Liquid Metal Cooling For High-Power Electronics: System Design Principles

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Cooling Technology Evolution and Objectives

Liquid metal cooling technology has evolved significantly over the past decades, transitioning from theoretical concepts to practical applications in high-power electronics. Initially developed for nuclear reactors in the 1950s, liquid metal coolants such as gallium, indium, and their alloys have gradually found their way into electronic cooling systems due to their exceptional thermal conductivity properties. The evolution accelerated in the 1990s when semiconductor devices began reaching thermal limits that conventional air and water cooling systems could not adequately address.

The fundamental advantage of liquid metals lies in their unique combination of metallic thermal conductivity and fluidic properties. Unlike traditional coolants, liquid metals can maintain electrical conductivity while offering thermal conductivity values 10-100 times higher than water, making them ideal for high-density power electronics. This characteristic has become increasingly valuable as power densities in electronic components continue to rise exponentially, following but exceeding Moore's Law predictions for computational density.

Recent technological breakthroughs have overcome historical limitations in liquid metal implementation. Advances in material science have addressed corrosion issues through the development of compatible containment materials and surface treatments. Modern manufacturing techniques have enabled the creation of micro-channel cooling structures that maximize the efficiency of liquid metal heat transfer while minimizing the required coolant volume.

The primary objective of liquid metal cooling technology development is to enable the next generation of high-power electronics that operate beyond current thermal limitations. Specific goals include achieving junction temperatures below 85°C while handling heat fluxes exceeding 500 W/cm², which represents a 3-5x improvement over advanced water cooling systems. Additionally, the technology aims to maintain these performance levels while reducing the overall cooling system footprint by 40-60% compared to conventional solutions.

Looking forward, the technology roadmap focuses on several key objectives: improving pump reliability for continuous operation exceeding 100,000 hours, developing non-toxic liquid metal formulations to address safety concerns, and creating standardized interface protocols for seamless integration with various electronic platforms. The ultimate goal is to establish liquid metal cooling as a mainstream thermal management solution that enables the development of more powerful, efficient, and compact electronic systems across multiple industries including data centers, electric vehicles, aerospace applications, and advanced defense systems.

The fundamental advantage of liquid metals lies in their unique combination of metallic thermal conductivity and fluidic properties. Unlike traditional coolants, liquid metals can maintain electrical conductivity while offering thermal conductivity values 10-100 times higher than water, making them ideal for high-density power electronics. This characteristic has become increasingly valuable as power densities in electronic components continue to rise exponentially, following but exceeding Moore's Law predictions for computational density.

Recent technological breakthroughs have overcome historical limitations in liquid metal implementation. Advances in material science have addressed corrosion issues through the development of compatible containment materials and surface treatments. Modern manufacturing techniques have enabled the creation of micro-channel cooling structures that maximize the efficiency of liquid metal heat transfer while minimizing the required coolant volume.

The primary objective of liquid metal cooling technology development is to enable the next generation of high-power electronics that operate beyond current thermal limitations. Specific goals include achieving junction temperatures below 85°C while handling heat fluxes exceeding 500 W/cm², which represents a 3-5x improvement over advanced water cooling systems. Additionally, the technology aims to maintain these performance levels while reducing the overall cooling system footprint by 40-60% compared to conventional solutions.

Looking forward, the technology roadmap focuses on several key objectives: improving pump reliability for continuous operation exceeding 100,000 hours, developing non-toxic liquid metal formulations to address safety concerns, and creating standardized interface protocols for seamless integration with various electronic platforms. The ultimate goal is to establish liquid metal cooling as a mainstream thermal management solution that enables the development of more powerful, efficient, and compact electronic systems across multiple industries including data centers, electric vehicles, aerospace applications, and advanced defense systems.

Market Demand Analysis for Advanced Thermal Management Solutions

The global market for advanced thermal management solutions is experiencing unprecedented growth, driven primarily by the rapid evolution of high-power electronics across multiple industries. Current market valuations indicate that the thermal management sector is projected to reach $20 billion by 2026, with liquid metal cooling technologies representing one of the fastest-growing segments at a compound annual growth rate of approximately 14.3%.

The demand for liquid metal cooling systems stems from critical limitations in conventional cooling technologies when applied to next-generation electronics. Traditional air cooling and even standard liquid cooling solutions are increasingly inadequate for managing thermal loads in high-performance computing centers, electric vehicle power systems, and advanced telecommunications infrastructure. Market research indicates that data centers alone face cooling costs that constitute 40% of their total operational expenses, creating strong economic incentives for more efficient thermal management solutions.

Electric vehicle manufacturers represent another significant market driver, as power electronics in EVs generate substantial heat during fast charging and high-performance operation. With the EV market expanding at over 25% annually, the need for compact, efficient cooling systems that can maintain optimal battery and inverter temperatures has become critical for vehicle performance, safety, and longevity.

The aerospace and defense sectors are similarly experiencing increased demand for advanced cooling technologies. Modern radar systems, directed energy weapons, and avionics generate heat loads that conventional cooling methods struggle to dissipate effectively. Market analysis reveals that military applications alone account for approximately 18% of the current demand for advanced thermal management solutions.

Consumer electronics manufacturers are also exploring liquid metal cooling options as devices become more powerful while simultaneously shrinking in size. The gaming and high-performance computing segments have begun incorporating liquid metal thermal interface materials, with premium products commanding price premiums of 15-30% when featuring advanced cooling technologies.

Geographically, North America and Asia-Pacific regions dominate market demand, collectively accounting for over 70% of global consumption. China's aggressive development in electronics manufacturing and data center construction has positioned it as the fastest-growing market for advanced cooling technologies, with annual growth exceeding 17%.

Industry surveys indicate that end-users are willing to pay premium prices for thermal management solutions that offer significant improvements in three key metrics: thermal performance (heat dissipation capacity), system reliability, and energy efficiency. The market increasingly values solutions that can demonstrate quantifiable reductions in energy consumption while maintaining or improving electronic performance parameters.

The demand for liquid metal cooling systems stems from critical limitations in conventional cooling technologies when applied to next-generation electronics. Traditional air cooling and even standard liquid cooling solutions are increasingly inadequate for managing thermal loads in high-performance computing centers, electric vehicle power systems, and advanced telecommunications infrastructure. Market research indicates that data centers alone face cooling costs that constitute 40% of their total operational expenses, creating strong economic incentives for more efficient thermal management solutions.

Electric vehicle manufacturers represent another significant market driver, as power electronics in EVs generate substantial heat during fast charging and high-performance operation. With the EV market expanding at over 25% annually, the need for compact, efficient cooling systems that can maintain optimal battery and inverter temperatures has become critical for vehicle performance, safety, and longevity.

The aerospace and defense sectors are similarly experiencing increased demand for advanced cooling technologies. Modern radar systems, directed energy weapons, and avionics generate heat loads that conventional cooling methods struggle to dissipate effectively. Market analysis reveals that military applications alone account for approximately 18% of the current demand for advanced thermal management solutions.

Consumer electronics manufacturers are also exploring liquid metal cooling options as devices become more powerful while simultaneously shrinking in size. The gaming and high-performance computing segments have begun incorporating liquid metal thermal interface materials, with premium products commanding price premiums of 15-30% when featuring advanced cooling technologies.

Geographically, North America and Asia-Pacific regions dominate market demand, collectively accounting for over 70% of global consumption. China's aggressive development in electronics manufacturing and data center construction has positioned it as the fastest-growing market for advanced cooling technologies, with annual growth exceeding 17%.

Industry surveys indicate that end-users are willing to pay premium prices for thermal management solutions that offer significant improvements in three key metrics: thermal performance (heat dissipation capacity), system reliability, and energy efficiency. The market increasingly values solutions that can demonstrate quantifiable reductions in energy consumption while maintaining or improving electronic performance parameters.

Current Challenges in High-Power Electronics Cooling

The rapid advancement of high-power electronics in sectors such as electric vehicles, data centers, and industrial automation has intensified thermal management challenges. Traditional cooling methods are increasingly inadequate as power densities continue to rise, with some modern processors and power electronics generating heat fluxes exceeding 500 W/cm². This creates a critical thermal bottleneck that limits performance, reliability, and further miniaturization of electronic systems.

Air cooling, the most widely implemented solution, has reached its practical limits with heat fluxes above 100 W/cm². Even with optimized heat sink designs and high-performance fans, air cooling struggles with the thermal demands of next-generation electronics, while also introducing noise and reliability concerns due to moving parts.

Conventional liquid cooling systems using water or dielectric fluids offer improved thermal performance but face significant challenges. These include complex plumbing requirements, potential for leakage, pump reliability issues, and limited heat transfer coefficients at the critical solid-liquid interface. The presence of thermal interface materials further reduces cooling efficiency by introducing additional thermal resistance.

Two-phase cooling technologies like heat pipes and vapor chambers provide enhanced performance through latent heat transfer but encounter limitations in orientation sensitivity, maximum heat flux capacity, and manufacturing complexity. Additionally, these solutions often struggle with non-uniform heat distribution across large chip areas, creating problematic hotspots that can lead to premature device failure.

Microfluidic cooling approaches show promise but face substantial hurdles in practical implementation, including channel clogging, high pressure drops, manufacturing difficulties, and integration challenges with existing electronic packaging technologies. The complexity of these systems also raises concerns about long-term reliability in commercial applications.

The thermal interface between cooling systems and electronic components represents another significant challenge. Traditional thermal interface materials introduce thermal resistance that becomes increasingly problematic as heat fluxes rise. Direct liquid cooling of electronic components is often hindered by compatibility issues between coolants and sensitive electronic materials.

Energy efficiency presents an additional challenge, as cooling systems themselves consume substantial power. In data centers, cooling can account for up to 40% of total energy consumption, highlighting the need for more efficient thermal management solutions that minimize parasitic power losses while maintaining effective cooling performance.

These challenges collectively underscore the urgent need for innovative cooling technologies like liquid metal systems that can address the thermal demands of next-generation high-power electronics while overcoming the limitations of conventional approaches.

Air cooling, the most widely implemented solution, has reached its practical limits with heat fluxes above 100 W/cm². Even with optimized heat sink designs and high-performance fans, air cooling struggles with the thermal demands of next-generation electronics, while also introducing noise and reliability concerns due to moving parts.

Conventional liquid cooling systems using water or dielectric fluids offer improved thermal performance but face significant challenges. These include complex plumbing requirements, potential for leakage, pump reliability issues, and limited heat transfer coefficients at the critical solid-liquid interface. The presence of thermal interface materials further reduces cooling efficiency by introducing additional thermal resistance.

Two-phase cooling technologies like heat pipes and vapor chambers provide enhanced performance through latent heat transfer but encounter limitations in orientation sensitivity, maximum heat flux capacity, and manufacturing complexity. Additionally, these solutions often struggle with non-uniform heat distribution across large chip areas, creating problematic hotspots that can lead to premature device failure.

Microfluidic cooling approaches show promise but face substantial hurdles in practical implementation, including channel clogging, high pressure drops, manufacturing difficulties, and integration challenges with existing electronic packaging technologies. The complexity of these systems also raises concerns about long-term reliability in commercial applications.

The thermal interface between cooling systems and electronic components represents another significant challenge. Traditional thermal interface materials introduce thermal resistance that becomes increasingly problematic as heat fluxes rise. Direct liquid cooling of electronic components is often hindered by compatibility issues between coolants and sensitive electronic materials.

Energy efficiency presents an additional challenge, as cooling systems themselves consume substantial power. In data centers, cooling can account for up to 40% of total energy consumption, highlighting the need for more efficient thermal management solutions that minimize parasitic power losses while maintaining effective cooling performance.

These challenges collectively underscore the urgent need for innovative cooling technologies like liquid metal systems that can address the thermal demands of next-generation high-power electronics while overcoming the limitations of conventional approaches.

Current Liquid Metal Cooling System Design Approaches

01 Liquid metal cooling for electronic devices

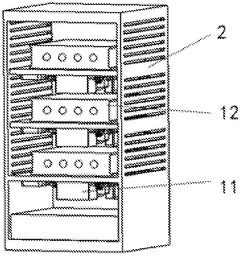

Liquid metal cooling systems are used in electronic devices to efficiently dissipate heat from components such as processors and graphics cards. These systems utilize the high thermal conductivity of liquid metals like gallium alloys to transfer heat away from critical components. The liquid metal can be applied directly between the heat source and heat sink, or circulated through cooling channels, providing superior thermal performance compared to traditional thermal interface materials.- Liquid metal cooling for electronic devices: Liquid metal cooling systems are used in electronic devices to efficiently dissipate heat from components such as processors and graphics cards. These systems utilize the high thermal conductivity of liquid metals like gallium alloys to transfer heat away from critical components to cooling elements. This approach provides superior thermal management compared to traditional cooling methods, allowing for better performance and longevity of electronic devices under high computational loads.

- Immersion cooling with liquid metal: Immersion cooling involves submerging electronic components directly in liquid metal coolants to maximize heat transfer efficiency. This technique eliminates thermal interface materials and air gaps that typically impede heat transfer in conventional cooling systems. The direct contact between the liquid metal and the heat-generating components allows for rapid heat dissipation, making it particularly effective for high-power density applications such as data centers and high-performance computing systems.

- Liquid metal cooling for renewable energy systems: Liquid metal cooling technologies are applied in renewable energy systems to enhance efficiency and reliability. In applications such as concentrated solar power, geothermal energy conversion, and advanced battery systems, liquid metals serve as both heat transfer media and thermal storage materials. Their high thermal conductivity and wide operating temperature range make them ideal for managing the thermal challenges associated with renewable energy generation and storage.

- Advanced liquid metal alloys for cooling applications: Specialized liquid metal alloys are developed specifically for cooling applications, offering improved thermal properties while addressing challenges such as corrosion, oxidation, and material compatibility. These engineered alloys typically contain gallium, indium, tin, or bismuth in various proportions to achieve desired melting points, viscosity, and thermal conductivity. Some formulations also incorporate additives to enhance wetting properties or reduce reactivity with container materials, making them more suitable for long-term cooling applications.

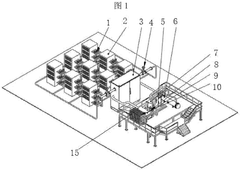

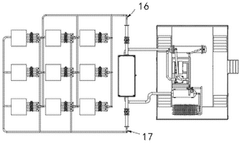

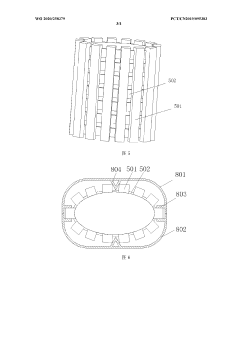

- Liquid metal cooling pumping and circulation systems: Specialized pumping and circulation systems are designed to handle the unique properties of liquid metals in cooling applications. These systems address challenges such as high density, surface tension, and potential reactivity of liquid metals. Advanced pump designs, electromagnetic pumping mechanisms, and specialized piping materials are employed to ensure reliable circulation of liquid metal coolants. These systems often incorporate sensors and control mechanisms to optimize flow rates based on thermal load requirements and prevent issues such as solidification or channel blockage.

02 Immersion cooling with liquid metal

Immersion cooling involves submerging electronic components directly in a liquid metal coolant. This approach provides direct contact between the coolant and heat-generating components, eliminating thermal interface resistance. The liquid metal efficiently absorbs and transfers heat away from the components, maintaining optimal operating temperatures even under high computational loads. This cooling method is particularly effective for high-performance computing systems and data centers where traditional air cooling is insufficient.Expand Specific Solutions03 Liquid metal cooling for power generation systems

Liquid metal cooling is employed in power generation systems to manage high heat loads. These cooling systems use liquid metals such as sodium, potassium, or their alloys to transfer heat from nuclear reactors or other high-temperature power generation equipment. The exceptional thermal conductivity of liquid metals allows for efficient heat transfer in compact designs, improving overall system efficiency while maintaining safe operating temperatures.Expand Specific Solutions04 Advanced liquid metal cooling circulation systems

Advanced liquid metal cooling circulation systems incorporate pumps, heat exchangers, and specialized piping to move liquid metal coolants through a closed loop. These systems are designed to handle the unique properties of liquid metals, including their high density, surface tension, and potential for corrosion. Innovations in pump design, flow control, and material compatibility have improved the reliability and performance of these circulation systems, making them suitable for long-term operation in critical applications.Expand Specific Solutions05 Liquid metal cooling materials and compositions

Research into liquid metal cooling materials focuses on developing optimized compositions with enhanced thermal properties and reduced environmental concerns. These materials include gallium-based alloys, indium-tin mixtures, and other metal combinations that remain liquid at operating temperatures. Additives and surface treatments are used to improve wetting characteristics, reduce oxidation, and prevent corrosion of contact surfaces. These specialized compositions are designed to maximize heat transfer efficiency while minimizing potential damage to the cooled components.Expand Specific Solutions

Key Industry Players in Liquid Metal Cooling Solutions

Liquid metal cooling for high-power electronics is currently in a growth phase, with the market expanding rapidly due to increasing demands for efficient thermal management solutions in data centers, AI systems, and high-performance computing. The global market is projected to reach significant scale as power densities in electronics continue to rise. Technologically, the field shows varying maturity levels across different applications. Industry leaders like IBM, Intel, and Vertiv have established robust liquid cooling solutions, while specialized innovators such as JETCOOL Technologies and Yunnan Jingchuang Liquid Metal Thermal Control Technology are advancing novel approaches. Academic-industrial collaborations involving Tsinghua University and Shanghai University are accelerating development. Companies like Asetek and Guangzhou Goaland are commercializing systems for specific market segments, indicating the technology's transition from research to practical implementation across multiple industries.

International Business Machines Corp.

Technical Solution: IBM has developed advanced liquid metal cooling systems for high-power electronics that utilize gallium-based alloys with high thermal conductivity (approximately 40 W/m·K). Their system design incorporates direct contact between the liquid metal and heat-generating components, creating efficient thermal interfaces with minimal thermal resistance. IBM's approach includes engineered micro-channels that maximize surface area contact while maintaining optimal flow dynamics. The system employs electromagnetic pumps to circulate the liquid metal without moving parts, reducing maintenance requirements and increasing reliability. IBM has also developed specialized containment materials resistant to the corrosive properties of liquid metals, including coatings that prevent amalgamation with sensitive electronic components. Their comprehensive thermal management solution integrates sensors and control systems that dynamically adjust cooling capacity based on real-time thermal loads[1][3].

Strengths: Superior thermal conductivity compared to traditional coolants, allowing for more efficient heat dissipation from high-density computing systems. The absence of moving parts in electromagnetic pumping systems increases reliability and reduces maintenance requirements. Weaknesses: Gallium-based liquid metals are corrosive to certain metals, requiring specialized containment materials and careful system design to prevent damage to electronic components.

Intel Corp.

Technical Solution: Intel has pioneered liquid metal cooling solutions specifically designed for high-performance processors and data center applications. Their system utilizes a eutectic gallium-indium alloy (GaIn) with thermal conductivity exceeding 80 W/m·K, significantly outperforming conventional thermal interface materials. Intel's design incorporates a dual-loop architecture where liquid metal serves as the primary cooling medium in direct contact with the CPU die, while a secondary conventional liquid cooling loop removes heat from the liquid metal circuit. This approach maximizes thermal transfer efficiency while containing the liquid metal within a controlled environment. Intel has developed proprietary surface treatments that prevent liquid metal migration and protect against galvanic corrosion between dissimilar metals. Their system includes precision-engineered micro-channels that optimize flow dynamics and heat transfer coefficients. Intel's liquid metal thermal interface materials (TIMs) have demonstrated up to 10°C lower operating temperatures compared to traditional thermal pastes in high-power density applications[2][5].

Strengths: Exceptional thermal conductivity enables handling of extreme thermal loads from high-performance processors. The dual-loop architecture provides safety redundancy while maximizing cooling efficiency. Weaknesses: Implementation complexity requires precise manufacturing tolerances and specialized handling procedures. Higher initial cost compared to conventional cooling solutions limits widespread adoption outside of high-end applications.

Critical Patents and Innovations in Liquid Metal Cooling

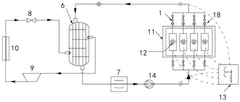

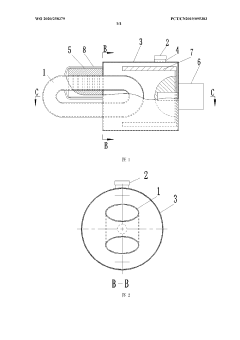

High-efficiency microcircuit thermal control system based on liquid metal cooling

PatentWO2025148566A1

Innovation

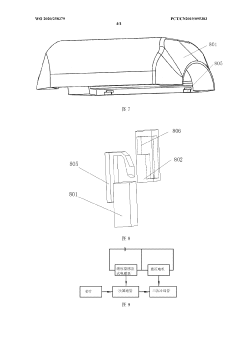

- Liquid metal is used as the cold-carrying working fluid, combined with the vapor compression refrigeration system, a multi-system online platform is designed, and the high thermal conductivity and low viscosity characteristics of liquid metal are used to set up a ridge-shaped micro-ribbing structure arranged in the fork arrangement inside the chip cooling platform to achieve efficient heat exchange between liquid metal and the chip, and the working status of each system is accurately monitored and regulated through an intelligent control system.

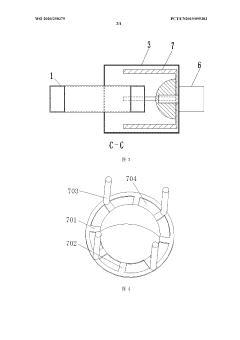

High-power chip closed liquid metal two-loop cooling system

PatentWO2020258379A1

Innovation

- A closed liquid metal secondary loop cooling system is adopted, which uses the primary coolant to transfer heat to the lower-temperature secondary coolant, and regulates the flow rate and radiant stirring through the stirring rod group and adaptive induction electromagnetic pump to improve the heat exchange capacity. Replenish secondary coolant regularly to keep the system stable.

Material Compatibility and Safety Considerations

Material compatibility represents a critical consideration in liquid metal cooling system design for high-power electronics. Gallium-based liquid metals, particularly gallium-indium-tin (GaInSn) alloys, exhibit aggressive corrosion behavior toward most conventional metals. Aluminum components experience particularly severe degradation through rapid amalgamation, resulting in structural failure within minutes of contact. Copper and nickel demonstrate better resistance but still undergo gradual degradation through interdiffusion mechanisms. Refractory metals like tungsten and molybdenum, along with certain ceramics and specialized polymers, offer superior compatibility and are increasingly utilized as protective barriers in critical system components.

Surface treatment technologies have emerged as essential mitigation strategies. Advanced coating methods including physical vapor deposition of titanium nitride, plasma-enhanced chemical vapor deposition of diamond-like carbon, and atomic layer deposition of aluminum oxide create effective diffusion barriers that significantly extend component lifespans. These treatments must maintain thermal conductivity while preventing liquid metal penetration, requiring precise thickness control and defect minimization.

Safety considerations for liquid metal cooling systems extend beyond material degradation. The relatively high density of liquid metals (approximately 6-7 g/cm³) necessitates robust structural support and careful flow management to prevent mechanical failures. Gallium's unique property of volume expansion during solidification (approximately 3.2%) creates additional design challenges, requiring expansion chambers and freeze-prevention systems to avoid catastrophic pressure buildup during thermal cycling.

Toxicological profiles of liquid metal coolants demand comprehensive risk assessment. While gallium-based alloys exhibit lower acute toxicity compared to mercury, their long-term environmental impacts remain under investigation. Workplace exposure guidelines typically recommend maintaining airborne concentrations below 0.1 mg/m³ for an 8-hour time-weighted average. Containment systems must incorporate redundant sealing mechanisms, leak detection sensors, and appropriate collection systems to manage potential releases.

Electrical safety presents another critical dimension, as liquid metals maintain excellent electrical conductivity. System designs must incorporate comprehensive electrical isolation strategies, including dielectric barriers between liquid metal pathways and electrical components. Proper grounding schemes prevent potential differences that could lead to electrolytic corrosion or electrical hazards during maintenance operations. These considerations become particularly important in high-voltage applications where breakdown voltages and insulation coordination require careful engineering.

Surface treatment technologies have emerged as essential mitigation strategies. Advanced coating methods including physical vapor deposition of titanium nitride, plasma-enhanced chemical vapor deposition of diamond-like carbon, and atomic layer deposition of aluminum oxide create effective diffusion barriers that significantly extend component lifespans. These treatments must maintain thermal conductivity while preventing liquid metal penetration, requiring precise thickness control and defect minimization.

Safety considerations for liquid metal cooling systems extend beyond material degradation. The relatively high density of liquid metals (approximately 6-7 g/cm³) necessitates robust structural support and careful flow management to prevent mechanical failures. Gallium's unique property of volume expansion during solidification (approximately 3.2%) creates additional design challenges, requiring expansion chambers and freeze-prevention systems to avoid catastrophic pressure buildup during thermal cycling.

Toxicological profiles of liquid metal coolants demand comprehensive risk assessment. While gallium-based alloys exhibit lower acute toxicity compared to mercury, their long-term environmental impacts remain under investigation. Workplace exposure guidelines typically recommend maintaining airborne concentrations below 0.1 mg/m³ for an 8-hour time-weighted average. Containment systems must incorporate redundant sealing mechanisms, leak detection sensors, and appropriate collection systems to manage potential releases.

Electrical safety presents another critical dimension, as liquid metals maintain excellent electrical conductivity. System designs must incorporate comprehensive electrical isolation strategies, including dielectric barriers between liquid metal pathways and electrical components. Proper grounding schemes prevent potential differences that could lead to electrolytic corrosion or electrical hazards during maintenance operations. These considerations become particularly important in high-voltage applications where breakdown voltages and insulation coordination require careful engineering.

Thermal Performance Benchmarking Methodologies

Establishing robust thermal performance benchmarking methodologies is critical for evaluating liquid metal cooling systems in high-power electronics applications. These methodologies must provide standardized frameworks for comparing different cooling solutions across various operational conditions and device configurations.

The primary benchmarking parameters include thermal resistance (°C/W), which quantifies a cooling system's ability to transfer heat away from electronic components. Lower thermal resistance values indicate superior cooling performance. Junction-to-ambient thermal resistance represents the total thermal path from the semiconductor junction to the ambient environment, serving as a comprehensive metric for overall cooling efficiency.

Heat flux handling capability (W/cm²) constitutes another essential benchmark, measuring the maximum heat energy a cooling system can dissipate per unit area. This parameter is particularly relevant for high-power density applications where thermal management challenges are most acute. Modern liquid metal cooling systems typically demonstrate capabilities exceeding 500 W/cm², significantly outperforming conventional cooling technologies.

Temperature uniformity assessment represents a critical benchmarking dimension often overlooked in conventional analyses. Non-uniform cooling can create thermal gradients across electronic components, potentially leading to mechanical stress, reliability issues, and performance degradation. Standard deviation of temperature across the cooled surface provides a quantitative measure of cooling uniformity.

Transient thermal response testing evaluates how quickly a cooling system can stabilize temperatures during power fluctuations. This involves measuring temperature rise times and thermal time constants under step-change power inputs. For high-performance computing and telecommunications applications where computational loads vary dynamically, superior transient response characteristics are essential.

Pumping power efficiency metrics establish the relationship between cooling performance and energy consumption. The coefficient of performance (COP), calculated as the ratio of heat removed to pumping power required, enables direct comparison between different liquid metal cooling implementations. Higher COP values indicate more energy-efficient cooling solutions.

Long-term stability testing protocols must assess performance degradation over time, particularly focusing on liquid metal oxidation, channel corrosion, and pump reliability. Accelerated life testing under elevated temperatures and thermal cycling provides insights into system durability and maintenance requirements.

Standardized testing conditions should include ambient temperature ranges (typically 20-40°C), controlled humidity levels, and specified power profiles that simulate real-world operational scenarios. These conditions ensure reproducibility and comparability of benchmark results across different research institutions and manufacturing environments.

The primary benchmarking parameters include thermal resistance (°C/W), which quantifies a cooling system's ability to transfer heat away from electronic components. Lower thermal resistance values indicate superior cooling performance. Junction-to-ambient thermal resistance represents the total thermal path from the semiconductor junction to the ambient environment, serving as a comprehensive metric for overall cooling efficiency.

Heat flux handling capability (W/cm²) constitutes another essential benchmark, measuring the maximum heat energy a cooling system can dissipate per unit area. This parameter is particularly relevant for high-power density applications where thermal management challenges are most acute. Modern liquid metal cooling systems typically demonstrate capabilities exceeding 500 W/cm², significantly outperforming conventional cooling technologies.

Temperature uniformity assessment represents a critical benchmarking dimension often overlooked in conventional analyses. Non-uniform cooling can create thermal gradients across electronic components, potentially leading to mechanical stress, reliability issues, and performance degradation. Standard deviation of temperature across the cooled surface provides a quantitative measure of cooling uniformity.

Transient thermal response testing evaluates how quickly a cooling system can stabilize temperatures during power fluctuations. This involves measuring temperature rise times and thermal time constants under step-change power inputs. For high-performance computing and telecommunications applications where computational loads vary dynamically, superior transient response characteristics are essential.

Pumping power efficiency metrics establish the relationship between cooling performance and energy consumption. The coefficient of performance (COP), calculated as the ratio of heat removed to pumping power required, enables direct comparison between different liquid metal cooling implementations. Higher COP values indicate more energy-efficient cooling solutions.

Long-term stability testing protocols must assess performance degradation over time, particularly focusing on liquid metal oxidation, channel corrosion, and pump reliability. Accelerated life testing under elevated temperatures and thermal cycling provides insights into system durability and maintenance requirements.

Standardized testing conditions should include ambient temperature ranges (typically 20-40°C), controlled humidity levels, and specified power profiles that simulate real-world operational scenarios. These conditions ensure reproducibility and comparability of benchmark results across different research institutions and manufacturing environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!