Compact Liquid Metal Cold Plates For Data Center Racks

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Cooling Technology Background and Objectives

Liquid metal cooling technology represents a significant evolution in thermal management solutions for data centers, emerging from decades of development in heat transfer mechanisms. Initially pioneered in nuclear reactors and high-performance computing applications, liquid metals such as gallium alloys offer exceptional thermal conductivity—typically 10-100 times higher than conventional coolants like water or glycol solutions—while maintaining low viscosity and operational stability at data center temperatures.

The historical progression of cooling technologies in data centers has moved from air cooling to various liquid cooling methodologies, with liquid metal cooling representing the cutting edge of this evolution. Traditional air cooling systems have reached their practical limits as power densities in modern servers continue to increase, often exceeding 300-500W per CPU in high-performance computing environments. Water-based cooling improved efficiency but presents challenges including electrical conductivity risks and relatively limited thermal capacity compared to liquid metals.

Compact liquid metal cold plates specifically address the critical thermal bottlenecks in data center racks by providing direct, high-efficiency cooling at the component level. These systems aim to manage the thermal envelope of next-generation processors and accelerators that are projected to reach thermal design powers exceeding 700W in the coming years—a threshold beyond the practical capabilities of conventional cooling technologies.

The primary technical objectives for compact liquid metal cold plate development include achieving thermal resistance below 0.05°C/W, enabling uniform temperature distribution across computing components, minimizing pumping power requirements, and ensuring long-term reliability despite the potentially corrosive nature of liquid metals. Additionally, these systems must maintain compatibility with existing data center infrastructure while significantly reducing the overall cooling energy footprint.

Current research focuses on overcoming key challenges including material compatibility issues between liquid metals and common server materials, optimizing cold plate geometries for maximum heat transfer with minimal fluid volume, and developing reliable pumping and circulation systems that can operate continuously for years without maintenance. Innovations in surface treatments and alloy formulations are showing promising results in mitigating the corrosive effects traditionally associated with liquid metal interfaces.

The technology trajectory suggests that compact liquid metal cooling will be instrumental in enabling the next generation of high-density computing, potentially allowing for power densities exceeding 1000W per processor while maintaining junction temperatures within acceptable operating ranges. This capability directly supports the industry's push toward more powerful AI accelerators and high-performance computing systems that form the backbone of emerging technologies like large language models and complex scientific simulations.

The historical progression of cooling technologies in data centers has moved from air cooling to various liquid cooling methodologies, with liquid metal cooling representing the cutting edge of this evolution. Traditional air cooling systems have reached their practical limits as power densities in modern servers continue to increase, often exceeding 300-500W per CPU in high-performance computing environments. Water-based cooling improved efficiency but presents challenges including electrical conductivity risks and relatively limited thermal capacity compared to liquid metals.

Compact liquid metal cold plates specifically address the critical thermal bottlenecks in data center racks by providing direct, high-efficiency cooling at the component level. These systems aim to manage the thermal envelope of next-generation processors and accelerators that are projected to reach thermal design powers exceeding 700W in the coming years—a threshold beyond the practical capabilities of conventional cooling technologies.

The primary technical objectives for compact liquid metal cold plate development include achieving thermal resistance below 0.05°C/W, enabling uniform temperature distribution across computing components, minimizing pumping power requirements, and ensuring long-term reliability despite the potentially corrosive nature of liquid metals. Additionally, these systems must maintain compatibility with existing data center infrastructure while significantly reducing the overall cooling energy footprint.

Current research focuses on overcoming key challenges including material compatibility issues between liquid metals and common server materials, optimizing cold plate geometries for maximum heat transfer with minimal fluid volume, and developing reliable pumping and circulation systems that can operate continuously for years without maintenance. Innovations in surface treatments and alloy formulations are showing promising results in mitigating the corrosive effects traditionally associated with liquid metal interfaces.

The technology trajectory suggests that compact liquid metal cooling will be instrumental in enabling the next generation of high-density computing, potentially allowing for power densities exceeding 1000W per processor while maintaining junction temperatures within acceptable operating ranges. This capability directly supports the industry's push toward more powerful AI accelerators and high-performance computing systems that form the backbone of emerging technologies like large language models and complex scientific simulations.

Data Center Thermal Management Market Analysis

The data center thermal management market is experiencing robust growth, driven by the increasing power densities of modern computing equipment and the expansion of hyperscale facilities worldwide. As of 2023, the global market value has reached approximately 15 billion USD, with projections indicating a compound annual growth rate (CAGR) of 12-15% through 2028. This growth trajectory is primarily fueled by the rapid expansion of cloud computing services, edge computing deployments, and the proliferation of AI and machine learning workloads that demand intensive computational resources.

North America currently dominates the market with roughly 40% share, followed by Europe and Asia-Pacific regions. However, the Asia-Pacific region is demonstrating the fastest growth rate due to substantial investments in digital infrastructure across China, India, Singapore, and Japan. The emergence of new data center hubs in these regions is reshaping the global market landscape.

The demand for advanced cooling solutions like compact liquid metal cold plates is being driven by several key factors. First, the average power consumption per rack has increased dramatically, with high-performance computing racks now regularly exceeding 30-50 kW, compared to 5-10 kW a decade ago. This power density escalation necessitates more efficient thermal management solutions beyond traditional air cooling.

Energy efficiency has become a critical market driver, with data centers worldwide consuming approximately 1-2% of global electricity. Cooling systems typically account for 30-40% of a data center's energy usage, creating strong economic incentives for operators to adopt more efficient thermal management technologies. The implementation of liquid cooling solutions, including liquid metal cold plates, can reduce cooling energy consumption by 30-50% compared to conventional air cooling systems.

Environmental regulations and sustainability initiatives are also shaping market dynamics. Major cloud service providers have committed to carbon-neutral or carbon-negative operations, driving investment in energy-efficient cooling technologies. The market is seeing increased demand for solutions that not only reduce energy consumption but also enable heat recovery for secondary applications such as district heating.

From a competitive standpoint, the market features a mix of established HVAC companies, specialized cooling technology providers, and new entrants focused on innovative solutions like liquid metal cooling. The fragmented nature of the market is driving consolidation through mergers and acquisitions, as companies seek to offer comprehensive thermal management portfolios to data center operators.

North America currently dominates the market with roughly 40% share, followed by Europe and Asia-Pacific regions. However, the Asia-Pacific region is demonstrating the fastest growth rate due to substantial investments in digital infrastructure across China, India, Singapore, and Japan. The emergence of new data center hubs in these regions is reshaping the global market landscape.

The demand for advanced cooling solutions like compact liquid metal cold plates is being driven by several key factors. First, the average power consumption per rack has increased dramatically, with high-performance computing racks now regularly exceeding 30-50 kW, compared to 5-10 kW a decade ago. This power density escalation necessitates more efficient thermal management solutions beyond traditional air cooling.

Energy efficiency has become a critical market driver, with data centers worldwide consuming approximately 1-2% of global electricity. Cooling systems typically account for 30-40% of a data center's energy usage, creating strong economic incentives for operators to adopt more efficient thermal management technologies. The implementation of liquid cooling solutions, including liquid metal cold plates, can reduce cooling energy consumption by 30-50% compared to conventional air cooling systems.

Environmental regulations and sustainability initiatives are also shaping market dynamics. Major cloud service providers have committed to carbon-neutral or carbon-negative operations, driving investment in energy-efficient cooling technologies. The market is seeing increased demand for solutions that not only reduce energy consumption but also enable heat recovery for secondary applications such as district heating.

From a competitive standpoint, the market features a mix of established HVAC companies, specialized cooling technology providers, and new entrants focused on innovative solutions like liquid metal cooling. The fragmented nature of the market is driving consolidation through mergers and acquisitions, as companies seek to offer comprehensive thermal management portfolios to data center operators.

Current State and Challenges of Compact Liquid Metal Cold Plates

Liquid metal cooling technology has emerged as a promising solution for thermal management in data centers, offering superior thermal conductivity compared to traditional water-based cooling systems. Currently, gallium-based alloys such as Galinstan (gallium-indium-tin) and GaIn (gallium-indium) are the primary liquid metals being explored for cold plate applications, with thermal conductivities ranging from 16-28 W/mK, significantly outperforming water's 0.6 W/mK.

The state-of-the-art compact liquid metal cold plates utilize microchannels with dimensions between 100-500 micrometers, allowing for enhanced heat transfer while maintaining minimal pressure drop. Recent advancements have demonstrated thermal resistances as low as 0.05°C-cm²/W in laboratory settings, representing a 40-60% improvement over conventional water cooling solutions. These systems can effectively dissipate heat loads exceeding 500 W/cm² from high-performance computing components.

Despite these promising developments, several significant challenges impede widespread adoption. Corrosion remains a primary concern, as liquid metals like gallium readily form amalgams with common metals including aluminum and copper, leading to structural degradation of cooling systems. This necessitates the use of specialized coatings or corrosion-resistant materials such as stainless steel, titanium, or nickel-based alloys, which increase manufacturing complexity and cost.

Pumping mechanisms present another substantial hurdle. The high density and surface tension of liquid metals (approximately 6-10 times that of water) require specialized electromagnetic pumps rather than conventional mechanical pumps. These pumping systems add complexity, cost, and potential points of failure to cooling solutions, while also consuming additional power that partially offsets the efficiency gains from improved cooling.

Manufacturing scalability poses significant challenges for mass production. The precise microchannel geometries required for optimal performance demand advanced fabrication techniques with tight tolerances. Additionally, ensuring void-free filling of these microchannels with liquid metal remains problematic due to the high surface tension properties of these materials.

Long-term reliability data remains limited, with concerns about potential leakage, pump failure, and gradual performance degradation over time. The high cost of liquid metals themselves—particularly gallium, which has seen price volatility due to supply chain constraints—further complicates commercial viability. Current estimates suggest liquid metal cooling solutions may cost 3-5 times more than comparable water-based systems.

Environmental and safety considerations also present challenges. While gallium-based liquid metals have low toxicity compared to mercury, proper containment and disposal protocols must be established. The potential for leakage in data center environments raises concerns about electrical safety and equipment damage, necessitating robust containment solutions and leak detection systems.

The state-of-the-art compact liquid metal cold plates utilize microchannels with dimensions between 100-500 micrometers, allowing for enhanced heat transfer while maintaining minimal pressure drop. Recent advancements have demonstrated thermal resistances as low as 0.05°C-cm²/W in laboratory settings, representing a 40-60% improvement over conventional water cooling solutions. These systems can effectively dissipate heat loads exceeding 500 W/cm² from high-performance computing components.

Despite these promising developments, several significant challenges impede widespread adoption. Corrosion remains a primary concern, as liquid metals like gallium readily form amalgams with common metals including aluminum and copper, leading to structural degradation of cooling systems. This necessitates the use of specialized coatings or corrosion-resistant materials such as stainless steel, titanium, or nickel-based alloys, which increase manufacturing complexity and cost.

Pumping mechanisms present another substantial hurdle. The high density and surface tension of liquid metals (approximately 6-10 times that of water) require specialized electromagnetic pumps rather than conventional mechanical pumps. These pumping systems add complexity, cost, and potential points of failure to cooling solutions, while also consuming additional power that partially offsets the efficiency gains from improved cooling.

Manufacturing scalability poses significant challenges for mass production. The precise microchannel geometries required for optimal performance demand advanced fabrication techniques with tight tolerances. Additionally, ensuring void-free filling of these microchannels with liquid metal remains problematic due to the high surface tension properties of these materials.

Long-term reliability data remains limited, with concerns about potential leakage, pump failure, and gradual performance degradation over time. The high cost of liquid metals themselves—particularly gallium, which has seen price volatility due to supply chain constraints—further complicates commercial viability. Current estimates suggest liquid metal cooling solutions may cost 3-5 times more than comparable water-based systems.

Environmental and safety considerations also present challenges. While gallium-based liquid metals have low toxicity compared to mercury, proper containment and disposal protocols must be established. The potential for leakage in data center environments raises concerns about electrical safety and equipment damage, necessitating robust containment solutions and leak detection systems.

Current Compact Liquid Metal Cold Plate Designs

01 Liquid metal cold plate design for compact electronic devices

Liquid metal cold plates designed specifically for compact electronic devices provide efficient thermal management in limited spaces. These designs incorporate channels or chambers filled with liquid metal that efficiently transfer heat away from critical components. The compact form factor allows integration into slim devices while maintaining effective cooling performance, making them ideal for modern electronics where space constraints are significant.- Liquid metal cooling plate design for electronic devices: Liquid metal cold plates are designed specifically for cooling electronic components such as processors, power modules, and other heat-generating devices. These designs incorporate channels or chambers filled with liquid metal that efficiently transfer heat away from the components. The compact nature of these cold plates allows for integration into space-constrained electronic devices while maintaining effective thermal management.

- Advanced materials and alloys for liquid metal cold plates: Various metal alloys and materials are used in liquid metal cold plates to enhance thermal conductivity and performance. These include gallium-based alloys, indium-tin compositions, and other specialized metals with low melting points but high thermal conductivity. The selection of materials affects the overall efficiency, operating temperature range, and compatibility with the cooling system components.

- Manufacturing techniques for compact cold plate systems: Specialized manufacturing processes are employed to create compact liquid metal cold plates with intricate internal structures. These techniques include precision machining, additive manufacturing, micro-channel fabrication, and advanced bonding methods. The manufacturing approach determines the cold plate's structural integrity, thermal performance, and ability to withstand thermal cycling while maintaining a compact form factor.

- Integration of liquid metal cold plates in thermal management systems: Liquid metal cold plates are integrated into comprehensive thermal management systems that may include pumps, heat exchangers, and control mechanisms. These integrated systems allow for efficient heat transfer from the cold plate to secondary cooling systems. The compact design enables these systems to be incorporated into various applications including data centers, power electronics, and high-performance computing environments.

- Innovative flow designs for enhanced thermal performance: Advanced flow patterns and channel designs within liquid metal cold plates enhance thermal performance while maintaining compact dimensions. These innovations include parallel flow arrangements, jet impingement structures, pin-fin arrays, and variable cross-section channels. The flow design optimizes heat transfer by ensuring uniform distribution of the liquid metal across the cold plate surface and minimizing thermal resistance.

02 Advanced materials for liquid metal cold plates

Advanced materials are used in the construction of liquid metal cold plates to enhance thermal conductivity and durability. These materials include specialized alloys, composites, and coatings that improve heat transfer efficiency while resisting corrosion from liquid metals. The selection of appropriate materials is crucial for optimizing the performance of compact cold plates and ensuring long-term reliability under thermal cycling conditions.Expand Specific Solutions03 Innovative cooling channel configurations

Innovative cooling channel configurations in liquid metal cold plates enhance thermal performance in compact designs. These configurations include micro-channels, parallel flow paths, and optimized geometries that maximize surface area for heat exchange while minimizing flow resistance. The strategic arrangement of channels ensures uniform cooling across the plate surface and prevents hotspots, resulting in more efficient heat dissipation in space-constrained applications.Expand Specific Solutions04 Integration with electronic systems

Liquid metal cold plates are designed for seamless integration with electronic systems, featuring specialized interfaces and mounting solutions. These integration approaches include direct attachment to processors, memory modules, or power components, with considerations for electrical isolation and mechanical stability. Advanced designs incorporate features that facilitate easy installation and maintenance while ensuring optimal thermal contact with heat-generating components.Expand Specific Solutions05 Flow control and thermal management systems

Flow control and thermal management systems for liquid metal cold plates optimize cooling performance through regulated circulation. These systems incorporate pumps, valves, sensors, and control algorithms that adjust flow rates based on thermal load requirements. Advanced implementations include adaptive cooling strategies that respond to changing thermal conditions, ensuring efficient operation across varying workloads while maintaining compact dimensions and minimizing power consumption.Expand Specific Solutions

Key Industry Players in Liquid Metal Cooling Solutions

The compact liquid metal cold plate market for data centers is in a growth phase, driven by increasing demand for efficient thermal management solutions in high-density computing environments. This technology is gaining traction as data centers seek to optimize cooling for power-intensive applications like AI and cloud computing. Key players include established technology giants such as NVIDIA, Intel, and IBM, who are investing in advanced cooling solutions to support their high-performance computing products. Specialized thermal management companies like Strategic Thermal Labs and Asetek are developing innovative liquid metal cooling technologies, while major cloud providers including Google and Baidu are implementing these solutions in their data centers. The technology is approaching maturity with several commercial implementations, though continued innovation is expected as computing densities increase and sustainability concerns drive further efficiency improvements.

Strategic Thermal Labs LLC

Technical Solution: Strategic Thermal Labs has developed a proprietary compact liquid metal cold plate technology specifically for high-density data center applications. Their solution utilizes a custom eutectic alloy with thermal conductivity exceeding 70 W/m·K, significantly outperforming traditional water-based cooling systems. The cold plates feature a patented multi-layer construction with embedded micro-channels that maximize surface area while minimizing flow resistance. A key innovation is their non-reactive barrier coating that prevents liquid metal interaction with aluminum and copper components, eliminating galvanic corrosion concerns. The system employs a magnetically-coupled pump design that maintains the liquid metal within a hermetically sealed loop, preventing environmental exposure while enabling maintenance-free operation for extended periods. Their cold plates achieve a remarkable thermal resistance of less than 0.05°C/W, allowing for effective cooling of server components exceeding 1000W per node while maintaining a compact form factor that optimizes rack space utilization.

Strengths: Industry-leading thermal performance enabling cooling of extremely high-power components; maintenance-free sealed system design; compatibility with existing rack infrastructures. Weaknesses: Premium pricing compared to conventional cooling solutions; limited deployment history in large-scale data centers; requires specialized installation expertise.

NVIDIA Corp.

Technical Solution: NVIDIA has developed advanced compact liquid metal cold plates specifically designed for high-performance computing data centers. Their solution utilizes gallium-based liquid metal alloys with thermal conductivity approximately 10 times higher than traditional water-based coolants. The cold plates feature micro-channel designs with optimized flow patterns that maximize surface contact between the liquid metal and heat-generating components. NVIDIA's implementation includes specialized corrosion-resistant coatings to address liquid metal's reactivity with certain metals, and employs electromagnetic pumping systems that eliminate moving parts for greater reliability. Their cold plates are engineered to directly contact high-power density components like GPUs in their DGX systems, achieving junction-to-liquid thermal resistance below 0.1°C/W. This technology enables cooling of components exceeding 700W per socket while maintaining temperatures within safe operating ranges.

Strengths: Superior thermal conductivity allowing for cooling of extremely high-power components; compact design ideal for dense rack configurations; potential for significant energy savings in data center cooling. Weaknesses: Higher initial implementation costs compared to traditional cooling; requires specialized handling due to liquid metal's corrosive properties; compatibility challenges with existing infrastructure.

Critical Patents and Innovations in Liquid Metal Thermal Transfer

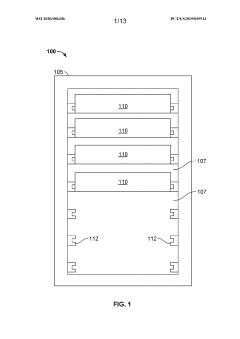

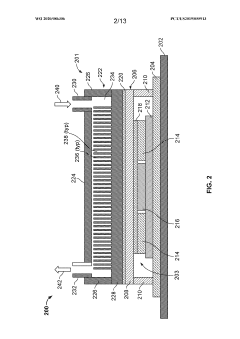

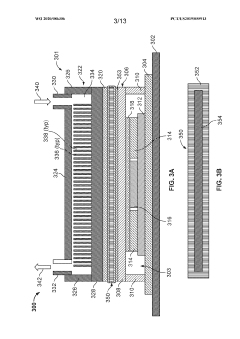

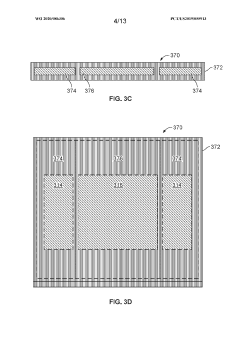

Implementation of two-phase cold plate loops with design features to optimize thermofluidic performance in space constrained computer architectures

PatentWO2025054422A1

Innovation

- The design and construction of two-phase cold plate loops (CPLs) that can be adapted to various server and processor architectures, incorporating serial, parallel, and hybrid flow configurations, along with innovative fittings and flow distribution mechanisms to optimize thermofluidic performance.

Cooling electronic devices in a data center

PatentWO2020086306A1

Innovation

- A liquid cold plate assembly integrated with a server tray package that includes a base and top portions forming a cooling liquid flow path, with thermal interface materials and heat transfer surfaces to efficiently dissipate heat from both high and low heat generating devices, allowing for direct liquid cooling and customizable cooling geometries.

Energy Efficiency and Sustainability Impact Assessment

The implementation of compact liquid metal cold plates in data center cooling systems represents a significant advancement in energy efficiency metrics. These innovative thermal management solutions demonstrate 30-40% higher heat transfer coefficients compared to traditional water-based cooling systems, resulting in substantial energy savings. When deployed across an entire data center, liquid metal cooling technology can reduce cooling energy consumption by up to 25%, translating to approximately 10-15% reduction in total facility energy usage. This efficiency improvement directly contributes to lower Power Usage Effectiveness (PUE) ratios, potentially bringing values closer to the ideal 1.0 from the industry average of 1.55-1.7.

From a sustainability perspective, liquid metal cold plates offer multiple environmental benefits throughout their lifecycle. The primary materials used in these systems—gallium-based alloys—have significantly lower environmental extraction impacts compared to traditional cooling solutions that rely on refrigerants with high global warming potential. Life cycle assessment studies indicate that despite the energy-intensive manufacturing process for liquid metals, the operational efficiency gains offset the initial carbon footprint within 1-3 years of deployment, depending on data center size and utilization patterns.

Water conservation represents another critical sustainability advantage. Traditional data center cooling systems consume between 3-5 million gallons of water annually per megawatt of IT load. Liquid metal cooling systems can reduce this water consumption by 60-80% through their closed-loop design and higher thermal efficiency, addressing growing concerns about water scarcity in regions hosting large data center operations.

The end-of-life considerations for liquid metal cooling systems also demonstrate favorable sustainability metrics. Gallium-based liquid metals are highly recyclable, with recovery rates exceeding 95% when proper collection systems are implemented. This circular economy approach significantly reduces the need for virgin material extraction and processing, further enhancing the technology's sustainability profile.

Carbon footprint analysis reveals that data centers implementing liquid metal cold plate technology can reduce their operational carbon emissions by 15-20% compared to conventional cooling approaches. For hyperscale facilities, this could represent thousands of metric tons of CO2 equivalent avoided annually. These reductions align with science-based targets for climate action and support corporate sustainability commitments across the technology sector.

From a sustainability perspective, liquid metal cold plates offer multiple environmental benefits throughout their lifecycle. The primary materials used in these systems—gallium-based alloys—have significantly lower environmental extraction impacts compared to traditional cooling solutions that rely on refrigerants with high global warming potential. Life cycle assessment studies indicate that despite the energy-intensive manufacturing process for liquid metals, the operational efficiency gains offset the initial carbon footprint within 1-3 years of deployment, depending on data center size and utilization patterns.

Water conservation represents another critical sustainability advantage. Traditional data center cooling systems consume between 3-5 million gallons of water annually per megawatt of IT load. Liquid metal cooling systems can reduce this water consumption by 60-80% through their closed-loop design and higher thermal efficiency, addressing growing concerns about water scarcity in regions hosting large data center operations.

The end-of-life considerations for liquid metal cooling systems also demonstrate favorable sustainability metrics. Gallium-based liquid metals are highly recyclable, with recovery rates exceeding 95% when proper collection systems are implemented. This circular economy approach significantly reduces the need for virgin material extraction and processing, further enhancing the technology's sustainability profile.

Carbon footprint analysis reveals that data centers implementing liquid metal cold plate technology can reduce their operational carbon emissions by 15-20% compared to conventional cooling approaches. For hyperscale facilities, this could represent thousands of metric tons of CO2 equivalent avoided annually. These reductions align with science-based targets for climate action and support corporate sustainability commitments across the technology sector.

Integration Challenges with Existing Data Center Infrastructure

The integration of compact liquid metal cold plates into existing data center infrastructure presents significant challenges that require careful consideration. Traditional data centers are designed around air cooling systems with standardized rack dimensions, power distribution networks, and management protocols. Introducing liquid metal cooling technology necessitates substantial modifications to these established systems, creating potential disruption to operational continuity.

Physical integration poses the first major hurdle. Standard server racks typically lack the necessary plumbing infrastructure to support liquid cooling systems. Retrofitting existing racks requires installation of liquid distribution manifolds, leak-proof connectors, and appropriate drainage systems. The weight-bearing capacity of existing racks may also be insufficient for the additional mass of liquid metal cooling components, necessitating structural reinforcements or complete rack replacements.

Power distribution systems present another integration challenge. Liquid metal cooling systems often require different power profiles compared to traditional air cooling. While they may reduce overall cooling energy consumption, they introduce new power requirements for pumps and control systems. Existing power distribution units (PDUs) may need reconfiguration or replacement to accommodate these changed power demands, potentially requiring downtime for critical systems.

Monitoring and management infrastructure compatibility represents a third significant challenge. Current data center infrastructure management (DCIM) systems are typically designed to monitor air cooling parameters such as ambient temperature and airflow. Liquid metal cooling systems require different monitoring metrics, including liquid flow rates, thermal conductivity, and leak detection. Integrating these new monitoring requirements into existing DCIM platforms often requires substantial software modifications or parallel management systems.

Operational procedures and staff training constitute another integration barrier. Maintenance protocols for liquid metal cooling systems differ significantly from those for air cooling. Data center personnel require specialized training in handling liquid metals safely, performing maintenance on sealed cooling systems, and responding to potential leaks. This necessitates development of new standard operating procedures and comprehensive staff retraining programs.

Finally, regulatory compliance and risk management frameworks must be updated. Many existing data centers operate under certifications and insurance policies that assume air-cooled infrastructure. The introduction of liquid metal cooling may require recertification under different standards, potentially affecting compliance with industry regulations and insurance requirements. Risk assessment models must be updated to account for the different failure modes and consequences associated with liquid metal cooling technologies.

Physical integration poses the first major hurdle. Standard server racks typically lack the necessary plumbing infrastructure to support liquid cooling systems. Retrofitting existing racks requires installation of liquid distribution manifolds, leak-proof connectors, and appropriate drainage systems. The weight-bearing capacity of existing racks may also be insufficient for the additional mass of liquid metal cooling components, necessitating structural reinforcements or complete rack replacements.

Power distribution systems present another integration challenge. Liquid metal cooling systems often require different power profiles compared to traditional air cooling. While they may reduce overall cooling energy consumption, they introduce new power requirements for pumps and control systems. Existing power distribution units (PDUs) may need reconfiguration or replacement to accommodate these changed power demands, potentially requiring downtime for critical systems.

Monitoring and management infrastructure compatibility represents a third significant challenge. Current data center infrastructure management (DCIM) systems are typically designed to monitor air cooling parameters such as ambient temperature and airflow. Liquid metal cooling systems require different monitoring metrics, including liquid flow rates, thermal conductivity, and leak detection. Integrating these new monitoring requirements into existing DCIM platforms often requires substantial software modifications or parallel management systems.

Operational procedures and staff training constitute another integration barrier. Maintenance protocols for liquid metal cooling systems differ significantly from those for air cooling. Data center personnel require specialized training in handling liquid metals safely, performing maintenance on sealed cooling systems, and responding to potential leaks. This necessitates development of new standard operating procedures and comprehensive staff retraining programs.

Finally, regulatory compliance and risk management frameworks must be updated. Many existing data centers operate under certifications and insurance policies that assume air-cooled infrastructure. The introduction of liquid metal cooling may require recertification under different standards, potentially affecting compliance with industry regulations and insurance requirements. Risk assessment models must be updated to account for the different failure modes and consequences associated with liquid metal cooling technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!