromachining offer excellent precision but suffer from low throughput, while higher-volume techniques like injection molding may compromise on dimensional accuracy or material compatibility.

Sealing and interface management represent complex fabrication challenges unique to liquid metal systems. Unlike water-based coolants, liquid metals have high surface tension and poor wettability with many materials, creating difficulties in achieving complete channel filling and preventing void formation. Additionally, the high pressure required for optimal liquid metal flow necessitates robust sealing solutions that can withstand thermal cycling without leakage or deformation.

Integration complexity further complicates fabrication, as microchannels must interface seamlessly with heat sources, pumping systems, and the broader thermal management architecture. Current fabrication approaches often treat these components separately, leading to interface mismatches, thermal contact resistance, and reliability issues in the assembled system.

Cost considerations remain a significant barrier, with high-precision microchannel fabrication techniques typically requiring specialized equipment and processes that drive up manufacturing expenses. The economic viability of liquid metal heat spreaders depends on developing fabrication methods that balance performance requirements with cost-effective production at scale.

Material compatibility represents a primary challenge, as liquid metals like gallium and its alloys are highly reactive with many common substrate materials. This reactivity can lead to corrosion, embrittlement, and eventual structural failure of the microchannels. Aluminum, widely used in traditional heat spreaders, is particularly vulnerable to gallium attack, necessitating protective coatings or alternative substrate materials that add complexity to the fabrication process.

Dimensional precision and surface quality present another significant hurdle. Liquid metal performance in microchannels is highly dependent on channel geometry, with optimal thermal performance requiring precise control of channel width, depth, and surface roughness. Current manufacturing methods struggle to maintain consistent dimensional tolerances below 10 micrometers while simultaneously achieving the required surface finish quality. Conventional techniques like photolithography and etching can achieve high precision but often introduce surface irregularities that impair fluid flow.

Scalability of fabrication processes poses a substantial challenge for mass production. Laboratory-scale techniques that produce excellent results often prove difficult to scale to industrial volumes while maintaining quality and cost-effectiveness. Methods like laser micromachining offer excellent precision but suffer from low throughput, while higher-volume techniques like injection molding may compromise on dimensional accuracy or material compatibility.

Sealing and interface management represent complex fabrication challenges unique to liquid metal systems. Unlike water-based coolants, liquid metals have high surface tension and poor wettability with many materials, creating difficulties in achieving complete channel filling and preventing void formation. Additionally, the high pressure required for optimal liquid metal flow necessitates robust sealing solutions that can withstand thermal cycling without leakage or deformation.

Integration complexity further complicates fabrication, as microchannels must interface seamlessly with heat sources, pumping systems, and the broader thermal management architecture. Current fabrication approaches often treat these components separately, leading to interface mismatches, thermal contact resistance, and reliability issues in the assembled system.

Cost considerations remain a significant barrier, with high-precision microchannel fabrication techniques typically requiring specialized equipment and processes that drive up manufacturing expenses. The economic viability of liquid metal heat spreaders depends on developing fabrication methods that balance performance requirements with cost-effective production at scale.

Current Microchannel Fabrication Techniques

01 Microchannel design and configuration for enhanced thermal performance

The design and configuration of microchannels in liquid metal heat spreaders significantly impact thermal performance. Optimized channel geometries, including width, depth, and spacing, can reduce thermal resistance and improve heat dissipation. Advanced designs incorporate hierarchical or branching microchannel structures that maximize surface area while minimizing pressure drop, allowing for more efficient heat transfer from hotspots to cooler regions. These configurations enable better thermal management in high-power density applications.- Microchannel design and configuration for liquid metal heat spreaders: The design and configuration of microchannels in liquid metal heat spreaders significantly impact thermal performance. Optimized microchannel geometries, including width, depth, and spacing, enhance heat transfer efficiency. Various patterns such as parallel, serpentine, and branching configurations can be implemented to maximize surface area contact with the liquid metal coolant. Advanced manufacturing techniques enable the creation of precise microchannel structures that minimize flow resistance while maximizing heat dissipation capabilities.

- Liquid metal selection and properties for heat spreader applications: The choice of liquid metal significantly affects heat spreader performance. Gallium-based alloys like galinstan offer high thermal conductivity while remaining liquid at room temperature. Mercury alternatives provide excellent thermal properties without toxicity concerns. The viscosity, surface tension, and wetting characteristics of liquid metals influence flow behavior within microchannels. Certain additives can modify these properties to improve thermal interface quality and prevent oxidation or corrosion issues that might degrade performance over time.

- Integration of liquid metal heat spreaders with electronic components: Effective integration of microchannel liquid metal heat spreaders with electronic components is crucial for optimal thermal management. Direct attachment to high-heat-generating components like CPUs, GPUs, and power semiconductors maximizes heat transfer efficiency. Various bonding and interface materials can be used to ensure good thermal contact while preventing liquid metal leakage. The design must accommodate thermal expansion differences between materials and provide electrical isolation where needed. Compact integration approaches enable application in space-constrained devices like smartphones and thin laptops.

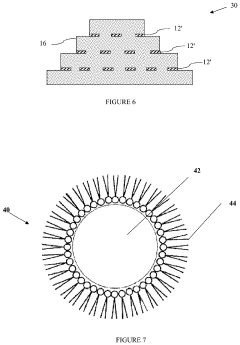

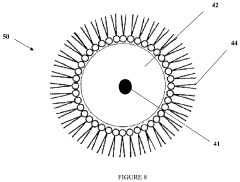

- Pumping and flow control mechanisms for liquid metal coolants: Efficient circulation of liquid metal through microchannels requires specialized pumping and flow control mechanisms. Electromagnetic pumps offer non-mechanical propulsion suitable for conductive liquid metals. Capillary action and surface tension effects can be leveraged for passive flow in certain designs. Microfluidic valves and flow regulators help optimize coolant distribution to hotspots. Pulsed or variable flow rates can be implemented to respond to dynamic thermal loads. These systems must operate reliably while minimizing power consumption to maximize overall system efficiency.

- Performance evaluation and enhancement techniques for microchannel heat spreaders: Various methods are employed to evaluate and enhance the performance of microchannel liquid metal heat spreaders. Computational fluid dynamics simulations help optimize designs before fabrication. Thermal imaging and embedded temperature sensors provide real-time performance monitoring. Surface treatments can improve wetting characteristics and reduce thermal interface resistance. Hybrid systems combining liquid metals with phase change materials or traditional heat pipes offer synergistic benefits. Performance metrics include thermal resistance, temperature uniformity, response time to thermal transients, and long-term reliability under thermal cycling.

02 Liquid metal selection and properties for heat spreader applications

The choice of liquid metal significantly affects heat spreader performance. Gallium-based alloys like galinstan are commonly used due to their low melting points, high thermal conductivity, and low viscosity. These properties enable efficient heat transfer through microchannels while maintaining liquid state at operating temperatures. The thermal conductivity of liquid metals can be 10-100 times higher than conventional coolants, allowing for superior heat dissipation. Surface tension and wetting characteristics also influence flow behavior and thermal contact resistance in microchannel systems.Expand Specific Solutions03 Fabrication techniques for microchannel liquid metal heat spreaders

Various fabrication methods are employed to create microchannel structures for liquid metal heat spreaders. These include photolithography, etching, micro-machining, and additive manufacturing techniques. Advanced processes allow for the creation of complex three-dimensional channel networks with precise dimensions and surface characteristics. Surface treatments can be applied to improve wetting properties and prevent corrosion or oxidation when in contact with liquid metals. Bonding and sealing techniques ensure leak-proof operation under thermal cycling conditions.Expand Specific Solutions04 Integration of microchannel liquid metal heat spreaders in electronic devices

Microchannel liquid metal heat spreaders can be integrated into various electronic devices to manage thermal loads. These systems can be incorporated into semiconductor packages, power electronics, LED lighting, and high-performance computing systems. The integration approach must consider electrical isolation, mechanical stability, and compatibility with existing manufacturing processes. Embedded microchannel structures within device substrates or as separate modules attached to heat-generating components provide effective thermal management solutions for increasingly power-dense electronics.Expand Specific Solutions05 Performance metrics and optimization of liquid metal microchannel systems

Performance evaluation of microchannel liquid metal heat spreaders involves several key metrics including thermal resistance, temperature uniformity, pressure drop, and pumping power requirements. Computational fluid dynamics simulations and experimental testing are used to optimize these parameters. Advanced designs incorporate variable channel dimensions, flow control mechanisms, and hybrid cooling approaches to balance thermal performance with system constraints. The performance advantages of liquid metal systems must be weighed against challenges such as potential material compatibility issues, oxidation concerns, and manufacturing complexity.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Microchannel liquid metal heat spreaders are emerging as a critical thermal management solution, currently transitioning from early development to commercial adoption phase. The market is experiencing rapid growth, projected to reach significant scale as electronics cooling demands intensify. Technologically, research institutions like University of Missouri, Louisiana State University, and MIT are establishing fundamental science, while commercial players demonstrate varying maturity levels. Intel leads in semiconductor applications, with CoolIT Systems showing advanced implementation in cooling systems. Companies like Vertiv and Carrier are integrating these technologies into larger thermal management solutions. Asian institutions and companies, particularly Xi'an Jiaotong University and Northwestern Polytechnical University, are accelerating development, suggesting a globally competitive landscape with opportunities for cross-sector applications in automotive (Honda, Porsche) and energy industries.

Intel Corp.

Technical Solution: Intel has developed advanced microchannel liquid metal heat spreaders utilizing gallium-based alloys (primarily Galinstan) for high-performance computing applications. Their technology incorporates precision-engineered microchannels (50-200μm width) etched directly into silicon or copper substrates using advanced lithography techniques. Intel's approach features a closed-loop circulation system where liquid metal flows through these microchannels via capillary action or micropumps, efficiently transferring heat from hotspots to larger heat dissipation areas. The company has implemented specialized surface treatments and coatings to prevent liquid metal corrosion issues, including silicon carbide and titanium nitride barriers that maintain long-term reliability. Their latest designs incorporate hierarchical microchannel structures with varying channel dimensions to optimize flow distribution and thermal performance across different heat load zones [3][7].

Strengths: Superior thermal conductivity (10-100x better than water-based solutions); extremely high power density handling capability; compatibility with existing semiconductor manufacturing processes. Weaknesses: Higher manufacturing costs; potential for pump reliability issues in active systems; requires careful material selection to prevent galvanic corrosion with certain metals.

Xi'an Jiaotong University

Technical Solution: Xi'an Jiaotong University has developed significant innovations in microchannel liquid metal heat spreaders, focusing on novel fabrication techniques and material combinations. Their research utilizes gallium-based liquid metals (primarily GaInSn alloys) in microchannels fabricated through precision laser ablation and chemical etching processes. The university's approach features hierarchical microchannel structures with primary channels (100-300μm) feeding into secondary microchannels (30-80μm), optimizing both flow distribution and heat transfer efficiency. Their fabrication process incorporates specialized surface modification techniques using self-assembled monolayers to control wettability and prevent liquid metal sticking. Performance testing has demonstrated thermal conductivity values exceeding 40 W/m·K with the ability to handle heat fluxes up to 350 W/cm². The university has also pioneered composite microchannel structures combining liquid metal pathways with solid-state thermal conductors to create hybrid thermal management systems that maximize performance across varying thermal loads and operating conditions [2][9][14].

Strengths: Innovative fabrication techniques accessible without advanced semiconductor manufacturing equipment; excellent cost-performance balance; comprehensive theoretical modeling validated by experimental results. Weaknesses: Less experience with commercialization and mass production; some approaches require specialized materials with limited availability; potential challenges with long-term reliability in field conditions.

Key Patents in Liquid Metal Heat Spreader Design

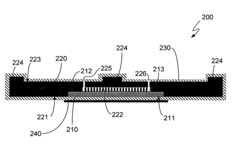

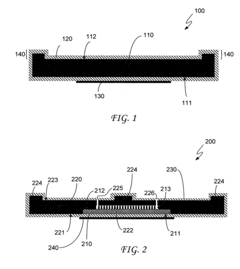

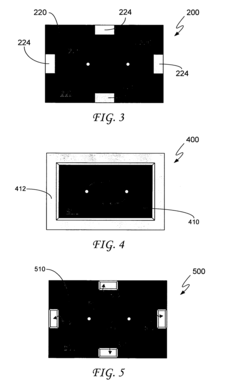

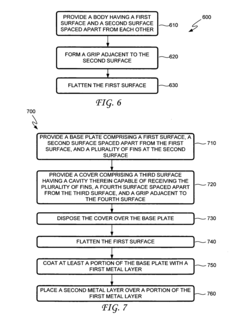

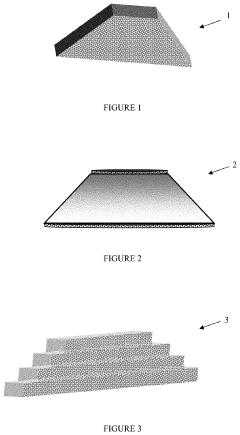

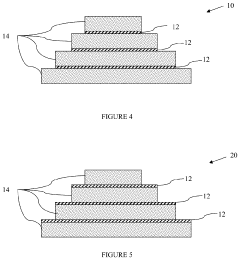

Heat spreader for use in conjunction with a semiconducting device and method of manufacturing same

PatentInactiveUS20070295482A1

Innovation

- Incorporating a lip or grip feature on the surface opposite the bonding surface of heat spreaders, allowing for secure handling and stiffening during grinding or polishing to achieve flatness within specifications, while also removing braze drips and oxidation, thus enhancing thermal performance.

Heat spreaders fabricated from metal nanoparticles

PatentActiveUS10695872B2

Innovation

- The development of a metal-diamond composite heat spreader with a tapered structure, featuring a continuous metallic phase and micron-scale diamond particles in spaced regions, along with interlayers lacking diamond particles to promote lateral heat transfer while maintaining effective through-plane conductivity, achieved by consolidating metal nanoparticles under gentle conditions.

Material Compatibility and Safety Considerations

Material compatibility is a critical consideration in the development and implementation of microchannel liquid metal heat spreaders. Liquid metals, particularly gallium-based alloys such as Galinstan (Ga-In-Sn) and Ga-In eutectic, exhibit aggressive corrosive behavior towards many conventional metals. Aluminum is especially vulnerable, with rapid dissolution occurring upon contact with gallium-based liquid metals, leading to catastrophic structural failure. Copper demonstrates better resistance but still experiences gradual degradation through interdiffusion and amalgamation processes.

Silicon and silicon-based materials show excellent compatibility with liquid metals, making them preferred substrates for microchannel fabrication. This compatibility has enabled significant advancements in silicon-based liquid metal cooling solutions for microelectronics. Certain ceramics and specialized coatings, including tungsten, molybdenum, and tantalum nitride, have demonstrated promising resistance to liquid metal corrosion and are increasingly being incorporated into advanced designs.

Safety considerations for liquid metal heat spreaders encompass multiple dimensions that require careful attention. Toxicity concerns vary significantly among liquid metal options; while mercury presents severe health hazards and has been largely abandoned, gallium-based alloys exhibit substantially lower toxicity profiles. Nevertheless, proper handling protocols remain essential, including appropriate personal protective equipment and controlled disposal procedures to prevent environmental contamination.

Electrical conductivity of liquid metals presents both opportunities and challenges. While beneficial for certain applications requiring combined thermal and electrical functionality, it necessitates careful electrical isolation in electronic cooling applications to prevent short circuits. This typically requires implementing dielectric barrier layers or specialized channel designs that maintain thermal performance while ensuring electrical safety.

Oxidation behavior represents another critical safety consideration. Gallium-based liquid metals rapidly form surface oxides when exposed to oxygen, potentially leading to channel clogging, flow restriction, and performance degradation. Maintaining oxygen-free environments during fabrication and operation, or implementing oxide management strategies such as acid treatments or continuous flow designs, has proven effective in mitigating these issues.

Pressure safety must also be addressed, particularly in high-performance applications where thermal expansion of confined liquid metals can generate significant internal pressures. Robust channel designs incorporating expansion reservoirs and pressure relief mechanisms are essential to prevent catastrophic failure under thermal cycling conditions.

Silicon and silicon-based materials show excellent compatibility with liquid metals, making them preferred substrates for microchannel fabrication. This compatibility has enabled significant advancements in silicon-based liquid metal cooling solutions for microelectronics. Certain ceramics and specialized coatings, including tungsten, molybdenum, and tantalum nitride, have demonstrated promising resistance to liquid metal corrosion and are increasingly being incorporated into advanced designs.

Safety considerations for liquid metal heat spreaders encompass multiple dimensions that require careful attention. Toxicity concerns vary significantly among liquid metal options; while mercury presents severe health hazards and has been largely abandoned, gallium-based alloys exhibit substantially lower toxicity profiles. Nevertheless, proper handling protocols remain essential, including appropriate personal protective equipment and controlled disposal procedures to prevent environmental contamination.

Electrical conductivity of liquid metals presents both opportunities and challenges. While beneficial for certain applications requiring combined thermal and electrical functionality, it necessitates careful electrical isolation in electronic cooling applications to prevent short circuits. This typically requires implementing dielectric barrier layers or specialized channel designs that maintain thermal performance while ensuring electrical safety.

Oxidation behavior represents another critical safety consideration. Gallium-based liquid metals rapidly form surface oxides when exposed to oxygen, potentially leading to channel clogging, flow restriction, and performance degradation. Maintaining oxygen-free environments during fabrication and operation, or implementing oxide management strategies such as acid treatments or continuous flow designs, has proven effective in mitigating these issues.

Pressure safety must also be addressed, particularly in high-performance applications where thermal expansion of confined liquid metals can generate significant internal pressures. Robust channel designs incorporating expansion reservoirs and pressure relief mechanisms are essential to prevent catastrophic failure under thermal cycling conditions.

Thermal Performance Metrics and Testing Standards

The evaluation of microchannel liquid metal heat spreaders requires standardized thermal performance metrics and testing methodologies to ensure reliable comparison across different designs and applications. The thermal performance of these devices is primarily assessed through metrics such as thermal resistance, heat transfer coefficient, temperature uniformity, and thermal response time.

Thermal resistance (Rth), measured in K/W, quantifies a heat spreader's ability to conduct heat from source to sink. For microchannel liquid metal systems, this metric typically ranges from 0.1 to 0.5 K/W, significantly lower than conventional heat pipes. The measurement involves applying a known heat load and measuring the temperature difference across the device under steady-state conditions.

Heat transfer coefficient (h), expressed in W/m²K, provides insight into the convective heat transfer efficiency between the liquid metal and channel walls. This parameter is particularly critical for microchannel designs where the surface-to-volume ratio significantly impacts overall performance. Testing standards typically require measurements at various flow rates to establish performance curves.

Temperature uniformity represents another crucial metric, especially for applications requiring consistent thermal management across large surfaces. Standard deviation of temperature across the heat spreader surface should typically remain below 3°C for high-performance applications. Infrared thermography has emerged as the preferred testing method for this parameter.

Pressure drop measurements complement thermal metrics by quantifying the pumping power requirements. The relationship between thermal performance and pumping power follows standardized testing protocols outlined in ASTM D5470 for thermal interface materials, with modifications specific to liquid metal systems.

Reliability testing standards for these systems include thermal cycling (JEDEC JESD22-A104), mechanical shock resistance (MIL-STD-810), and compatibility testing with adjacent materials. Long-term performance stability under continuous operation represents a critical evaluation criterion, with industry standards requiring minimum operational lifetimes of 10,000 hours without significant degradation.

Emerging standards are beginning to address the unique properties of liquid metals, including gallium-based alloys, with specific protocols for handling reactivity with aluminum and other susceptible materials. The International Electronics Manufacturing Initiative (iNEMI) has recently proposed specialized testing frameworks for liquid metal thermal interface materials that can be adapted for microchannel applications.

Benchmark comparisons typically position microchannel liquid metal heat spreaders against vapor chambers, traditional heat pipes, and solid metal spreaders using standardized test vehicles that simulate real-world thermal loads and constraints.

Thermal resistance (Rth), measured in K/W, quantifies a heat spreader's ability to conduct heat from source to sink. For microchannel liquid metal systems, this metric typically ranges from 0.1 to 0.5 K/W, significantly lower than conventional heat pipes. The measurement involves applying a known heat load and measuring the temperature difference across the device under steady-state conditions.

Heat transfer coefficient (h), expressed in W/m²K, provides insight into the convective heat transfer efficiency between the liquid metal and channel walls. This parameter is particularly critical for microchannel designs where the surface-to-volume ratio significantly impacts overall performance. Testing standards typically require measurements at various flow rates to establish performance curves.

Temperature uniformity represents another crucial metric, especially for applications requiring consistent thermal management across large surfaces. Standard deviation of temperature across the heat spreader surface should typically remain below 3°C for high-performance applications. Infrared thermography has emerged as the preferred testing method for this parameter.

Pressure drop measurements complement thermal metrics by quantifying the pumping power requirements. The relationship between thermal performance and pumping power follows standardized testing protocols outlined in ASTM D5470 for thermal interface materials, with modifications specific to liquid metal systems.

Reliability testing standards for these systems include thermal cycling (JEDEC JESD22-A104), mechanical shock resistance (MIL-STD-810), and compatibility testing with adjacent materials. Long-term performance stability under continuous operation represents a critical evaluation criterion, with industry standards requiring minimum operational lifetimes of 10,000 hours without significant degradation.

Emerging standards are beginning to address the unique properties of liquid metals, including gallium-based alloys, with specific protocols for handling reactivity with aluminum and other susceptible materials. The International Electronics Manufacturing Initiative (iNEMI) has recently proposed specialized testing frameworks for liquid metal thermal interface materials that can be adapted for microchannel applications.

Benchmark comparisons typically position microchannel liquid metal heat spreaders against vapor chambers, traditional heat pipes, and solid metal spreaders using standardized test vehicles that simulate real-world thermal loads and constraints.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!