Reliability Testing Protocols For Liquid Metal Thermal Solutions

AUG 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Thermal Solutions Background and Objectives

Liquid metal thermal solutions have emerged as a revolutionary approach to thermal management in high-performance computing and electronics cooling applications. These materials, primarily gallium-based alloys such as Galinstan (gallium-indium-tin) and gallium-indium eutectic, possess exceptional thermal conductivity ranging from 16 to 84 W/m·K, significantly outperforming traditional thermal interface materials like thermal pastes (1-10 W/m·K) and even approaching some metals like aluminum (237 W/m·K).

The evolution of liquid metal technology for thermal applications began in the early 2000s, primarily in research laboratories exploring alternatives to mercury. By 2010, commercial applications started emerging in high-performance computing, with enthusiasts adopting these materials for CPU cooling. The technology has since gained significant traction, with major thermal solution providers incorporating liquid metals into their product portfolios between 2015-2020.

Current market adoption is accelerating due to increasing thermal demands from advanced semiconductor devices. Modern CPUs and GPUs generate heat fluxes exceeding 100 W/cm², pushing traditional thermal interface materials to their limits. This trend is expected to continue as processor architectures advance toward higher power densities and 3D stacking technologies.

Despite their superior thermal performance, liquid metal solutions face significant reliability challenges that have limited widespread adoption. These include potential electrical conductivity risks, corrosion of certain metals (particularly aluminum), long-term stability concerns, and application complexity. The development of standardized reliability testing protocols represents a critical step toward addressing these limitations.

The primary technical objective of reliability testing protocols for liquid metal thermal solutions is to establish standardized methodologies for evaluating performance consistency, material stability, compatibility with various substrate materials, and long-term reliability under diverse operating conditions. These protocols must address thermal cycling resilience, pump-out resistance, corrosion mitigation, and application uniformity.

Secondary objectives include quantifying the relationship between application methods and thermal performance, establishing accelerated aging protocols that correlate with real-world performance, and developing non-destructive testing methods for quality control in manufacturing environments. The ultimate goal is to enable confident adoption of liquid metal thermal solutions across broader market segments by providing manufacturers and end-users with reliable performance expectations and design guidelines.

As the electronics industry continues to push thermal boundaries, liquid metal solutions represent a promising pathway to managing ever-increasing thermal loads. Establishing comprehensive reliability testing protocols will be instrumental in transitioning these materials from niche applications to mainstream thermal management solutions.

The evolution of liquid metal technology for thermal applications began in the early 2000s, primarily in research laboratories exploring alternatives to mercury. By 2010, commercial applications started emerging in high-performance computing, with enthusiasts adopting these materials for CPU cooling. The technology has since gained significant traction, with major thermal solution providers incorporating liquid metals into their product portfolios between 2015-2020.

Current market adoption is accelerating due to increasing thermal demands from advanced semiconductor devices. Modern CPUs and GPUs generate heat fluxes exceeding 100 W/cm², pushing traditional thermal interface materials to their limits. This trend is expected to continue as processor architectures advance toward higher power densities and 3D stacking technologies.

Despite their superior thermal performance, liquid metal solutions face significant reliability challenges that have limited widespread adoption. These include potential electrical conductivity risks, corrosion of certain metals (particularly aluminum), long-term stability concerns, and application complexity. The development of standardized reliability testing protocols represents a critical step toward addressing these limitations.

The primary technical objective of reliability testing protocols for liquid metal thermal solutions is to establish standardized methodologies for evaluating performance consistency, material stability, compatibility with various substrate materials, and long-term reliability under diverse operating conditions. These protocols must address thermal cycling resilience, pump-out resistance, corrosion mitigation, and application uniformity.

Secondary objectives include quantifying the relationship between application methods and thermal performance, establishing accelerated aging protocols that correlate with real-world performance, and developing non-destructive testing methods for quality control in manufacturing environments. The ultimate goal is to enable confident adoption of liquid metal thermal solutions across broader market segments by providing manufacturers and end-users with reliable performance expectations and design guidelines.

As the electronics industry continues to push thermal boundaries, liquid metal solutions represent a promising pathway to managing ever-increasing thermal loads. Establishing comprehensive reliability testing protocols will be instrumental in transitioning these materials from niche applications to mainstream thermal management solutions.

Market Demand Analysis for Advanced Thermal Management

The thermal management market is experiencing unprecedented growth driven by the increasing power density and miniaturization of electronic devices across multiple industries. Current projections indicate the global thermal management market will reach approximately $20 billion by 2026, with a compound annual growth rate exceeding 8%. Within this broader market, advanced thermal solutions—particularly liquid metal thermal interfaces—are emerging as a critical segment due to their superior thermal conductivity compared to traditional thermal pastes and pads.

The demand for liquid metal thermal solutions is primarily fueled by high-performance computing, gaming systems, data centers, and telecommunications infrastructure. Gaming consoles and high-end PCs represent the earliest adoption markets, where thermal throttling directly impacts user experience and product performance. Industry surveys indicate that over 70% of gaming hardware manufacturers are exploring liquid metal solutions to address thermal constraints in next-generation products.

Data center operators face mounting challenges in cooling increasingly dense server configurations while managing operational costs. Energy efficiency has become a paramount concern, with cooling systems accounting for approximately 40% of data center energy consumption. Liquid metal thermal interfaces offer potential energy savings of 15-20% compared to conventional solutions, creating strong economic incentives for adoption despite higher initial implementation costs.

The automotive sector, particularly electric vehicles, represents another significant growth vector. As power electronics in EVs operate at higher temperatures and require more efficient thermal management, liquid metal solutions are gaining attention from major manufacturers. Market research indicates that thermal management systems in electric vehicles will grow at nearly twice the rate of the overall thermal management market.

Consumer electronics manufacturers are also exploring liquid metal solutions as devices become thinner while processing requirements increase. The smartphone and tablet segments alone could represent a market opportunity exceeding $1 billion for advanced thermal solutions by 2025.

However, market penetration faces significant barriers related to reliability concerns. Potential users consistently cite long-term stability, compatibility with different materials, and standardized testing protocols as primary concerns inhibiting wider adoption. Survey data reveals that 65% of potential industrial users consider reliability verification as the most critical factor in their purchasing decisions for advanced thermal solutions.

This market landscape creates a compelling opportunity for companies that can develop and validate reliable liquid metal thermal solutions with comprehensive testing protocols. The establishment of industry-standard reliability testing methodologies could potentially accelerate market adoption by 30-40% according to industry analysts, highlighting the strategic importance of addressing reliability concerns through rigorous testing frameworks.

The demand for liquid metal thermal solutions is primarily fueled by high-performance computing, gaming systems, data centers, and telecommunications infrastructure. Gaming consoles and high-end PCs represent the earliest adoption markets, where thermal throttling directly impacts user experience and product performance. Industry surveys indicate that over 70% of gaming hardware manufacturers are exploring liquid metal solutions to address thermal constraints in next-generation products.

Data center operators face mounting challenges in cooling increasingly dense server configurations while managing operational costs. Energy efficiency has become a paramount concern, with cooling systems accounting for approximately 40% of data center energy consumption. Liquid metal thermal interfaces offer potential energy savings of 15-20% compared to conventional solutions, creating strong economic incentives for adoption despite higher initial implementation costs.

The automotive sector, particularly electric vehicles, represents another significant growth vector. As power electronics in EVs operate at higher temperatures and require more efficient thermal management, liquid metal solutions are gaining attention from major manufacturers. Market research indicates that thermal management systems in electric vehicles will grow at nearly twice the rate of the overall thermal management market.

Consumer electronics manufacturers are also exploring liquid metal solutions as devices become thinner while processing requirements increase. The smartphone and tablet segments alone could represent a market opportunity exceeding $1 billion for advanced thermal solutions by 2025.

However, market penetration faces significant barriers related to reliability concerns. Potential users consistently cite long-term stability, compatibility with different materials, and standardized testing protocols as primary concerns inhibiting wider adoption. Survey data reveals that 65% of potential industrial users consider reliability verification as the most critical factor in their purchasing decisions for advanced thermal solutions.

This market landscape creates a compelling opportunity for companies that can develop and validate reliable liquid metal thermal solutions with comprehensive testing protocols. The establishment of industry-standard reliability testing methodologies could potentially accelerate market adoption by 30-40% according to industry analysts, highlighting the strategic importance of addressing reliability concerns through rigorous testing frameworks.

Current Challenges in Liquid Metal Reliability Testing

Despite significant advancements in liquid metal thermal interface materials (TIMs), standardized reliability testing protocols remain underdeveloped. The industry faces a critical challenge in establishing consistent methodologies to evaluate long-term performance and reliability of these advanced thermal solutions. Current testing approaches vary widely across manufacturers and research institutions, making comparative analysis difficult and hindering widespread adoption.

One fundamental challenge is the lack of accelerated aging test standards specifically designed for liquid metal TIMs. While traditional thermal greases have established testing protocols, liquid metals exhibit unique physical and chemical properties that render conventional methods inadequate. Their gallium-based compositions interact differently with various substrate materials, particularly aluminum, creating complex degradation mechanisms that are difficult to predict through existing test frameworks.

Thermal cycling reliability presents another significant hurdle. The industry lacks consensus on appropriate temperature ranges, ramp rates, and cycle counts that accurately simulate real-world conditions while providing meaningful data about potential failure modes. The liquid-solid phase transitions that some formulations undergo during thermal cycling further complicate the development of standardized protocols, as these transitions can significantly impact material performance and reliability over time.

Oxidation and corrosion testing methodologies remain inconsistent across the industry. The high reactivity of liquid metals with oxygen and certain metals necessitates specialized testing approaches that can accurately quantify degradation rates under various environmental conditions. Current methods often fail to account for the complex interplay between humidity, temperature fluctuations, and surface chemistry that influences corrosion behavior in actual applications.

Pump-out and migration testing represents another area lacking standardization. The tendency of liquid metals to migrate under certain conditions can lead to electrical shorts and performance degradation. However, no widely accepted test methodology exists to quantify this behavior or establish acceptable thresholds for different application scenarios.

Contact resistance stability assessment methods also require refinement. The interface between liquid metal TIMs and various substrate materials changes over time due to intermetallic compound formation and other chemical interactions. Current testing approaches inadequately capture these dynamic changes, particularly over extended operational periods relevant to high-reliability applications.

Finally, the industry faces challenges in developing non-destructive evaluation techniques for in-situ monitoring of liquid metal TIM reliability. Unlike traditional thermal interface materials, liquid metals often require specialized approaches to assess degradation without disassembling the thermal solution, creating significant barriers to effective quality control and predictive maintenance protocols.

One fundamental challenge is the lack of accelerated aging test standards specifically designed for liquid metal TIMs. While traditional thermal greases have established testing protocols, liquid metals exhibit unique physical and chemical properties that render conventional methods inadequate. Their gallium-based compositions interact differently with various substrate materials, particularly aluminum, creating complex degradation mechanisms that are difficult to predict through existing test frameworks.

Thermal cycling reliability presents another significant hurdle. The industry lacks consensus on appropriate temperature ranges, ramp rates, and cycle counts that accurately simulate real-world conditions while providing meaningful data about potential failure modes. The liquid-solid phase transitions that some formulations undergo during thermal cycling further complicate the development of standardized protocols, as these transitions can significantly impact material performance and reliability over time.

Oxidation and corrosion testing methodologies remain inconsistent across the industry. The high reactivity of liquid metals with oxygen and certain metals necessitates specialized testing approaches that can accurately quantify degradation rates under various environmental conditions. Current methods often fail to account for the complex interplay between humidity, temperature fluctuations, and surface chemistry that influences corrosion behavior in actual applications.

Pump-out and migration testing represents another area lacking standardization. The tendency of liquid metals to migrate under certain conditions can lead to electrical shorts and performance degradation. However, no widely accepted test methodology exists to quantify this behavior or establish acceptable thresholds for different application scenarios.

Contact resistance stability assessment methods also require refinement. The interface between liquid metal TIMs and various substrate materials changes over time due to intermetallic compound formation and other chemical interactions. Current testing approaches inadequately capture these dynamic changes, particularly over extended operational periods relevant to high-reliability applications.

Finally, the industry faces challenges in developing non-destructive evaluation techniques for in-situ monitoring of liquid metal TIM reliability. Unlike traditional thermal interface materials, liquid metals often require specialized approaches to assess degradation without disassembling the thermal solution, creating significant barriers to effective quality control and predictive maintenance protocols.

Current Testing Methodologies for Liquid Metal Reliability

01 Liquid metal thermal interface materials for electronic cooling

Liquid metals are used as thermal interface materials in electronic devices to enhance heat dissipation. These materials offer superior thermal conductivity compared to conventional thermal pastes, allowing for more efficient cooling of high-power electronic components. The liquid nature ensures complete contact with irregular surfaces, minimizing thermal resistance at interfaces. These solutions are particularly valuable in applications requiring reliable thermal management under demanding conditions.- Liquid metal thermal interface materials for electronic devices: Liquid metal thermal interface materials are used in electronic devices to improve heat dissipation and thermal management. These materials provide excellent thermal conductivity between heat-generating components and heat sinks, enhancing the overall reliability of electronic systems. The liquid nature of these metals allows for better surface contact and filling of microscopic gaps, resulting in improved thermal transfer efficiency compared to traditional thermal interface materials.

- Reliability enhancement techniques for liquid metal cooling systems: Various techniques are employed to enhance the reliability of liquid metal cooling systems, including surface treatments, encapsulation methods, and anti-corrosion measures. These techniques address common reliability concerns such as metal migration, oxidation, and compatibility with surrounding materials. By implementing these enhancement methods, the long-term stability and performance of liquid metal thermal solutions can be significantly improved, making them suitable for demanding applications requiring consistent thermal management.

- Gallium-based liquid metal alloys for thermal management: Gallium-based liquid metal alloys, including gallium-indium-tin compositions, offer superior thermal conductivity while remaining liquid at room temperature. These alloys provide excellent heat transfer capabilities in thermal management applications while addressing some of the safety concerns associated with traditional liquid metals like mercury. Their unique properties make them particularly suitable for advanced cooling solutions in high-performance computing, power electronics, and other heat-intensive applications.

- Containment and pumping systems for liquid metal coolants: Specialized containment and pumping systems are critical for the reliable operation of liquid metal cooling solutions. These systems address challenges related to the high density, surface tension, and potential reactivity of liquid metals. Advanced pump designs, compatible materials for piping and heat exchangers, and innovative sealing technologies ensure the safe circulation of liquid metal coolants while preventing leakage or contamination. Proper containment systems significantly enhance the overall reliability and service life of liquid metal thermal management solutions.

- Testing and qualification methods for liquid metal thermal solutions: Comprehensive testing and qualification methods are essential for evaluating the reliability of liquid metal thermal solutions. These methods include accelerated aging tests, thermal cycling, vibration testing, and long-term performance monitoring. Advanced analytical techniques are used to assess material compatibility, thermal conductivity stability, and potential failure mechanisms. By implementing rigorous testing protocols, manufacturers can ensure that liquid metal thermal solutions maintain their performance characteristics throughout their intended operational lifetime under various environmental conditions.

02 Reliability enhancement techniques for liquid metal thermal solutions

Various techniques have been developed to improve the reliability of liquid metal thermal solutions. These include encapsulation methods to prevent leakage, surface treatments to control wetting properties, and the addition of stabilizing agents to prevent oxidation and degradation over time. Advanced packaging designs incorporate containment structures that maintain the liquid metal in the desired location while accommodating thermal expansion. These enhancements address common reliability concerns such as migration, corrosion, and long-term stability.Expand Specific Solutions03 Gallium-based liquid metal alloys for thermal management

Gallium-based liquid metal alloys, including combinations with indium, tin, and zinc, offer excellent thermal properties while remaining liquid at room temperature. These alloys provide high thermal conductivity with relatively low viscosity, making them ideal for thermal management applications. Their low melting points allow for easy application and rework, while their non-toxic nature makes them environmentally preferable to mercury-based alternatives. Research focuses on optimizing composition to balance thermal performance with other properties like surface tension and chemical compatibility.Expand Specific Solutions04 Manufacturing and application methods for liquid metal thermal solutions

Specialized manufacturing and application techniques have been developed for liquid metal thermal solutions. These include injection methods, printing processes, and vacuum deposition approaches that ensure precise placement and uniform distribution. Automated dispensing systems control the exact amount of liquid metal applied, while surface preparation protocols enhance adhesion and wetting characteristics. These methods address challenges related to handling liquid metals, such as preventing oxidation during application and ensuring consistent performance across production batches.Expand Specific Solutions05 Testing and qualification standards for liquid metal thermal solution reliability

Comprehensive testing methodologies have been established to evaluate the reliability of liquid metal thermal solutions. These include thermal cycling tests to assess performance under temperature fluctuations, accelerated aging studies to predict long-term behavior, and mechanical shock testing to ensure stability under physical stress. Standardized measurement techniques quantify thermal conductivity, viscosity changes over time, and chemical stability with various substrate materials. These qualification standards help engineers select appropriate liquid metal solutions for specific application requirements and operating environments.Expand Specific Solutions

Key Industry Players in Thermal Solution Development

The liquid metal thermal solutions market is currently in a growth phase, characterized by increasing demand for advanced cooling technologies in high-performance computing and electronics. The global market size is expanding rapidly, driven by data center proliferation and AI infrastructure development. From a technological maturity perspective, the field shows varying levels of advancement among key players. Companies like Huawei, Infineon, and GLOBALFOUNDRIES are leading commercial implementation, while academic institutions such as Xi'an Jiaotong University and Shanghai University are contributing fundamental research. Siemens and Resonac are developing standardized testing protocols, while specialized thermal management firms like Process Metrix are advancing measurement technologies. The competitive landscape reflects a blend of semiconductor manufacturers, research institutions, and specialized thermal solution providers working to establish reliability standards.

Xi'an Jiaotong University

Technical Solution: Xi'an Jiaotong University has developed sophisticated reliability testing protocols for liquid metal thermal solutions, focusing on fundamental material science aspects. Their approach includes microstructural stability analysis using scanning electron microscopy to track changes in the liquid metal-substrate interface over thousands of thermal cycles. They employ impedance spectroscopy to characterize the formation and growth of intermetallic compounds at interfaces, which can significantly impact thermal performance over time. The university has pioneered accelerated corrosion testing methodologies specifically calibrated for gallium-based liquid metals, using electrochemical techniques to quantify corrosion rates under various operating conditions. Their testing protocol includes rheological characterization to monitor changes in flow properties over time, particularly important for pump-driven liquid metal cooling systems. Additionally, they've developed specialized wettability testing to evaluate long-term contact angle stability between liquid metals and various substrate materials, a critical factor in thermal interface performance degradation.

Strengths: Exceptionally strong fundamental materials science approach with advanced characterization techniques. Comprehensive understanding of interfacial phenomena and degradation mechanisms. Weaknesses: Testing protocols may be more academically oriented and less focused on manufacturing scalability. Limited integration with system-level reliability testing compared to industry approaches.

Infineon Technologies AG

Technical Solution: Infineon Technologies has developed specialized reliability testing protocols for liquid metal thermal solutions in power electronics applications. Their methodology focuses on high-temperature stability testing (up to 200°C) to evaluate liquid metal performance in IGBT and power semiconductor cooling applications. They employ automated thermal cycling systems capable of executing 10,000+ cycles while continuously monitoring thermal resistance changes to detect gradual degradation. Infineon's testing protocol includes electrical isolation verification throughout thermal cycling, critical for ensuring that conductive liquid metals don't compromise device safety over time. They've developed specialized test fixtures that simulate actual product mounting conditions, including clamping pressures and surface preparations representative of production environments. Their approach incorporates accelerated humidity testing (85°C/85% RH) combined with thermal cycling to evaluate potential corrosion mechanisms at the liquid metal-substrate interface. Additionally, Infineon implements power cycling with actual semiconductor devices to evaluate liquid metal thermal solutions under realistic electrical and thermal load conditions, providing direct correlation between thermal interface reliability and device performance.

Strengths: Testing protocols directly tied to actual semiconductor device performance rather than just thermal metrics. Excellent focus on electrical isolation reliability, critical for conductive liquid metal applications. Weaknesses: Testing methodology primarily optimized for power electronics applications and may need modification for other use cases. Limited evaluation of pump-driven liquid metal systems compared to static thermal interface applications.

Critical Technical Standards and Testing Protocols

Thermal interface materials comprising liquid metal droplets and solid thermally conductive particles, circuit assemblies formed therefrom, and methods of manufacture thereof

PatentWO2025128172A1

Innovation

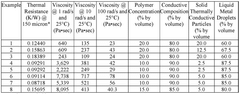

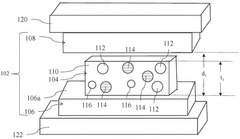

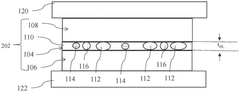

- A thermal interface material comprising 5% to 80% by volume of a polymer component and 20% to 95% by volume of a conductive component, where the conductive component includes 25% to 99% by volume of liquid metal droplets and 1% to 75% by volume of solid thermally conductive particles, dispersed throughout the polymer component.

Liquid metal manufacturing method having excellent abrasion resistance, corrosion resistance and processability

PatentInactiveKR1020200023118A

Innovation

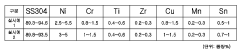

- A composition optimized for liquid metal comprising 304 stainless steel, nickel, chromium, titanium, zirconium, copper, manganese, and silicon, with a sequential melting process to maintain the melting temperature, preventing oxidation and ensuring proper mixing and aggregation.

Material Compatibility and Corrosion Prevention Strategies

Material compatibility represents a critical challenge in liquid metal thermal solution implementation, as gallium-based liquid metals are highly reactive with certain metals, particularly aluminum. When in contact with aluminum, gallium rapidly diffuses into the metal's grain boundaries, causing catastrophic structural degradation known as liquid metal embrittlement. This phenomenon necessitates careful material selection and protective strategies to ensure long-term reliability.

The primary corrosion prevention approach involves utilizing compatible materials that demonstrate resistance to liquid metal attack. Nickel-plated surfaces have emerged as an industry standard protective barrier, creating an effective diffusion barrier between liquid metals and vulnerable substrates. Research indicates that nickel coatings with thicknesses of 3-5 μm provide optimal protection while maintaining thermal performance.

Alternative coating technologies showing promise include titanium nitride (TiN) and diamond-like carbon (DLC) films, which offer excellent chemical stability against gallium alloys. These coatings can be applied through physical vapor deposition (PVD) or chemical vapor deposition (CVD) processes, creating uniform protective layers even on complex geometries.

Surface passivation techniques represent another viable approach, where controlled oxidation creates a thin, stable oxide layer that inhibits liquid metal interaction with the underlying substrate. This method has proven particularly effective with copper and copper alloys, which are commonly used in thermal management applications.

Polymer-based barriers and encapsulation methods provide additional protection options, especially in scenarios where direct metal-to-metal contact cannot be completely eliminated. Specialized polymers like polyimide and certain fluoropolymers demonstrate remarkable resistance to liquid metal penetration while maintaining acceptable thermal conductivity at interface regions.

Testing protocols must evaluate material compatibility under accelerated aging conditions, simulating years of operational exposure. Standard methodologies include extended temperature cycling between operational extremes (-40°C to 150°C), thermal shock testing, and prolonged isothermal aging at elevated temperatures. Metallographic analysis and electron microscopy are employed to detect early signs of material degradation or intermetallic compound formation.

Emerging research focuses on self-healing protective coatings that can automatically repair minor damage and prevent progressive corrosion. These advanced materials incorporate microcapsules containing reactive agents that are released upon coating breach, rapidly forming new protective barriers before significant damage occurs to the underlying substrate.

The primary corrosion prevention approach involves utilizing compatible materials that demonstrate resistance to liquid metal attack. Nickel-plated surfaces have emerged as an industry standard protective barrier, creating an effective diffusion barrier between liquid metals and vulnerable substrates. Research indicates that nickel coatings with thicknesses of 3-5 μm provide optimal protection while maintaining thermal performance.

Alternative coating technologies showing promise include titanium nitride (TiN) and diamond-like carbon (DLC) films, which offer excellent chemical stability against gallium alloys. These coatings can be applied through physical vapor deposition (PVD) or chemical vapor deposition (CVD) processes, creating uniform protective layers even on complex geometries.

Surface passivation techniques represent another viable approach, where controlled oxidation creates a thin, stable oxide layer that inhibits liquid metal interaction with the underlying substrate. This method has proven particularly effective with copper and copper alloys, which are commonly used in thermal management applications.

Polymer-based barriers and encapsulation methods provide additional protection options, especially in scenarios where direct metal-to-metal contact cannot be completely eliminated. Specialized polymers like polyimide and certain fluoropolymers demonstrate remarkable resistance to liquid metal penetration while maintaining acceptable thermal conductivity at interface regions.

Testing protocols must evaluate material compatibility under accelerated aging conditions, simulating years of operational exposure. Standard methodologies include extended temperature cycling between operational extremes (-40°C to 150°C), thermal shock testing, and prolonged isothermal aging at elevated temperatures. Metallographic analysis and electron microscopy are employed to detect early signs of material degradation or intermetallic compound formation.

Emerging research focuses on self-healing protective coatings that can automatically repair minor damage and prevent progressive corrosion. These advanced materials incorporate microcapsules containing reactive agents that are released upon coating breach, rapidly forming new protective barriers before significant damage occurs to the underlying substrate.

Environmental Impact and Safety Considerations

Liquid metal thermal solutions, while offering superior thermal conductivity for cooling applications, present significant environmental and safety challenges that must be addressed through comprehensive reliability testing protocols. The most common liquid metal thermal interface materials (TIMs) contain gallium alloys which, despite their excellent thermal properties, pose potential environmental hazards throughout their lifecycle. When improperly disposed of, these materials can contaminate soil and water systems, potentially affecting aquatic ecosystems due to metal bioaccumulation. Testing protocols must therefore include leachability assessments under various environmental conditions to predict long-term ecological impacts.

Safety considerations for liquid metal TIMs are equally critical due to their inherent chemical properties. Gallium-based liquid metals are highly corrosive to certain metals, particularly aluminum, which necessitates rigorous compatibility testing with all potential contact materials in thermal management systems. Reliability testing must incorporate accelerated corrosion tests that simulate worst-case scenarios of liquid metal contact with system components over extended periods. Additionally, electrical conductivity of these materials presents potential short-circuit risks, requiring protocols that evaluate electrical isolation integrity under thermal cycling and mechanical stress.

Toxicological considerations form another crucial aspect of environmental and safety testing. While gallium alloys are generally considered to have low toxicity compared to mercury-based alternatives, comprehensive testing protocols should include cytotoxicity assessments and dermal exposure evaluations. These tests help establish handling guidelines and determine appropriate personal protective equipment requirements for manufacturing, maintenance, and disposal processes.

The regulatory landscape surrounding liquid metal thermal solutions continues to evolve, with increasing focus on sustainable electronics and responsible materials management. Testing protocols must align with international standards such as RoHS, REACH, and WEEE directives, while anticipating future regulatory developments. End-of-life considerations should be incorporated into reliability testing, evaluating recyclability and developing procedures for safe recovery of gallium and other constituent metals from decommissioned systems.

Containment reliability represents perhaps the most critical safety aspect of liquid metal thermal solutions. Testing protocols must evaluate the long-term integrity of encapsulation methods under various mechanical stresses, thermal cycles, and aging conditions. Accelerated life testing should simulate years of operational conditions to identify potential failure modes that could lead to leakage. Non-destructive evaluation techniques, including advanced imaging methods, should be incorporated into testing regimes to detect early signs of containment degradation before catastrophic failures occur.

Safety considerations for liquid metal TIMs are equally critical due to their inherent chemical properties. Gallium-based liquid metals are highly corrosive to certain metals, particularly aluminum, which necessitates rigorous compatibility testing with all potential contact materials in thermal management systems. Reliability testing must incorporate accelerated corrosion tests that simulate worst-case scenarios of liquid metal contact with system components over extended periods. Additionally, electrical conductivity of these materials presents potential short-circuit risks, requiring protocols that evaluate electrical isolation integrity under thermal cycling and mechanical stress.

Toxicological considerations form another crucial aspect of environmental and safety testing. While gallium alloys are generally considered to have low toxicity compared to mercury-based alternatives, comprehensive testing protocols should include cytotoxicity assessments and dermal exposure evaluations. These tests help establish handling guidelines and determine appropriate personal protective equipment requirements for manufacturing, maintenance, and disposal processes.

The regulatory landscape surrounding liquid metal thermal solutions continues to evolve, with increasing focus on sustainable electronics and responsible materials management. Testing protocols must align with international standards such as RoHS, REACH, and WEEE directives, while anticipating future regulatory developments. End-of-life considerations should be incorporated into reliability testing, evaluating recyclability and developing procedures for safe recovery of gallium and other constituent metals from decommissioned systems.

Containment reliability represents perhaps the most critical safety aspect of liquid metal thermal solutions. Testing protocols must evaluate the long-term integrity of encapsulation methods under various mechanical stresses, thermal cycles, and aging conditions. Accelerated life testing should simulate years of operational conditions to identify potential failure modes that could lead to leakage. Non-destructive evaluation techniques, including advanced imaging methods, should be incorporated into testing regimes to detect early signs of containment degradation before catastrophic failures occur.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!