Interface Stability And Corrosion Control In Gallium Alloy Cooling Systems

AUG 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gallium Alloy Cooling Technology Background and Objectives

Gallium-based liquid metal cooling systems represent a significant advancement in thermal management technology, offering superior heat transfer capabilities compared to traditional cooling methods. The evolution of this technology can be traced back to the early 2000s when researchers began exploring alternatives to conventional water and air cooling systems for high-performance electronics and power generation applications. Gallium alloys, particularly eutectic gallium-indium (EGaIn) and gallium-indium-tin (Galinstan), emerged as promising candidates due to their exceptional thermal conductivity, low melting points, and liquid state at room temperature.

The development trajectory of gallium alloy cooling technology has been accelerated by increasing thermal management demands in various sectors, including data centers, electric vehicles, aerospace applications, and concentrated solar power systems. As power densities in electronic components continue to rise exponentially, conventional cooling methods have approached their fundamental limits, creating an urgent need for more efficient thermal management solutions.

Despite the promising thermal properties of gallium alloys, widespread adoption has been hindered by significant challenges related to interface stability and corrosion. Gallium and its alloys are highly reactive with most conventional engineering metals, particularly aluminum, causing rapid degradation of cooling system components through processes such as liquid metal embrittlement and dissolution corrosion.

The primary technical objective in this field is to develop effective strategies for controlling the interfacial reactions between gallium alloys and containment materials while maintaining optimal heat transfer performance. This includes the design of corrosion-resistant coatings, development of compatible structural materials, and engineering of stable interfaces that can withstand long-term operation under thermal cycling conditions.

Secondary objectives include optimizing the thermophysical properties of gallium alloys through compositional adjustments, understanding the fundamental mechanisms of corrosion at the molecular level, and establishing standardized testing protocols for evaluating long-term reliability of gallium-based cooling systems.

Recent technological breakthroughs in surface engineering, nanomaterials, and computational modeling have opened new avenues for addressing these challenges. Advanced coating technologies such as atomic layer deposition, self-healing materials, and engineered oxide layers have shown promise in mitigating corrosion while maintaining thermal performance. Additionally, the integration of real-time monitoring systems for early detection of corrosion phenomena represents an important direction for ensuring operational reliability.

The successful development of stable and corrosion-resistant gallium alloy cooling systems would enable transformative improvements in thermal management efficiency, potentially reducing energy consumption in data centers by up to 40%, extending the range of electric vehicles, and enhancing the performance of high-power electronics in critical applications.

The development trajectory of gallium alloy cooling technology has been accelerated by increasing thermal management demands in various sectors, including data centers, electric vehicles, aerospace applications, and concentrated solar power systems. As power densities in electronic components continue to rise exponentially, conventional cooling methods have approached their fundamental limits, creating an urgent need for more efficient thermal management solutions.

Despite the promising thermal properties of gallium alloys, widespread adoption has been hindered by significant challenges related to interface stability and corrosion. Gallium and its alloys are highly reactive with most conventional engineering metals, particularly aluminum, causing rapid degradation of cooling system components through processes such as liquid metal embrittlement and dissolution corrosion.

The primary technical objective in this field is to develop effective strategies for controlling the interfacial reactions between gallium alloys and containment materials while maintaining optimal heat transfer performance. This includes the design of corrosion-resistant coatings, development of compatible structural materials, and engineering of stable interfaces that can withstand long-term operation under thermal cycling conditions.

Secondary objectives include optimizing the thermophysical properties of gallium alloys through compositional adjustments, understanding the fundamental mechanisms of corrosion at the molecular level, and establishing standardized testing protocols for evaluating long-term reliability of gallium-based cooling systems.

Recent technological breakthroughs in surface engineering, nanomaterials, and computational modeling have opened new avenues for addressing these challenges. Advanced coating technologies such as atomic layer deposition, self-healing materials, and engineered oxide layers have shown promise in mitigating corrosion while maintaining thermal performance. Additionally, the integration of real-time monitoring systems for early detection of corrosion phenomena represents an important direction for ensuring operational reliability.

The successful development of stable and corrosion-resistant gallium alloy cooling systems would enable transformative improvements in thermal management efficiency, potentially reducing energy consumption in data centers by up to 40%, extending the range of electric vehicles, and enhancing the performance of high-power electronics in critical applications.

Market Analysis for Liquid Metal Thermal Management Solutions

The liquid metal thermal management solutions market is experiencing significant growth, driven by increasing demands for efficient cooling systems in high-performance computing, data centers, and power electronics. The global market value for advanced thermal management solutions reached approximately $12.3 billion in 2022 and is projected to grow at a CAGR of 8.7% through 2028, with liquid metal solutions representing the fastest-growing segment at 14.2% annual growth.

Gallium-based liquid metal cooling systems are gaining particular attention due to their superior thermal conductivity compared to traditional cooling methods. These systems offer thermal conductivity values of 16-30 W/m·K, significantly outperforming conventional water-based cooling solutions (0.6 W/m·K) and even heat pipes in certain applications. This performance advantage translates to temperature reductions of 15-30°C in high-power density electronics.

The primary market segments for gallium alloy cooling systems include data centers (38% of market share), high-performance computing (27%), telecommunications equipment (15%), electric vehicle battery thermal management (12%), and other applications (8%). The data center segment alone represents a $2.1 billion opportunity for advanced cooling technologies, with liquid metal solutions poised to capture an increasing portion as energy efficiency requirements become more stringent.

Regionally, North America leads the market with 42% share, followed by Asia-Pacific (31%), Europe (21%), and rest of world (6%). However, the Asia-Pacific region is expected to show the highest growth rate at 16.3% annually, driven by expanding data center infrastructure and electronics manufacturing.

Key market drivers include the exponential increase in data center power densities, which have risen from 5-10 kW per rack to 30-50 kW per rack in high-performance applications. Additionally, the push for greater energy efficiency, with PUE (Power Usage Effectiveness) targets below 1.2 for new facilities, is accelerating adoption of advanced cooling technologies.

Market barriers include concerns about long-term corrosion effects of gallium alloys on common metals, higher initial implementation costs (typically 2.5-3x that of traditional cooling systems), and technical challenges related to pumping and interface stability. Despite these challenges, the performance benefits are compelling enough that early adopters are willing to invest in these solutions, particularly for critical high-value applications where thermal management limitations constrain system performance.

Gallium-based liquid metal cooling systems are gaining particular attention due to their superior thermal conductivity compared to traditional cooling methods. These systems offer thermal conductivity values of 16-30 W/m·K, significantly outperforming conventional water-based cooling solutions (0.6 W/m·K) and even heat pipes in certain applications. This performance advantage translates to temperature reductions of 15-30°C in high-power density electronics.

The primary market segments for gallium alloy cooling systems include data centers (38% of market share), high-performance computing (27%), telecommunications equipment (15%), electric vehicle battery thermal management (12%), and other applications (8%). The data center segment alone represents a $2.1 billion opportunity for advanced cooling technologies, with liquid metal solutions poised to capture an increasing portion as energy efficiency requirements become more stringent.

Regionally, North America leads the market with 42% share, followed by Asia-Pacific (31%), Europe (21%), and rest of world (6%). However, the Asia-Pacific region is expected to show the highest growth rate at 16.3% annually, driven by expanding data center infrastructure and electronics manufacturing.

Key market drivers include the exponential increase in data center power densities, which have risen from 5-10 kW per rack to 30-50 kW per rack in high-performance applications. Additionally, the push for greater energy efficiency, with PUE (Power Usage Effectiveness) targets below 1.2 for new facilities, is accelerating adoption of advanced cooling technologies.

Market barriers include concerns about long-term corrosion effects of gallium alloys on common metals, higher initial implementation costs (typically 2.5-3x that of traditional cooling systems), and technical challenges related to pumping and interface stability. Despite these challenges, the performance benefits are compelling enough that early adopters are willing to invest in these solutions, particularly for critical high-value applications where thermal management limitations constrain system performance.

Interface Stability Challenges in Gallium-Based Cooling Systems

The interface between gallium alloys and container materials presents significant challenges in liquid metal cooling systems. Gallium and its alloys, while offering exceptional thermal conductivity, exhibit highly reactive behavior that can compromise system integrity. These liquid metals readily form intermetallic compounds with most engineering metals, leading to dissolution, embrittlement, and eventual structural failure. The wetting characteristics of gallium alloys further complicate interface management, as they can penetrate grain boundaries and accelerate corrosion processes.

A primary stability challenge involves the formation of oxide layers on gallium alloy surfaces. When exposed to oxygen, gallium forms a thin oxide film that alters surface tension properties and can impede heat transfer efficiency. This oxidation behavior varies significantly with temperature, flow conditions, and the presence of other elements in the system, making it difficult to predict and control interface dynamics over extended operational periods.

Electrochemical interactions at the interface create galvanic coupling effects that accelerate corrosion. The substantial electrochemical potential difference between gallium and common container materials establishes conditions for preferential dissolution of anodic components. This phenomenon is particularly problematic in systems with multiple metallic components, where complex galvanic series can develop and create localized corrosion hotspots.

Temperature fluctuations introduce additional interface stability concerns through thermal expansion mismatch. The coefficient of thermal expansion for gallium alloys differs significantly from most container materials, generating mechanical stresses during thermal cycling that can compromise protective coatings and accelerate interface degradation. These thermal effects become particularly pronounced at the triple-phase boundaries where solid, liquid, and gas phases meet.

Flow-induced erosion represents another critical challenge, as the movement of gallium alloys can mechanically remove protective surface layers. This is especially problematic in high-velocity regions of cooling systems where shear forces are maximized. The combination of chemical dissolution and mechanical erosion creates synergistic degradation mechanisms that accelerate material loss rates beyond what would be predicted by either mechanism alone.

The presence of impurities in the gallium alloy significantly impacts interface stability. Even trace amounts of certain elements can dramatically alter wetting behavior, oxide formation kinetics, and corrosion rates. These impurity effects are often non-linear and can trigger unexpected degradation mechanisms that are difficult to model or predict using conventional approaches.

Addressing these interface stability challenges requires integrated solutions that combine materials science, surface engineering, and system design approaches. The development of effective interface management strategies represents a critical enabling technology for the broader adoption of gallium-based cooling systems across high-performance computing, power electronics, and energy conversion applications.

A primary stability challenge involves the formation of oxide layers on gallium alloy surfaces. When exposed to oxygen, gallium forms a thin oxide film that alters surface tension properties and can impede heat transfer efficiency. This oxidation behavior varies significantly with temperature, flow conditions, and the presence of other elements in the system, making it difficult to predict and control interface dynamics over extended operational periods.

Electrochemical interactions at the interface create galvanic coupling effects that accelerate corrosion. The substantial electrochemical potential difference between gallium and common container materials establishes conditions for preferential dissolution of anodic components. This phenomenon is particularly problematic in systems with multiple metallic components, where complex galvanic series can develop and create localized corrosion hotspots.

Temperature fluctuations introduce additional interface stability concerns through thermal expansion mismatch. The coefficient of thermal expansion for gallium alloys differs significantly from most container materials, generating mechanical stresses during thermal cycling that can compromise protective coatings and accelerate interface degradation. These thermal effects become particularly pronounced at the triple-phase boundaries where solid, liquid, and gas phases meet.

Flow-induced erosion represents another critical challenge, as the movement of gallium alloys can mechanically remove protective surface layers. This is especially problematic in high-velocity regions of cooling systems where shear forces are maximized. The combination of chemical dissolution and mechanical erosion creates synergistic degradation mechanisms that accelerate material loss rates beyond what would be predicted by either mechanism alone.

The presence of impurities in the gallium alloy significantly impacts interface stability. Even trace amounts of certain elements can dramatically alter wetting behavior, oxide formation kinetics, and corrosion rates. These impurity effects are often non-linear and can trigger unexpected degradation mechanisms that are difficult to model or predict using conventional approaches.

Addressing these interface stability challenges requires integrated solutions that combine materials science, surface engineering, and system design approaches. The development of effective interface management strategies represents a critical enabling technology for the broader adoption of gallium-based cooling systems across high-performance computing, power electronics, and energy conversion applications.

Current Interface Corrosion Control Methodologies

01 Surface treatment techniques for gallium alloy interfaces

Various surface treatment methods can be applied to improve the interface stability between gallium alloys and cooling system components. These treatments include oxidation resistance coatings, surface passivation techniques, and chemical modifications that create protective barrier layers. These approaches help prevent unwanted reactions between the liquid metal and substrate materials, enhancing long-term stability and reducing degradation at critical interfaces.- Surface treatment techniques for gallium alloy interfaces: Various surface treatment methods can be applied to improve the interface stability between gallium alloys and cooling system components. These treatments include oxidation resistance coatings, passivation layers, and surface modification techniques that enhance wettability while reducing corrosion. Such treatments create protective barriers that prevent direct contact between the gallium alloy and susceptible materials, significantly improving long-term stability and reducing interface degradation in cooling applications.

- Corrosion inhibitors and additives for gallium cooling systems: Specific corrosion inhibitors and chemical additives can be incorporated into gallium-based cooling systems to control corrosion. These compounds form protective films on metal surfaces or neutralize corrosive byproducts in the system. Effective additives include certain organic compounds, metal passivators, and pH regulators that maintain optimal chemical conditions within the cooling system, extending component lifespan and preserving thermal performance.

- Compatible materials selection for gallium cooling systems: Careful selection of materials that resist gallium corrosion is crucial for cooling system longevity. Materials such as certain ceramics, specific stainless steel alloys, titanium-based composites, and specially treated aluminum alloys demonstrate superior resistance to gallium attack. The compatibility between gallium alloys and system components depends on factors including operating temperature, pressure conditions, and flow dynamics, requiring comprehensive material testing under application-specific conditions.

- Interface design and engineering for stability enhancement: Advanced interface engineering approaches can significantly improve the stability of gallium alloy cooling systems. These include creating diffusion barrier layers, implementing gradient interfaces that distribute mechanical stress, and designing microstructured surfaces that control wetting behavior. Specialized joining techniques and interface geometries can minimize areas susceptible to corrosion while maximizing heat transfer efficiency across the interface, balancing thermal performance with long-term stability.

- Monitoring and maintenance strategies for gallium cooling systems: Implementing effective monitoring and maintenance protocols is essential for managing corrosion in gallium alloy cooling systems. These strategies include real-time corrosion sensors, periodic inspection procedures, filtration systems to remove corrosion products, and scheduled maintenance intervals based on system performance metrics. Preventative maintenance approaches can detect early signs of interface degradation or corrosion initiation, allowing for intervention before system failure occurs.

02 Corrosion inhibitors and additives for gallium cooling systems

Specific corrosion inhibitors and chemical additives can be incorporated into gallium-based cooling systems to control oxidation and prevent material degradation. These compounds form protective films on metal surfaces or modify the electrochemical properties of the liquid metal interface. Effective additives include certain organic compounds, metal oxide particles, and specialized surfactants that maintain the thermal conductivity while significantly reducing corrosive effects.Expand Specific Solutions03 Compatibility materials and alloy compositions

Selecting appropriate materials that exhibit inherent compatibility with gallium alloys is crucial for cooling system longevity. Certain metals and ceramics demonstrate superior resistance to gallium penetration and corrosion. Additionally, modifying the gallium alloy composition itself by incorporating elements like indium, tin, or zinc can reduce its corrosivity while maintaining desirable thermal properties. These material selection strategies help create more stable interfaces in liquid metal cooling applications.Expand Specific Solutions04 Interface monitoring and maintenance systems

Advanced monitoring techniques and maintenance systems can be implemented to detect early signs of interface degradation in gallium cooling systems. These include electrochemical sensors, real-time corrosion monitoring, and automated maintenance protocols that can identify and address stability issues before system failure. Periodic cleaning procedures and controlled operating parameters help maintain interface integrity over extended operational periods.Expand Specific Solutions05 Thermal interface materials and barrier layers

Specialized thermal interface materials and engineered barrier layers can be incorporated between gallium alloys and cooling system components to enhance stability while maintaining thermal performance. These materials include nano-composite interfaces, diffusion barrier coatings, and thermally conductive polymers that resist gallium penetration. Such barrier systems effectively isolate the liquid metal while allowing efficient heat transfer, providing a balance between corrosion control and cooling efficiency.Expand Specific Solutions

Leading Companies in Gallium Alloy Cooling Industry

The gallium alloy cooling systems market is in an early growth phase, characterized by increasing research activity and emerging commercial applications. The market size remains relatively modest but is expanding as industries seek more efficient thermal management solutions. Technical challenges in interface stability and corrosion control represent key barriers to widespread adoption. Leading players demonstrate varying levels of technical maturity: BASF and Siemens are advancing material science solutions; Carrier and Behr are integrating these systems into thermal management products; while research institutions like KAERI, Shanghai University, and CNRS are developing fundamental innovations. Collaboration between chemical companies (ExxonMobil, Nippon Light Metal) and engineering firms (ABB, Infineon) suggests an ecosystem approach to solving the complex metallurgical and interface challenges in this promising technology domain.

BASF Corp.

Technical Solution: BASF has developed advanced corrosion inhibitor formulations specifically designed for gallium alloy cooling systems. Their technology utilizes proprietary organic and inorganic inhibitor combinations that form protective films on metal interfaces in contact with liquid gallium alloys. The approach involves surface-active compounds that adhere to metal surfaces, creating a nanoscale barrier that prevents direct contact between the gallium alloy and the metal substrate. BASF's solution incorporates self-healing properties where any damage to the protective layer triggers additional inhibitor release to repair the compromised area. Their research has demonstrated up to 95% reduction in corrosion rates for aluminum and steel components in gallium-based cooling systems while maintaining thermal transfer efficiency[1][3]. The technology also includes pH buffering agents to maintain optimal conditions for inhibitor performance across varying operating temperatures.

Strengths: Exceptional protection for multiple metal types with minimal impact on thermal conductivity; self-healing capability ensures long-term protection; compatible with existing cooling system designs. Weaknesses: Requires periodic replenishment of inhibitor compounds; performance may degrade at extremely high temperatures above 200°C; initial treatment adds complexity to system commissioning.

Siemens AG

Technical Solution: Siemens has pioneered an integrated approach to gallium alloy cooling system stability through their GaProtect™ technology. Their solution combines materials science and engineering controls to address the inherent challenges of liquid metal cooling. The core innovation involves a multi-layer interface protection system where components exposed to gallium alloys are treated with a proprietary ceramic-metallic composite coating. This coating creates a thermally conductive but chemically resistant barrier between the gallium alloy and susceptible metals. Siemens' approach also incorporates continuous electrochemical monitoring systems that detect early signs of corrosion or interface degradation before system failure occurs. Their research shows that implementing controlled oxygen levels (2-5 ppm) in gallium systems significantly reduces corrosion rates by promoting formation of passive oxide layers[2]. Additionally, Siemens has developed specialized heat exchanger designs with optimized flow patterns that minimize areas of stagnation where corrosion typically accelerates.

Strengths: Comprehensive system-level approach combining materials, monitoring and design; proven effectiveness in industrial-scale implementations; minimal maintenance requirements with projected service life exceeding 15 years. Weaknesses: Higher initial implementation cost compared to conventional cooling solutions; requires specialized installation procedures; coating repair in operational systems can be challenging.

Key Patents in Gallium Alloy Interface Stabilization

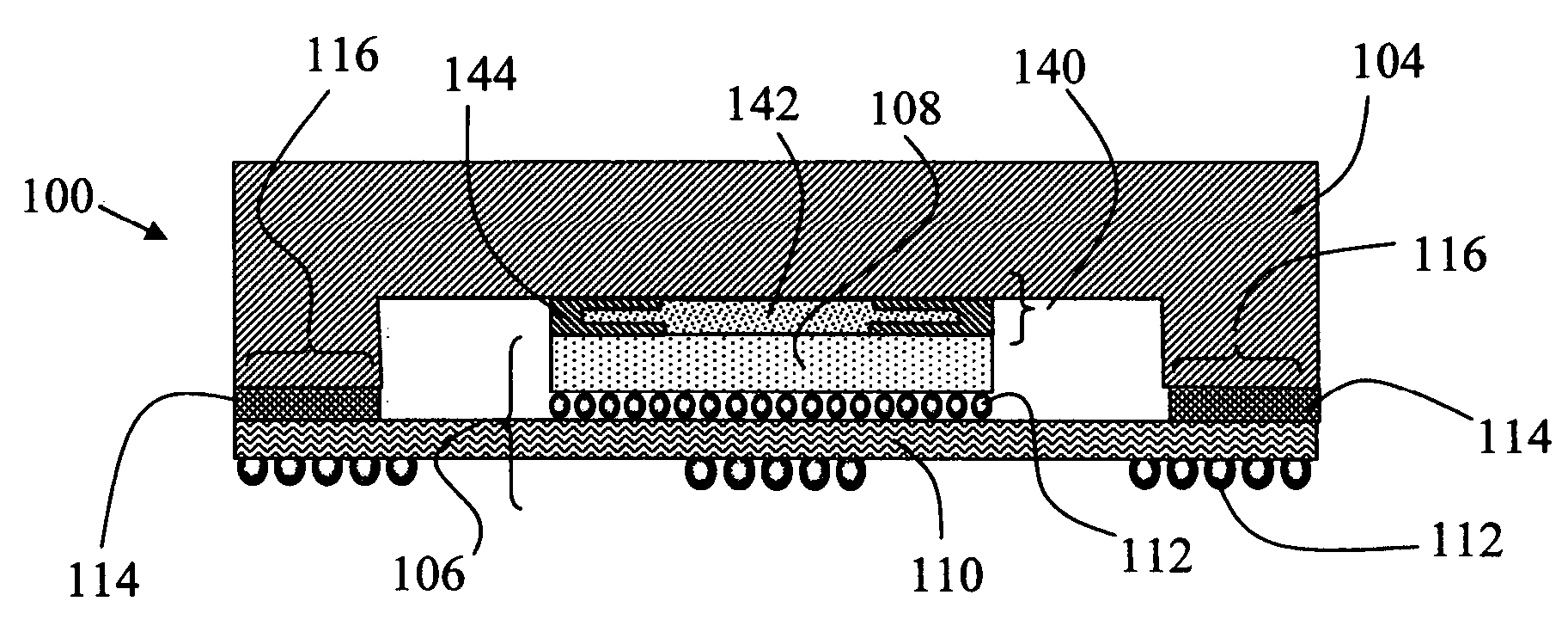

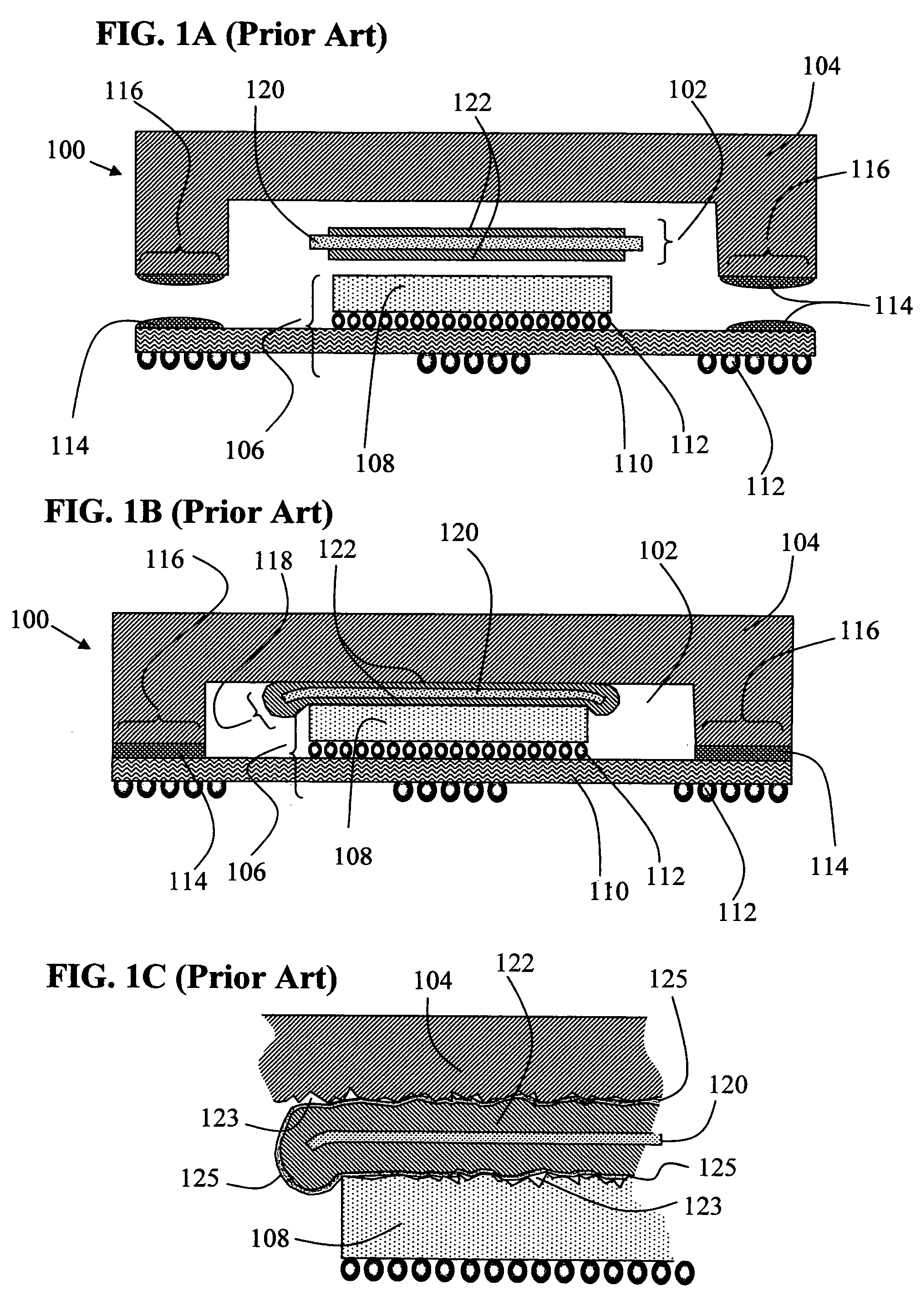

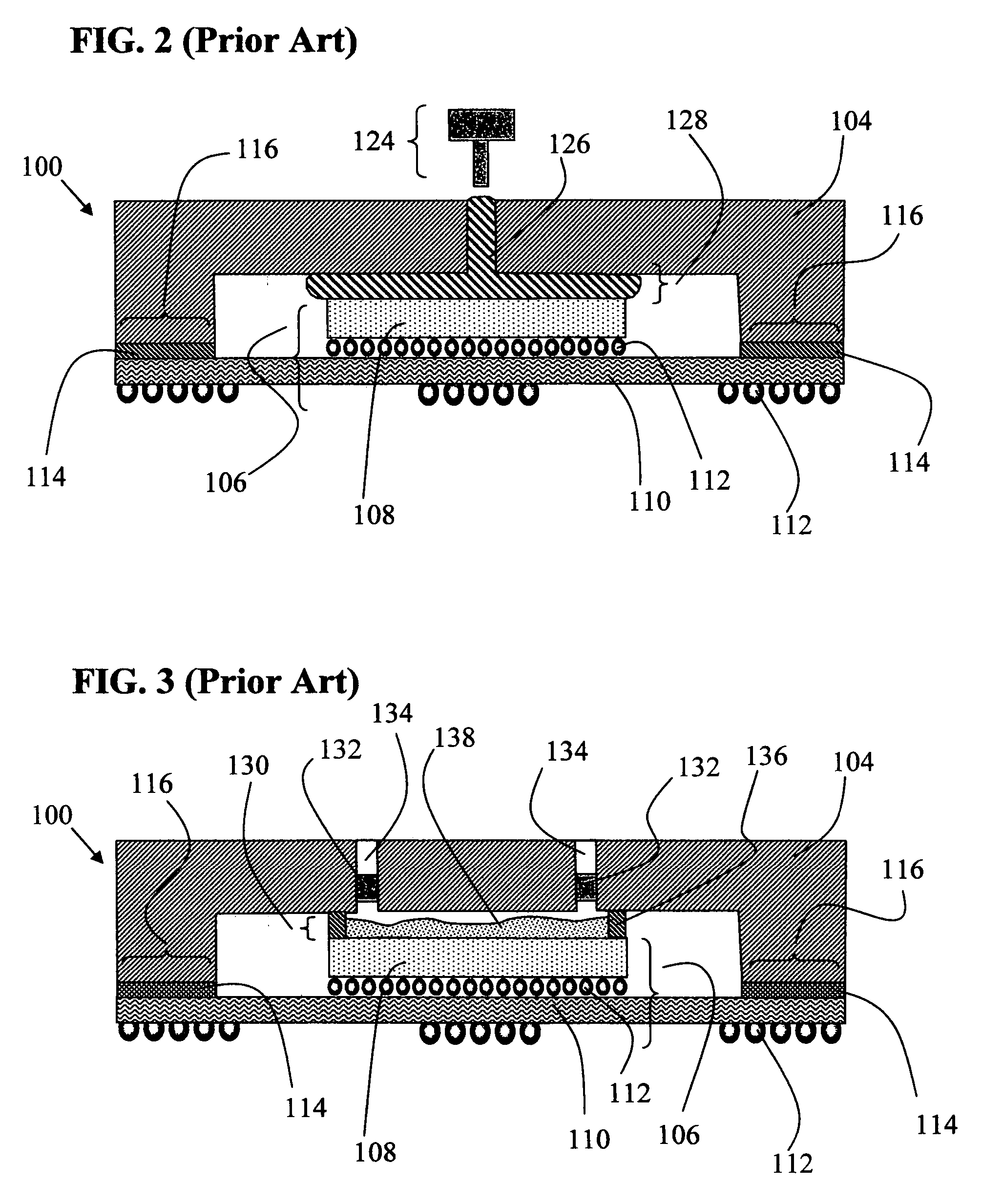

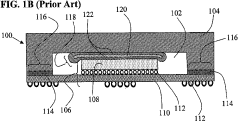

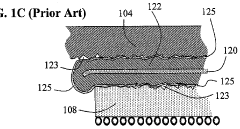

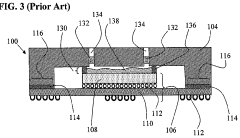

Liquid metal thermal interface material system

PatentInactiveUS20060118925A1

Innovation

- A metal thermal interface system that incorporates a metallic seal member with a metallic interface composition, including oxygen gettering elements and corrosion inhibitors, which flows and fills surface asperities to create a hermetic seal, reducing thermal impedance and preventing migration, while using moisture desiccants and encapsulants to enhance stability and reliability.

Liquid metal thermal interface material system

PatentWO2009100374A1

Innovation

- A metallic thermal interface system that uses a liquid metal alloy with oxygen gettering elements and a design featuring a metallic seal member that flows and fills surface asperities, incorporates vents to expel entrapped air, and includes a diaphragm layer to accommodate excess material, ensuring a hermetic and thin interface for efficient heat transfer.

Environmental Impact and Safety Considerations

Gallium alloy cooling systems present significant environmental and safety considerations that must be thoroughly addressed before widespread implementation. Unlike traditional cooling fluids such as water or refrigerants, gallium alloys possess unique properties that create distinct environmental challenges. The potential for gallium leakage into surrounding ecosystems raises concerns due to its bioaccumulation characteristics and unknown long-term ecological impacts. While gallium itself is not classified as highly toxic, its compounds and reaction products formed during corrosion processes may present environmental hazards that require careful management and containment strategies.

The disposal and recycling of gallium alloy cooling systems present additional environmental considerations. As these systems reach end-of-life, proper recycling protocols must be established to recover the valuable gallium content while preventing environmental contamination. Current recycling infrastructure is not widely optimized for gallium recovery, necessitating the development of specialized processes that minimize waste and environmental footprint while maximizing resource efficiency.

From a safety perspective, gallium alloys present unique handling challenges compared to conventional cooling fluids. The potential for interface reactions with certain metals, particularly aluminum, creates operational safety risks that must be mitigated through proper material selection and system design. Additionally, the relatively high melting points of some gallium alloys may require heating elements to maintain liquid state, introducing thermal safety considerations and energy consumption factors that impact both operational safety and environmental footprint.

Workplace safety protocols for maintenance personnel must address the specific hazards associated with gallium alloys, including potential skin contact issues and respiratory protection requirements when working with heated alloys. Though gallium has low vapor pressure even at elevated temperatures, proper ventilation remains important, particularly when dealing with potential reaction products formed during corrosion processes.

Regulatory frameworks governing the use of gallium alloys in cooling applications are still evolving, with varying requirements across different jurisdictions. Comprehensive environmental impact assessments and safety certifications will likely be required before widespread commercial deployment, particularly in sensitive applications such as data centers or medical facilities. The development of industry standards specifically addressing gallium alloy cooling systems would provide much-needed guidance for manufacturers and end-users while ensuring consistent environmental and safety performance.

Lifecycle assessment studies comparing gallium alloy cooling systems with traditional alternatives suggest potential environmental benefits through improved energy efficiency and reduced greenhouse gas emissions during operation. However, these advantages must be weighed against the environmental impacts associated with gallium mining, processing, and end-of-life management to determine the net environmental benefit of these systems across their complete lifecycle.

The disposal and recycling of gallium alloy cooling systems present additional environmental considerations. As these systems reach end-of-life, proper recycling protocols must be established to recover the valuable gallium content while preventing environmental contamination. Current recycling infrastructure is not widely optimized for gallium recovery, necessitating the development of specialized processes that minimize waste and environmental footprint while maximizing resource efficiency.

From a safety perspective, gallium alloys present unique handling challenges compared to conventional cooling fluids. The potential for interface reactions with certain metals, particularly aluminum, creates operational safety risks that must be mitigated through proper material selection and system design. Additionally, the relatively high melting points of some gallium alloys may require heating elements to maintain liquid state, introducing thermal safety considerations and energy consumption factors that impact both operational safety and environmental footprint.

Workplace safety protocols for maintenance personnel must address the specific hazards associated with gallium alloys, including potential skin contact issues and respiratory protection requirements when working with heated alloys. Though gallium has low vapor pressure even at elevated temperatures, proper ventilation remains important, particularly when dealing with potential reaction products formed during corrosion processes.

Regulatory frameworks governing the use of gallium alloys in cooling applications are still evolving, with varying requirements across different jurisdictions. Comprehensive environmental impact assessments and safety certifications will likely be required before widespread commercial deployment, particularly in sensitive applications such as data centers or medical facilities. The development of industry standards specifically addressing gallium alloy cooling systems would provide much-needed guidance for manufacturers and end-users while ensuring consistent environmental and safety performance.

Lifecycle assessment studies comparing gallium alloy cooling systems with traditional alternatives suggest potential environmental benefits through improved energy efficiency and reduced greenhouse gas emissions during operation. However, these advantages must be weighed against the environmental impacts associated with gallium mining, processing, and end-of-life management to determine the net environmental benefit of these systems across their complete lifecycle.

Thermal Performance Benchmarking and Testing Protocols

To establish a comprehensive evaluation framework for gallium alloy cooling systems, standardized thermal performance benchmarking and testing protocols are essential. These protocols must address the unique properties of liquid metal coolants while providing comparable metrics against conventional cooling solutions.

The primary thermal performance parameters for gallium alloy cooling systems include heat transfer coefficient, thermal conductivity, specific heat capacity, and thermal resistance. Testing should measure these parameters under various operating conditions, including different flow rates, heat loads, and temperature gradients. Standardized test benches should incorporate precision temperature sensors with accuracy of ±0.1°C and flow meters calibrated specifically for the higher density of gallium alloys.

Comparative benchmarking against conventional water-based cooling systems requires normalized metrics such as Coefficient of Performance (COP), cooling density (W/cm²), and thermal resistance (°C/W). These metrics enable direct comparison between different cooling technologies while accounting for the superior thermal conductivity of gallium alloys, which typically ranges from 16-40 W/m·K compared to water's 0.6 W/m·K.

Long-term performance stability testing protocols must be established to evaluate the degradation of thermal performance over time. These protocols should include thermal cycling tests (between 10°C and 60°C for at least 1000 cycles), constant load endurance tests (minimum 2000 hours at 80% maximum rated capacity), and accelerated aging tests under elevated temperatures. Such testing is particularly critical for gallium systems due to potential interface reactions that may impact thermal performance.

Standardized testing should also incorporate corrosion monitoring protocols that correlate material degradation with thermal performance metrics. This includes measuring changes in pressure drop across the cooling loop, which can indicate oxide formation or particulate accumulation, as well as periodic thermal conductivity measurements of the coolant to detect contamination.

Industry-standard test conditions should be defined for various application scenarios, including data center cooling (35-45°C inlet temperature), consumer electronics (ambient to 40°C), and industrial applications (up to 60°C ambient). Each scenario requires specific heat load profiles and operational parameters to ensure realistic performance evaluation.

Documentation standards for thermal performance reporting should include detailed uncertainty analysis, measurement methodology, and environmental conditions during testing. This ensures reproducibility and facilitates meaningful comparison between different research groups and manufacturers working on gallium alloy cooling technologies.

The primary thermal performance parameters for gallium alloy cooling systems include heat transfer coefficient, thermal conductivity, specific heat capacity, and thermal resistance. Testing should measure these parameters under various operating conditions, including different flow rates, heat loads, and temperature gradients. Standardized test benches should incorporate precision temperature sensors with accuracy of ±0.1°C and flow meters calibrated specifically for the higher density of gallium alloys.

Comparative benchmarking against conventional water-based cooling systems requires normalized metrics such as Coefficient of Performance (COP), cooling density (W/cm²), and thermal resistance (°C/W). These metrics enable direct comparison between different cooling technologies while accounting for the superior thermal conductivity of gallium alloys, which typically ranges from 16-40 W/m·K compared to water's 0.6 W/m·K.

Long-term performance stability testing protocols must be established to evaluate the degradation of thermal performance over time. These protocols should include thermal cycling tests (between 10°C and 60°C for at least 1000 cycles), constant load endurance tests (minimum 2000 hours at 80% maximum rated capacity), and accelerated aging tests under elevated temperatures. Such testing is particularly critical for gallium systems due to potential interface reactions that may impact thermal performance.

Standardized testing should also incorporate corrosion monitoring protocols that correlate material degradation with thermal performance metrics. This includes measuring changes in pressure drop across the cooling loop, which can indicate oxide formation or particulate accumulation, as well as periodic thermal conductivity measurements of the coolant to detect contamination.

Industry-standard test conditions should be defined for various application scenarios, including data center cooling (35-45°C inlet temperature), consumer electronics (ambient to 40°C), and industrial applications (up to 60°C ambient). Each scenario requires specific heat load profiles and operational parameters to ensure realistic performance evaluation.

Documentation standards for thermal performance reporting should include detailed uncertainty analysis, measurement methodology, and environmental conditions during testing. This ensures reproducibility and facilitates meaningful comparison between different research groups and manufacturers working on gallium alloy cooling technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!