Comparing Liquid Metal Cooling With Immersion And Air Cooling At Scale

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Cooling Evolution and Objectives

Liquid metal cooling technology has evolved significantly over the past decades, transitioning from theoretical concepts to practical applications in high-performance computing environments. Initially developed for specialized applications in nuclear reactors and industrial processes in the 1950s and 1960s, liquid metal cooling has gradually found its way into electronics cooling solutions due to its exceptional thermal conductivity properties. Metals such as gallium, indium, and their alloys have emerged as promising candidates for advanced cooling systems, offering thermal conductivity values 10-100 times higher than conventional coolants.

The evolution of liquid metal cooling has been accelerated by the increasing power densities in modern computing systems, which have rendered traditional air cooling methods increasingly inadequate. While air cooling dominated the market for decades due to its simplicity and cost-effectiveness, its physical limitations became apparent as processor thermal design power (TDP) values continued to rise beyond 250W for high-performance applications.

Immersion cooling emerged as an intermediate solution, offering significantly improved heat transfer coefficients compared to air cooling. However, even immersion cooling faces efficiency challenges when dealing with extreme heat densities in hyperscale data centers and supercomputing facilities. This technological gap has created the opportunity for liquid metal cooling to establish itself as a next-generation thermal management solution.

Recent advancements in liquid metal formulations have addressed historical concerns regarding corrosivity, toxicity, and pump compatibility. Modern gallium-based alloys feature passivation technologies that minimize reactivity with common metals used in computing infrastructure, while maintaining the exceptional thermal properties that make liquid metals attractive for cooling applications.

The primary objective of liquid metal cooling technology is to enable the next generation of high-density computing by providing thermal management solutions capable of handling heat fluxes exceeding 500 W/cm². Secondary objectives include improving energy efficiency by reducing cooling overhead, minimizing system footprint through higher density deployments, and enabling more aggressive processor designs that would otherwise be thermally constrained.

As data centers continue to expand and artificial intelligence workloads drive demand for increasingly powerful computing resources, the trajectory of liquid metal cooling technology points toward broader adoption in specialized high-performance environments. Research efforts are currently focused on scaling these solutions cost-effectively while addressing remaining challenges related to long-term reliability, maintenance requirements, and system integration complexities.

The evolution of liquid metal cooling has been accelerated by the increasing power densities in modern computing systems, which have rendered traditional air cooling methods increasingly inadequate. While air cooling dominated the market for decades due to its simplicity and cost-effectiveness, its physical limitations became apparent as processor thermal design power (TDP) values continued to rise beyond 250W for high-performance applications.

Immersion cooling emerged as an intermediate solution, offering significantly improved heat transfer coefficients compared to air cooling. However, even immersion cooling faces efficiency challenges when dealing with extreme heat densities in hyperscale data centers and supercomputing facilities. This technological gap has created the opportunity for liquid metal cooling to establish itself as a next-generation thermal management solution.

Recent advancements in liquid metal formulations have addressed historical concerns regarding corrosivity, toxicity, and pump compatibility. Modern gallium-based alloys feature passivation technologies that minimize reactivity with common metals used in computing infrastructure, while maintaining the exceptional thermal properties that make liquid metals attractive for cooling applications.

The primary objective of liquid metal cooling technology is to enable the next generation of high-density computing by providing thermal management solutions capable of handling heat fluxes exceeding 500 W/cm². Secondary objectives include improving energy efficiency by reducing cooling overhead, minimizing system footprint through higher density deployments, and enabling more aggressive processor designs that would otherwise be thermally constrained.

As data centers continue to expand and artificial intelligence workloads drive demand for increasingly powerful computing resources, the trajectory of liquid metal cooling technology points toward broader adoption in specialized high-performance environments. Research efforts are currently focused on scaling these solutions cost-effectively while addressing remaining challenges related to long-term reliability, maintenance requirements, and system integration complexities.

Data Center Cooling Market Analysis

The data center cooling market is experiencing unprecedented growth, driven by the exponential increase in data processing demands and the proliferation of hyperscale facilities worldwide. Current market valuations place the global data center cooling sector at approximately $8 billion, with projections indicating a compound annual growth rate of 12-15% through 2028. This acceleration is primarily fueled by the rapid expansion of cloud computing services, artificial intelligence applications, and the increasing density of computing infrastructure.

Traditional air cooling solutions currently dominate the market with roughly 65% market share, though this percentage is steadily declining as more efficient alternatives gain traction. Liquid cooling technologies, including both immersion and direct-to-chip solutions, are experiencing the fastest growth segment at 24% annually, reflecting the industry's shift toward more energy-efficient cooling methodologies.

The emerging liquid metal cooling technology represents a small but rapidly expanding niche, currently accounting for less than 5% of the cooling market but demonstrating superior thermal performance metrics that suggest significant future growth potential. Early adopters report 30-40% improvements in cooling efficiency compared to traditional methods, particularly in high-density computing environments.

Regional analysis reveals North America leading the market with approximately 38% share, followed by Asia-Pacific at 32%, which is experiencing the fastest growth rate due to massive data center investments in China, Singapore, and India. European markets contribute roughly 25%, with particular emphasis on sustainable cooling solutions driven by stringent environmental regulations.

Market segmentation by industry shows financial services, telecommunications, and cloud service providers as the primary consumers of advanced cooling technologies, collectively representing over 60% of the total market demand. These sectors demonstrate greater willingness to invest in premium cooling solutions that offer improved reliability and performance metrics.

The competitive landscape features established HVAC corporations increasingly competing with specialized cooling technology startups. Recent market consolidation has seen five major acquisitions of cooling technology innovators by larger infrastructure providers, indicating the strategic importance of advanced cooling solutions in comprehensive data center offerings.

Energy efficiency remains the primary market driver, with cooling systems typically representing 35-40% of a data center's total energy consumption. Solutions that demonstrably reduce this percentage command premium pricing and faster market adoption, positioning liquid metal cooling advantageously against both traditional air cooling and standard immersion techniques in terms of long-term operational expenditure considerations.

Traditional air cooling solutions currently dominate the market with roughly 65% market share, though this percentage is steadily declining as more efficient alternatives gain traction. Liquid cooling technologies, including both immersion and direct-to-chip solutions, are experiencing the fastest growth segment at 24% annually, reflecting the industry's shift toward more energy-efficient cooling methodologies.

The emerging liquid metal cooling technology represents a small but rapidly expanding niche, currently accounting for less than 5% of the cooling market but demonstrating superior thermal performance metrics that suggest significant future growth potential. Early adopters report 30-40% improvements in cooling efficiency compared to traditional methods, particularly in high-density computing environments.

Regional analysis reveals North America leading the market with approximately 38% share, followed by Asia-Pacific at 32%, which is experiencing the fastest growth rate due to massive data center investments in China, Singapore, and India. European markets contribute roughly 25%, with particular emphasis on sustainable cooling solutions driven by stringent environmental regulations.

Market segmentation by industry shows financial services, telecommunications, and cloud service providers as the primary consumers of advanced cooling technologies, collectively representing over 60% of the total market demand. These sectors demonstrate greater willingness to invest in premium cooling solutions that offer improved reliability and performance metrics.

The competitive landscape features established HVAC corporations increasingly competing with specialized cooling technology startups. Recent market consolidation has seen five major acquisitions of cooling technology innovators by larger infrastructure providers, indicating the strategic importance of advanced cooling solutions in comprehensive data center offerings.

Energy efficiency remains the primary market driver, with cooling systems typically representing 35-40% of a data center's total energy consumption. Solutions that demonstrably reduce this percentage command premium pricing and faster market adoption, positioning liquid metal cooling advantageously against both traditional air cooling and standard immersion techniques in terms of long-term operational expenditure considerations.

Current Cooling Technologies Assessment

The current data center cooling landscape is dominated by three primary technologies: air cooling, immersion cooling, and the emerging liquid metal cooling solutions. Traditional air cooling remains the most widely implemented approach, utilizing fans and heat sinks to dissipate heat from computing components. This method typically achieves a Power Usage Effectiveness (PUE) ranging from 1.2 to 1.8, depending on facility design and environmental conditions. Despite its widespread adoption, air cooling faces significant limitations when handling high-density computing environments exceeding 15-20kW per rack.

Immersion cooling has gained substantial traction in recent years, particularly for high-performance computing applications. This technology involves submerging server components directly in dielectric fluids, enabling heat dissipation capabilities of up to 100kW per rack. Two primary variants exist: single-phase immersion, using fluids like mineral oil that remain in liquid form, and two-phase immersion, employing engineered fluids that vaporize and condense in a closed system. Immersion cooling systems demonstrate PUE values as low as 1.03-1.10, representing substantial efficiency improvements over air cooling.

Liquid metal cooling represents the cutting edge of thermal management technologies. Utilizing gallium-based alloys with thermal conductivities 10-100 times higher than water, these systems offer unprecedented heat transfer efficiency. Early implementations show potential for handling power densities exceeding 150kW per rack while maintaining component temperatures within optimal operating ranges. The non-reactive nature of engineered liquid metals with computing components addresses historical concerns about metal coolants.

Each technology presents distinct operational characteristics. Air cooling offers the lowest initial capital expenditure but incurs higher operational costs and spatial requirements. Immersion cooling requires moderate to high initial investment but delivers significant operational savings through reduced energy consumption and higher computing density. Liquid metal cooling currently demands the highest upfront investment but promises the greatest efficiency and density benefits at scale.

From a sustainability perspective, the technologies demonstrate varying environmental impacts. Air cooling systems consume substantial electricity for fans and chillers, contributing to higher carbon footprints. Immersion cooling significantly reduces energy requirements but raises concerns regarding the environmental impact of dielectric fluids. Liquid metal cooling offers the lowest energy consumption profile, though questions remain about the long-term recyclability and environmental impact of gallium-based coolants.

The selection of optimal cooling technology increasingly depends on specific deployment scenarios, with hyperscale data centers and high-performance computing facilities leading the transition toward liquid-based cooling solutions as computational densities continue to rise.

Immersion cooling has gained substantial traction in recent years, particularly for high-performance computing applications. This technology involves submerging server components directly in dielectric fluids, enabling heat dissipation capabilities of up to 100kW per rack. Two primary variants exist: single-phase immersion, using fluids like mineral oil that remain in liquid form, and two-phase immersion, employing engineered fluids that vaporize and condense in a closed system. Immersion cooling systems demonstrate PUE values as low as 1.03-1.10, representing substantial efficiency improvements over air cooling.

Liquid metal cooling represents the cutting edge of thermal management technologies. Utilizing gallium-based alloys with thermal conductivities 10-100 times higher than water, these systems offer unprecedented heat transfer efficiency. Early implementations show potential for handling power densities exceeding 150kW per rack while maintaining component temperatures within optimal operating ranges. The non-reactive nature of engineered liquid metals with computing components addresses historical concerns about metal coolants.

Each technology presents distinct operational characteristics. Air cooling offers the lowest initial capital expenditure but incurs higher operational costs and spatial requirements. Immersion cooling requires moderate to high initial investment but delivers significant operational savings through reduced energy consumption and higher computing density. Liquid metal cooling currently demands the highest upfront investment but promises the greatest efficiency and density benefits at scale.

From a sustainability perspective, the technologies demonstrate varying environmental impacts. Air cooling systems consume substantial electricity for fans and chillers, contributing to higher carbon footprints. Immersion cooling significantly reduces energy requirements but raises concerns regarding the environmental impact of dielectric fluids. Liquid metal cooling offers the lowest energy consumption profile, though questions remain about the long-term recyclability and environmental impact of gallium-based coolants.

The selection of optimal cooling technology increasingly depends on specific deployment scenarios, with hyperscale data centers and high-performance computing facilities leading the transition toward liquid-based cooling solutions as computational densities continue to rise.

Comparative Analysis of Cooling Methods

01 Liquid Metal Cooling Systems

Liquid metal cooling systems utilize metals with high thermal conductivity that remain liquid at operating temperatures to efficiently transfer heat away from components. These systems offer superior thermal conductivity compared to traditional coolants, making them particularly effective for high-power density applications. The low viscosity of liquid metals allows for efficient heat transfer with minimal pumping power, while their high boiling points prevent phase change issues at high temperatures. These systems are increasingly being implemented in advanced computing and power electronics applications.- Liquid Metal Cooling Systems: Liquid metal cooling systems utilize metals with high thermal conductivity that remain in liquid state at operating temperatures. These systems offer superior heat transfer capabilities compared to traditional coolants, making them ideal for high-performance computing and power electronics. Liquid metals like gallium alloys can efficiently remove heat from hotspots and maintain lower operating temperatures, resulting in improved system performance and reliability. These cooling solutions are particularly effective in applications requiring extreme thermal management.

- Immersion Cooling Technology: Immersion cooling involves submerging electronic components directly in a dielectric fluid that conducts heat but not electricity. This approach eliminates thermal interface materials and provides direct contact between the coolant and heat-generating components. Two primary methods exist: single-phase immersion where the fluid remains liquid, and two-phase immersion where the fluid vaporizes and condenses in a closed loop. Immersion cooling significantly reduces energy consumption for cooling systems while allowing for higher component density and performance.

- Air Cooling Optimization: Air cooling remains the most widely used thermal management approach due to its simplicity and cost-effectiveness. Advanced air cooling systems incorporate optimized heat sink designs, strategic airflow management, and high-efficiency fans to maximize cooling performance. Computational fluid dynamics modeling helps design systems that minimize air resistance and hotspots. Recent innovations include variable-speed fan control based on thermal load, ducted airflow paths, and heat pipe integration to enhance the efficiency of air cooling solutions while reducing noise and energy consumption.

- Hybrid Cooling Solutions: Hybrid cooling systems combine multiple cooling technologies to leverage the advantages of each method while mitigating their limitations. These solutions typically integrate air cooling for less thermally demanding components with liquid or immersion cooling for high-heat-generating elements. Hybrid approaches allow for targeted cooling where needed most, optimizing overall system efficiency and performance. These systems can dynamically adjust cooling methods based on workload demands, ambient conditions, and energy efficiency requirements, providing flexible thermal management for complex electronic systems.

- Cooling Efficiency Measurement and Optimization: Accurate measurement and optimization of cooling efficiency are critical for developing effective thermal management solutions. Advanced monitoring systems track temperature distribution, coolant flow rates, and power consumption to calculate cooling efficiency metrics such as Coefficient of Performance (COP) and Power Usage Effectiveness (PUE). Machine learning algorithms can analyze thermal data to identify inefficiencies and suggest optimizations. Testing methodologies include thermal imaging, computational modeling, and standardized benchmarks to compare different cooling technologies under consistent conditions, enabling data-driven decisions for cooling system design.

02 Immersion Cooling Technology

Immersion cooling involves submerging electronic components directly in a dielectric fluid that conducts heat but not electricity. This approach eliminates thermal interface materials and provides direct contact between the coolant and heat-generating components, significantly improving cooling efficiency. Two main types exist: single-phase immersion, where the coolant remains liquid, and two-phase immersion, where the coolant evaporates and condenses in a closed system. Immersion cooling is particularly beneficial for high-density server environments and data centers, offering reduced energy consumption and enabling higher component density.Expand Specific Solutions03 Air Cooling Systems and Optimization

Air cooling remains the most widely used thermal management approach due to its simplicity and cost-effectiveness. Modern air cooling systems incorporate advanced heat sink designs, optimized fan configurations, and intelligent airflow management to maximize cooling efficiency. Computational fluid dynamics is increasingly used to model and optimize airflow patterns within enclosures. Enhanced air cooling techniques include directed airflow systems, variable-speed fans controlled by thermal sensors, and ducted cooling paths that minimize recirculation of heated air. These improvements allow air cooling to remain viable even as component power densities increase.Expand Specific Solutions04 Hybrid Cooling Solutions

Hybrid cooling approaches combine multiple cooling technologies to leverage the advantages of each while mitigating their limitations. Common combinations include air cooling for low-power components with liquid cooling for high-power components, or using immersion cooling for processors while employing air cooling for peripheral components. These hybrid systems often incorporate sophisticated thermal management controllers that dynamically adjust cooling parameters based on workload and environmental conditions. By targeting specific cooling technologies to the components that benefit most from them, hybrid solutions optimize overall system cooling efficiency while managing implementation costs.Expand Specific Solutions05 Cooling Efficiency Measurement and Comparison

Standardized metrics and testing methodologies have been developed to objectively compare the efficiency of different cooling technologies. Key performance indicators include thermal resistance (°C/W), coefficient of performance (COP), power usage effectiveness (PUE), and cooling capacity factor. Advanced testing approaches utilize thermal imaging, embedded temperature sensors, and computational modeling to provide comprehensive performance data. Comparative studies consistently show that liquid metal cooling offers the highest thermal conductivity but at higher cost and complexity, while immersion cooling provides excellent performance with simplified design but requires specialized fluids. Air cooling remains the most cost-effective solution for moderate thermal loads but becomes increasingly inefficient as power density increases.Expand Specific Solutions

Leading Cooling Solution Providers

The liquid metal cooling technology market is currently in an early growth phase, characterized by increasing adoption as data centers seek more efficient thermal management solutions. The global market for advanced cooling technologies is expanding rapidly, driven by the growing demand for high-performance computing and AI applications. Technologically, liquid metal cooling represents an evolution beyond traditional air cooling and immersion cooling, offering superior thermal conductivity and energy efficiency. Companies like Intel, Huawei, and Microsoft are leading innovation in this space, while specialized cooling technology providers such as Iceotope, Submer Technologies, and ExaScaler are developing proprietary solutions. OEMs including Wiwynn, Inventec, and Pegatron are integrating these advanced cooling systems into their server designs, creating a competitive ecosystem that balances performance gains against implementation complexity and cost considerations.

Intel Corp.

Technical Solution: Intel has developed a comprehensive liquid cooling technology portfolio that includes both direct-to-chip liquid cooling and immersion solutions, with recent research into liquid metal thermal interfaces for extreme cooling scenarios. Their Engineered Thermal Solution (ETS) platform incorporates cold plate technology that can be implemented with various coolants, including specialized applications using liquid metal thermal interface materials between high-power Xeon processors and cooling solutions. Intel's research has demonstrated that their liquid metal interface materials can improve thermal conductivity by 5-10X compared to standard thermal compounds, significantly enhancing heat transfer efficiency. For scale deployments, Intel has partnered with data center operators to implement their Direct-to-Chip (D2C) cooling architecture, which has shown cooling efficiency improvements of up to 90% for targeted components compared to air cooling. In testing environments with their 4th Gen Xeon Scalable processors under heavy computational loads, liquid metal interfaces reduced junction temperatures by up to 15°C compared to standard thermal compounds, allowing for higher sustained performance. Intel's cooling technologies are designed with modularity in mind, enabling data centers to implement hybrid approaches that combine the benefits of liquid metal interfaces, direct liquid cooling, and traditional air cooling based on specific deployment requirements.

Strengths: Comprehensive cooling portfolio that can be tailored to specific deployment needs, extensive testing with their own processor technologies ensures compatibility, modular approach allows for gradual implementation, and significant thermal performance improvements enable higher sustained processor performance. Weaknesses: Solutions often require specialized installation procedures, liquid metal interfaces require careful application to prevent electrical shorts, cooling efficiency benefits vary significantly based on workload types, and full implementation requires substantial infrastructure modifications.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has developed an innovative hybrid cooling solution that incorporates elements of both liquid metal and immersion cooling technologies for large-scale data centers. Their FusionCol (Fusion Cooling) system utilizes direct-to-chip liquid cooling with specialized liquid metal thermal interface materials for primary heat sources like CPUs and GPUs, while employing a partial immersion approach for secondary components. The liquid metal interfaces provide thermal conductivity exceeding 70 W/m·K, significantly outperforming traditional thermal compounds. Huawei's implementation circulates a proprietary coolant through sealed server modules where heat is efficiently transferred via the liquid metal interfaces to the cooling loop. This system has demonstrated the ability to cool server racks with power densities exceeding 50kW while maintaining component temperatures below critical thresholds. In large-scale deployments, Huawei reports energy savings of 30-40% compared to traditional air cooling, with water consumption reduced by up to 80%. The technology has been successfully implemented in several of Huawei's cloud data centers across Asia.

Strengths: Exceptional thermal conductivity from liquid metal interfaces, significantly reduced energy consumption, supports very high power density deployments, and minimizes water usage compared to traditional cooling methods. Weaknesses: Requires specialized training for maintenance personnel, potential issues with liquid metal migration over time, higher initial implementation costs, and proprietary nature limits compatibility with third-party hardware.

Technical Deep Dive: Liquid Metal Properties

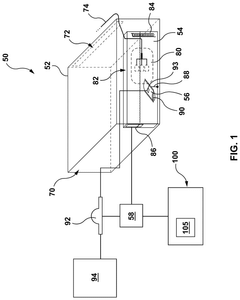

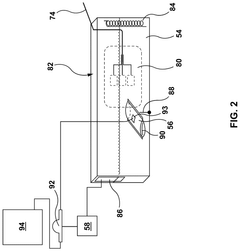

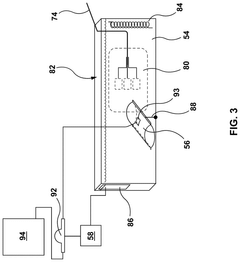

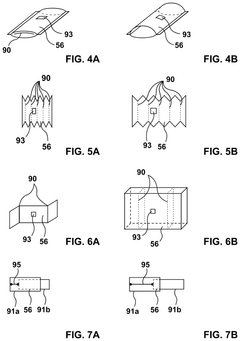

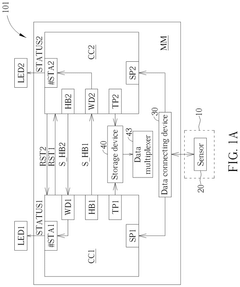

Immersion cooling systems for electronic components

PatentActiveUS12120846B2

Innovation

- A bladder system configurable between expanded and contracted states, integrated with a controller, allows for modulation of the immersion cooling liquid level within the immersion case, reducing the volume of liquid required and enabling efficient cooling while minimizing liquid loss during transport.

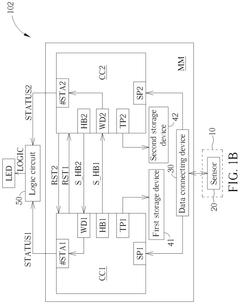

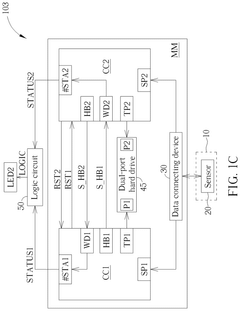

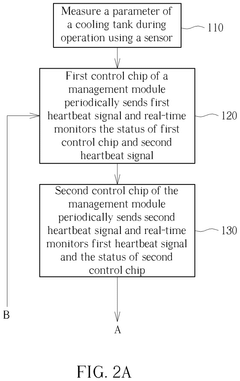

Immersion cooling system and related immersion cooling method

PatentPendingUS20240365509A1

Innovation

- The implementation of a dual-control chip management module system within the immersion cooling system, where two control chips (a main and a backup) monitor each other's heartbeat signals and operational status, allowing for seamless switching between them in case of failure, and providing a flexible backup scheme that can be configured based on application needs.

Energy Efficiency and Sustainability Impact

Energy efficiency has become a critical factor in data center operations, with cooling systems accounting for approximately 40% of total energy consumption. Liquid metal cooling demonstrates significant advantages in this domain, achieving up to 90% reduction in cooling energy requirements compared to traditional air cooling systems. This remarkable efficiency stems from liquid metal's superior thermal conductivity properties, which enable more effective heat transfer with minimal energy input. When implemented at scale, liquid metal cooling systems can reduce a data center's Power Usage Effectiveness (PUE) from the typical 1.6-1.8 range for air cooling to potentially below 1.2, representing a substantial improvement in overall energy efficiency.

From a sustainability perspective, liquid metal cooling offers several environmental benefits. The dramatic reduction in energy consumption directly translates to lower carbon emissions, with potential CO2 reductions of 30-50% compared to air-cooled facilities. Additionally, liquid metal cooling systems typically have longer operational lifespans than conventional cooling infrastructure, reducing waste generation and resource consumption associated with equipment replacement.

Water conservation represents another significant sustainability advantage of liquid metal cooling. Unlike immersion cooling, which can consume substantial amounts of water through evaporation and requires chemical treatments, liquid metal systems operate in closed loops with minimal water requirements. In regions facing water scarcity, this characteristic makes liquid metal cooling particularly valuable from an environmental standpoint.

The recyclability of liquid metal coolants further enhances their sustainability profile. Most gallium-based liquid metals can be reclaimed and reused at end-of-life, creating a more circular resource utilization pattern compared to traditional coolants. This recyclability, combined with the non-toxic nature of many liquid metal formulations, results in a significantly reduced environmental footprint throughout the technology lifecycle.

When evaluating total environmental impact, lifecycle assessment studies indicate that despite higher initial manufacturing impacts, liquid metal cooling systems typically achieve carbon payback within 1-3 years of operation through their operational efficiency gains. This favorable sustainability profile is further enhanced by the potential for heat recovery applications, where waste heat from liquid metal cooling systems can be effectively captured and repurposed for district heating or other secondary uses, improving overall system efficiency.

From a sustainability perspective, liquid metal cooling offers several environmental benefits. The dramatic reduction in energy consumption directly translates to lower carbon emissions, with potential CO2 reductions of 30-50% compared to air-cooled facilities. Additionally, liquid metal cooling systems typically have longer operational lifespans than conventional cooling infrastructure, reducing waste generation and resource consumption associated with equipment replacement.

Water conservation represents another significant sustainability advantage of liquid metal cooling. Unlike immersion cooling, which can consume substantial amounts of water through evaporation and requires chemical treatments, liquid metal systems operate in closed loops with minimal water requirements. In regions facing water scarcity, this characteristic makes liquid metal cooling particularly valuable from an environmental standpoint.

The recyclability of liquid metal coolants further enhances their sustainability profile. Most gallium-based liquid metals can be reclaimed and reused at end-of-life, creating a more circular resource utilization pattern compared to traditional coolants. This recyclability, combined with the non-toxic nature of many liquid metal formulations, results in a significantly reduced environmental footprint throughout the technology lifecycle.

When evaluating total environmental impact, lifecycle assessment studies indicate that despite higher initial manufacturing impacts, liquid metal cooling systems typically achieve carbon payback within 1-3 years of operation through their operational efficiency gains. This favorable sustainability profile is further enhanced by the potential for heat recovery applications, where waste heat from liquid metal cooling systems can be effectively captured and repurposed for district heating or other secondary uses, improving overall system efficiency.

Total Cost of Ownership Evaluation

When evaluating cooling solutions for data centers and large-scale computing environments, Total Cost of Ownership (TCO) represents a critical metric that extends beyond initial capital expenditure. For liquid metal cooling compared to immersion and air cooling systems, TCO analysis must account for multiple cost factors across the entire lifecycle of the cooling infrastructure.

Initial acquisition costs for liquid metal cooling systems typically exceed traditional air cooling solutions by 30-45%, primarily due to specialized heat transfer components and the liquid metal medium itself. However, this gap narrows when compared to immersion cooling, which often requires custom server designs and substantial facility modifications. A 500-rack data center implementation shows liquid metal cooling installations averaging $4,200-5,800 per rack versus $2,800-3,500 for air cooling and $5,000-7,000 for immersion solutions.

Operational expenditure presents significant differentiation among these cooling technologies. Liquid metal cooling demonstrates 25-40% lower energy consumption compared to air cooling systems, translating to approximately $0.8-1.2 million annual savings for a 10MW data center. While immersion cooling offers comparable efficiency benefits, liquid metal solutions typically require less pumping energy due to superior thermal conductivity properties, resulting in 5-10% additional operational savings over immersion alternatives.

Maintenance requirements and associated costs vary substantially across cooling methodologies. Air cooling systems demand regular filter replacements, fan maintenance, and airflow optimization, averaging annual maintenance costs of 4-6% of initial capital expenditure. Immersion cooling reduces mechanical component maintenance but introduces fluid monitoring, filtration, and periodic replacement costs. Liquid metal systems present unique maintenance considerations related to oxidation prevention and potential corrosion management, though their sealed design minimizes routine intervention.

Infrastructure lifespan and depreciation schedules also impact TCO calculations. Liquid metal cooling systems typically extend server lifespan by 15-20% compared to air cooling by maintaining more consistent operating temperatures and reducing thermal cycling. This extension translates to deferred replacement costs and improved return on hardware investments, particularly for high-density computing applications where thermal management directly affects component reliability.

Space utilization efficiency represents another TCO factor, with liquid metal cooling enabling 30-45% higher compute density than traditional air cooling. This density advantage reduces facility footprint requirements and associated real estate costs, particularly valuable in regions with premium data center space pricing. While immersion cooling offers similar density benefits, liquid metal solutions typically require less extensive facility modifications for implementation.

Initial acquisition costs for liquid metal cooling systems typically exceed traditional air cooling solutions by 30-45%, primarily due to specialized heat transfer components and the liquid metal medium itself. However, this gap narrows when compared to immersion cooling, which often requires custom server designs and substantial facility modifications. A 500-rack data center implementation shows liquid metal cooling installations averaging $4,200-5,800 per rack versus $2,800-3,500 for air cooling and $5,000-7,000 for immersion solutions.

Operational expenditure presents significant differentiation among these cooling technologies. Liquid metal cooling demonstrates 25-40% lower energy consumption compared to air cooling systems, translating to approximately $0.8-1.2 million annual savings for a 10MW data center. While immersion cooling offers comparable efficiency benefits, liquid metal solutions typically require less pumping energy due to superior thermal conductivity properties, resulting in 5-10% additional operational savings over immersion alternatives.

Maintenance requirements and associated costs vary substantially across cooling methodologies. Air cooling systems demand regular filter replacements, fan maintenance, and airflow optimization, averaging annual maintenance costs of 4-6% of initial capital expenditure. Immersion cooling reduces mechanical component maintenance but introduces fluid monitoring, filtration, and periodic replacement costs. Liquid metal systems present unique maintenance considerations related to oxidation prevention and potential corrosion management, though their sealed design minimizes routine intervention.

Infrastructure lifespan and depreciation schedules also impact TCO calculations. Liquid metal cooling systems typically extend server lifespan by 15-20% compared to air cooling by maintaining more consistent operating temperatures and reducing thermal cycling. This extension translates to deferred replacement costs and improved return on hardware investments, particularly for high-density computing applications where thermal management directly affects component reliability.

Space utilization efficiency represents another TCO factor, with liquid metal cooling enabling 30-45% higher compute density than traditional air cooling. This density advantage reduces facility footprint requirements and associated real estate costs, particularly valuable in regions with premium data center space pricing. While immersion cooling offers similar density benefits, liquid metal solutions typically require less extensive facility modifications for implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!