Adsorption Technologies For VOC Removal: Activated Carbon Versus Zeolites

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

VOC Removal Background and Objectives

Volatile Organic Compounds (VOCs) represent a significant environmental and health concern globally, with their emissions stemming from various industrial processes, transportation activities, and consumer products. These compounds, characterized by their high vapor pressure at room temperature, contribute substantially to air pollution, formation of ground-level ozone, and various adverse health effects ranging from eye irritation to more severe respiratory and neurological disorders.

The historical trajectory of VOC control technologies has evolved significantly over the past several decades. Initial approaches in the 1970s focused primarily on end-of-pipe solutions with limited efficiency. The 1980s and 1990s witnessed the emergence of more sophisticated treatment methods, including thermal oxidation, catalytic oxidation, and adsorption technologies, which have since become mainstream solutions.

Among these technologies, adsorption has gained particular prominence due to its versatility, cost-effectiveness, and efficiency in removing VOCs from gas streams. The principle of adsorption involves the accumulation of gas molecules on the surface of a solid material, driven by physical forces (physisorption) or chemical bonds (chemisorption). This mechanism allows for the capture and concentration of VOCs from dilute gas streams, facilitating their subsequent recovery or destruction.

Activated carbon has traditionally dominated the adsorption landscape for VOC removal, owing to its high surface area, well-developed pore structure, and relatively low cost. However, zeolites have emerged as compelling alternatives, offering unique advantages such as uniform pore size distribution, thermal stability, and selectivity for specific VOC molecules.

The primary objective of this technical research report is to conduct a comprehensive comparative analysis of activated carbon and zeolite-based adsorption technologies for VOC removal. This analysis aims to evaluate their respective performance characteristics, operational parameters, economic considerations, and environmental impacts across various industrial applications.

Furthermore, this report seeks to identify the technological trends shaping the evolution of these adsorption materials, including recent innovations in material synthesis, surface modification techniques, and hybrid systems that combine multiple treatment approaches. The integration of adsorption technologies with emerging concepts such as circular economy principles and sustainable manufacturing practices represents a particularly promising direction for future development.

By examining the strengths and limitations of both activated carbon and zeolites in VOC removal applications, this report aims to provide valuable insights for technology selection, optimization strategies, and potential research directions to address the growing challenges of VOC emissions in an increasingly environmentally conscious industrial landscape.

The historical trajectory of VOC control technologies has evolved significantly over the past several decades. Initial approaches in the 1970s focused primarily on end-of-pipe solutions with limited efficiency. The 1980s and 1990s witnessed the emergence of more sophisticated treatment methods, including thermal oxidation, catalytic oxidation, and adsorption technologies, which have since become mainstream solutions.

Among these technologies, adsorption has gained particular prominence due to its versatility, cost-effectiveness, and efficiency in removing VOCs from gas streams. The principle of adsorption involves the accumulation of gas molecules on the surface of a solid material, driven by physical forces (physisorption) or chemical bonds (chemisorption). This mechanism allows for the capture and concentration of VOCs from dilute gas streams, facilitating their subsequent recovery or destruction.

Activated carbon has traditionally dominated the adsorption landscape for VOC removal, owing to its high surface area, well-developed pore structure, and relatively low cost. However, zeolites have emerged as compelling alternatives, offering unique advantages such as uniform pore size distribution, thermal stability, and selectivity for specific VOC molecules.

The primary objective of this technical research report is to conduct a comprehensive comparative analysis of activated carbon and zeolite-based adsorption technologies for VOC removal. This analysis aims to evaluate their respective performance characteristics, operational parameters, economic considerations, and environmental impacts across various industrial applications.

Furthermore, this report seeks to identify the technological trends shaping the evolution of these adsorption materials, including recent innovations in material synthesis, surface modification techniques, and hybrid systems that combine multiple treatment approaches. The integration of adsorption technologies with emerging concepts such as circular economy principles and sustainable manufacturing practices represents a particularly promising direction for future development.

By examining the strengths and limitations of both activated carbon and zeolites in VOC removal applications, this report aims to provide valuable insights for technology selection, optimization strategies, and potential research directions to address the growing challenges of VOC emissions in an increasingly environmentally conscious industrial landscape.

Market Analysis for VOC Adsorption Solutions

The global market for Volatile Organic Compound (VOC) adsorption technologies has experienced significant growth in recent years, driven by increasingly stringent environmental regulations and growing awareness of indoor air quality concerns. The market for VOC removal solutions is projected to reach $3.5 billion by 2027, with a compound annual growth rate of 5.8% from 2022 to 2027.

Industrial sectors represent the largest market segment for VOC adsorption technologies, particularly chemical processing, petrochemical, automotive manufacturing, and pharmaceutical industries. These sectors face strict emission control regulations and require efficient VOC removal systems to maintain compliance. The industrial segment currently accounts for approximately 65% of the total market value.

Commercial and residential applications are emerging as rapidly growing segments, with increasing demand for indoor air quality solutions in office buildings, healthcare facilities, and homes. This growth is particularly pronounced in regions with severe air pollution challenges such as China, India, and parts of Southeast Asia, where the market is expanding at rates exceeding 7% annually.

Geographically, North America and Europe dominate the market due to stringent environmental regulations and mature industrial sectors. However, the Asia-Pacific region is witnessing the fastest growth rate, driven by rapid industrialization, urbanization, and the implementation of stricter environmental policies in countries like China and India.

The activated carbon segment currently holds the largest market share (approximately 58%) due to its versatility, cost-effectiveness, and established supply chains. However, zeolite-based solutions are gaining traction rapidly, with a projected growth rate of 6.5% annually, outpacing the overall market growth.

Key market drivers include increasingly stringent VOC emission regulations worldwide, growing health awareness regarding indoor air quality, and industrial expansion in developing economies. The COVID-19 pandemic has further accelerated market growth by heightening awareness of air quality issues in enclosed spaces.

Market challenges include high initial installation costs for advanced adsorption systems, operational complexities in maintaining optimal performance, and competition from alternative VOC removal technologies such as thermal oxidation and biofiltration. Additionally, the fluctuating costs of raw materials for adsorbent production present challenges for manufacturers in maintaining competitive pricing.

The market is witnessing a trend toward hybrid solutions that combine different adsorption materials to optimize performance for specific VOC profiles, as well as increasing integration of digital monitoring and control systems for enhanced efficiency and reduced operational costs.

Industrial sectors represent the largest market segment for VOC adsorption technologies, particularly chemical processing, petrochemical, automotive manufacturing, and pharmaceutical industries. These sectors face strict emission control regulations and require efficient VOC removal systems to maintain compliance. The industrial segment currently accounts for approximately 65% of the total market value.

Commercial and residential applications are emerging as rapidly growing segments, with increasing demand for indoor air quality solutions in office buildings, healthcare facilities, and homes. This growth is particularly pronounced in regions with severe air pollution challenges such as China, India, and parts of Southeast Asia, where the market is expanding at rates exceeding 7% annually.

Geographically, North America and Europe dominate the market due to stringent environmental regulations and mature industrial sectors. However, the Asia-Pacific region is witnessing the fastest growth rate, driven by rapid industrialization, urbanization, and the implementation of stricter environmental policies in countries like China and India.

The activated carbon segment currently holds the largest market share (approximately 58%) due to its versatility, cost-effectiveness, and established supply chains. However, zeolite-based solutions are gaining traction rapidly, with a projected growth rate of 6.5% annually, outpacing the overall market growth.

Key market drivers include increasingly stringent VOC emission regulations worldwide, growing health awareness regarding indoor air quality, and industrial expansion in developing economies. The COVID-19 pandemic has further accelerated market growth by heightening awareness of air quality issues in enclosed spaces.

Market challenges include high initial installation costs for advanced adsorption systems, operational complexities in maintaining optimal performance, and competition from alternative VOC removal technologies such as thermal oxidation and biofiltration. Additionally, the fluctuating costs of raw materials for adsorbent production present challenges for manufacturers in maintaining competitive pricing.

The market is witnessing a trend toward hybrid solutions that combine different adsorption materials to optimize performance for specific VOC profiles, as well as increasing integration of digital monitoring and control systems for enhanced efficiency and reduced operational costs.

Current Adsorption Technologies and Challenges

Volatile Organic Compounds (VOCs) represent a significant environmental and health concern, necessitating effective removal technologies. Currently, adsorption stands as one of the most widely implemented approaches for VOC control across various industries. The global landscape of VOC removal technologies is dominated by two primary adsorbent materials: activated carbon and zeolites, each with distinct characteristics and performance profiles.

Activated carbon has established itself as the traditional industry standard for VOC adsorption due to its high surface area (typically 500-1500 m²/g) and well-developed pore structure. Its hydrophobic nature makes it particularly effective for organic compound capture in humid environments. However, activated carbon faces several limitations, including reduced efficiency at higher temperatures, potential for spontaneous combustion during regeneration, and limited selectivity among different VOC compounds.

Zeolites, crystalline aluminosilicates with uniform pore structures, have emerged as promising alternatives. Their precisely engineered microporous framework allows for molecular sieving capabilities and higher thermal stability (up to 500°C compared to activated carbon's 200-300°C limit). Modern synthetic zeolites can be tailored with specific pore sizes and surface chemistries to target particular VOC molecules, offering superior selectivity compared to activated carbon.

The current technological landscape reveals a significant challenge in balancing adsorption capacity with regeneration efficiency. While activated carbon typically offers higher overall capacity, zeolites generally demonstrate better regeneration characteristics and longer operational lifespans. This trade-off represents a critical decision point for industrial applications based on specific operational requirements.

Humidity control presents another major challenge, particularly for hydrophilic zeolites where water molecules can compete with VOCs for adsorption sites. Recent innovations have focused on developing hydrophobic zeolites through silica-enrichment and surface modifications to overcome this limitation, though these solutions often come with increased production costs.

Cost considerations remain a significant barrier to widespread adoption of advanced adsorbent technologies. Traditional activated carbon maintains a competitive edge in terms of initial investment (approximately $2-5/kg versus $8-20/kg for specialized zeolites), though total lifecycle analysis increasingly favors zeolites when accounting for regeneration frequency and operational longevity.

Emerging hybrid systems combining both materials represent the cutting edge of current technology, attempting to leverage the complementary strengths of each adsorbent. These systems typically employ activated carbon for high-concentration VOC capture followed by zeolite polishing stages for more complete removal, particularly in applications requiring extremely low outlet concentrations.

Activated carbon has established itself as the traditional industry standard for VOC adsorption due to its high surface area (typically 500-1500 m²/g) and well-developed pore structure. Its hydrophobic nature makes it particularly effective for organic compound capture in humid environments. However, activated carbon faces several limitations, including reduced efficiency at higher temperatures, potential for spontaneous combustion during regeneration, and limited selectivity among different VOC compounds.

Zeolites, crystalline aluminosilicates with uniform pore structures, have emerged as promising alternatives. Their precisely engineered microporous framework allows for molecular sieving capabilities and higher thermal stability (up to 500°C compared to activated carbon's 200-300°C limit). Modern synthetic zeolites can be tailored with specific pore sizes and surface chemistries to target particular VOC molecules, offering superior selectivity compared to activated carbon.

The current technological landscape reveals a significant challenge in balancing adsorption capacity with regeneration efficiency. While activated carbon typically offers higher overall capacity, zeolites generally demonstrate better regeneration characteristics and longer operational lifespans. This trade-off represents a critical decision point for industrial applications based on specific operational requirements.

Humidity control presents another major challenge, particularly for hydrophilic zeolites where water molecules can compete with VOCs for adsorption sites. Recent innovations have focused on developing hydrophobic zeolites through silica-enrichment and surface modifications to overcome this limitation, though these solutions often come with increased production costs.

Cost considerations remain a significant barrier to widespread adoption of advanced adsorbent technologies. Traditional activated carbon maintains a competitive edge in terms of initial investment (approximately $2-5/kg versus $8-20/kg for specialized zeolites), though total lifecycle analysis increasingly favors zeolites when accounting for regeneration frequency and operational longevity.

Emerging hybrid systems combining both materials represent the cutting edge of current technology, attempting to leverage the complementary strengths of each adsorbent. These systems typically employ activated carbon for high-concentration VOC capture followed by zeolite polishing stages for more complete removal, particularly in applications requiring extremely low outlet concentrations.

Activated Carbon vs Zeolites: Technical Comparison

01 Activated carbon adsorption systems for VOC removal

Activated carbon is widely used in VOC removal systems due to its high adsorption capacity and efficiency. These systems typically incorporate activated carbon filters or beds that capture volatile organic compounds from gas streams. The porous structure of activated carbon provides a large surface area for adsorption, making it effective for removing a wide range of VOCs from industrial emissions and indoor air. These systems can be designed with different configurations to optimize the contact time between the gas and the adsorbent material.- Activated carbon adsorption systems for VOC removal: Activated carbon is widely used in VOC removal systems due to its high adsorption capacity and efficiency. These systems typically incorporate activated carbon filters or beds that capture volatile organic compounds from gas streams. The porous structure of activated carbon provides a large surface area for adsorption, making it effective for removing a wide range of VOCs from industrial emissions and indoor air. These systems can be designed with regeneration capabilities to extend the lifespan of the carbon media.

- Zeolite-based adsorption technology for VOC control: Zeolites offer selective adsorption properties for VOC removal due to their uniform pore structure and molecular sieving capabilities. These aluminosilicate materials can be tailored to target specific VOC compounds based on molecular size and polarity. Zeolite-based systems are particularly effective for removing VOCs from humid air streams where activated carbon may be less efficient. The crystalline structure of zeolites allows for efficient regeneration through temperature or pressure swing processes, making them suitable for continuous operation in industrial settings.

- Hybrid adsorption systems combining activated carbon and zeolites: Hybrid systems that integrate both activated carbon and zeolites leverage the complementary properties of both adsorbents to enhance VOC removal efficiency. These systems typically arrange the adsorbents in series or as mixed media to target a broader spectrum of VOC compounds. The activated carbon component provides high capacity for hydrophobic VOCs, while zeolites effectively capture smaller, more polar compounds. This combination approach overcomes the limitations of single-adsorbent systems and offers improved performance across varying operating conditions and contaminant profiles.

- Modular and portable VOC adsorption units: Modular and portable adsorption units have been developed for flexible VOC removal applications. These compact systems incorporate activated carbon, zeolites, or combinations thereof in easily transportable configurations. The modular design allows for scalability and adaptation to different space constraints and treatment requirements. These units are particularly valuable for temporary VOC control needs, emergency response situations, or applications where permanent installation is not feasible. The portable nature enables deployment in various locations while maintaining effective VOC removal capabilities.

- Advanced regeneration techniques for adsorbent materials: Innovative regeneration techniques have been developed to extend the service life of activated carbon and zeolite adsorbents used in VOC removal. These methods include thermal regeneration, pressure swing processes, steam treatment, and microwave-assisted regeneration. Advanced regeneration approaches minimize adsorbent degradation while effectively desorbing captured VOCs for recovery or destruction. Continuous or semi-continuous regeneration systems enable longer operational periods and reduce replacement costs. These techniques improve the overall sustainability and economic viability of adsorption-based VOC control technologies.

02 Zeolite-based adsorption technology for VOC control

Zeolites are crystalline aluminosilicate materials with uniform pore structures that make them highly selective adsorbents for VOC removal. Their molecular sieve properties allow them to separate VOCs based on molecular size and polarity. Zeolite-based systems can be particularly effective for removing specific VOCs that activated carbon might not capture efficiently. These materials can be modified or tailored to enhance their adsorption capacity for particular VOC compounds, providing targeted removal solutions for industrial applications.Expand Specific Solutions03 Combined activated carbon and zeolite adsorption systems

Hybrid systems that combine both activated carbon and zeolites can provide enhanced VOC removal performance. These systems leverage the complementary properties of both adsorbents - the high capacity of activated carbon and the selectivity of zeolites. The combination allows for more comprehensive VOC removal across a wider range of compounds and concentrations. Such hybrid systems can be designed with sequential beds or mixed media configurations to optimize adsorption efficiency and extend operational lifetime before regeneration is required.Expand Specific Solutions04 Regeneration and recovery systems for adsorbents

Advanced VOC removal systems incorporate regeneration technologies to restore the adsorption capacity of saturated activated carbon or zeolites. These systems typically use temperature swing adsorption (TSA), pressure swing adsorption (PSA), or vacuum swing adsorption (VSA) methods to desorb captured VOCs. The regeneration process not only extends the life of the adsorbent materials but can also enable the recovery of valuable VOCs for reuse. Efficient regeneration systems minimize downtime and reduce the operational costs associated with adsorbent replacement.Expand Specific Solutions05 Integrated VOC removal systems with enhanced efficiency

Integrated systems combine adsorption technologies with additional treatment methods to achieve higher VOC removal efficiency. These systems may incorporate pre-treatment stages such as condensation or filtration, or post-treatment processes like catalytic oxidation. The integration of multiple technologies addresses the limitations of individual methods and provides more robust VOC control. Advanced monitoring and control systems optimize the operation of these integrated systems, adjusting parameters based on inlet VOC concentration, humidity, and temperature to maintain removal efficiency while minimizing energy consumption.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The VOC removal technology market is currently in a growth phase, with increasing environmental regulations driving demand. The global market size for VOC control equipment is projected to expand significantly, reaching several billion dollars by 2030. Activated carbon technology represents the mature segment with widespread industrial adoption, while zeolite-based solutions are gaining momentum due to superior thermal stability and selectivity for specific VOCs. Leading research institutions like Korea Research Institute of Chemical Technology and Centre National de la Recherche Scientifique are advancing fundamental understanding, while industrial players such as Sinopec, Mitsubishi Chemical, and LG Chem are commercializing innovative solutions. Academic-industrial partnerships between universities (Taiyuan University of Technology, University of Minho) and companies are accelerating technology transfer and application-specific optimizations.

Korea Research Institute of Chemical Technology

Technical Solution: Korea Research Institute of Chemical Technology (KRICT) has developed advanced zeolite-based VOC removal systems that utilize hierarchical zeolite structures with optimized pore architectures. Their technology combines microporous and mesoporous zeolite frameworks to enhance adsorption capacity and diffusion kinetics. KRICT has pioneered metal-exchanged zeolites (particularly Cu-ZSM-5 and Ag-Y) that demonstrate exceptional selectivity for specific VOC compounds through π-complexation mechanisms. Their research has shown that these modified zeolites can achieve up to 30% higher adsorption capacity for aromatic VOCs compared to conventional activated carbon. Additionally, KRICT has developed hydrophobic zeolite formulations that maintain performance in humid conditions, addressing a critical limitation in traditional zeolite applications. Their regeneration protocols enable multiple adsorption-desorption cycles with minimal loss of capacity (less than 5% after 10 cycles), significantly extending adsorbent lifespan.

Strengths: Superior selectivity for specific VOC compounds, excellent performance in humid conditions, and enhanced regeneration capabilities. Their metal-exchanged zeolites show particular effectiveness for aromatic VOCs in industrial settings. Weaknesses: Higher production costs compared to activated carbon, more complex synthesis procedures, and potential metal leaching during long-term operation that may require additional treatment steps.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a proprietary activated carbon technology for VOC removal that utilizes petroleum-based precursors to create highly microporous carbon structures with surface areas exceeding 1200 m²/g. Their manufacturing process incorporates chemical activation with phosphoric acid and potassium hydroxide to enhance pore development and surface functionality. Sinopec's activated carbon technology features tailored pore size distributions optimized for different VOC molecular weights, with specialized grades for aromatic, aliphatic, and oxygenated compounds. Their honeycomb-structured activated carbon monoliths provide low pressure drop in high flow applications while maintaining high VOC removal efficiency (>95% for BTEX compounds). Sinopec has also developed impregnation techniques using metal oxides (Cu, Mn) to enhance adsorption of specific VOCs through chemisorption mechanisms. Their regeneration system employs temperature swing adsorption with steam stripping, allowing for VOC recovery and adsorbent reuse with minimal degradation over multiple cycles.

Strengths: Cost-effective production using petroleum byproducts as raw materials, excellent adsorption capacity for a broad spectrum of VOCs, and established large-scale manufacturing capabilities. Their activated carbon shows particular effectiveness in high-concentration VOC streams. Weaknesses: Lower selectivity compared to zeolites, reduced performance in humid conditions, and higher energy requirements for regeneration that increase operational costs in long-term applications.

Key Patents and Research in Adsorption Materials

Volatile organic compound adsorbent and adsorption filter renewable by light energy, and manufacturing method thereof

PatentActiveKR1020230061640A

Innovation

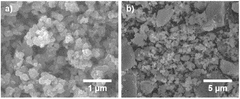

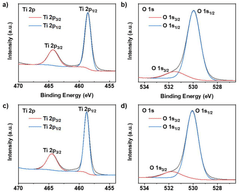

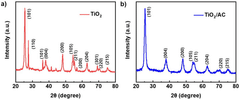

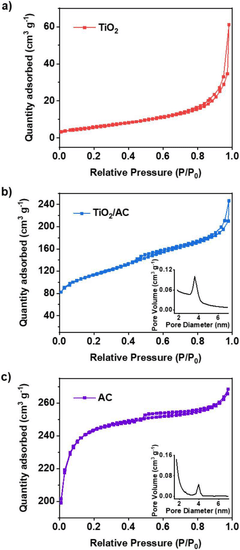

- A composite adsorbent composed of titanium dioxide (TiO2) supported on activated carbon, which regenerates adsorption capacity through light energy irradiation, such as UV rays, maintaining high efficiency and reusability.

Environmental Regulations and Compliance Standards

The regulatory landscape governing Volatile Organic Compounds (VOCs) has evolved significantly over the past decades, creating a complex framework that directly impacts adsorption technology selection and implementation. At the international level, the United Nations Framework Convention on Climate Change and various regional agreements have established broad guidelines for reducing atmospheric pollutants, including VOCs that contribute to ground-level ozone formation and photochemical smog.

In the United States, the Clean Air Act and its amendments form the cornerstone of VOC regulation, with the Environmental Protection Agency (EPA) establishing National Ambient Air Quality Standards (NAAQS) that set permissible concentration limits. The EPA's Maximum Achievable Control Technology (MACT) standards specifically target industrial emissions, requiring facilities to implement the most effective available technologies for VOC reduction, which often includes adsorption systems using either activated carbon or zeolites.

The European Union's regulatory framework is equally stringent, with the Industrial Emissions Directive (IED) and the VOC Solvents Emissions Directive establishing emission limit values and monitoring requirements. These directives have progressively lowered acceptable emission thresholds, driving industries toward more efficient adsorption technologies with higher removal efficiencies.

Asian countries, particularly China and Japan, have recently strengthened their environmental regulations in response to severe air quality challenges. China's Air Pollution Prevention and Control Law now includes specific VOC emission standards for key industries, while Japan's Air Pollution Control Law implements a comprehensive permitting system with technology-based standards.

Compliance standards typically specify performance metrics rather than mandating specific technologies, allowing facilities to select between activated carbon and zeolite adsorption systems based on their particular operational conditions. These standards generally focus on removal efficiency (typically requiring 95-99% for hazardous VOCs), breakthrough time, and total emission load. Many regulations also address secondary concerns such as spent adsorbent disposal and regeneration processes.

Industry-specific regulations create additional complexity, with particularly stringent requirements for pharmaceutical, semiconductor, and chemical manufacturing sectors. These specialized standards often necessitate customized adsorption solutions that leverage the specific advantages of either activated carbon or zeolites depending on the VOC composition and concentration profiles.

The regulatory trend clearly points toward increasingly stringent emission limits and broader coverage of industrial processes, suggesting that future adsorption technologies will need to demonstrate higher efficiency, greater specificity, and improved regeneration capabilities to maintain compliance in a tightening regulatory environment.

In the United States, the Clean Air Act and its amendments form the cornerstone of VOC regulation, with the Environmental Protection Agency (EPA) establishing National Ambient Air Quality Standards (NAAQS) that set permissible concentration limits. The EPA's Maximum Achievable Control Technology (MACT) standards specifically target industrial emissions, requiring facilities to implement the most effective available technologies for VOC reduction, which often includes adsorption systems using either activated carbon or zeolites.

The European Union's regulatory framework is equally stringent, with the Industrial Emissions Directive (IED) and the VOC Solvents Emissions Directive establishing emission limit values and monitoring requirements. These directives have progressively lowered acceptable emission thresholds, driving industries toward more efficient adsorption technologies with higher removal efficiencies.

Asian countries, particularly China and Japan, have recently strengthened their environmental regulations in response to severe air quality challenges. China's Air Pollution Prevention and Control Law now includes specific VOC emission standards for key industries, while Japan's Air Pollution Control Law implements a comprehensive permitting system with technology-based standards.

Compliance standards typically specify performance metrics rather than mandating specific technologies, allowing facilities to select between activated carbon and zeolite adsorption systems based on their particular operational conditions. These standards generally focus on removal efficiency (typically requiring 95-99% for hazardous VOCs), breakthrough time, and total emission load. Many regulations also address secondary concerns such as spent adsorbent disposal and regeneration processes.

Industry-specific regulations create additional complexity, with particularly stringent requirements for pharmaceutical, semiconductor, and chemical manufacturing sectors. These specialized standards often necessitate customized adsorption solutions that leverage the specific advantages of either activated carbon or zeolites depending on the VOC composition and concentration profiles.

The regulatory trend clearly points toward increasingly stringent emission limits and broader coverage of industrial processes, suggesting that future adsorption technologies will need to demonstrate higher efficiency, greater specificity, and improved regeneration capabilities to maintain compliance in a tightening regulatory environment.

Cost-Benefit Analysis of Adsorption Systems

When evaluating adsorption systems for VOC removal, a comprehensive cost-benefit analysis reveals significant economic considerations between activated carbon and zeolite technologies. Initial capital expenditure for activated carbon systems typically ranges from $50,000 to $500,000 depending on scale, while zeolite systems generally command a 20-40% premium due to more complex manufacturing processes and material costs.

Operational expenses present notable differences. Activated carbon systems consume approximately 0.1-0.5 kWh per 1000 m³ of treated air, whereas zeolite systems require 0.3-0.8 kWh for the same volume due to higher pressure drop characteristics. However, zeolites often demonstrate superior regeneration efficiency, requiring 15-25% less energy during thermal regeneration processes compared to activated carbon.

Replacement frequency significantly impacts long-term economics. Activated carbon typically requires replacement every 1-3 years in industrial applications, while zeolites can maintain performance for 3-7 years under similar conditions. This extended service life partially offsets zeolites' higher initial cost, particularly in applications with aggressive contaminants that rapidly degrade carbon media.

Recovery value represents another economic dimension. Certain zeolite systems enable efficient recovery of valuable VOCs at 85-95% purity, creating potential revenue streams that can offset operational costs. Activated carbon systems typically achieve lower recovery rates of 60-80% with additional processing requirements.

Regulatory compliance costs favor technologies with higher removal efficiencies. Zeolites' superior performance for specific compounds (particularly polar VOCs) can reduce compliance risk and associated penalties, which may exceed $10,000 per violation in many jurisdictions.

Total lifecycle assessment indicates that while activated carbon systems present lower barriers to entry with capital costs 20-40% below zeolite alternatives, the 5-year total cost of ownership often converges when accounting for replacement frequency, energy consumption, and recovery value. For facilities processing high-value recoverable solvents, zeolite systems may demonstrate positive ROI within 2-3 years despite higher initial investment.

Market analysis suggests a 7-12% annual growth in advanced adsorption technologies, with zeolite systems gaining market share in high-performance applications where regulatory requirements are stringent or recovered VOCs hold significant value.

Operational expenses present notable differences. Activated carbon systems consume approximately 0.1-0.5 kWh per 1000 m³ of treated air, whereas zeolite systems require 0.3-0.8 kWh for the same volume due to higher pressure drop characteristics. However, zeolites often demonstrate superior regeneration efficiency, requiring 15-25% less energy during thermal regeneration processes compared to activated carbon.

Replacement frequency significantly impacts long-term economics. Activated carbon typically requires replacement every 1-3 years in industrial applications, while zeolites can maintain performance for 3-7 years under similar conditions. This extended service life partially offsets zeolites' higher initial cost, particularly in applications with aggressive contaminants that rapidly degrade carbon media.

Recovery value represents another economic dimension. Certain zeolite systems enable efficient recovery of valuable VOCs at 85-95% purity, creating potential revenue streams that can offset operational costs. Activated carbon systems typically achieve lower recovery rates of 60-80% with additional processing requirements.

Regulatory compliance costs favor technologies with higher removal efficiencies. Zeolites' superior performance for specific compounds (particularly polar VOCs) can reduce compliance risk and associated penalties, which may exceed $10,000 per violation in many jurisdictions.

Total lifecycle assessment indicates that while activated carbon systems present lower barriers to entry with capital costs 20-40% below zeolite alternatives, the 5-year total cost of ownership often converges when accounting for replacement frequency, energy consumption, and recovery value. For facilities processing high-value recoverable solvents, zeolite systems may demonstrate positive ROI within 2-3 years despite higher initial investment.

Market analysis suggests a 7-12% annual growth in advanced adsorption technologies, with zeolite systems gaining market share in high-performance applications where regulatory requirements are stringent or recovered VOCs hold significant value.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!