Pumping And Control Strategies For Liquid Metal Thermal Loops

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Thermal Loop Technology Background and Objectives

Liquid metal thermal loops represent a significant advancement in thermal management systems, with origins dating back to the mid-20th century. Initially developed for nuclear reactor cooling applications, these systems have evolved considerably over the decades. The fundamental principle involves utilizing liquid metals such as sodium, NaK alloys, gallium, and more recently, gallium-indium-tin eutectic alloys (Galinstan) as heat transfer media due to their exceptional thermal conductivity properties that far exceed conventional coolants like water or oils.

The evolution of liquid metal thermal management has been marked by several key milestones. Early applications focused primarily on nuclear power generation, where liquid sodium became the coolant of choice for fast breeder reactors. The 1980s and 1990s saw expanded research into non-nuclear applications, particularly in aerospace and defense sectors. The 2000s brought renewed interest as electronics thermal management challenges intensified with increasing power densities in computing systems.

Current technological trends indicate a growing focus on miniaturization and integration of liquid metal thermal loops into compact systems. This trend is driven by the escalating thermal management challenges in high-performance computing, power electronics, and concentrated solar power applications. The inherent advantages of liquid metals—high thermal conductivity, wide operating temperature ranges, and low vapor pressure—position them as ideal candidates for next-generation cooling solutions.

The primary technical objectives in this field center around overcoming the persistent challenges that have limited widespread commercial adoption. These objectives include developing reliable pumping mechanisms that can handle the unique properties of liquid metals, creating corrosion-resistant containment materials, implementing precise flow control strategies, and designing effective safety systems to manage risks associated with liquid metal handling.

Electromagnetic pumping technologies have emerged as particularly promising for liquid metal circulation, as they eliminate moving parts that would otherwise be vulnerable to corrosion and wear. However, significant challenges remain in optimizing these systems for efficiency, reliability, and scalability across different application domains.

The integration of advanced sensors and control systems represents another critical objective, enabling real-time monitoring and adjustment of liquid metal flow rates, temperatures, and pressures to optimize thermal performance while ensuring system safety. Machine learning algorithms are increasingly being explored to predict system behavior and preemptively adjust operating parameters.

As energy efficiency becomes increasingly paramount across industries, liquid metal thermal loops offer potential advantages through their superior heat transfer capabilities, potentially reducing overall energy consumption in cooling-intensive applications. This aligns with broader sustainability goals and regulatory trends toward reduced energy usage and carbon emissions.

The evolution of liquid metal thermal management has been marked by several key milestones. Early applications focused primarily on nuclear power generation, where liquid sodium became the coolant of choice for fast breeder reactors. The 1980s and 1990s saw expanded research into non-nuclear applications, particularly in aerospace and defense sectors. The 2000s brought renewed interest as electronics thermal management challenges intensified with increasing power densities in computing systems.

Current technological trends indicate a growing focus on miniaturization and integration of liquid metal thermal loops into compact systems. This trend is driven by the escalating thermal management challenges in high-performance computing, power electronics, and concentrated solar power applications. The inherent advantages of liquid metals—high thermal conductivity, wide operating temperature ranges, and low vapor pressure—position them as ideal candidates for next-generation cooling solutions.

The primary technical objectives in this field center around overcoming the persistent challenges that have limited widespread commercial adoption. These objectives include developing reliable pumping mechanisms that can handle the unique properties of liquid metals, creating corrosion-resistant containment materials, implementing precise flow control strategies, and designing effective safety systems to manage risks associated with liquid metal handling.

Electromagnetic pumping technologies have emerged as particularly promising for liquid metal circulation, as they eliminate moving parts that would otherwise be vulnerable to corrosion and wear. However, significant challenges remain in optimizing these systems for efficiency, reliability, and scalability across different application domains.

The integration of advanced sensors and control systems represents another critical objective, enabling real-time monitoring and adjustment of liquid metal flow rates, temperatures, and pressures to optimize thermal performance while ensuring system safety. Machine learning algorithms are increasingly being explored to predict system behavior and preemptively adjust operating parameters.

As energy efficiency becomes increasingly paramount across industries, liquid metal thermal loops offer potential advantages through their superior heat transfer capabilities, potentially reducing overall energy consumption in cooling-intensive applications. This aligns with broader sustainability goals and regulatory trends toward reduced energy usage and carbon emissions.

Market Analysis for Liquid Metal Cooling Systems

The liquid metal cooling systems market is experiencing significant growth driven by increasing demands for efficient thermal management solutions in high-performance computing, data centers, and advanced electronics. The global market value for liquid metal cooling technologies is projected to reach $2.3 billion by 2027, with a compound annual growth rate of 11.8% from 2022 to 2027. This growth trajectory is primarily fueled by the escalating power densities in electronic components and the subsequent need for more effective cooling solutions.

Data centers represent the largest market segment, accounting for approximately 38% of the total market share. The continuous expansion of cloud computing infrastructure and the proliferation of artificial intelligence applications have intensified cooling requirements, making liquid metal thermal loops an attractive alternative to conventional cooling methods. The gaming PC segment follows closely, constituting about 24% of the market, as enthusiasts seek superior thermal performance for overclocked systems.

Geographically, North America leads the market with a 42% share, followed by Asia-Pacific at 31% and Europe at 22%. The Asia-Pacific region is expected to witness the fastest growth rate of 14.3% annually, driven by rapid industrialization and technological advancement in countries like China, South Korea, and Japan.

Customer demand analysis reveals a strong preference for solutions that offer not only superior thermal conductivity but also reliability and ease of integration. End-users are increasingly willing to pay premium prices for cooling systems that can significantly extend the lifespan of their electronic components while enabling higher performance thresholds.

Market barriers include concerns about the corrosive nature of certain liquid metals, compatibility issues with existing systems, and relatively high initial implementation costs. The average cost of implementing a liquid metal cooling system remains approximately 2.5 times higher than traditional cooling solutions, presenting a significant adoption hurdle for price-sensitive segments.

Emerging market opportunities exist in renewable energy applications, particularly in concentrated solar power systems where efficient heat transfer is critical. The electric vehicle sector also presents substantial growth potential, with liquid metal cooling systems being explored for battery thermal management to enhance charging speeds and extend battery life.

Industry surveys indicate that 73% of potential adopters cite performance improvements as their primary motivation, while 58% express concerns about long-term reliability and maintenance requirements. This highlights the need for manufacturers to address these concerns through improved design and comprehensive service offerings.

Data centers represent the largest market segment, accounting for approximately 38% of the total market share. The continuous expansion of cloud computing infrastructure and the proliferation of artificial intelligence applications have intensified cooling requirements, making liquid metal thermal loops an attractive alternative to conventional cooling methods. The gaming PC segment follows closely, constituting about 24% of the market, as enthusiasts seek superior thermal performance for overclocked systems.

Geographically, North America leads the market with a 42% share, followed by Asia-Pacific at 31% and Europe at 22%. The Asia-Pacific region is expected to witness the fastest growth rate of 14.3% annually, driven by rapid industrialization and technological advancement in countries like China, South Korea, and Japan.

Customer demand analysis reveals a strong preference for solutions that offer not only superior thermal conductivity but also reliability and ease of integration. End-users are increasingly willing to pay premium prices for cooling systems that can significantly extend the lifespan of their electronic components while enabling higher performance thresholds.

Market barriers include concerns about the corrosive nature of certain liquid metals, compatibility issues with existing systems, and relatively high initial implementation costs. The average cost of implementing a liquid metal cooling system remains approximately 2.5 times higher than traditional cooling solutions, presenting a significant adoption hurdle for price-sensitive segments.

Emerging market opportunities exist in renewable energy applications, particularly in concentrated solar power systems where efficient heat transfer is critical. The electric vehicle sector also presents substantial growth potential, with liquid metal cooling systems being explored for battery thermal management to enhance charging speeds and extend battery life.

Industry surveys indicate that 73% of potential adopters cite performance improvements as their primary motivation, while 58% express concerns about long-term reliability and maintenance requirements. This highlights the need for manufacturers to address these concerns through improved design and comprehensive service offerings.

Current Challenges in Liquid Metal Pumping Technologies

Despite significant advancements in liquid metal thermal management systems, several critical challenges persist in pumping technologies that limit wider adoption and optimal performance. Electromagnetic (EM) pumps, while theoretically ideal for liquid metals due to their non-mechanical operation, suffer from low efficiency, typically ranging between 10-40% compared to 70-90% for conventional mechanical pumps. This efficiency gap represents a substantial barrier for applications where energy consumption is a critical factor.

Material compatibility issues present another significant challenge. The highly corrosive nature of liquid metals, particularly at elevated temperatures, severely restricts material selection for pump components. Conventional materials experience accelerated degradation through mechanisms including dissolution, intergranular penetration, and mass transfer effects. Even specialized alloys like stainless steel 316L show limited resistance in prolonged exposure to liquid metals such as sodium, gallium, or lead-bismuth eutectic.

Sealing and containment problems remain persistent engineering challenges. The low viscosity and high surface tension of liquid metals make them prone to leakage through even microscopic gaps. Traditional sealing technologies developed for water or oil-based systems prove inadequate, necessitating specialized solutions that can maintain integrity under thermal cycling and potential freezing-thawing scenarios.

Control system complexity represents another significant hurdle. Liquid metal flows exhibit unique magnetohydrodynamic (MHD) effects that create complex, non-linear behaviors difficult to model and predict. Conventional PID control algorithms often fail to provide stable operation across varying thermal loads and flow conditions. Advanced control strategies incorporating real-time flow modeling and predictive algorithms are needed but remain computationally intensive.

Measurement and instrumentation limitations further complicate effective pump control. Traditional flow measurement techniques like ultrasonic or Coriolis methods face significant challenges in liquid metal environments due to high temperatures, opacity, and electromagnetic interference. Non-invasive measurement technologies remain in early development stages, with limited accuracy and response times inadequate for precise control applications.

Scaling challenges persist when transitioning from laboratory to industrial applications. Small-scale demonstrations often fail to address the complex fluid dynamics, thermal management, and structural integrity issues that emerge at larger scales. The lack of standardized design methodologies and limited operational experience with large-scale liquid metal systems creates significant uncertainty in performance predictions and reliability assessments.

Material compatibility issues present another significant challenge. The highly corrosive nature of liquid metals, particularly at elevated temperatures, severely restricts material selection for pump components. Conventional materials experience accelerated degradation through mechanisms including dissolution, intergranular penetration, and mass transfer effects. Even specialized alloys like stainless steel 316L show limited resistance in prolonged exposure to liquid metals such as sodium, gallium, or lead-bismuth eutectic.

Sealing and containment problems remain persistent engineering challenges. The low viscosity and high surface tension of liquid metals make them prone to leakage through even microscopic gaps. Traditional sealing technologies developed for water or oil-based systems prove inadequate, necessitating specialized solutions that can maintain integrity under thermal cycling and potential freezing-thawing scenarios.

Control system complexity represents another significant hurdle. Liquid metal flows exhibit unique magnetohydrodynamic (MHD) effects that create complex, non-linear behaviors difficult to model and predict. Conventional PID control algorithms often fail to provide stable operation across varying thermal loads and flow conditions. Advanced control strategies incorporating real-time flow modeling and predictive algorithms are needed but remain computationally intensive.

Measurement and instrumentation limitations further complicate effective pump control. Traditional flow measurement techniques like ultrasonic or Coriolis methods face significant challenges in liquid metal environments due to high temperatures, opacity, and electromagnetic interference. Non-invasive measurement technologies remain in early development stages, with limited accuracy and response times inadequate for precise control applications.

Scaling challenges persist when transitioning from laboratory to industrial applications. Small-scale demonstrations often fail to address the complex fluid dynamics, thermal management, and structural integrity issues that emerge at larger scales. The lack of standardized design methodologies and limited operational experience with large-scale liquid metal systems creates significant uncertainty in performance predictions and reliability assessments.

State-of-the-Art Pumping and Control Mechanisms

01 Electromagnetic pumping systems for liquid metal thermal loops

Electromagnetic pumps are used in liquid metal thermal loops to circulate the liquid metal without mechanical moving parts. These systems utilize electromagnetic forces to propel conductive liquid metals like sodium, gallium, or mercury through cooling loops. The electromagnetic pumping approach offers advantages such as no sealing requirements, reduced maintenance, and reliable operation at high temperatures, making it particularly suitable for nuclear reactor cooling systems and advanced electronics thermal management.- Electromagnetic pumping systems for liquid metal thermal loops: Electromagnetic pumps are used in liquid metal thermal loops to move the conductive fluid without mechanical parts. These systems use electromagnetic forces to propel the liquid metal through the loop, offering advantages such as no moving parts, reduced maintenance, and reliable operation at high temperatures. The electromagnetic field interacts with the conductive liquid metal to create a pumping force, enabling efficient heat transfer in various applications including nuclear reactors and advanced cooling systems.

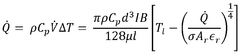

- Temperature and flow control strategies for liquid metal cooling: Advanced control strategies are implemented to regulate temperature and flow rates in liquid metal thermal loops. These include feedback control systems that monitor temperature differentials across the loop, adaptive algorithms that adjust pumping power based on thermal load requirements, and predictive control methods that anticipate changes in cooling demands. Such control strategies ensure optimal thermal management, prevent overheating, and maintain system stability while maximizing energy efficiency in high-performance cooling applications.

- Mechanical pumping mechanisms for liquid metal heat transfer: Mechanical pumping solutions for liquid metal thermal loops include specialized designs that address the challenges of handling high-temperature, corrosive liquid metals. These systems utilize sealed pumps with specialized materials and configurations to prevent leakage and contamination. Innovations include magnetically-coupled impellers, positive displacement pumps with protective linings, and hybrid systems that combine mechanical and electromagnetic principles to achieve reliable circulation of liquid metals while maintaining thermal efficiency and system integrity.

- Integration of liquid metal cooling in electronic systems: Liquid metal thermal loops are increasingly integrated into electronic cooling systems to manage high heat fluxes in compact devices. These implementations feature miniaturized pumping systems, specialized heat exchangers, and precise control mechanisms tailored for electronics cooling. The integration includes custom thermal interfaces that maximize heat transfer from electronic components to the liquid metal, along with safety features to prevent electrical shorts and material compatibility issues. These systems enable significant improvements in thermal management for high-performance computing, power electronics, and telecommunications equipment.

- Novel materials and designs for liquid metal thermal management: Innovative materials and designs enhance the performance and reliability of liquid metal thermal loops. These include corrosion-resistant alloys and coatings that extend system lifespan, composite materials that improve thermal conductivity at interfaces, and novel loop geometries that optimize flow distribution and heat transfer. Advanced manufacturing techniques enable complex channel structures and integrated sensors for real-time monitoring. These innovations address historical challenges with liquid metal systems such as corrosion, oxidation, and material compatibility, making liquid metal cooling more practical for a wider range of applications.

02 Temperature and flow control strategies for liquid metal cooling

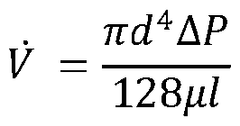

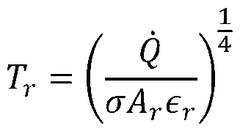

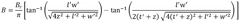

Advanced control strategies are implemented to regulate temperature and flow rates in liquid metal thermal loops. These include feedback control systems that monitor temperature differentials across heat exchangers, pressure sensors to detect flow irregularities, and automated valve systems to adjust flow distribution. Some systems incorporate predictive algorithms to anticipate cooling needs based on thermal load patterns, ensuring optimal thermal performance while preventing potential issues like freezing or overheating of the liquid metal coolant.Expand Specific Solutions03 Mechanical pumping and circulation techniques for liquid metal coolants

Mechanical pumping solutions for liquid metal thermal loops include specialized centrifugal pumps with appropriate materials to withstand corrosion and high temperatures. These systems often feature specialized impeller designs that optimize flow characteristics for high-density liquid metals. Some implementations use hybrid approaches combining mechanical pumping with gravity-assisted circulation to enhance reliability. Mechanical systems typically require careful consideration of sealing technologies to prevent leakage of potentially hazardous liquid metals while maintaining operational efficiency.Expand Specific Solutions04 Liquid metal interface materials and thermal management for electronics

Liquid metal thermal interfaces are used in advanced electronics cooling applications to maximize heat transfer between components. These systems employ gallium-based alloys or other low-melting-point metals that remain liquid at operating temperatures. The thermal loops incorporate micropumping mechanisms to circulate the liquid metal through miniaturized channels, often using capillary action or micro-electromechanical systems. Control strategies focus on maintaining optimal thermal contact while preventing metal migration that could cause electrical shorts in sensitive electronic components.Expand Specific Solutions05 Safety and containment systems for liquid metal thermal loops

Safety systems for liquid metal thermal loops include specialized containment vessels, leak detection sensors, and emergency shutdown protocols. These systems often incorporate secondary containment loops to capture any leakage and prevent environmental contamination. Advanced monitoring systems continuously assess the integrity of the thermal loop, detecting changes in pressure, flow rate, or electrical conductivity that might indicate a developing problem. Some designs feature passive safety mechanisms that automatically respond to abnormal conditions without requiring external power or operator intervention.Expand Specific Solutions

Leading Companies in Liquid Metal Thermal Loop Industry

The liquid metal thermal loop technology market is currently in an early growth phase, characterized by significant research activity but limited commercial deployment. The market size is estimated to be relatively modest but growing, driven by increasing demand for high-efficiency thermal management systems in nuclear, aerospace, and advanced manufacturing sectors. From a technical maturity perspective, the field shows varying levels of development across players. Academic institutions like Xi'an Jiaotong University, Beihang University, and Harbin Institute of Technology are advancing fundamental research, while industrial players demonstrate different specialization areas: GE Technology and China Nuclear Power Technology Research Institute focus on nuclear applications; Boeing and Raytheon on aerospace implementations; and companies like Bürkert and TMT on industrial control systems for liquid metal handling. The competitive landscape reflects a mix of established industrial conglomerates and specialized research-oriented organizations working to overcome the significant technical challenges of liquid metal pumping and control.

Xi'an Jiaotong University

Technical Solution: Xi'an Jiaotong University has developed advanced electromagnetic pumping systems for liquid metal thermal loops, particularly focusing on magnetohydrodynamic (MHD) pumps. Their technology utilizes traveling magnetic fields to create Lorentz forces that drive liquid metals like gallium, sodium, and lead-bismuth eutectic through cooling loops without moving parts. The university's research includes novel control strategies that dynamically adjust magnetic field strength and frequency based on thermal load requirements, enabling precise flow regulation. They've also pioneered hybrid pumping systems that combine electromagnetic forces with mechanical assistance for improved efficiency across different operating conditions. Their control algorithms incorporate real-time temperature feedback from multiple loop locations to optimize heat transfer while minimizing power consumption, particularly important for nuclear and concentrated solar applications.

Strengths: Complete elimination of mechanical wear components increases reliability and system lifetime; sophisticated control algorithms enable precise flow modulation without mechanical valves; zero-leakage design is critical for hazardous liquid metals. Weaknesses: Higher power consumption compared to mechanical pumps; magnetic field generation equipment adds significant weight and complexity; performance decreases with increasing temperature due to reduced electrical conductivity of liquid metals.

The Georgia Tech Research Corp.

Technical Solution: Georgia Tech Research Corp has developed an innovative pulsed electromagnetic pumping system for liquid metal thermal management in high-performance computing and power electronics applications. Their technology employs precisely timed electromagnetic pulses to create traveling pressure waves in gallium-based liquid metal coolants, achieving flow rates up to 3 L/min with lower power consumption than continuous electromagnetic pumps. The system incorporates advanced microcontroller-based feedback control that monitors thermal conditions at multiple points and dynamically adjusts pulse frequency, amplitude, and phase to optimize cooling efficiency. A key innovation is their segmented pump design that allows for zonal flow control within complex cooling loops, enabling targeted cooling of hotspots while maintaining overall thermal equilibrium. The control strategy includes predictive algorithms that anticipate thermal loads based on system usage patterns, preemptively adjusting flow parameters to prevent temperature spikes.

Strengths: Pulsed operation significantly reduces power consumption compared to continuous electromagnetic pumping; sophisticated zonal control enables precise thermal management for non-uniform heat sources; compact design integrates well with existing electronic systems. Weaknesses: Complex control electronics add cost and potential failure points; performance limited to lower-temperature liquid metals (primarily gallium alloys); electromagnetic interference may affect nearby sensitive electronic components.

Key Patents in Liquid Metal Flow Control Systems

Magnetohydrodynamically pumped liquid metal loops for spacecraft thermal control

PatentWO2024249383A2

Innovation

- A magnetohydrodynamic (MHD) pumped liquid metal loop system that uses a Lorentz force to drive liquid metal flow without moving parts, reducing mass and increasing reliability, and can be used for both small and high-power spacecraft systems.

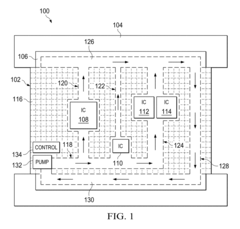

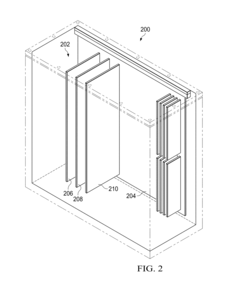

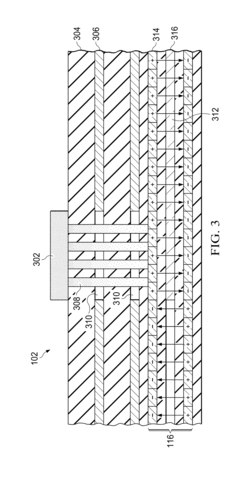

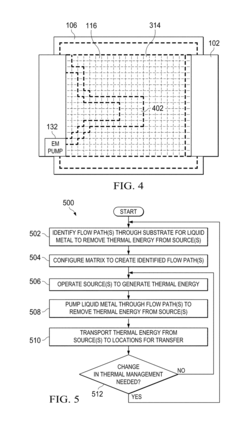

Apparatus and method for reconfigurable thermal management using flow control of liquid metal

PatentActiveUS20180352678A1

Innovation

- A reconfigurable thermal management system using liquid metal flow control, where an electrostatic matrix embedded within a substrate dynamically defines flow paths for liquid metal to remove heat from heat-generating components, utilizing electromagnetic pumps for efficient thermal energy transport.

Material Compatibility and Corrosion Mitigation Strategies

Material compatibility represents a critical challenge in liquid metal thermal loop systems, particularly when considering the highly reactive nature of liquid metals such as sodium, NaK, gallium, and lead-bismuth eutectic (LBE). These metals can aggressively attack containment materials, leading to degradation of system components and potential catastrophic failures. The corrosion mechanisms typically involve dissolution of container materials, intergranular penetration, and formation of intermetallic compounds that compromise structural integrity.

Austenitic stainless steels (304, 316) have emerged as primary containment materials for many liquid metal systems, offering reasonable corrosion resistance at moderate temperatures. However, at elevated temperatures exceeding 500°C, even these alloys experience accelerated degradation. Refractory metals including molybdenum, tungsten, and niobium demonstrate superior compatibility with alkali metals but present challenges in fabrication and joining processes.

Oxygen control has proven essential in mitigating corrosion, particularly in sodium and lead-bismuth systems. Maintaining oxygen concentrations below critical thresholds (typically <5 ppm for sodium systems) significantly reduces oxidation and mass transfer effects. Advanced monitoring technologies, including ceramic oxygen sensors based on yttria-stabilized zirconia, enable real-time oxygen level measurement and control in operational systems.

Surface modification techniques offer promising solutions for enhancing material compatibility. Aluminizing treatments create protective aluminum oxide layers that resist liquid metal attack, while GESA (Gepulste ElektronenStrahlAnlage) surface treatments modify the near-surface microstructure to enhance corrosion resistance. These approaches have demonstrated particular effectiveness in lead and LBE systems.

Cold traps represent another critical mitigation strategy, operating on temperature-dependent solubility principles to remove corrosion products and impurities from the liquid metal. By cooling a portion of the circulating metal below the main loop temperature, these devices precipitate and capture dissolved materials, preventing their redeposition elsewhere in the system.

Recent research has focused on developing self-healing materials and advanced ceramics for extreme environments. Silicon carbide composites and MAX phase materials (e.g., Ti3SiC2) show promising resistance to liquid metal attack while maintaining mechanical properties at elevated temperatures. Additionally, the introduction of sacrificial elements or inhibitors into liquid metal systems can significantly reduce corrosion rates by forming protective films on container surfaces.

Comprehensive testing protocols combining accelerated corrosion testing, post-exposure metallographic analysis, and in-situ monitoring techniques are essential for validating material compatibility in specific operational conditions. These methodologies enable accurate prediction of component lifetimes and inform maintenance schedules for liquid metal thermal management systems.

Austenitic stainless steels (304, 316) have emerged as primary containment materials for many liquid metal systems, offering reasonable corrosion resistance at moderate temperatures. However, at elevated temperatures exceeding 500°C, even these alloys experience accelerated degradation. Refractory metals including molybdenum, tungsten, and niobium demonstrate superior compatibility with alkali metals but present challenges in fabrication and joining processes.

Oxygen control has proven essential in mitigating corrosion, particularly in sodium and lead-bismuth systems. Maintaining oxygen concentrations below critical thresholds (typically <5 ppm for sodium systems) significantly reduces oxidation and mass transfer effects. Advanced monitoring technologies, including ceramic oxygen sensors based on yttria-stabilized zirconia, enable real-time oxygen level measurement and control in operational systems.

Surface modification techniques offer promising solutions for enhancing material compatibility. Aluminizing treatments create protective aluminum oxide layers that resist liquid metal attack, while GESA (Gepulste ElektronenStrahlAnlage) surface treatments modify the near-surface microstructure to enhance corrosion resistance. These approaches have demonstrated particular effectiveness in lead and LBE systems.

Cold traps represent another critical mitigation strategy, operating on temperature-dependent solubility principles to remove corrosion products and impurities from the liquid metal. By cooling a portion of the circulating metal below the main loop temperature, these devices precipitate and capture dissolved materials, preventing their redeposition elsewhere in the system.

Recent research has focused on developing self-healing materials and advanced ceramics for extreme environments. Silicon carbide composites and MAX phase materials (e.g., Ti3SiC2) show promising resistance to liquid metal attack while maintaining mechanical properties at elevated temperatures. Additionally, the introduction of sacrificial elements or inhibitors into liquid metal systems can significantly reduce corrosion rates by forming protective films on container surfaces.

Comprehensive testing protocols combining accelerated corrosion testing, post-exposure metallographic analysis, and in-situ monitoring techniques are essential for validating material compatibility in specific operational conditions. These methodologies enable accurate prediction of component lifetimes and inform maintenance schedules for liquid metal thermal management systems.

Safety Standards and Risk Assessment for Liquid Metal Systems

Liquid metal thermal loops present unique safety challenges due to the reactive nature of liquid metals and their high operating temperatures. Comprehensive safety standards and risk assessment protocols are essential for the safe implementation of these systems. The International Atomic Energy Agency (IAEA) and various national regulatory bodies have established specific guidelines for liquid metal systems, particularly those using sodium, lead, or gallium-based alloys. These standards address containment requirements, fire prevention measures, and emergency response procedures tailored to the chemical properties of each liquid metal.

Risk assessment methodologies for liquid metal thermal loops must consider both common industrial hazards and metal-specific risks. Quantitative risk assessment techniques such as Failure Mode and Effects Analysis (FMEA) and Probabilistic Risk Assessment (PRA) are widely applied to identify potential failure points in pumping systems and control mechanisms. For sodium-based systems, particular attention is given to sodium-water reaction risks, requiring specialized detection systems and isolation strategies. Lead-bismuth systems present different challenges, primarily related to corrosion and activation product management.

Material compatibility represents a critical safety consideration in liquid metal systems. Safety standards mandate rigorous testing protocols to ensure structural materials can withstand the corrosive effects of liquid metals under operational conditions. The American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code Section III provides specific guidance for liquid metal containment systems, while European standards EN 13445 and EN 13480 address pressure equipment requirements applicable to these specialized thermal loops.

Instrumentation and control system safety receives particular emphasis in modern standards. Redundant monitoring systems for flow rates, temperatures, and leak detection are required, with specific performance criteria for sensors operating in liquid metal environments. The IEC 61508 functional safety standard provides a framework for safety instrumented systems in liquid metal applications, with required Safety Integrity Levels (SIL) determined based on risk assessment outcomes.

Operational safety procedures constitute another vital component of liquid metal system standards. These include detailed protocols for system filling, draining, and maintenance operations where exposure risks are highest. Training requirements for personnel are typically more stringent than for conventional thermal systems, with specialized certification programs developed by organizations such as the Electric Power Research Institute (EPRI) and the Nuclear Energy Institute (NEI) for nuclear applications of liquid metal technology.

Risk assessment methodologies for liquid metal thermal loops must consider both common industrial hazards and metal-specific risks. Quantitative risk assessment techniques such as Failure Mode and Effects Analysis (FMEA) and Probabilistic Risk Assessment (PRA) are widely applied to identify potential failure points in pumping systems and control mechanisms. For sodium-based systems, particular attention is given to sodium-water reaction risks, requiring specialized detection systems and isolation strategies. Lead-bismuth systems present different challenges, primarily related to corrosion and activation product management.

Material compatibility represents a critical safety consideration in liquid metal systems. Safety standards mandate rigorous testing protocols to ensure structural materials can withstand the corrosive effects of liquid metals under operational conditions. The American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code Section III provides specific guidance for liquid metal containment systems, while European standards EN 13445 and EN 13480 address pressure equipment requirements applicable to these specialized thermal loops.

Instrumentation and control system safety receives particular emphasis in modern standards. Redundant monitoring systems for flow rates, temperatures, and leak detection are required, with specific performance criteria for sensors operating in liquid metal environments. The IEC 61508 functional safety standard provides a framework for safety instrumented systems in liquid metal applications, with required Safety Integrity Levels (SIL) determined based on risk assessment outcomes.

Operational safety procedures constitute another vital component of liquid metal system standards. These include detailed protocols for system filling, draining, and maintenance operations where exposure risks are highest. Training requirements for personnel are typically more stringent than for conventional thermal systems, with specialized certification programs developed by organizations such as the Electric Power Research Institute (EPRI) and the Nuclear Energy Institute (NEI) for nuclear applications of liquid metal technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!