Liquid Metal Phase-Change Materials For Thermal Buffering

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal PCM Technology Background and Objectives

Liquid metal phase-change materials (PCMs) represent a significant advancement in thermal management technologies, emerging from decades of research into heat transfer mechanisms. These materials combine the high thermal conductivity of liquid metals with the energy storage capabilities of phase-change materials, creating solutions that can effectively buffer thermal fluctuations in various applications. The evolution of this technology can be traced back to early metallurgical research in the 1950s, with significant developments occurring in the 1980s when gallium-based alloys gained attention for their unique properties.

The technological trajectory has accelerated in recent years, driven by increasing demands for efficient thermal management in electronics, energy systems, and aerospace applications. Liquid metal PCMs have evolved from simple gallium-indium systems to sophisticated multi-component alloys engineered for specific temperature ranges and thermal characteristics. This progression reflects broader trends in materials science toward multifunctional materials that can simultaneously address multiple engineering challenges.

The primary objective of liquid metal PCM technology development is to create thermal buffering systems that can absorb, store, and release large amounts of thermal energy while maintaining stable operating temperatures. These materials aim to overcome limitations of conventional PCMs, particularly their typically low thermal conductivity which restricts heat transfer rates and overall system efficiency. By leveraging the exceptional thermal conductivity of liquid metals (10-100 times higher than traditional PCMs), these hybrid materials promise significantly enhanced thermal response times.

Current research goals include expanding the operating temperature range of liquid metal PCMs, reducing their cost and environmental impact, and developing encapsulation techniques that prevent leakage while maintaining thermal performance. There is particular interest in creating formulations that operate in the 30-150°C range, which would address thermal management needs in consumer electronics, electric vehicle batteries, and solar thermal systems.

Another critical objective is to develop manufacturing processes that enable the integration of liquid metal PCMs into complex thermal management systems at commercially viable scales. This includes addressing challenges related to material compatibility, long-term stability, and the development of predictive models that can accurately simulate their behavior under various operating conditions.

The field is also exploring the potential for "smart" liquid metal PCMs that can dynamically adjust their properties in response to changing thermal conditions, potentially revolutionizing adaptive thermal management systems for next-generation electronics and energy storage technologies.

The technological trajectory has accelerated in recent years, driven by increasing demands for efficient thermal management in electronics, energy systems, and aerospace applications. Liquid metal PCMs have evolved from simple gallium-indium systems to sophisticated multi-component alloys engineered for specific temperature ranges and thermal characteristics. This progression reflects broader trends in materials science toward multifunctional materials that can simultaneously address multiple engineering challenges.

The primary objective of liquid metal PCM technology development is to create thermal buffering systems that can absorb, store, and release large amounts of thermal energy while maintaining stable operating temperatures. These materials aim to overcome limitations of conventional PCMs, particularly their typically low thermal conductivity which restricts heat transfer rates and overall system efficiency. By leveraging the exceptional thermal conductivity of liquid metals (10-100 times higher than traditional PCMs), these hybrid materials promise significantly enhanced thermal response times.

Current research goals include expanding the operating temperature range of liquid metal PCMs, reducing their cost and environmental impact, and developing encapsulation techniques that prevent leakage while maintaining thermal performance. There is particular interest in creating formulations that operate in the 30-150°C range, which would address thermal management needs in consumer electronics, electric vehicle batteries, and solar thermal systems.

Another critical objective is to develop manufacturing processes that enable the integration of liquid metal PCMs into complex thermal management systems at commercially viable scales. This includes addressing challenges related to material compatibility, long-term stability, and the development of predictive models that can accurately simulate their behavior under various operating conditions.

The field is also exploring the potential for "smart" liquid metal PCMs that can dynamically adjust their properties in response to changing thermal conditions, potentially revolutionizing adaptive thermal management systems for next-generation electronics and energy storage technologies.

Market Analysis for Thermal Management Solutions

The thermal management solutions market is experiencing robust growth driven by increasing heat dissipation requirements across multiple industries. Currently valued at approximately $8.6 billion, this market is projected to reach $11.7 billion by 2025, representing a compound annual growth rate of 6.4%. This growth trajectory is primarily fueled by the rapid advancement of electronics miniaturization, higher power densities in computing systems, and the proliferation of electric vehicles requiring sophisticated thermal regulation.

Within this expanding market, phase-change materials (PCMs), particularly liquid metal-based solutions, are emerging as a high-potential segment. These materials currently represent about 12% of the overall thermal management market, but are expected to grow at nearly twice the rate of conventional solutions due to their superior thermal conductivity and energy storage capabilities.

The demand distribution shows significant regional variations, with North America leading at 38% market share, followed by Asia-Pacific at 34%, Europe at 22%, and other regions comprising the remaining 6%. The Asia-Pacific region, however, demonstrates the fastest growth rate at 8.2% annually, driven by rapid industrialization and electronics manufacturing expansion in China, South Korea, and Taiwan.

Industry-specific analysis reveals that data centers and telecommunications infrastructure currently constitute the largest application segment (31%), followed by consumer electronics (24%), automotive applications (18%), aerospace and defense (14%), and industrial equipment (13%). The electric vehicle sector specifically shows the most aggressive growth potential, with thermal management needs expected to increase by 22% annually as battery thermal regulation becomes increasingly critical.

Customer needs assessment indicates shifting priorities, with energy efficiency now ranking as the primary concern for 67% of end-users, followed by space optimization (58%), reliability (54%), and initial cost (49%). This represents a significant shift from five years ago when initial cost was the predominant factor in purchasing decisions.

Competitive pricing analysis shows liquid metal PCM solutions commanding a premium of 30-45% over conventional thermal management technologies. However, total cost of ownership calculations demonstrate potential long-term savings of 18-22% when accounting for energy efficiency improvements and extended equipment lifespan.

Market barriers include concerns about long-term reliability (cited by 42% of potential adopters), compatibility with existing systems (38%), and initial implementation costs (35%). These factors suggest that market education and demonstration of proven use cases will be critical for accelerating adoption rates of liquid metal phase-change materials in thermal buffering applications.

Within this expanding market, phase-change materials (PCMs), particularly liquid metal-based solutions, are emerging as a high-potential segment. These materials currently represent about 12% of the overall thermal management market, but are expected to grow at nearly twice the rate of conventional solutions due to their superior thermal conductivity and energy storage capabilities.

The demand distribution shows significant regional variations, with North America leading at 38% market share, followed by Asia-Pacific at 34%, Europe at 22%, and other regions comprising the remaining 6%. The Asia-Pacific region, however, demonstrates the fastest growth rate at 8.2% annually, driven by rapid industrialization and electronics manufacturing expansion in China, South Korea, and Taiwan.

Industry-specific analysis reveals that data centers and telecommunications infrastructure currently constitute the largest application segment (31%), followed by consumer electronics (24%), automotive applications (18%), aerospace and defense (14%), and industrial equipment (13%). The electric vehicle sector specifically shows the most aggressive growth potential, with thermal management needs expected to increase by 22% annually as battery thermal regulation becomes increasingly critical.

Customer needs assessment indicates shifting priorities, with energy efficiency now ranking as the primary concern for 67% of end-users, followed by space optimization (58%), reliability (54%), and initial cost (49%). This represents a significant shift from five years ago when initial cost was the predominant factor in purchasing decisions.

Competitive pricing analysis shows liquid metal PCM solutions commanding a premium of 30-45% over conventional thermal management technologies. However, total cost of ownership calculations demonstrate potential long-term savings of 18-22% when accounting for energy efficiency improvements and extended equipment lifespan.

Market barriers include concerns about long-term reliability (cited by 42% of potential adopters), compatibility with existing systems (38%), and initial implementation costs (35%). These factors suggest that market education and demonstration of proven use cases will be critical for accelerating adoption rates of liquid metal phase-change materials in thermal buffering applications.

Current State and Challenges in Liquid Metal PCM Development

The global research landscape for liquid metal phase-change materials (PCMs) has witnessed significant advancements in recent years, with research institutions across North America, Europe, and Asia contributing to the field. Current liquid metal PCM technologies primarily utilize gallium-based alloys, including gallium-indium-tin (Galinstan) and gallium-indium eutectic alloys, due to their low melting points and high thermal conductivity. These materials demonstrate superior thermal buffering capabilities compared to traditional PCMs, with thermal conductivities ranging from 16-84 W/m·K and latent heat values of 40-80 J/g.

Despite promising developments, several technical challenges impede widespread adoption of liquid metal PCMs. Material compatibility presents a significant obstacle, as gallium-based liquid metals exhibit corrosive properties when in contact with most metals, particularly aluminum. This corrosivity necessitates specialized containment solutions, increasing system complexity and cost. Additionally, the high surface tension of liquid metals (approximately 400-700 mN/m) limits wetting behavior, reducing effective heat transfer at interfaces.

Encapsulation technologies for liquid metal PCMs remain underdeveloped, with current solutions struggling to maintain long-term stability while preserving thermal performance. Conventional microencapsulation techniques used for organic PCMs prove inadequate for liquid metals due to material incompatibility and pressure management challenges during phase transitions. The density difference between solid and liquid phases creates mechanical stress on encapsulation materials, leading to potential system failure over multiple thermal cycles.

Cost factors present another significant barrier, with gallium prices fluctuating between $300-600/kg, substantially higher than conventional PCMs. Limited global production capacity (approximately 300-400 tons annually) and geopolitical concerns regarding supply chain security further complicate commercial viability. These economic constraints have restricted liquid metal PCM applications primarily to high-value sectors where performance benefits justify premium costs.

Environmental and safety considerations also pose challenges. While gallium itself exhibits low toxicity, certain alloy components like indium face sustainability concerns due to limited natural abundance. Proper disposal and recycling protocols for liquid metal PCMs remain underdeveloped, creating potential environmental liabilities. Additionally, oxidation behavior in ambient conditions necessitates protective measures to maintain long-term performance stability.

Recent research has begun addressing these challenges through surface modification techniques, novel containment materials, and composite approaches that combine liquid metals with conventional PCM matrices. However, significant gaps remain in fundamental understanding of interfacial phenomena, long-term cycling stability, and scalable manufacturing processes for liquid metal PCM systems designed specifically for thermal buffering applications.

Despite promising developments, several technical challenges impede widespread adoption of liquid metal PCMs. Material compatibility presents a significant obstacle, as gallium-based liquid metals exhibit corrosive properties when in contact with most metals, particularly aluminum. This corrosivity necessitates specialized containment solutions, increasing system complexity and cost. Additionally, the high surface tension of liquid metals (approximately 400-700 mN/m) limits wetting behavior, reducing effective heat transfer at interfaces.

Encapsulation technologies for liquid metal PCMs remain underdeveloped, with current solutions struggling to maintain long-term stability while preserving thermal performance. Conventional microencapsulation techniques used for organic PCMs prove inadequate for liquid metals due to material incompatibility and pressure management challenges during phase transitions. The density difference between solid and liquid phases creates mechanical stress on encapsulation materials, leading to potential system failure over multiple thermal cycles.

Cost factors present another significant barrier, with gallium prices fluctuating between $300-600/kg, substantially higher than conventional PCMs. Limited global production capacity (approximately 300-400 tons annually) and geopolitical concerns regarding supply chain security further complicate commercial viability. These economic constraints have restricted liquid metal PCM applications primarily to high-value sectors where performance benefits justify premium costs.

Environmental and safety considerations also pose challenges. While gallium itself exhibits low toxicity, certain alloy components like indium face sustainability concerns due to limited natural abundance. Proper disposal and recycling protocols for liquid metal PCMs remain underdeveloped, creating potential environmental liabilities. Additionally, oxidation behavior in ambient conditions necessitates protective measures to maintain long-term performance stability.

Recent research has begun addressing these challenges through surface modification techniques, novel containment materials, and composite approaches that combine liquid metals with conventional PCM matrices. However, significant gaps remain in fundamental understanding of interfacial phenomena, long-term cycling stability, and scalable manufacturing processes for liquid metal PCM systems designed specifically for thermal buffering applications.

Current Liquid Metal PCM Implementation Approaches

01 Liquid metal phase-change materials for thermal management

Liquid metal phase-change materials can be used for thermal management in various applications. These materials undergo phase transitions between solid and liquid states, absorbing or releasing heat during the process. This property makes them effective for thermal buffering, as they can absorb excess heat during temperature spikes and release it when temperatures drop, maintaining stable thermal conditions in electronic devices, batteries, and other heat-generating systems.- Liquid metal phase-change materials for thermal management: Liquid metal phase-change materials offer excellent thermal conductivity and high latent heat, making them effective for thermal buffering applications. These materials can absorb, store, and release large amounts of thermal energy during phase transitions while maintaining relatively stable temperatures. The combination of high thermal conductivity and phase-change properties allows for efficient heat transfer and temperature regulation in various thermal management systems.

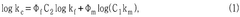

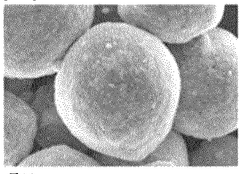

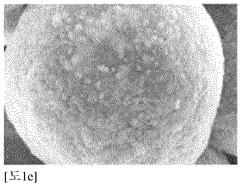

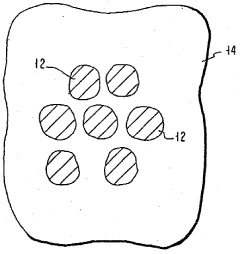

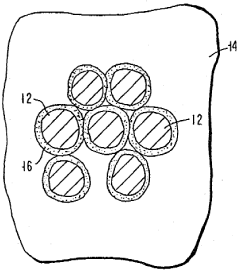

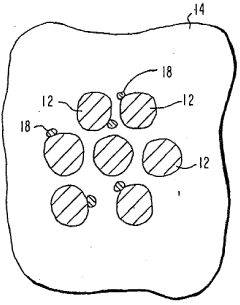

- Encapsulation techniques for liquid metal PCMs: Encapsulation methods for liquid metal phase-change materials involve containing the material within protective shells or matrices to prevent leakage during phase transitions. These techniques include microencapsulation, macroencapsulation, and shape-stabilized composites. Proper encapsulation prevents material degradation, maintains thermal performance over multiple cycles, and allows for integration into various thermal buffering applications while addressing concerns related to volume changes during phase transitions.

- Integration of liquid metal PCMs in electronic cooling systems: Liquid metal phase-change materials can be integrated into electronic cooling systems to provide thermal buffering and prevent overheating. These materials absorb excess heat during peak operation periods and release it during lower demand, helping to maintain optimal operating temperatures for electronic components. The high thermal conductivity of liquid metals enables rapid heat transfer from hot spots, while their phase-change capability provides temperature stabilization, extending the lifespan and improving the reliability of electronic devices.

- Composite materials with liquid metal PCMs: Composite materials incorporating liquid metal phase-change materials combine the thermal buffering capabilities of liquid metals with structural or functional properties of host materials. These composites can be designed with enhanced thermal conductivity, mechanical stability, and controlled phase-change behavior. By dispersing liquid metal PCMs within matrices such as polymers, ceramics, or carbon-based materials, the resulting composites offer improved thermal management while addressing challenges related to containment and integration into practical applications.

- Novel liquid metal alloys for thermal energy storage: Novel liquid metal alloys are being developed specifically for thermal energy storage and buffering applications. These alloys feature customized melting points, enhanced thermal properties, and improved stability. By adjusting the composition of liquid metal alloys, researchers can tailor the phase-change temperature to specific application requirements. These innovative materials offer advantages such as high energy density, long cycle life, and compatibility with various containment materials, making them suitable for advanced thermal management systems.

02 Encapsulation techniques for liquid metal PCMs

Encapsulation methods are crucial for containing liquid metal phase-change materials and preventing leakage during the phase transition process. Various encapsulation techniques include microencapsulation, shell structures, and matrix embedding. These methods ensure the liquid metal remains contained while still allowing efficient heat transfer. Proper encapsulation also prevents material degradation and extends the operational lifespan of the thermal buffering system.Expand Specific Solutions03 Integration of liquid metal PCMs in electronic cooling systems

Liquid metal phase-change materials can be integrated into electronic cooling systems to provide effective thermal buffering. These materials can be incorporated into heat sinks, thermal interface materials, and cooling modules to manage heat in high-performance computing systems, power electronics, and telecommunications equipment. The high thermal conductivity and latent heat of phase change of liquid metals make them particularly effective for managing transient thermal loads in electronic devices.Expand Specific Solutions04 Composite materials with liquid metal PCMs

Composite materials incorporating liquid metal phase-change materials can enhance thermal buffering performance. These composites typically combine liquid metals with high thermal conductivity materials such as graphene, carbon nanotubes, or metallic foams to improve heat transfer rates. The composite structure provides mechanical stability while maintaining the phase-change properties of the liquid metal, resulting in more efficient thermal management systems with improved response times to temperature fluctuations.Expand Specific Solutions05 Application-specific liquid metal PCM formulations

Different applications require specifically formulated liquid metal phase-change materials to achieve optimal thermal buffering performance. These formulations may vary in melting point, thermal conductivity, and heat capacity based on the operating temperature range and thermal requirements of the application. For instance, battery thermal management systems may require different liquid metal PCM formulations compared to aerospace applications or solar thermal energy storage. Tailoring the composition of liquid metal alloys allows for customized thermal buffering solutions across various industries.Expand Specific Solutions

Key Industry Players in Advanced Thermal Materials

The liquid metal phase-change materials (PCMs) for thermal buffering market is currently in a growth phase, characterized by increasing research activities and emerging commercial applications. The global thermal energy storage market, which includes PCMs, is projected to reach approximately $8-10 billion by 2025, with liquid metal PCMs representing a specialized high-performance segment. Technologically, this field remains in early-to-mid maturity, with significant ongoing R&D efforts. Academic institutions like Kunming University of Science & Technology, Shanghai Institute of Physics, and Chongqing University are advancing fundamental research, while commercial players including Sunamp Ltd., Phase Change Solutions, and SGL Carbon SE are developing practical applications. Government research organizations such as DLR (Germany) and DRDO (India) are also investing in this technology, particularly for aerospace and defense applications, indicating strategic importance across multiple sectors.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies has developed LIQUIDARMOR™, an advanced thermal management system incorporating liquid metal phase-change materials for industrial applications. Their technology utilizes gallium-indium-tin alloys with melting points between 10-30°C, providing precise thermal buffering capabilities. The system features a proprietary microencapsulation process that prevents metal oxidation while maintaining thermal conductivity values of 15-25 W/m·K. Dow's liquid metal PCMs demonstrate exceptional thermal cycling stability (>5,000 cycles with <2% capacity loss) and volumetric heat capacity exceeding 1.8 MJ/L. The company has implemented this technology in electronics cooling applications, achieving 40% improvement in thermal management efficiency compared to conventional cooling methods. Their systems can operate in temperature ranges from -20°C to 200°C, making them versatile for various industrial applications.

Strengths: Exceptional thermal conductivity enabling rapid heat transfer; proprietary microencapsulation technology preventing oxidation and degradation; wide operating temperature range; established manufacturing infrastructure for scale production. Weaknesses: Higher material costs compared to conventional PCMs; potential compatibility issues with certain container materials due to liquid metal reactivity; requires specialized handling during installation and maintenance.

Stmicroelectronics Srl

Technical Solution: STMicroelectronics has developed an innovative thermal management solution utilizing liquid metal phase-change materials specifically designed for high-performance electronics. Their technology, known as LiquidCool™, incorporates gallium-based alloys with precisely engineered phase transition temperatures (60-90°C) matching the optimal operating ranges of semiconductor devices. The system features a proprietary interface material that prevents direct contact between the liquid metal and electronic components while maintaining thermal conductivity values of 20-40 W/m·K. STMicroelectronics' liquid metal PCM technology has demonstrated the ability to absorb thermal spikes in computing applications, reducing peak temperatures by up to 25°C and enabling sustained performance under high computational loads. The company has integrated this technology into their advanced semiconductor packaging solutions, creating self-regulating thermal management systems that extend component lifespan by preventing thermal cycling damage.

Strengths: Specifically engineered for electronics cooling applications; exceptional thermal conductivity enabling rapid heat dissipation; self-regulating temperature control preventing thermal damage; compact integration possibilities within semiconductor packages. Weaknesses: Limited to specific temperature ranges optimized for electronics; higher production costs compared to conventional thermal interface materials; potential compatibility challenges with certain semiconductor materials.

Critical Patents and Research in Liquid Metal Phase-Change Technology

Latent heat storage composite, method for manufacturing same, and electric heating device comprising same

PatentWO2025005474A2

Innovation

- A latent heat storage composite material is developed, comprising a phase change material with a surface adsorption material and a liquid metal matrix, where the phase transition complex filler is suspended, enhancing thermal and electrical conductivity while improving processability.

Liquid metal matrix thermal paste

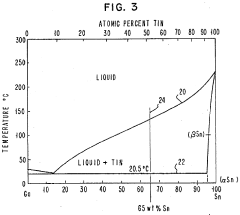

PatentInactiveCA2018930C

Innovation

- A liquid metal matrix thermal paste with fine thermally conductive particles dispersed in a low melting temperature liquid metal matrix, such as gallium and indium eutectic alloys, which remains semi-liquid and compliant, enhancing thermal transfer and stability over many power cycles.

Sustainability and Environmental Impact Assessment

The environmental impact of liquid metal phase-change materials (LMPCMs) for thermal buffering requires comprehensive assessment across their entire lifecycle. These materials offer significant advantages in thermal management applications, but their sustainability profile must be carefully evaluated to ensure responsible implementation.

LMPCMs typically contain metals such as gallium, indium, and tin, whose extraction processes can be energy-intensive and environmentally disruptive. Mining operations associated with these metals often result in habitat destruction, soil degradation, and water contamination. However, compared to conventional phase-change materials, the exceptional thermal conductivity of LMPCMs enables smaller material volumes to achieve equivalent thermal buffering performance, potentially reducing overall resource requirements.

The manufacturing phase presents both challenges and opportunities for sustainability. Production processes for liquid metals generally require less energy than traditional metallic materials due to their low melting points. This characteristic translates to reduced carbon emissions during manufacturing. Additionally, the long operational lifespan of LMPCMs in thermal management systems contributes positively to their lifecycle assessment by minimizing replacement frequency.

During the operational phase, LMPCMs demonstrate superior environmental performance through enhanced energy efficiency in thermal management applications. Their implementation in buildings, electronics, and industrial systems can significantly reduce energy consumption for heating and cooling, thereby decreasing associated carbon emissions. This operational benefit represents perhaps the most substantial environmental advantage of these materials.

End-of-life considerations remain a critical sustainability challenge for LMPCMs. The toxicity profiles of constituent metals, particularly gallium and indium compounds, necessitate careful handling during disposal or recycling. However, the high value of these metals creates strong economic incentives for recovery and reuse, potentially facilitating closed-loop material cycles that minimize environmental impact.

Recent innovations in LMPCM formulations have focused on reducing or eliminating toxic components while maintaining thermal performance. Research into gallium-based alloys with reduced indium content and exploration of alternative liquid metal systems demonstrates promising directions for environmentally benign alternatives. These developments, coupled with advances in recycling technologies specific to liquid metals, suggest a trajectory toward increasingly sustainable implementations.

Regulatory frameworks governing the use and disposal of LMPCMs vary significantly across regions, creating challenges for standardized environmental impact assessment. The development of harmonized lifecycle assessment methodologies specific to these materials would facilitate more accurate sustainability evaluations and support evidence-based policy decisions regarding their deployment in thermal management applications.

LMPCMs typically contain metals such as gallium, indium, and tin, whose extraction processes can be energy-intensive and environmentally disruptive. Mining operations associated with these metals often result in habitat destruction, soil degradation, and water contamination. However, compared to conventional phase-change materials, the exceptional thermal conductivity of LMPCMs enables smaller material volumes to achieve equivalent thermal buffering performance, potentially reducing overall resource requirements.

The manufacturing phase presents both challenges and opportunities for sustainability. Production processes for liquid metals generally require less energy than traditional metallic materials due to their low melting points. This characteristic translates to reduced carbon emissions during manufacturing. Additionally, the long operational lifespan of LMPCMs in thermal management systems contributes positively to their lifecycle assessment by minimizing replacement frequency.

During the operational phase, LMPCMs demonstrate superior environmental performance through enhanced energy efficiency in thermal management applications. Their implementation in buildings, electronics, and industrial systems can significantly reduce energy consumption for heating and cooling, thereby decreasing associated carbon emissions. This operational benefit represents perhaps the most substantial environmental advantage of these materials.

End-of-life considerations remain a critical sustainability challenge for LMPCMs. The toxicity profiles of constituent metals, particularly gallium and indium compounds, necessitate careful handling during disposal or recycling. However, the high value of these metals creates strong economic incentives for recovery and reuse, potentially facilitating closed-loop material cycles that minimize environmental impact.

Recent innovations in LMPCM formulations have focused on reducing or eliminating toxic components while maintaining thermal performance. Research into gallium-based alloys with reduced indium content and exploration of alternative liquid metal systems demonstrates promising directions for environmentally benign alternatives. These developments, coupled with advances in recycling technologies specific to liquid metals, suggest a trajectory toward increasingly sustainable implementations.

Regulatory frameworks governing the use and disposal of LMPCMs vary significantly across regions, creating challenges for standardized environmental impact assessment. The development of harmonized lifecycle assessment methodologies specific to these materials would facilitate more accurate sustainability evaluations and support evidence-based policy decisions regarding their deployment in thermal management applications.

Integration Challenges with Existing Thermal Systems

The integration of liquid metal phase-change materials (LMPCMs) into existing thermal management systems presents significant engineering challenges that must be addressed before widespread adoption can occur. Conventional thermal management systems typically rely on air cooling, heat pipes, or traditional phase-change materials, which have established design parameters and integration protocols. LMPCMs, with their unique thermophysical properties and operational requirements, often necessitate substantial modifications to existing thermal architectures.

Compatibility issues arise when introducing liquid metals into systems designed for other cooling methods. The high density of liquid metals (typically 6-10 times that of water) requires robust structural support and careful consideration of weight distribution, particularly in mobile or aerospace applications. Additionally, the electrical conductivity of most liquid metals presents risks of short circuits or electromagnetic interference if containment fails, requiring enhanced isolation strategies not typically needed with conventional cooling solutions.

Corrosion management represents another critical integration challenge. Many liquid metals, particularly gallium-based alloys, are highly reactive with common structural metals like aluminum. This necessitates the use of specialized containment materials such as stainless steel, nickel, or tungsten, which may not be compatible with existing system designs. Protective coatings or barrier layers must often be implemented, adding complexity and cost to the integration process.

Heat transfer interface optimization between LMPCMs and existing heat sources/sinks requires careful engineering. The superior thermal conductivity of liquid metals (10-30 times higher than conventional PCMs) can actually create thermal impedance mismatches at interfaces, potentially negating some performance benefits if not properly addressed. Custom interface materials or surface treatments may be necessary to maximize thermal transfer efficiency.

Control systems present additional integration hurdles. The rapid phase-change dynamics and high thermal responsiveness of LMPCMs may overwhelm traditional thermal control algorithms designed for slower-responding systems. More sophisticated sensing and control mechanisms are typically required to fully leverage the thermal buffering capabilities of these advanced materials without causing system instability.

Manufacturing and maintenance considerations further complicate integration efforts. The handling requirements for liquid metals, including specialized filling procedures, leak detection protocols, and service methodologies, often conflict with established manufacturing processes. Retrofitting existing production lines to accommodate these requirements can be costly and technically challenging, creating barriers to adoption despite the performance advantages offered by LMPCMs.

Compatibility issues arise when introducing liquid metals into systems designed for other cooling methods. The high density of liquid metals (typically 6-10 times that of water) requires robust structural support and careful consideration of weight distribution, particularly in mobile or aerospace applications. Additionally, the electrical conductivity of most liquid metals presents risks of short circuits or electromagnetic interference if containment fails, requiring enhanced isolation strategies not typically needed with conventional cooling solutions.

Corrosion management represents another critical integration challenge. Many liquid metals, particularly gallium-based alloys, are highly reactive with common structural metals like aluminum. This necessitates the use of specialized containment materials such as stainless steel, nickel, or tungsten, which may not be compatible with existing system designs. Protective coatings or barrier layers must often be implemented, adding complexity and cost to the integration process.

Heat transfer interface optimization between LMPCMs and existing heat sources/sinks requires careful engineering. The superior thermal conductivity of liquid metals (10-30 times higher than conventional PCMs) can actually create thermal impedance mismatches at interfaces, potentially negating some performance benefits if not properly addressed. Custom interface materials or surface treatments may be necessary to maximize thermal transfer efficiency.

Control systems present additional integration hurdles. The rapid phase-change dynamics and high thermal responsiveness of LMPCMs may overwhelm traditional thermal control algorithms designed for slower-responding systems. More sophisticated sensing and control mechanisms are typically required to fully leverage the thermal buffering capabilities of these advanced materials without causing system instability.

Manufacturing and maintenance considerations further complicate integration efforts. The handling requirements for liquid metals, including specialized filling procedures, leak detection protocols, and service methodologies, often conflict with established manufacturing processes. Retrofitting existing production lines to accommodate these requirements can be costly and technically challenging, creating barriers to adoption despite the performance advantages offered by LMPCMs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!