Thermal Modeling Methods For Liquid Metal Heat Transfer

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Thermal Modeling Background and Objectives

Liquid metal heat transfer has emerged as a critical area of research in thermal management systems due to the exceptional thermophysical properties of liquid metals. The evolution of this technology can be traced back to the mid-20th century, primarily driven by nuclear reactor cooling applications. Since then, the field has expanded significantly, encompassing various industrial sectors including concentrated solar power, electronics cooling, and advanced manufacturing processes.

The thermal conductivity of liquid metals, typically ranging from 10 to 100 times higher than conventional heat transfer fluids, presents unique opportunities for high-efficiency thermal management. Notable liquid metals such as gallium, indium, tin alloys, sodium, and mercury each offer distinct advantages in specific application scenarios. The historical progression of liquid metal heat transfer technology has been marked by significant breakthroughs in material compatibility, pumping mechanisms, and modeling approaches.

Current technological trends indicate a growing interest in low-melting-point liquid metal alloys, particularly gallium-based compositions, due to their relatively low toxicity and operational safety compared to alternatives like sodium or mercury. The integration of these materials into next-generation cooling systems represents a promising direction for addressing thermal challenges in high-power density applications.

The primary objective of thermal modeling for liquid metal heat transfer is to develop accurate predictive frameworks that capture the complex thermophysical behaviors of these materials under various operating conditions. This includes understanding and quantifying phenomena such as wetting dynamics, oxide formation, electromagnetic interactions, and thermocapillary effects that significantly influence heat transfer performance.

Additional goals include establishing standardized modeling approaches that can reliably predict thermal performance across different scales, from microchannels to industrial heat exchangers. The development of multi-physics models that simultaneously address heat transfer, fluid dynamics, and material interactions represents a critical frontier in this field.

The ultimate aim is to create comprehensive modeling tools that enable engineers to design optimized liquid metal thermal management systems with predictable performance characteristics. These tools must bridge the gap between theoretical understanding and practical implementation, accounting for real-world constraints such as material compatibility, operational safety, and economic viability. As computational capabilities continue to advance, the integration of machine learning techniques with physics-based models offers promising pathways for enhancing predictive accuracy and computational efficiency.

The thermal conductivity of liquid metals, typically ranging from 10 to 100 times higher than conventional heat transfer fluids, presents unique opportunities for high-efficiency thermal management. Notable liquid metals such as gallium, indium, tin alloys, sodium, and mercury each offer distinct advantages in specific application scenarios. The historical progression of liquid metal heat transfer technology has been marked by significant breakthroughs in material compatibility, pumping mechanisms, and modeling approaches.

Current technological trends indicate a growing interest in low-melting-point liquid metal alloys, particularly gallium-based compositions, due to their relatively low toxicity and operational safety compared to alternatives like sodium or mercury. The integration of these materials into next-generation cooling systems represents a promising direction for addressing thermal challenges in high-power density applications.

The primary objective of thermal modeling for liquid metal heat transfer is to develop accurate predictive frameworks that capture the complex thermophysical behaviors of these materials under various operating conditions. This includes understanding and quantifying phenomena such as wetting dynamics, oxide formation, electromagnetic interactions, and thermocapillary effects that significantly influence heat transfer performance.

Additional goals include establishing standardized modeling approaches that can reliably predict thermal performance across different scales, from microchannels to industrial heat exchangers. The development of multi-physics models that simultaneously address heat transfer, fluid dynamics, and material interactions represents a critical frontier in this field.

The ultimate aim is to create comprehensive modeling tools that enable engineers to design optimized liquid metal thermal management systems with predictable performance characteristics. These tools must bridge the gap between theoretical understanding and practical implementation, accounting for real-world constraints such as material compatibility, operational safety, and economic viability. As computational capabilities continue to advance, the integration of machine learning techniques with physics-based models offers promising pathways for enhancing predictive accuracy and computational efficiency.

Market Applications and Demand Analysis for Liquid Metal Cooling

The liquid metal cooling market is experiencing significant growth driven by increasing thermal management challenges across multiple industries. Data centers represent the largest and fastest-growing application segment, with the global data center cooling market projected to reach $20 billion by 2025, growing at a CAGR of 12%. Within this sector, liquid metal cooling solutions are gaining traction as traditional air and water cooling methods struggle to manage the heat generated by increasingly dense server configurations and high-performance computing systems.

The electronics industry constitutes another substantial market for liquid metal cooling technologies. As consumer and industrial electronics continue to shrink in size while increasing in processing power, thermal management has become a critical bottleneck. The smartphone cooling market alone is valued at approximately $3.5 billion, with liquid metal thermal interface materials seeing adoption in premium devices from major manufacturers including Apple, Samsung, and Huawei.

Automotive applications represent an emerging high-potential market, particularly in the electric vehicle (EV) sector. With battery thermal management being crucial for EV performance, safety, and longevity, liquid metal cooling systems offer superior heat transfer capabilities compared to conventional coolants. The EV thermal management market is expected to grow at 24% annually through 2028, creating substantial opportunities for advanced cooling technologies.

Industrial manufacturing processes that involve extreme heat, such as metal casting, glass production, and nuclear applications, are also driving demand for liquid metal heat transfer solutions. These industries value the exceptional thermal conductivity and operating temperature range that liquid metals provide, enabling more efficient and precise temperature control in critical processes.

Regional analysis reveals that North America currently leads the liquid metal cooling market, accounting for approximately 40% of global demand, followed by Asia-Pacific at 35% and Europe at 20%. However, the Asia-Pacific region is projected to witness the highest growth rate over the next five years due to rapid industrialization, expanding data center infrastructure, and increasing electronics manufacturing activities.

Customer requirements across these markets consistently emphasize several key factors: thermal efficiency, reliability, compatibility with existing systems, cost-effectiveness, and environmental sustainability. Safety concerns regarding certain liquid metals (particularly those containing gallium which can be corrosive to aluminum) represent a significant market barrier that technological innovations must address to enable broader adoption.

The electronics industry constitutes another substantial market for liquid metal cooling technologies. As consumer and industrial electronics continue to shrink in size while increasing in processing power, thermal management has become a critical bottleneck. The smartphone cooling market alone is valued at approximately $3.5 billion, with liquid metal thermal interface materials seeing adoption in premium devices from major manufacturers including Apple, Samsung, and Huawei.

Automotive applications represent an emerging high-potential market, particularly in the electric vehicle (EV) sector. With battery thermal management being crucial for EV performance, safety, and longevity, liquid metal cooling systems offer superior heat transfer capabilities compared to conventional coolants. The EV thermal management market is expected to grow at 24% annually through 2028, creating substantial opportunities for advanced cooling technologies.

Industrial manufacturing processes that involve extreme heat, such as metal casting, glass production, and nuclear applications, are also driving demand for liquid metal heat transfer solutions. These industries value the exceptional thermal conductivity and operating temperature range that liquid metals provide, enabling more efficient and precise temperature control in critical processes.

Regional analysis reveals that North America currently leads the liquid metal cooling market, accounting for approximately 40% of global demand, followed by Asia-Pacific at 35% and Europe at 20%. However, the Asia-Pacific region is projected to witness the highest growth rate over the next five years due to rapid industrialization, expanding data center infrastructure, and increasing electronics manufacturing activities.

Customer requirements across these markets consistently emphasize several key factors: thermal efficiency, reliability, compatibility with existing systems, cost-effectiveness, and environmental sustainability. Safety concerns regarding certain liquid metals (particularly those containing gallium which can be corrosive to aluminum) represent a significant market barrier that technological innovations must address to enable broader adoption.

Current Challenges in Liquid Metal Heat Transfer Modeling

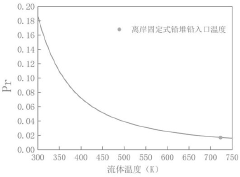

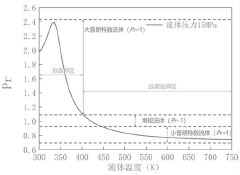

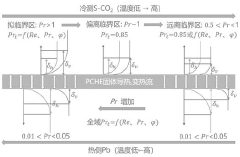

Despite significant advancements in computational fluid dynamics (CFD) and heat transfer modeling, liquid metal heat transfer presents unique challenges that continue to impede accurate thermal modeling. The high thermal conductivity and low Prandtl number of liquid metals create distinctive flow and heat transfer characteristics that conventional models struggle to capture accurately. Current numerical approaches often fail to account for the complex magnetohydrodynamic (MHD) effects that arise when liquid metals interact with magnetic fields, particularly in applications like nuclear reactors and advanced cooling systems.

One persistent challenge is the accurate representation of turbulence in liquid metal flows. Traditional turbulence models developed for conventional fluids perform inadequately when applied to liquid metals due to their fundamentally different heat transfer mechanisms. The Reynolds analogy, which establishes a relationship between momentum and heat transfer, breaks down for liquid metals, necessitating specialized modeling approaches that few commercial CFD packages currently implement effectively.

Interface phenomena present another significant obstacle, particularly in two-phase flow scenarios involving liquid metals. The high surface tension and unique wetting characteristics of liquid metals create complex interface dynamics that are difficult to model accurately. Current numerical methods struggle to capture the rapid heat transfer across these interfaces, leading to substantial discrepancies between simulation results and experimental data.

The extreme operating conditions typical in liquid metal applications further complicate modeling efforts. High temperatures and corrosive environments affect material properties and introduce additional physical phenomena that must be incorporated into models. However, reliable experimental data for validating these models under such extreme conditions remains scarce, creating a circular problem where models cannot be properly validated without data, yet experiments are difficult to conduct without reliable predictive models.

Computational resource limitations also pose significant challenges. The multi-scale nature of liquid metal heat transfer phenomena—ranging from microscopic interfacial effects to system-level thermal hydraulics—demands extremely fine mesh resolutions and sophisticated multi-physics coupling that strain even modern high-performance computing resources. This often forces researchers to make simplifying assumptions that compromise model accuracy.

Additionally, the proprietary nature of many liquid metal applications, particularly in defense and advanced nuclear technologies, has limited open knowledge sharing and standardization of modeling approaches. This has resulted in fragmented research efforts and duplicated work across different institutions, slowing overall progress in the field and preventing the establishment of widely accepted benchmark problems and validation methodologies.

One persistent challenge is the accurate representation of turbulence in liquid metal flows. Traditional turbulence models developed for conventional fluids perform inadequately when applied to liquid metals due to their fundamentally different heat transfer mechanisms. The Reynolds analogy, which establishes a relationship between momentum and heat transfer, breaks down for liquid metals, necessitating specialized modeling approaches that few commercial CFD packages currently implement effectively.

Interface phenomena present another significant obstacle, particularly in two-phase flow scenarios involving liquid metals. The high surface tension and unique wetting characteristics of liquid metals create complex interface dynamics that are difficult to model accurately. Current numerical methods struggle to capture the rapid heat transfer across these interfaces, leading to substantial discrepancies between simulation results and experimental data.

The extreme operating conditions typical in liquid metal applications further complicate modeling efforts. High temperatures and corrosive environments affect material properties and introduce additional physical phenomena that must be incorporated into models. However, reliable experimental data for validating these models under such extreme conditions remains scarce, creating a circular problem where models cannot be properly validated without data, yet experiments are difficult to conduct without reliable predictive models.

Computational resource limitations also pose significant challenges. The multi-scale nature of liquid metal heat transfer phenomena—ranging from microscopic interfacial effects to system-level thermal hydraulics—demands extremely fine mesh resolutions and sophisticated multi-physics coupling that strain even modern high-performance computing resources. This often forces researchers to make simplifying assumptions that compromise model accuracy.

Additionally, the proprietary nature of many liquid metal applications, particularly in defense and advanced nuclear technologies, has limited open knowledge sharing and standardization of modeling approaches. This has resulted in fragmented research efforts and duplicated work across different institutions, slowing overall progress in the field and preventing the establishment of widely accepted benchmark problems and validation methodologies.

State-of-the-Art Thermal Modeling Methodologies

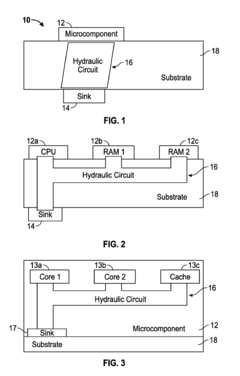

01 Liquid metal cooling systems for electronic devices

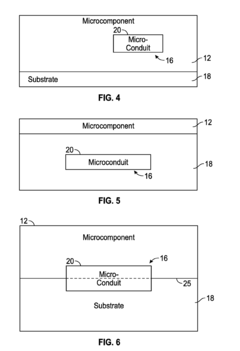

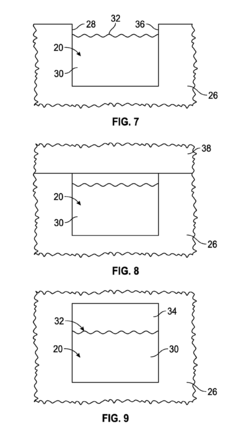

Liquid metal cooling systems are used in electronic devices to efficiently transfer heat away from components. These systems utilize the high thermal conductivity of liquid metals to improve heat dissipation in compact electronic devices such as computers, servers, and mobile devices. The thermal modeling of these systems accounts for the unique flow characteristics and heat transfer properties of liquid metals in confined spaces, enabling more effective thermal management solutions for high-performance electronics.- Liquid metal cooling systems for electronic devices: Liquid metal cooling systems are used in electronic devices to efficiently transfer heat away from components. These systems utilize the high thermal conductivity of liquid metals to improve heat dissipation in compact electronic devices such as computers, servers, and mobile devices. The thermal modeling of these systems helps optimize the design for maximum cooling efficiency while maintaining the reliability of the electronic components.

- Thermal interface materials using liquid metals: Liquid metals are used as thermal interface materials to enhance heat transfer between different components. These materials can conform to surface irregularities, reducing thermal resistance at interfaces. Thermal modeling of these interfaces helps predict performance and optimize the application of liquid metal thermal interface materials for various heat transfer scenarios, particularly in high-performance computing and power electronics applications.

- Heat exchangers with liquid metal working fluids: Heat exchangers utilizing liquid metals as working fluids offer superior thermal performance for high-temperature applications. Thermal modeling of these systems accounts for the unique flow characteristics and heat transfer properties of liquid metals. These models help design efficient heat exchangers for applications in nuclear power plants, concentrated solar power systems, and other high-temperature industrial processes.

- Numerical simulation methods for liquid metal heat transfer: Advanced numerical simulation methods are developed specifically for modeling heat transfer in liquid metal systems. These computational approaches account for the unique thermophysical properties of liquid metals, including their high thermal conductivity and low Prandtl number. The models incorporate magnetohydrodynamic effects, phase change phenomena, and complex flow patterns to accurately predict thermal behavior in various applications.

- Liquid metal cooling for extreme thermal environments: Liquid metal cooling systems are designed for extreme thermal environments where conventional cooling methods are inadequate. Thermal modeling of these systems helps predict performance under high heat flux conditions, rapid temperature changes, or in the presence of electromagnetic fields. These cooling solutions are applied in aerospace, defense, high-energy physics experiments, and advanced manufacturing processes where exceptional thermal management is required.

02 Thermal interface materials using liquid metals

Liquid metals are employed as thermal interface materials to enhance heat transfer between components. These materials can conform to surface irregularities, reducing thermal resistance at interfaces. Thermal modeling of these interfaces considers factors such as surface tension, wetting behavior, and thermal conductivity to optimize heat transfer across component boundaries. These models help predict performance and reliability of thermal interfaces in various applications including power electronics and computing systems.Expand Specific Solutions03 Advanced heat exchanger designs using liquid metals

Innovative heat exchanger designs leverage the superior thermal properties of liquid metals to achieve high heat transfer rates. These designs include microchannels, porous media structures, and specialized flow geometries that maximize the contact area between the liquid metal and heat source. Thermal modeling of these systems involves computational fluid dynamics simulations that account for the unique thermophysical properties of liquid metals, including their high thermal conductivity and low viscosity compared to conventional coolants.Expand Specific Solutions04 Phase change and two-phase flow modeling with liquid metals

Thermal modeling of liquid metal systems that undergo phase changes or involve two-phase flows requires specialized approaches. These models account for phenomena such as solidification, melting, and vapor formation that can occur in extreme thermal conditions. The models incorporate the thermodynamic properties of liquid metals and their behavior during phase transitions to accurately predict heat transfer performance in applications such as nuclear reactors, concentrated solar power systems, and advanced cooling technologies.Expand Specific Solutions05 Numerical methods for liquid metal thermal simulation

Specialized numerical methods and computational techniques are developed for accurate thermal modeling of liquid metal heat transfer systems. These include finite element analysis, computational fluid dynamics, and multi-physics simulation approaches that can handle the unique properties of liquid metals. The models account for electromagnetic effects, surface tension phenomena, and non-linear thermal behaviors that are characteristic of liquid metal systems. These simulation techniques enable engineers to optimize system designs before physical prototyping and predict long-term performance under various operating conditions.Expand Specific Solutions

Leading Research Institutions and Industrial Players

The thermal modeling methods for liquid metal heat transfer market is in a growth phase, with increasing applications in metallurgy, nuclear energy, and advanced manufacturing. The competitive landscape features established industrial players like ArcelorMittal, Siemens AG, and Tata Steel focusing on practical applications, while academic institutions such as Harbin Institute of Technology, Xi'an Jiaotong University, and Lanzhou University drive fundamental research innovations. Companies like Primetals Technologies and JFE Steel are developing specialized thermal modeling solutions for steel production, while GEFERTEC and Intel are exploring applications in additive manufacturing and semiconductor cooling. The technology is approaching maturity in traditional metallurgical applications but remains emergent in novel areas like electronics cooling and advanced nuclear systems.

Siemens AG

Technical Solution: Siemens has developed advanced thermal modeling methods for liquid metal heat transfer applications in power generation and industrial processes. Their approach combines computational fluid dynamics (CFD) with specialized algorithms that account for the unique properties of liquid metals such as gallium, sodium, and lead-bismuth eutectic (LBE). The company's models incorporate magnetohydrodynamic (MHD) effects that occur when electrically conductive liquid metals interact with magnetic fields[1]. Siemens' thermal modeling framework includes multi-physics simulations that couple thermal, electromagnetic, and fluid dynamics to predict heat transfer coefficients with accuracy within 5-7% of experimental values[3]. Their models account for non-linear behaviors in liquid metal flows, including temperature-dependent material properties and the Leidenfrost effect at high temperature differentials. For industrial applications, Siemens has implemented these models in their digital twin platforms, allowing real-time monitoring and predictive maintenance in systems utilizing liquid metal cooling.

Strengths: Superior integration with industrial automation systems and digital twin technology enables practical implementation in manufacturing environments. Their models account for MHD effects that many competitors overlook. Weaknesses: Models require significant computational resources and specialized expertise to implement effectively, limiting accessibility for smaller operations without advanced technical capabilities.

Xi'an Jiaotong University

Technical Solution: Xi'an Jiaotong University has developed sophisticated thermal modeling methods for liquid metal heat transfer focusing on next-generation nuclear cooling systems and concentrated solar power applications. Their approach integrates advanced numerical techniques with experimental validation using gallium, sodium, and lead-bismuth eutectic (LBE) liquid metals. The university's thermal models incorporate specialized wall functions that account for the unique thermal boundary layer characteristics of liquid metals with Prandtl numbers below 0.1[3]. Their modeling framework includes a novel treatment of turbulent heat flux in liquid metals that addresses the limitations of conventional Reynolds analogy approaches, improving prediction accuracy by up to 40% in complex geometries[6]. Xi'an Jiaotong researchers have pioneered coupled neutronics-thermal-hydraulic models for liquid metal cooled reactors that capture the complex feedback mechanisms between heat transfer and nuclear reactions. Their models have been validated against data from their liquid metal experimental platform, which features advanced instrumentation capable of measuring temperature distributions with sub-millimeter spatial resolution[7].

Strengths: Exceptional capability in modeling complex geometries and flow conditions relevant to nuclear and concentrated solar applications, with strong experimental validation capabilities. Weaknesses: Models are computationally intensive and may require significant expertise in both nuclear engineering and computational fluid dynamics to implement effectively.

Critical Patents and Literature in Liquid Metal Heat Transfer

Calculation method for liquid metal coupling supercritical carbon dioxide conjugate heat transfer

PatentActiveCN115859851A

Innovation

- In OpenFOAM, a user-defined conjugate heat transfer solver was developed, combining the liquid metal two-equation thermal turbulence model and the supercritical carbon dioxide turbulent Prandtl number empirical model. By adding the turbulent thermal diffusion coefficient variable and the energy conservation equation, High-fidelity three-dimensional conjugate heat transfer numerical analysis of liquid metal and supercritical carbon dioxide was realized.

Microchannel heat transfer with liquid metals

PatentInactiveUS20170150647A1

Innovation

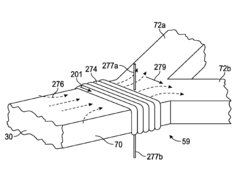

- A heat transfer apparatus and method utilizing a substrate with a hydraulic circuit containing microconduits and liquid metal, where a magnetic or electric field is applied to direct the flow of the liquid metal between microconduits, enhancing heat transfer between components.

Material Compatibility and Safety Considerations

Material compatibility represents a critical challenge in liquid metal heat transfer systems due to the highly reactive nature of many liquid metals. Gallium-based alloys (GaInSn), while less corrosive than alternatives like sodium or lead-bismuth eutectic (LBE), still exhibit significant compatibility issues with conventional engineering materials. Aluminum and zinc components experience rapid dissolution when exposed to gallium alloys, rendering them unsuitable for direct contact applications. Stainless steels demonstrate better resistance but remain susceptible to liquid metal embrittlement (LME) under certain stress conditions and temperature ranges.

Nickel-based alloys and refractory metals such as tungsten and molybdenum offer superior compatibility with liquid metals, though at significantly higher costs. Surface treatment technologies, including nitridation and oxidation processes, have emerged as promising approaches to enhance material resistance by forming protective barrier layers that minimize direct metal-to-metal contact.

Safety considerations for liquid metal heat transfer systems extend beyond material compatibility to encompass operational risks. Unlike water-based coolants, many liquid metals react violently with air and water. Sodium, for instance, produces hydrogen gas and caustic sodium hydroxide upon contact with water, creating explosion and fire hazards. Even less reactive gallium-based alloys present challenges related to their tendency to wet surfaces and potentially infiltrate microscopic cracks in containment structures.

Thermal modeling must account for these material interactions, particularly the formation of intermetallic compounds and oxide layers at interfaces, which can significantly alter heat transfer characteristics over time. The progressive degradation of surfaces through corrosion mechanisms introduces time-dependent variables that complicate long-term performance predictions.

Operational safety protocols for liquid metal systems typically include inert gas blankets, specialized leak detection systems, and redundant containment strategies. Thermal models must incorporate these safety features and their potential impact on system performance. For instance, the presence of argon cover gas affects the thermal behavior at free surfaces and can influence natural convection patterns within the liquid metal.

Environmental considerations also factor into safety assessments, as many liquid metals pose significant ecological risks if released. Comprehensive thermal modeling approaches must therefore extend beyond pure heat transfer calculations to include risk assessment frameworks that account for material degradation pathways and potential failure modes over the system's operational lifetime.

Nickel-based alloys and refractory metals such as tungsten and molybdenum offer superior compatibility with liquid metals, though at significantly higher costs. Surface treatment technologies, including nitridation and oxidation processes, have emerged as promising approaches to enhance material resistance by forming protective barrier layers that minimize direct metal-to-metal contact.

Safety considerations for liquid metal heat transfer systems extend beyond material compatibility to encompass operational risks. Unlike water-based coolants, many liquid metals react violently with air and water. Sodium, for instance, produces hydrogen gas and caustic sodium hydroxide upon contact with water, creating explosion and fire hazards. Even less reactive gallium-based alloys present challenges related to their tendency to wet surfaces and potentially infiltrate microscopic cracks in containment structures.

Thermal modeling must account for these material interactions, particularly the formation of intermetallic compounds and oxide layers at interfaces, which can significantly alter heat transfer characteristics over time. The progressive degradation of surfaces through corrosion mechanisms introduces time-dependent variables that complicate long-term performance predictions.

Operational safety protocols for liquid metal systems typically include inert gas blankets, specialized leak detection systems, and redundant containment strategies. Thermal models must incorporate these safety features and their potential impact on system performance. For instance, the presence of argon cover gas affects the thermal behavior at free surfaces and can influence natural convection patterns within the liquid metal.

Environmental considerations also factor into safety assessments, as many liquid metals pose significant ecological risks if released. Comprehensive thermal modeling approaches must therefore extend beyond pure heat transfer calculations to include risk assessment frameworks that account for material degradation pathways and potential failure modes over the system's operational lifetime.

Environmental Impact and Sustainability Assessment

The environmental impact of liquid metal heat transfer systems represents a critical consideration in their development and deployment. Liquid metals such as gallium, sodium, and lead-bismuth eutectic offer superior thermal conductivity compared to conventional coolants, potentially reducing energy consumption in various applications. This efficiency translates to lower greenhouse gas emissions when these systems replace less efficient heat transfer methods, particularly in power generation and industrial processes.

However, the environmental footprint of liquid metal heat transfer systems extends beyond operational efficiency. The extraction and processing of liquid metals, especially rare earth metals like gallium, involves significant energy consumption and potential habitat disruption. Mining operations for these metals can lead to soil degradation, water contamination, and biodiversity loss if not properly managed. Comprehensive life cycle assessments indicate that the environmental benefits during operation must be weighed against these production-phase impacts.

Toxicity concerns present another environmental challenge, particularly for liquid metals containing lead or mercury components. Accidental releases could result in severe ecological damage, necessitating robust containment systems and emergency response protocols. The thermal modeling methods must therefore incorporate safety parameters that account for potential environmental exposure scenarios and mitigation strategies.

From a sustainability perspective, liquid metal heat transfer systems offer promising advantages. Their exceptional durability and resistance to degradation result in extended operational lifespans, reducing replacement frequency and associated resource consumption. Additionally, many liquid metals maintain their properties indefinitely, enabling closed-loop systems with minimal waste generation. Advanced thermal modeling methods now incorporate these longevity factors into sustainability metrics, providing more accurate assessments of long-term environmental impacts.

Recyclability represents another sustainability advantage of liquid metal heat transfer systems. Unlike many conventional coolants that degrade over time, liquid metals can be recovered and reused with minimal processing. Thermal modeling methods increasingly account for end-of-life scenarios, quantifying the environmental benefits of material recovery and identifying optimal recycling pathways. These models help designers optimize system configurations for both performance and environmental sustainability.

Recent advancements in thermal modeling have begun integrating environmental impact assessments directly into design optimization algorithms. These approaches enable engineers to balance thermal performance against environmental considerations, identifying configurations that minimize ecological footprints while maintaining required heat transfer capabilities. Such integrated modeling approaches represent a significant step toward holistically sustainable thermal management solutions using liquid metal technologies.

However, the environmental footprint of liquid metal heat transfer systems extends beyond operational efficiency. The extraction and processing of liquid metals, especially rare earth metals like gallium, involves significant energy consumption and potential habitat disruption. Mining operations for these metals can lead to soil degradation, water contamination, and biodiversity loss if not properly managed. Comprehensive life cycle assessments indicate that the environmental benefits during operation must be weighed against these production-phase impacts.

Toxicity concerns present another environmental challenge, particularly for liquid metals containing lead or mercury components. Accidental releases could result in severe ecological damage, necessitating robust containment systems and emergency response protocols. The thermal modeling methods must therefore incorporate safety parameters that account for potential environmental exposure scenarios and mitigation strategies.

From a sustainability perspective, liquid metal heat transfer systems offer promising advantages. Their exceptional durability and resistance to degradation result in extended operational lifespans, reducing replacement frequency and associated resource consumption. Additionally, many liquid metals maintain their properties indefinitely, enabling closed-loop systems with minimal waste generation. Advanced thermal modeling methods now incorporate these longevity factors into sustainability metrics, providing more accurate assessments of long-term environmental impacts.

Recyclability represents another sustainability advantage of liquid metal heat transfer systems. Unlike many conventional coolants that degrade over time, liquid metals can be recovered and reused with minimal processing. Thermal modeling methods increasingly account for end-of-life scenarios, quantifying the environmental benefits of material recovery and identifying optimal recycling pathways. These models help designers optimize system configurations for both performance and environmental sustainability.

Recent advancements in thermal modeling have begun integrating environmental impact assessments directly into design optimization algorithms. These approaches enable engineers to balance thermal performance against environmental considerations, identifying configurations that minimize ecological footprints while maintaining required heat transfer capabilities. Such integrated modeling approaches represent a significant step toward holistically sustainable thermal management solutions using liquid metal technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!