Filtration And Contamination Control In Liquid Metal Loops

AUG 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Filtration Technology Background and Objectives

Liquid metal cooling systems have been integral to advanced nuclear reactors since the mid-20th century, with significant developments occurring during the 1950s and 1960s in the United States, Soviet Union, and later in France, Japan, and China. These systems utilize metals such as sodium, lead, lead-bismuth eutectic (LBE), and NaK alloys due to their exceptional heat transfer properties and low neutron absorption characteristics, making them ideal coolants for fast neutron reactors.

The evolution of liquid metal technology has been marked by several significant milestones, including the operation of the Experimental Breeder Reactor I (EBR-I) in 1951, which demonstrated the feasibility of liquid metal cooling in nuclear applications. Subsequent developments in the Soviet BN-series reactors and the French Phénix and Superphénix further advanced this technology, establishing its viability for commercial power generation.

Despite these advances, contamination control in liquid metal loops remains a persistent challenge. Impurities in liquid metal systems can lead to corrosion, mass transfer, flow restrictions, and component degradation, ultimately compromising system efficiency and safety. The primary contaminants include oxygen, hydrogen, carbon, nitrogen, and various metallic impurities that can form oxides, hydrides, carbides, and other compounds that affect system performance.

The technical objectives for filtration and contamination control in liquid metal loops are multifaceted. First, to develop efficient filtration systems capable of removing particulate matter and chemical impurities without significantly impeding flow or heat transfer. Second, to establish reliable monitoring systems that can detect contamination levels in real-time, allowing for proactive maintenance. Third, to design materials and components resistant to corrosion and degradation in the harsh liquid metal environment.

Current research trends focus on advanced filtration technologies, including cold traps, hot traps, mechanical filters, and electromagnetic filters. There is also significant interest in developing novel materials with enhanced corrosion resistance and improved compatibility with liquid metals. Additionally, the integration of online monitoring systems using advanced sensors and analytical techniques represents a growing area of research.

The future trajectory of liquid metal filtration technology is expected to align with the broader development of Generation IV nuclear reactors, molten salt energy storage systems, and concentrated solar power applications. As these technologies mature, the demand for more sophisticated filtration and contamination control solutions will increase, driving innovation in this specialized field.

The evolution of liquid metal technology has been marked by several significant milestones, including the operation of the Experimental Breeder Reactor I (EBR-I) in 1951, which demonstrated the feasibility of liquid metal cooling in nuclear applications. Subsequent developments in the Soviet BN-series reactors and the French Phénix and Superphénix further advanced this technology, establishing its viability for commercial power generation.

Despite these advances, contamination control in liquid metal loops remains a persistent challenge. Impurities in liquid metal systems can lead to corrosion, mass transfer, flow restrictions, and component degradation, ultimately compromising system efficiency and safety. The primary contaminants include oxygen, hydrogen, carbon, nitrogen, and various metallic impurities that can form oxides, hydrides, carbides, and other compounds that affect system performance.

The technical objectives for filtration and contamination control in liquid metal loops are multifaceted. First, to develop efficient filtration systems capable of removing particulate matter and chemical impurities without significantly impeding flow or heat transfer. Second, to establish reliable monitoring systems that can detect contamination levels in real-time, allowing for proactive maintenance. Third, to design materials and components resistant to corrosion and degradation in the harsh liquid metal environment.

Current research trends focus on advanced filtration technologies, including cold traps, hot traps, mechanical filters, and electromagnetic filters. There is also significant interest in developing novel materials with enhanced corrosion resistance and improved compatibility with liquid metals. Additionally, the integration of online monitoring systems using advanced sensors and analytical techniques represents a growing area of research.

The future trajectory of liquid metal filtration technology is expected to align with the broader development of Generation IV nuclear reactors, molten salt energy storage systems, and concentrated solar power applications. As these technologies mature, the demand for more sophisticated filtration and contamination control solutions will increase, driving innovation in this specialized field.

Market Analysis for Liquid Metal Filtration Systems

The global market for liquid metal filtration systems is experiencing significant growth, driven by increasing applications in nuclear power, concentrated solar power (CSP), and advanced manufacturing sectors. Current market valuations indicate that the liquid metal filtration segment represents approximately 8% of the broader industrial filtration market, with projections showing accelerated growth at a compound annual rate of 6.2% through 2030.

Nuclear power generation remains the dominant application sector, accounting for nearly 65% of liquid metal filtration system deployments. This dominance stems from the critical role these systems play in sodium-cooled fast reactors and lead-cooled reactor designs, where contamination control directly impacts operational safety and efficiency. The recent resurgence in nuclear energy investments, particularly in China, Russia, and India, has substantially expanded market opportunities.

Concentrated solar power applications represent the fastest-growing segment, with market penetration increasing by approximately 12% annually. This growth correlates directly with the adoption of liquid metal heat transfer fluids in next-generation CSP installations, which offer superior thermal efficiency compared to conventional molten salt systems. The European market leads this segment, driven by substantial renewable energy initiatives and favorable regulatory frameworks.

Regional analysis reveals Asia-Pacific as the largest market by volume, capturing 42% of global demand, followed by North America (27%) and Europe (23%). China's ambitious nuclear expansion program and Japan's renewed focus on advanced reactor technologies have positioned Asia-Pacific as the primary growth engine for liquid metal filtration technologies.

Customer segmentation shows distinct market tiers: Tier 1 comprises national nuclear authorities and major energy corporations with sophisticated procurement processes and stringent technical requirements; Tier 2 includes research institutions and specialized industrial applications; while Tier 3 encompasses emerging applications in sectors like electronics manufacturing and metallurgical processing.

Price sensitivity varies significantly across these segments, with Tier 1 customers prioritizing performance and reliability over cost considerations. The average implementation cost for comprehensive liquid metal filtration systems ranges from $450,000 to $2.8 million, depending on scale and application requirements.

Market barriers include high initial capital requirements, complex regulatory approval processes for nuclear applications, and limited standardization across different liquid metal mediums. These factors have contributed to market concentration, with the top five suppliers controlling approximately 73% of global market share.

Future market expansion will likely be driven by innovations in filtration materials that can withstand extreme temperatures and corrosive environments, alongside growing applications in advanced manufacturing processes where ultra-pure liquid metals are essential for product quality.

Nuclear power generation remains the dominant application sector, accounting for nearly 65% of liquid metal filtration system deployments. This dominance stems from the critical role these systems play in sodium-cooled fast reactors and lead-cooled reactor designs, where contamination control directly impacts operational safety and efficiency. The recent resurgence in nuclear energy investments, particularly in China, Russia, and India, has substantially expanded market opportunities.

Concentrated solar power applications represent the fastest-growing segment, with market penetration increasing by approximately 12% annually. This growth correlates directly with the adoption of liquid metal heat transfer fluids in next-generation CSP installations, which offer superior thermal efficiency compared to conventional molten salt systems. The European market leads this segment, driven by substantial renewable energy initiatives and favorable regulatory frameworks.

Regional analysis reveals Asia-Pacific as the largest market by volume, capturing 42% of global demand, followed by North America (27%) and Europe (23%). China's ambitious nuclear expansion program and Japan's renewed focus on advanced reactor technologies have positioned Asia-Pacific as the primary growth engine for liquid metal filtration technologies.

Customer segmentation shows distinct market tiers: Tier 1 comprises national nuclear authorities and major energy corporations with sophisticated procurement processes and stringent technical requirements; Tier 2 includes research institutions and specialized industrial applications; while Tier 3 encompasses emerging applications in sectors like electronics manufacturing and metallurgical processing.

Price sensitivity varies significantly across these segments, with Tier 1 customers prioritizing performance and reliability over cost considerations. The average implementation cost for comprehensive liquid metal filtration systems ranges from $450,000 to $2.8 million, depending on scale and application requirements.

Market barriers include high initial capital requirements, complex regulatory approval processes for nuclear applications, and limited standardization across different liquid metal mediums. These factors have contributed to market concentration, with the top five suppliers controlling approximately 73% of global market share.

Future market expansion will likely be driven by innovations in filtration materials that can withstand extreme temperatures and corrosive environments, alongside growing applications in advanced manufacturing processes where ultra-pure liquid metals are essential for product quality.

Current Challenges in Liquid Metal Contamination Control

Liquid metal contamination control faces significant challenges that impede the efficient operation and longevity of liquid metal loop systems. One of the primary obstacles is the high chemical reactivity of liquid metals, particularly sodium, lithium, and lead-bismuth eutectic (LBE), with oxygen and moisture. Even trace amounts of these contaminants can lead to oxide formation, which subsequently causes flow blockages, heat transfer degradation, and accelerated corrosion rates in critical system components.

The detection and monitoring of impurities present another substantial challenge. Current technologies often struggle to provide real-time, accurate measurements of contaminant levels, especially at the low concentrations that can still cause significant damage. Conventional sampling methods may alter the composition during extraction, leading to inaccurate readings and delayed response to contamination events.

Material compatibility issues further complicate contamination control efforts. The selection of appropriate filtration materials that can withstand the aggressive nature of liquid metals while maintaining structural integrity at high temperatures remains problematic. Many conventional filter materials degrade rapidly or become ineffective when exposed to liquid metals, limiting filtration efficiency and operational lifespans.

Temperature management during filtration processes poses additional difficulties. Filtration systems must operate across wide temperature ranges without compromising performance. Cold traps, a common purification method, require precise temperature control to effectively precipitate and capture impurities without causing unwanted solidification of the liquid metal itself.

The removal of non-metallic inclusions, particularly carbon and nitrogen compounds, represents a persistent technical hurdle. These contaminants can form complex compounds that are difficult to filter using conventional methods and may require specialized approaches that are not yet fully developed or commercially viable.

Maintenance and operational challenges also plague current systems. The need for regular filter replacement or regeneration often necessitates system shutdown, reducing operational efficiency. Additionally, the handling of contaminated filter media presents safety and disposal concerns, particularly in nuclear applications where radioactive materials may be present.

Scale-up issues further limit industrial implementation of advanced filtration technologies. Laboratory-proven methods often encounter unforeseen challenges when deployed at industrial scales, including flow distribution problems, pressure drop increases, and reduced filtration efficiency.

Finally, regulatory and safety requirements add layers of complexity to contamination control strategies, particularly in nuclear applications where liquid metal coolants are common. Meeting these stringent standards while maintaining system performance and economic viability requires innovative approaches that balance multiple competing factors.

The detection and monitoring of impurities present another substantial challenge. Current technologies often struggle to provide real-time, accurate measurements of contaminant levels, especially at the low concentrations that can still cause significant damage. Conventional sampling methods may alter the composition during extraction, leading to inaccurate readings and delayed response to contamination events.

Material compatibility issues further complicate contamination control efforts. The selection of appropriate filtration materials that can withstand the aggressive nature of liquid metals while maintaining structural integrity at high temperatures remains problematic. Many conventional filter materials degrade rapidly or become ineffective when exposed to liquid metals, limiting filtration efficiency and operational lifespans.

Temperature management during filtration processes poses additional difficulties. Filtration systems must operate across wide temperature ranges without compromising performance. Cold traps, a common purification method, require precise temperature control to effectively precipitate and capture impurities without causing unwanted solidification of the liquid metal itself.

The removal of non-metallic inclusions, particularly carbon and nitrogen compounds, represents a persistent technical hurdle. These contaminants can form complex compounds that are difficult to filter using conventional methods and may require specialized approaches that are not yet fully developed or commercially viable.

Maintenance and operational challenges also plague current systems. The need for regular filter replacement or regeneration often necessitates system shutdown, reducing operational efficiency. Additionally, the handling of contaminated filter media presents safety and disposal concerns, particularly in nuclear applications where radioactive materials may be present.

Scale-up issues further limit industrial implementation of advanced filtration technologies. Laboratory-proven methods often encounter unforeseen challenges when deployed at industrial scales, including flow distribution problems, pressure drop increases, and reduced filtration efficiency.

Finally, regulatory and safety requirements add layers of complexity to contamination control strategies, particularly in nuclear applications where liquid metal coolants are common. Meeting these stringent standards while maintaining system performance and economic viability requires innovative approaches that balance multiple competing factors.

Current Filtration Solutions for Liquid Metal Loops

01 Mechanical filtration systems for liquid metal loops

Mechanical filtration systems are employed in liquid metal loops to remove solid contaminants and impurities. These systems typically use mesh screens, porous media, or specialized filter elements to physically trap particles while allowing the liquid metal to flow through. The filtration systems can be designed for specific particle size ranges and can be integrated at strategic points in the liquid metal loop to ensure effective contamination control.- Mechanical filtration systems for liquid metal loops: Mechanical filtration systems are employed to remove solid contaminants from liquid metal loops. These systems typically use filters, screens, or traps to physically separate particulate matter from the liquid metal flow. The filtration mechanisms can include mesh screens, porous media, or specialized filter elements designed to withstand high temperatures and corrosive environments associated with liquid metals. These systems are crucial for preventing blockages and maintaining the integrity of liquid metal cooling systems.

- Chemical purification methods for liquid metal contamination control: Chemical purification methods involve the use of chemical reactions to remove impurities from liquid metal loops. These techniques include gettering, where reactive materials selectively bind with impurities, and cold trapping, where impurities are precipitated out of solution at lower temperatures. Chemical purification is particularly effective for removing dissolved oxygen, nitrogen, and other non-metallic elements that can cause corrosion or degradation of system components in liquid metal cooling systems.

- Electromagnetic filtration techniques for liquid metals: Electromagnetic filtration techniques leverage the conductive properties of liquid metals to separate impurities. These systems use magnetic fields to influence the flow of liquid metals and separate non-magnetic contaminants. Electromagnetic pumps and separators can be integrated into liquid metal loops to provide continuous filtration without mechanical components that might fail under extreme conditions. This approach is particularly valuable for high-temperature liquid metal applications where traditional filtration methods may be less effective.

- Monitoring and detection systems for liquid metal purity: Advanced monitoring and detection systems are essential for maintaining liquid metal purity in operational loops. These systems include sensors that can detect contaminant levels, oxygen content, and other impurities in real-time. Continuous monitoring allows for immediate intervention when contamination exceeds acceptable thresholds, preventing potential damage to system components. Technologies such as electrochemical sensors, spectroscopic analyzers, and ultrasonic detectors provide comprehensive data on liquid metal purity throughout the operational cycle.

- Integrated contamination control systems for liquid metal loops: Integrated contamination control systems combine multiple filtration and purification technologies to provide comprehensive protection for liquid metal loops. These systems typically incorporate mechanical filters, chemical purification units, and monitoring equipment in a coordinated design. The integration allows for optimized performance across various operating conditions and contaminant types. Advanced systems may include automated control mechanisms that adjust filtration parameters based on real-time monitoring data, ensuring consistent liquid metal purity with minimal operator intervention.

02 Chemical purification methods for liquid metals

Chemical purification methods are used to control contamination in liquid metal loops by removing dissolved impurities through chemical reactions. These methods include gettering, where reactive materials selectively bind with impurities, and cold trapping, where impurities are precipitated out of solution at lower temperatures. Chemical purification helps maintain the desired properties of the liquid metal and prevents corrosion or degradation of the loop components.Expand Specific Solutions03 Monitoring and control systems for liquid metal purity

Advanced monitoring and control systems are implemented to continuously assess and maintain the purity of liquid metals in circulation loops. These systems utilize sensors to detect contaminants, measure impurity levels, and trigger appropriate filtration or purification responses. Real-time monitoring enables proactive contamination control, helping to prevent system failures and extend the operational life of liquid metal loops in various applications.Expand Specific Solutions04 Specialized materials for liquid metal filtration

Specialized materials are developed specifically for liquid metal filtration applications to withstand high temperatures and corrosive environments. These materials include ceramic filters, sintered metal meshes, and composite structures that offer both thermal stability and chemical resistance. The selection of appropriate filtration materials is crucial for ensuring effective contamination control while maintaining the integrity of the filtration system over extended operational periods.Expand Specific Solutions05 Integrated loop design for contamination management

Integrated loop designs incorporate multiple contamination control strategies within the liquid metal circulation system. These designs feature strategically placed filtration units, purification zones, and bypass systems that work together to maintain metal purity. The integrated approach addresses various contamination sources and mechanisms, providing comprehensive protection against both particulate and dissolved impurities while optimizing system performance and efficiency.Expand Specific Solutions

Key Industry Players in Liquid Metal Purification

The filtration and contamination control in liquid metal loops market is in a growth phase, driven by increasing demand for advanced manufacturing processes in industries like steel production and semiconductor fabrication. The market size is expanding as industries adopt liquid metal technologies for improved efficiency and performance. From a technological maturity perspective, established players like NIPPON STEEL, ABB Group, and FANUC Corp. lead with comprehensive solutions, while specialized companies such as Control Components and Servimetal focus on niche applications. Research institutions including Xi'an Jiaotong University and Hebei University of Technology are advancing fundamental technologies. The competitive landscape features both traditional industrial giants (Maanshan Iron & Steel, Nanjing Iron & Steel) and technology innovators (BOE Technology, United Microelectronics), indicating a market transitioning from specialized industrial applications toward broader technological integration.

Nanjing Iron & Steel Co., Ltd.

Technical Solution: Nanjing Iron & Steel has developed an integrated liquid metal filtration system specifically tailored for steel production environments. Their technology combines traditional ceramic filters with electromagnetic separation techniques to address both non-metallic inclusions and metallic impurities. The company's multi-stage filtration approach begins with coarse filtration using reticulated ceramic filters followed by fine filtration through specially designed filter beds with controlled porosity. Their system incorporates temperature-controlled filter preheating to prevent thermal shock and premature filter failure when contacting high-temperature liquid metals. Nanjing's contamination control strategy also includes specialized tundish designs that optimize flow patterns to enhance natural separation of inclusions through flotation before the filtration stage. The company has implemented automated filter monitoring systems that track pressure differentials across filter elements to predict maintenance needs and prevent catastrophic filter failures during operation.

Strengths: Specialized solutions optimized for steel production environments; integrated approach combining multiple filtration mechanisms. Weaknesses: Systems primarily optimized for steel applications with limited adaptability to other liquid metal types; requires significant technical expertise for proper implementation and maintenance.

Zhongtian Iron & Steel Group Co., Ltd.

Technical Solution: Zhongtian Iron & Steel has developed proprietary filtration technology for liquid metal purification in continuous casting operations. Their system employs a combination of ceramic foam filters and deep-bed granular media specifically engineered to withstand the thermal and chemical challenges of molten steel processing. The company's filtration approach incorporates staged filtration with progressively finer filter elements to efficiently remove inclusions across a wide size range while maintaining operational flow rates. Zhongtian's contamination control strategy includes specialized filter pretreatment processes that enhance filter wettability and chemical resistance, extending operational life in aggressive liquid metal environments. Their system features modular filter housings designed for rapid replacement during production, minimizing downtime during filter changes. Additionally, the company has implemented computational fluid dynamics modeling to optimize filter geometry and placement, ensuring uniform flow distribution and maximizing filtration efficiency while minimizing pressure drop across the filtration system.

Strengths: Practical solutions designed for industrial-scale implementation; focus on operational reliability and maintenance efficiency. Weaknesses: Less advanced in real-time monitoring capabilities compared to competitors; systems primarily optimized for specific steel grades with less flexibility for other applications.

Critical Patents in Liquid Metal Contamination Control

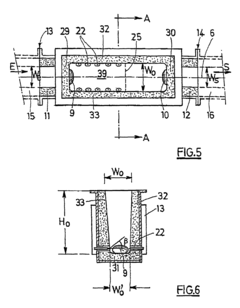

Mechanically and physiochemically effective filtration block for liquid metals and alloys, and process for producing said block

PatentInactiveEP0014165A1

Innovation

- A filtration block with a mechanical and physico-chemical effect, using an agglomeration of active mineral compounds with a melting point higher than the metal, forming a porous structure with open pores, which combines mechanical filtration and physico-chemical purification by a solid flux with a high contact surface, effectively trapping inclusions at the flux-liquid metal interface.

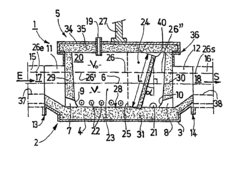

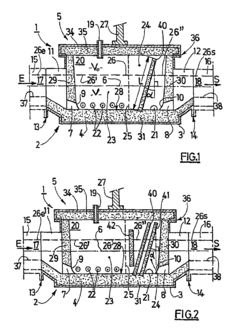

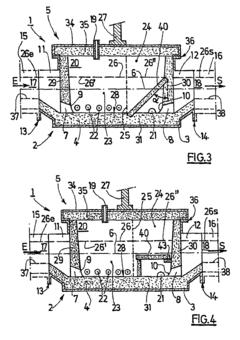

Device for the in-line treatment of liquid metal by means of gas and filtration

PatentInactiveUS7648674B2

Innovation

- A compact treatment device integrating gas injection means upstream and filtration means downstream within a single treatment compartment, which enhances treatment efficiency by preventing solid inclusion accumulation and promoting liquid metal recirculation, thereby improving the treatment process and simplifying maintenance.

Material Compatibility and Corrosion Management

Material compatibility represents a critical challenge in liquid metal cooling systems, particularly in nuclear reactors and advanced energy systems. The interaction between liquid metals such as sodium, lead-bismuth eutectic (LBE), or gallium with containment materials creates complex corrosion mechanisms that must be thoroughly understood and managed. These interactions are temperature-dependent, with corrosion rates typically accelerating at higher operating temperatures, creating additional challenges for high-temperature applications.

The selection of appropriate structural materials requires careful consideration of several factors. Austenitic and ferritic-martensitic steels have demonstrated reasonable compatibility with liquid sodium, while refractory metals like molybdenum and tungsten show promising resistance to lead and LBE systems. However, even these materials face limitations at elevated temperatures or under specific operating conditions, necessitating comprehensive testing under representative conditions.

Oxygen control emerges as a fundamental strategy for corrosion management in liquid metal systems. For lead and LBE systems, maintaining oxygen concentrations within a narrow operational window (typically 10^-6 to 10^-8 wt%) promotes the formation of protective oxide layers on structural materials while preventing oxide precipitation in the coolant. This delicate balance requires sophisticated oxygen monitoring and control systems, including oxygen sensors capable of functioning reliably in harsh liquid metal environments.

Surface modification techniques offer additional protection strategies. Aluminizing, chromizing, and silicon-enrichment processes create diffusion barriers that significantly enhance corrosion resistance. Advanced coating technologies, including GESA (Gepulste Elektronen Strahl Anlage) surface treatment and plasma-sprayed ceramic coatings, have demonstrated promising results in laboratory testing, though long-term performance validation remains ongoing.

Mass transfer effects present another significant challenge, particularly in non-isothermal systems where temperature gradients drive dissolution of structural materials in hot regions and deposition in cooler sections. This phenomenon necessitates careful system design and potentially the implementation of cold traps or other mechanisms to capture dissolved materials before they can precipitate in undesirable locations.

Monitoring and predictive modeling of material degradation have advanced significantly, with electrochemical techniques adapted for liquid metal environments and computational models increasingly capable of predicting long-term corrosion behavior. These tools enable more effective lifecycle management and maintenance scheduling, reducing operational risks and extending system lifetimes.

The integration of filtration systems with material compatibility considerations represents an emerging area of development, where filter materials must themselves withstand the corrosive environment while effectively removing contaminants that could accelerate corrosion processes elsewhere in the system.

The selection of appropriate structural materials requires careful consideration of several factors. Austenitic and ferritic-martensitic steels have demonstrated reasonable compatibility with liquid sodium, while refractory metals like molybdenum and tungsten show promising resistance to lead and LBE systems. However, even these materials face limitations at elevated temperatures or under specific operating conditions, necessitating comprehensive testing under representative conditions.

Oxygen control emerges as a fundamental strategy for corrosion management in liquid metal systems. For lead and LBE systems, maintaining oxygen concentrations within a narrow operational window (typically 10^-6 to 10^-8 wt%) promotes the formation of protective oxide layers on structural materials while preventing oxide precipitation in the coolant. This delicate balance requires sophisticated oxygen monitoring and control systems, including oxygen sensors capable of functioning reliably in harsh liquid metal environments.

Surface modification techniques offer additional protection strategies. Aluminizing, chromizing, and silicon-enrichment processes create diffusion barriers that significantly enhance corrosion resistance. Advanced coating technologies, including GESA (Gepulste Elektronen Strahl Anlage) surface treatment and plasma-sprayed ceramic coatings, have demonstrated promising results in laboratory testing, though long-term performance validation remains ongoing.

Mass transfer effects present another significant challenge, particularly in non-isothermal systems where temperature gradients drive dissolution of structural materials in hot regions and deposition in cooler sections. This phenomenon necessitates careful system design and potentially the implementation of cold traps or other mechanisms to capture dissolved materials before they can precipitate in undesirable locations.

Monitoring and predictive modeling of material degradation have advanced significantly, with electrochemical techniques adapted for liquid metal environments and computational models increasingly capable of predicting long-term corrosion behavior. These tools enable more effective lifecycle management and maintenance scheduling, reducing operational risks and extending system lifetimes.

The integration of filtration systems with material compatibility considerations represents an emerging area of development, where filter materials must themselves withstand the corrosive environment while effectively removing contaminants that could accelerate corrosion processes elsewhere in the system.

Safety Standards and Environmental Considerations

The operation of liquid metal loops necessitates adherence to stringent safety standards and environmental regulations due to the inherent hazards associated with these systems. Regulatory frameworks such as ASME Boiler and Pressure Vessel Code Section III and the Nuclear Regulatory Commission's guidelines establish comprehensive requirements for the design, construction, and operation of liquid metal systems, particularly in nuclear applications. These standards mandate specific filtration efficiency metrics, contamination monitoring protocols, and material compatibility assessments to prevent catastrophic failures.

Environmental considerations have become increasingly prominent in liquid metal loop operations, with regulatory bodies worldwide implementing stricter controls on potential releases and waste management. The Environmental Protection Agency's Resource Conservation and Recovery Act classifies certain liquid metal wastes as hazardous materials, requiring specialized handling and disposal procedures. Filtration systems must therefore not only protect the operational integrity of the loop but also prevent environmental contamination through leakage or improper waste disposal.

Risk assessment methodologies specific to liquid metal systems have evolved significantly, incorporating both deterministic and probabilistic approaches. These assessments evaluate potential failure modes of filtration systems and their environmental consequences, informing the development of multi-layered containment strategies. Modern safety standards emphasize defense-in-depth principles, requiring redundant filtration systems and real-time monitoring capabilities to detect contamination breaches before they escalate to environmental releases.

Worker safety considerations represent another critical dimension of regulatory compliance. Exposure limits for various liquid metals (particularly sodium, lead, and mercury) are strictly regulated by occupational health authorities, necessitating sophisticated filtration and ventilation systems in operational environments. Personal protective equipment requirements and emergency response protocols are directly influenced by the effectiveness of contamination control systems.

The international harmonization of safety standards for liquid metal systems remains an ongoing challenge, with significant variations existing between regulatory regimes. Organizations such as the International Atomic Energy Agency have attempted to establish consensus guidelines, particularly for nuclear applications of liquid metal technology. These efforts have resulted in the development of internationally recognized best practices for filtration system design, maintenance protocols, and contamination monitoring methodologies.

Emerging environmental regulations increasingly focus on the entire lifecycle of liquid metal systems, from initial commissioning through decommissioning and waste management. This holistic approach requires filtration and contamination control strategies that anticipate end-of-life challenges, including the removal and safe disposal of accumulated contaminants. Advanced filtration technologies are being developed specifically to address these long-term environmental considerations, ensuring sustainable operation throughout the system lifecycle.

Environmental considerations have become increasingly prominent in liquid metal loop operations, with regulatory bodies worldwide implementing stricter controls on potential releases and waste management. The Environmental Protection Agency's Resource Conservation and Recovery Act classifies certain liquid metal wastes as hazardous materials, requiring specialized handling and disposal procedures. Filtration systems must therefore not only protect the operational integrity of the loop but also prevent environmental contamination through leakage or improper waste disposal.

Risk assessment methodologies specific to liquid metal systems have evolved significantly, incorporating both deterministic and probabilistic approaches. These assessments evaluate potential failure modes of filtration systems and their environmental consequences, informing the development of multi-layered containment strategies. Modern safety standards emphasize defense-in-depth principles, requiring redundant filtration systems and real-time monitoring capabilities to detect contamination breaches before they escalate to environmental releases.

Worker safety considerations represent another critical dimension of regulatory compliance. Exposure limits for various liquid metals (particularly sodium, lead, and mercury) are strictly regulated by occupational health authorities, necessitating sophisticated filtration and ventilation systems in operational environments. Personal protective equipment requirements and emergency response protocols are directly influenced by the effectiveness of contamination control systems.

The international harmonization of safety standards for liquid metal systems remains an ongoing challenge, with significant variations existing between regulatory regimes. Organizations such as the International Atomic Energy Agency have attempted to establish consensus guidelines, particularly for nuclear applications of liquid metal technology. These efforts have resulted in the development of internationally recognized best practices for filtration system design, maintenance protocols, and contamination monitoring methodologies.

Emerging environmental regulations increasingly focus on the entire lifecycle of liquid metal systems, from initial commissioning through decommissioning and waste management. This holistic approach requires filtration and contamination control strategies that anticipate end-of-life challenges, including the removal and safe disposal of accumulated contaminants. Advanced filtration technologies are being developed specifically to address these long-term environmental considerations, ensuring sustainable operation throughout the system lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!