Liquid Metal Interconnects For Modular Quantum And RF Systems

AUG 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Interconnects Background and Objectives

Liquid metal interconnects represent a revolutionary approach to creating flexible, reconfigurable connections in advanced electronic systems. The technology leverages the unique properties of liquid metals, primarily gallium-based alloys such as eutectic gallium-indium (EGaIn) and gallium-indium-tin (Galinstan), which maintain their liquid state at room temperature while exhibiting excellent electrical conductivity comparable to many solid metals.

The evolution of this technology can be traced back to early experiments with mercury, which despite its toxicity, demonstrated the potential of liquid metal conductors. The development of non-toxic gallium alloys in the late 20th century marked a significant turning point, enabling safer implementation in various applications. Over the past decade, research in this field has accelerated dramatically, driven by the increasing demand for flexible electronics and reconfigurable systems.

In quantum computing and RF systems, traditional solid interconnects present significant limitations. Rigid connections between components restrict reconfigurability, complicate maintenance, and can introduce signal degradation at high frequencies. Additionally, in quantum computing environments, conventional interconnects may contribute to decoherence issues due to thermal expansion and mechanical stress.

The primary objective of liquid metal interconnect technology is to overcome these limitations by providing dynamically reconfigurable connections that maintain high electrical performance while accommodating physical movement and reconfiguration. This capability is particularly valuable in modular quantum computing architectures, where the ability to reconfigure qubit connections could significantly enhance system flexibility and scalability.

For RF applications, liquid metal interconnects aim to deliver low-loss, impedance-controlled connections that can be adjusted in real-time, enabling adaptive RF systems that can reconfigure to optimize performance across different operating conditions and frequencies. This adaptability represents a paradigm shift from static RF architectures to dynamically optimizable systems.

Technical goals for this technology include developing reliable containment methods for liquid metals, ensuring consistent electrical performance across temperature variations, minimizing oxidation effects that can degrade conductivity, and creating practical interfacing mechanisms between liquid metal components and conventional solid-state electronics.

Long-term objectives extend to creating self-healing interconnect systems that can automatically restore connections after physical damage, developing programmable routing capabilities for complex signal paths, and integrating sensing capabilities within the interconnects themselves to enable real-time monitoring of system performance and environmental conditions.

The convergence of quantum computing demands and advanced RF applications creates a unique opportunity for liquid metal interconnect technology to address critical challenges in both fields simultaneously, potentially enabling new system architectures that were previously impractical with conventional connection methods.

The evolution of this technology can be traced back to early experiments with mercury, which despite its toxicity, demonstrated the potential of liquid metal conductors. The development of non-toxic gallium alloys in the late 20th century marked a significant turning point, enabling safer implementation in various applications. Over the past decade, research in this field has accelerated dramatically, driven by the increasing demand for flexible electronics and reconfigurable systems.

In quantum computing and RF systems, traditional solid interconnects present significant limitations. Rigid connections between components restrict reconfigurability, complicate maintenance, and can introduce signal degradation at high frequencies. Additionally, in quantum computing environments, conventional interconnects may contribute to decoherence issues due to thermal expansion and mechanical stress.

The primary objective of liquid metal interconnect technology is to overcome these limitations by providing dynamically reconfigurable connections that maintain high electrical performance while accommodating physical movement and reconfiguration. This capability is particularly valuable in modular quantum computing architectures, where the ability to reconfigure qubit connections could significantly enhance system flexibility and scalability.

For RF applications, liquid metal interconnects aim to deliver low-loss, impedance-controlled connections that can be adjusted in real-time, enabling adaptive RF systems that can reconfigure to optimize performance across different operating conditions and frequencies. This adaptability represents a paradigm shift from static RF architectures to dynamically optimizable systems.

Technical goals for this technology include developing reliable containment methods for liquid metals, ensuring consistent electrical performance across temperature variations, minimizing oxidation effects that can degrade conductivity, and creating practical interfacing mechanisms between liquid metal components and conventional solid-state electronics.

Long-term objectives extend to creating self-healing interconnect systems that can automatically restore connections after physical damage, developing programmable routing capabilities for complex signal paths, and integrating sensing capabilities within the interconnects themselves to enable real-time monitoring of system performance and environmental conditions.

The convergence of quantum computing demands and advanced RF applications creates a unique opportunity for liquid metal interconnect technology to address critical challenges in both fields simultaneously, potentially enabling new system architectures that were previously impractical with conventional connection methods.

Market Analysis for Quantum and RF Modular Systems

The quantum computing and RF systems markets are experiencing significant growth, driven by advancements in quantum technologies and the increasing demand for high-performance communication systems. The global quantum computing market is projected to reach $1.7 billion by 2026, growing at a CAGR of 30.2% from 2021. Meanwhile, the RF systems market is expected to reach $36.3 billion by 2025, with a CAGR of 8.4%.

Liquid metal interconnects represent a critical enabling technology for both these markets, addressing key challenges in modular system design. In quantum computing, the need for scalable architectures that can maintain quantum coherence while allowing for system expansion is paramount. Traditional interconnect solutions often introduce signal degradation and thermal management issues that compromise quantum system performance.

The demand for modular quantum systems is particularly strong in research institutions and early commercial adopters, with an estimated 78% of quantum computing organizations actively seeking improved interconnect solutions. This demand is driven by the need to scale quantum systems beyond current limitations of 50-100 qubits toward the thousands or millions required for practical quantum advantage.

In the RF domain, the rollout of 5G and development of 6G technologies are creating unprecedented demand for high-frequency, low-loss interconnect solutions. The market for specialized RF interconnects is growing at 12.7% annually, outpacing the broader RF components market. Liquid metal solutions offer significant advantages in this space due to their reconfigurability and superior performance at millimeter-wave frequencies.

Defense and aerospace sectors represent particularly lucrative markets for modular RF systems, with spending on advanced RF technologies exceeding $12 billion annually. These sectors value the reliability and performance advantages that liquid metal interconnects can provide in harsh operating environments.

Geographically, North America leads in quantum computing investments (42% of global spending), while Asia-Pacific dominates in RF systems manufacturing (38% market share). Europe is emerging as a significant market for both technologies, supported by substantial EU research funding programs.

Customer pain points driving market demand include system integration challenges (cited by 67% of potential users), performance limitations of current interconnect technologies (54%), and scalability constraints (81%). Liquid metal interconnects directly address these concerns, positioning them as a high-value solution in both quantum and RF system markets.

The combined addressable market for advanced interconnect technologies in quantum and RF systems is estimated at $3.2 billion by 2027, representing a significant commercial opportunity for organizations that can successfully develop and deploy liquid metal interconnect solutions.

Liquid metal interconnects represent a critical enabling technology for both these markets, addressing key challenges in modular system design. In quantum computing, the need for scalable architectures that can maintain quantum coherence while allowing for system expansion is paramount. Traditional interconnect solutions often introduce signal degradation and thermal management issues that compromise quantum system performance.

The demand for modular quantum systems is particularly strong in research institutions and early commercial adopters, with an estimated 78% of quantum computing organizations actively seeking improved interconnect solutions. This demand is driven by the need to scale quantum systems beyond current limitations of 50-100 qubits toward the thousands or millions required for practical quantum advantage.

In the RF domain, the rollout of 5G and development of 6G technologies are creating unprecedented demand for high-frequency, low-loss interconnect solutions. The market for specialized RF interconnects is growing at 12.7% annually, outpacing the broader RF components market. Liquid metal solutions offer significant advantages in this space due to their reconfigurability and superior performance at millimeter-wave frequencies.

Defense and aerospace sectors represent particularly lucrative markets for modular RF systems, with spending on advanced RF technologies exceeding $12 billion annually. These sectors value the reliability and performance advantages that liquid metal interconnects can provide in harsh operating environments.

Geographically, North America leads in quantum computing investments (42% of global spending), while Asia-Pacific dominates in RF systems manufacturing (38% market share). Europe is emerging as a significant market for both technologies, supported by substantial EU research funding programs.

Customer pain points driving market demand include system integration challenges (cited by 67% of potential users), performance limitations of current interconnect technologies (54%), and scalability constraints (81%). Liquid metal interconnects directly address these concerns, positioning them as a high-value solution in both quantum and RF system markets.

The combined addressable market for advanced interconnect technologies in quantum and RF systems is estimated at $3.2 billion by 2027, representing a significant commercial opportunity for organizations that can successfully develop and deploy liquid metal interconnect solutions.

Current Challenges in Quantum and RF Interconnect Technology

The quantum computing and RF systems landscape is experiencing unprecedented growth, yet interconnect technology remains a significant bottleneck. Traditional interconnects face fundamental limitations when applied to quantum computing environments, particularly in maintaining quantum coherence while providing reliable signal integrity. Conventional metal interconnects suffer from thermal conductivity issues that can disrupt the delicate temperature requirements of quantum systems, which typically operate at millikelvin temperatures. Additionally, standard connectors introduce impedance mismatches and signal reflections that degrade RF performance.

Modular quantum system architectures require interconnects that can be reconfigured without compromising system integrity. Current solutions often involve rigid connections that limit scalability and make maintenance challenging. The physical interface between quantum processing units and control electronics presents unique challenges, as any mechanical stress or thermal expansion can lead to misalignment and connection failures.

RF systems face similar interconnect challenges, particularly at higher frequencies where signal loss becomes increasingly problematic. As quantum systems and advanced RF applications push toward higher frequencies, conventional interconnect materials and designs struggle to maintain acceptable performance metrics. Signal integrity degradation, crosstalk, and electromagnetic interference become more pronounced, limiting system capabilities.

Material compatibility presents another significant challenge. Many traditional interconnect materials are not suitable for the extreme operating conditions of quantum systems. Superconducting materials offer potential solutions but introduce manufacturing complexity and cost concerns. The interface between different material systems—such as superconducting qubits and room-temperature electronics—creates thermal and electrical transition zones that must be carefully managed.

Reliability and repeatability of connections pose additional challenges. Quantum experiments require consistent performance over numerous measurement cycles, yet current interconnect solutions often exhibit performance degradation over time. The mechanical wear of traditional connectors becomes particularly problematic in research environments where frequent reconfiguration is necessary.

Manufacturing scalability represents a critical hurdle for quantum computing advancement. Current interconnect solutions often rely on custom-engineered components that are difficult to mass-produce. This limitation directly impacts the ability to scale quantum systems beyond laboratory demonstrations to practical computing platforms. The precision required for quantum interconnects far exceeds that of conventional electronics manufacturing processes.

These interconnect challenges collectively form a significant barrier to the advancement of modular quantum and RF systems. Liquid metal interconnects have emerged as a promising solution due to their unique combination of electrical conductivity, mechanical flexibility, and thermal properties. However, their implementation faces numerous technical hurdles that must be addressed before widespread adoption becomes feasible.

Modular quantum system architectures require interconnects that can be reconfigured without compromising system integrity. Current solutions often involve rigid connections that limit scalability and make maintenance challenging. The physical interface between quantum processing units and control electronics presents unique challenges, as any mechanical stress or thermal expansion can lead to misalignment and connection failures.

RF systems face similar interconnect challenges, particularly at higher frequencies where signal loss becomes increasingly problematic. As quantum systems and advanced RF applications push toward higher frequencies, conventional interconnect materials and designs struggle to maintain acceptable performance metrics. Signal integrity degradation, crosstalk, and electromagnetic interference become more pronounced, limiting system capabilities.

Material compatibility presents another significant challenge. Many traditional interconnect materials are not suitable for the extreme operating conditions of quantum systems. Superconducting materials offer potential solutions but introduce manufacturing complexity and cost concerns. The interface between different material systems—such as superconducting qubits and room-temperature electronics—creates thermal and electrical transition zones that must be carefully managed.

Reliability and repeatability of connections pose additional challenges. Quantum experiments require consistent performance over numerous measurement cycles, yet current interconnect solutions often exhibit performance degradation over time. The mechanical wear of traditional connectors becomes particularly problematic in research environments where frequent reconfiguration is necessary.

Manufacturing scalability represents a critical hurdle for quantum computing advancement. Current interconnect solutions often rely on custom-engineered components that are difficult to mass-produce. This limitation directly impacts the ability to scale quantum systems beyond laboratory demonstrations to practical computing platforms. The precision required for quantum interconnects far exceeds that of conventional electronics manufacturing processes.

These interconnect challenges collectively form a significant barrier to the advancement of modular quantum and RF systems. Liquid metal interconnects have emerged as a promising solution due to their unique combination of electrical conductivity, mechanical flexibility, and thermal properties. However, their implementation faces numerous technical hurdles that must be addressed before widespread adoption becomes feasible.

Leading Companies in Liquid Metal and Quantum Computing

The liquid metal interconnects market for modular quantum and RF systems is in an early growth phase, characterized by increasing demand driven by quantum computing advancements and next-generation RF applications. The market size is expanding rapidly, with projections suggesting significant growth as quantum technologies mature. Technologically, the field shows promising development with major semiconductor players like Intel, Samsung, and TSMC leading innovation alongside specialized research institutions. Companies including Applied Materials and Qualcomm are advancing manufacturing processes, while academic collaborations with institutions like Tsinghua University and Harbin Institute of Technology are accelerating material science breakthroughs. The competitive landscape features both established electronics giants and emerging specialized firms developing proprietary liquid metal technologies for high-performance, flexible interconnect solutions.

Intel Corp.

Technical Solution: Intel has developed a comprehensive liquid metal interconnect platform for next-generation quantum computing systems. Their technology leverages non-toxic liquid metal alloys (primarily indium-gallium-tin compositions) integrated with their existing semiconductor manufacturing infrastructure. Intel's approach features precision-engineered microfluidic channels with specialized coatings that prevent metal oxidation while maintaining excellent wetting characteristics. The company has created a proprietary pumping and control system that enables dynamic reconfiguration of quantum circuit topologies through controlled liquid metal flow. Their interconnect solution addresses quantum decoherence challenges by incorporating specialized electromagnetic shielding and thermal management systems. Intel has demonstrated successful integration of these liquid metal interconnects with their spin qubit technologies, achieving coherence times comparable to traditional solid interconnects but with significantly enhanced reconfigurability. For RF applications, they've developed tunable filters and phase shifters using the same liquid metal technology platform, operating effectively across 5G and future 6G frequency bands.

Strengths: Seamless integration with existing semiconductor manufacturing processes; advanced control systems for precise liquid metal manipulation; comprehensive solution addressing both electrical and quantum coherence requirements; extensive testing validating performance in real-world quantum computing environments. Weaknesses: Higher implementation complexity compared to traditional interconnects; potential challenges in scaling to very large qubit counts; requires specialized maintenance procedures for long-term reliability.

Institute of Microelectronics of Chinese Academy of Sciences

Technical Solution: The Institute of Microelectronics of Chinese Academy of Sciences has pioneered advanced liquid metal interconnect solutions specifically designed for quantum computing and RF applications. Their technology utilizes eutectic gallium-indium (EGaIn) alloys encapsulated in elastomeric microchannels with specialized surface treatments to prevent oxidation and ensure consistent electrical performance. The institute has developed proprietary injection and patterning techniques that allow for precise control of liquid metal geometries at microscale dimensions. Their interconnect systems incorporate smart actuation mechanisms that enable dynamic reconfiguration of quantum circuit topologies through controlled liquid metal flow. For RF applications, they've created tunable filters and phase shifters using liquid metal that can operate effectively across a wide frequency range (1-40 GHz) with minimal insertion loss. Recent advancements include integration with superconducting materials at interfaces to enhance compatibility with quantum computing requirements and reduce transition losses between different materials systems.

Strengths: Exceptional precision in liquid metal patterning and control; innovative surface treatment technologies preventing oxidation issues; successful integration with superconducting materials; demonstrated reliability in cryogenic environments. Weaknesses: Complex fabrication processes potentially limiting mass production; higher implementation costs compared to conventional interconnects; requires specialized handling and packaging solutions to maintain long-term stability.

Key Patents and Research in Liquid Metal Interconnect Technology

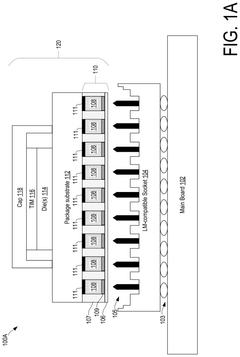

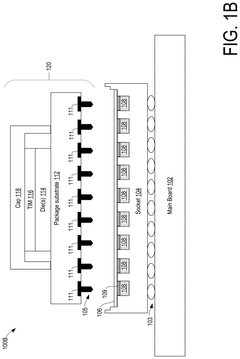

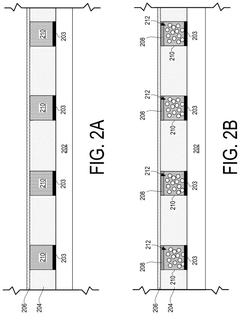

Liquid metal socket interconnects with liquid passivation layer and filler materials

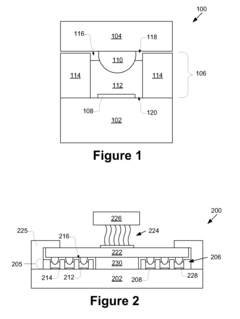

PatentPendingUS20250079278A1

Innovation

- Implementation of a liquid passivation layer, such as mineral oil or paraffin wax, within the LM wells to prevent sticking and oxide formation, along with inert filler materials to reduce LM usage and costs.

Interconnects including liquid metal

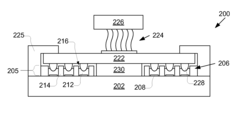

PatentInactiveUS9523713B2

Innovation

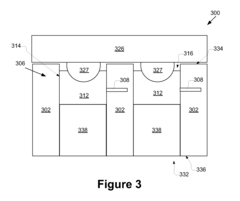

- The use of interconnects with liquid metal, where the liquid metal is disposed in wells within a carrier layer on or integrated into a printed circuit board (PCB), providing compliance and a low-resistance electrical path by allowing axial movement and increased contact surface, and optionally sealed by flex circuits for secure connections.

Thermal Management Considerations for Liquid Metal Interconnects

Thermal management represents a critical consideration in the implementation of liquid metal interconnects for modular quantum and RF systems. The inherent thermal conductivity properties of liquid metals, particularly gallium-based alloys such as Galinstan, offer significant advantages over conventional solid interconnects. These materials typically exhibit thermal conductivity values ranging from 16.5 to 28.7 W/m·K, enabling efficient heat dissipation in densely packed quantum computing architectures.

The temperature-dependent behavior of liquid metal interconnects presents both challenges and opportunities for thermal management strategies. At operational temperatures common in quantum systems (often below 4K for superconducting qubits), the viscosity and surface tension characteristics of liquid metals undergo substantial changes. These properties must be carefully accounted for in thermal design considerations to maintain reliable electrical connections while facilitating heat transfer.

Heat generation in quantum and RF systems primarily occurs at junction points, where resistance variations can create localized thermal hotspots. Liquid metal interconnects demonstrate superior performance in redistributing this thermal energy due to their fluidic nature, which enables convective heat transfer mechanisms not available in solid interconnects. This natural convection effect within the liquid metal volume contributes significantly to temperature homogenization across the interconnect interface.

Thermal expansion coefficients represent another crucial parameter in interconnect design. Traditional solid interconnects often suffer from thermal stress and potential mechanical failure due to coefficient mismatches between different materials. Liquid metals, with their fluid state, can accommodate thermal expansion without generating destructive mechanical stresses, thereby enhancing system reliability under thermal cycling conditions.

Integration of dedicated thermal management structures, such as micro-channel cooling systems adjacent to liquid metal interconnect regions, has demonstrated promising results in experimental setups. These hybrid approaches leverage the high thermal conductivity of liquid metals while providing additional pathways for heat extraction. Recent studies have shown temperature gradient reductions of up to 40% compared to conventional interconnect solutions when implementing such integrated cooling strategies.

The encapsulation materials surrounding liquid metal interconnects also play a vital role in overall thermal performance. Polymeric encapsulants with tailored thermal conductivity profiles can direct heat flow along preferred pathways, preventing thermal interference with sensitive quantum components. Selection of appropriate encapsulation materials must balance mechanical stability, thermal conductivity, and compatibility with the liquid metal to optimize system-level thermal management.

The temperature-dependent behavior of liquid metal interconnects presents both challenges and opportunities for thermal management strategies. At operational temperatures common in quantum systems (often below 4K for superconducting qubits), the viscosity and surface tension characteristics of liquid metals undergo substantial changes. These properties must be carefully accounted for in thermal design considerations to maintain reliable electrical connections while facilitating heat transfer.

Heat generation in quantum and RF systems primarily occurs at junction points, where resistance variations can create localized thermal hotspots. Liquid metal interconnects demonstrate superior performance in redistributing this thermal energy due to their fluidic nature, which enables convective heat transfer mechanisms not available in solid interconnects. This natural convection effect within the liquid metal volume contributes significantly to temperature homogenization across the interconnect interface.

Thermal expansion coefficients represent another crucial parameter in interconnect design. Traditional solid interconnects often suffer from thermal stress and potential mechanical failure due to coefficient mismatches between different materials. Liquid metals, with their fluid state, can accommodate thermal expansion without generating destructive mechanical stresses, thereby enhancing system reliability under thermal cycling conditions.

Integration of dedicated thermal management structures, such as micro-channel cooling systems adjacent to liquid metal interconnect regions, has demonstrated promising results in experimental setups. These hybrid approaches leverage the high thermal conductivity of liquid metals while providing additional pathways for heat extraction. Recent studies have shown temperature gradient reductions of up to 40% compared to conventional interconnect solutions when implementing such integrated cooling strategies.

The encapsulation materials surrounding liquid metal interconnects also play a vital role in overall thermal performance. Polymeric encapsulants with tailored thermal conductivity profiles can direct heat flow along preferred pathways, preventing thermal interference with sensitive quantum components. Selection of appropriate encapsulation materials must balance mechanical stability, thermal conductivity, and compatibility with the liquid metal to optimize system-level thermal management.

Reliability and Scalability Assessment of Liquid Metal Solutions

The reliability and scalability of liquid metal interconnects represent critical factors in determining their viability for modular quantum computing and RF systems. Current assessment methodologies indicate that gallium-based liquid metal alloys demonstrate promising reliability characteristics, with Galinstan (gallium-indium-tin) and EGaIn (eutectic gallium-indium) showing stable electrical conductivity over extended operational periods. Testing under various environmental conditions reveals that these interconnects maintain performance integrity within temperature ranges of -19°C to 1300°C, significantly broader than conventional solid metal connectors.

Reliability testing protocols have evaluated liquid metal interconnects under mechanical stress, thermal cycling, and vibration conditions. Results demonstrate self-healing properties that conventional interconnects lack, as liquid metals can automatically restore electrical pathways after physical disruption. This characteristic proves particularly valuable in quantum computing environments where system stability is paramount. Accelerated aging tests suggest potential operational lifespans exceeding 10 years under standard conditions, though long-term data remains limited.

Scalability assessments indicate both advantages and challenges. The fluidic nature of liquid metal allows for reconfigurable connections that can adapt to evolving system architectures, supporting the modular approach essential for quantum computing advancement. However, current manufacturing processes face limitations in miniaturization below certain thresholds (approximately 10μm channel width) due to surface tension effects and oxidation concerns.

Integration density represents another critical scalability metric. Research demonstrates that liquid metal interconnects can achieve connection densities approaching 1000 connections per square centimeter, comparable to advanced PCB technologies. This density supports the complex interconnection requirements of modular quantum systems, though further improvements are necessary to match the trajectory of quantum processing unit development.

Reliability degradation mechanisms have been identified, including gallium diffusion into substrate materials, oxidation at interfaces, and potential embrittlement of adjacent components. Mitigation strategies include specialized encapsulation techniques, surface treatments to control wetting behaviors, and development of compatible substrate materials that resist gallium penetration. These approaches have demonstrated significant improvements in mean time between failures (MTBF) metrics.

Standardized testing frameworks for liquid metal interconnect reliability remain underdeveloped compared to conventional electronics. Industry collaboration is emerging to establish consistent evaluation methodologies that address the unique characteristics of these materials, particularly focusing on quantum-specific requirements such as cryogenic performance and electromagnetic interference shielding capabilities.

Reliability testing protocols have evaluated liquid metal interconnects under mechanical stress, thermal cycling, and vibration conditions. Results demonstrate self-healing properties that conventional interconnects lack, as liquid metals can automatically restore electrical pathways after physical disruption. This characteristic proves particularly valuable in quantum computing environments where system stability is paramount. Accelerated aging tests suggest potential operational lifespans exceeding 10 years under standard conditions, though long-term data remains limited.

Scalability assessments indicate both advantages and challenges. The fluidic nature of liquid metal allows for reconfigurable connections that can adapt to evolving system architectures, supporting the modular approach essential for quantum computing advancement. However, current manufacturing processes face limitations in miniaturization below certain thresholds (approximately 10μm channel width) due to surface tension effects and oxidation concerns.

Integration density represents another critical scalability metric. Research demonstrates that liquid metal interconnects can achieve connection densities approaching 1000 connections per square centimeter, comparable to advanced PCB technologies. This density supports the complex interconnection requirements of modular quantum systems, though further improvements are necessary to match the trajectory of quantum processing unit development.

Reliability degradation mechanisms have been identified, including gallium diffusion into substrate materials, oxidation at interfaces, and potential embrittlement of adjacent components. Mitigation strategies include specialized encapsulation techniques, surface treatments to control wetting behaviors, and development of compatible substrate materials that resist gallium penetration. These approaches have demonstrated significant improvements in mean time between failures (MTBF) metrics.

Standardized testing frameworks for liquid metal interconnect reliability remain underdeveloped compared to conventional electronics. Industry collaboration is emerging to establish consistent evaluation methodologies that address the unique characteristics of these materials, particularly focusing on quantum-specific requirements such as cryogenic performance and electromagnetic interference shielding capabilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!