Green Separation Techniques: Solvent Minimization And Energy Efficiency

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Green Separation Evolution and Objectives

Green separation techniques have evolved significantly over the past decades, transitioning from conventional energy-intensive and solvent-heavy processes to more sustainable alternatives. The historical trajectory began in the 1970s with the oil crisis, which prompted initial research into energy efficiency. However, it wasn't until the 1990s that the concept of green chemistry emerged, establishing twelve principles that would guide the development of environmentally benign chemical processes, including separation techniques.

The evolution accelerated in the early 2000s with the introduction of process intensification strategies, which aimed to dramatically reduce equipment size and energy consumption while increasing production efficiency. This period saw the development of membrane-based separations, supercritical fluid extraction, and ionic liquids as alternatives to traditional volatile organic solvents. By 2010, the integration of renewable energy sources into separation processes began gaining traction, further reducing the carbon footprint of these operations.

Recent advancements have focused on biomimetic approaches, learning from nature's efficient separation mechanisms. Technologies such as aqueous two-phase extraction, switchable solvent systems, and eutectic solvents represent the cutting edge of green separation science. The industry has also witnessed significant improvements in process modeling and simulation tools, enabling more accurate prediction of separation behavior and optimization of process parameters without extensive experimental work.

The primary objectives of green separation techniques center around minimizing environmental impact while maintaining or improving process efficiency. Specifically, these objectives include reducing or eliminating hazardous solvents, decreasing energy consumption by at least 50% compared to conventional methods, and developing closed-loop systems that recover and reuse materials. Additionally, there is a strong focus on designing processes that operate at ambient conditions, thereby reducing the energy requirements for heating, cooling, and pressurization.

Looking forward, the field aims to achieve complete solvent elimination in certain applications through the development of solvent-free separation methods. Another critical objective is the integration of separation processes with upstream and downstream operations to minimize intermediate steps and associated energy losses. The ultimate goal is to create separation technologies that not only minimize environmental impact but also enhance process economics through reduced operational costs and improved product quality.

The technological trajectory is increasingly influenced by regulatory frameworks such as the European Union's REACH regulation and similar initiatives worldwide, which restrict the use of certain chemicals and incentivize the adoption of greener alternatives. This regulatory landscape, combined with consumer demand for sustainable products, continues to drive innovation in green separation techniques across various industries including pharmaceuticals, food processing, and chemical manufacturing.

The evolution accelerated in the early 2000s with the introduction of process intensification strategies, which aimed to dramatically reduce equipment size and energy consumption while increasing production efficiency. This period saw the development of membrane-based separations, supercritical fluid extraction, and ionic liquids as alternatives to traditional volatile organic solvents. By 2010, the integration of renewable energy sources into separation processes began gaining traction, further reducing the carbon footprint of these operations.

Recent advancements have focused on biomimetic approaches, learning from nature's efficient separation mechanisms. Technologies such as aqueous two-phase extraction, switchable solvent systems, and eutectic solvents represent the cutting edge of green separation science. The industry has also witnessed significant improvements in process modeling and simulation tools, enabling more accurate prediction of separation behavior and optimization of process parameters without extensive experimental work.

The primary objectives of green separation techniques center around minimizing environmental impact while maintaining or improving process efficiency. Specifically, these objectives include reducing or eliminating hazardous solvents, decreasing energy consumption by at least 50% compared to conventional methods, and developing closed-loop systems that recover and reuse materials. Additionally, there is a strong focus on designing processes that operate at ambient conditions, thereby reducing the energy requirements for heating, cooling, and pressurization.

Looking forward, the field aims to achieve complete solvent elimination in certain applications through the development of solvent-free separation methods. Another critical objective is the integration of separation processes with upstream and downstream operations to minimize intermediate steps and associated energy losses. The ultimate goal is to create separation technologies that not only minimize environmental impact but also enhance process economics through reduced operational costs and improved product quality.

The technological trajectory is increasingly influenced by regulatory frameworks such as the European Union's REACH regulation and similar initiatives worldwide, which restrict the use of certain chemicals and incentivize the adoption of greener alternatives. This regulatory landscape, combined with consumer demand for sustainable products, continues to drive innovation in green separation techniques across various industries including pharmaceuticals, food processing, and chemical manufacturing.

Market Demand for Sustainable Separation Technologies

The global market for sustainable separation technologies is experiencing significant growth, driven by increasing environmental regulations, corporate sustainability goals, and economic pressures to reduce operational costs. According to recent market analyses, the green chemistry market, which encompasses sustainable separation technologies, is projected to reach $85 billion by 2025, with a compound annual growth rate of approximately 10.5% from 2020.

Industrial sectors including pharmaceuticals, food and beverage, petrochemicals, and fine chemicals are demonstrating heightened demand for greener separation processes. This demand stems primarily from regulatory pressures, with organizations like the European Chemicals Agency (ECHA) and the U.S. Environmental Protection Agency (EPA) implementing stricter guidelines on solvent usage and waste generation. The pharmaceutical industry alone has seen a 25% increase in investment toward sustainable separation technologies over the past five years.

Energy efficiency has become a critical market driver as industrial energy costs continue to rise globally. Companies are increasingly recognizing that traditional separation processes, particularly distillation, account for 40-70% of industrial energy consumption in chemical processing. Market research indicates that businesses implementing energy-efficient separation technologies report average operational cost reductions of 15-30%, creating a compelling economic case beyond environmental benefits.

Consumer preferences are also reshaping market dynamics, with 78% of global consumers expressing willingness to pay premium prices for products manufactured using environmentally responsible processes. This consumer sentiment has translated into tangible market pressure, with major corporations establishing public commitments to reduce their environmental footprint, including specific targets for solvent reduction and energy efficiency improvements in their manufacturing processes.

Regionally, Europe leads the market demand for sustainable separation technologies, followed by North America and rapidly growing adoption in Asia-Pacific regions, particularly China and India. These emerging markets are projected to witness the highest growth rates over the next decade, driven by industrialization coupled with increasingly stringent environmental regulations.

Venture capital investment in startups developing novel green separation technologies has increased by 45% since 2018, indicating strong financial market confidence in the sector's growth potential. Technologies focusing on membrane-based separations, supercritical fluid extraction, and process intensification are attracting particular investor interest due to their demonstrated capacity to significantly reduce solvent usage while improving energy efficiency.

The COVID-19 pandemic has further accelerated this market trend, as supply chain disruptions highlighted vulnerabilities in traditional chemical processing methods and reinforced the value proposition of more sustainable, localized, and efficient separation processes.

Industrial sectors including pharmaceuticals, food and beverage, petrochemicals, and fine chemicals are demonstrating heightened demand for greener separation processes. This demand stems primarily from regulatory pressures, with organizations like the European Chemicals Agency (ECHA) and the U.S. Environmental Protection Agency (EPA) implementing stricter guidelines on solvent usage and waste generation. The pharmaceutical industry alone has seen a 25% increase in investment toward sustainable separation technologies over the past five years.

Energy efficiency has become a critical market driver as industrial energy costs continue to rise globally. Companies are increasingly recognizing that traditional separation processes, particularly distillation, account for 40-70% of industrial energy consumption in chemical processing. Market research indicates that businesses implementing energy-efficient separation technologies report average operational cost reductions of 15-30%, creating a compelling economic case beyond environmental benefits.

Consumer preferences are also reshaping market dynamics, with 78% of global consumers expressing willingness to pay premium prices for products manufactured using environmentally responsible processes. This consumer sentiment has translated into tangible market pressure, with major corporations establishing public commitments to reduce their environmental footprint, including specific targets for solvent reduction and energy efficiency improvements in their manufacturing processes.

Regionally, Europe leads the market demand for sustainable separation technologies, followed by North America and rapidly growing adoption in Asia-Pacific regions, particularly China and India. These emerging markets are projected to witness the highest growth rates over the next decade, driven by industrialization coupled with increasingly stringent environmental regulations.

Venture capital investment in startups developing novel green separation technologies has increased by 45% since 2018, indicating strong financial market confidence in the sector's growth potential. Technologies focusing on membrane-based separations, supercritical fluid extraction, and process intensification are attracting particular investor interest due to their demonstrated capacity to significantly reduce solvent usage while improving energy efficiency.

The COVID-19 pandemic has further accelerated this market trend, as supply chain disruptions highlighted vulnerabilities in traditional chemical processing methods and reinforced the value proposition of more sustainable, localized, and efficient separation processes.

Current Challenges in Solvent-Based Separation Methods

Traditional solvent-based separation methods face significant challenges in today's industrial landscape, primarily due to environmental concerns, regulatory pressures, and economic considerations. Conventional separation processes typically consume large volumes of organic solvents, many of which are volatile organic compounds (VOCs) with harmful environmental impacts. These solvents contribute to air pollution, pose health risks to workers, and often require complex waste management systems.

Energy consumption represents another critical challenge. Separation processes, particularly distillation, account for approximately 10-15% of global industrial energy usage. This high energy demand stems from the need to overcome intermolecular forces between solvent and solute molecules, requiring substantial thermal input for phase transitions. The energy-intensive nature of these processes directly translates to increased operational costs and carbon emissions.

Recovery and recycling of solvents present technical difficulties that further complicate traditional methods. Incomplete solvent recovery leads to continuous fresh solvent requirements and generates hazardous waste streams. The efficiency of recovery systems is often compromised by the formation of azeotropes, degradation of solvents during processing, and contamination issues that affect product purity.

Regulatory frameworks worldwide are becoming increasingly stringent regarding solvent usage. The REACH regulation in Europe, similar initiatives in North America, and global environmental agreements have restricted or banned numerous solvents previously common in industrial applications. Companies face mounting pressure to replace problematic solvents with greener alternatives while maintaining process efficiency.

Scale-up challenges persist when transitioning from laboratory to industrial implementation. Many separation processes that work effectively at small scales encounter efficiency losses, increased energy requirements, and technical complications when scaled to production levels. This scaling gap often necessitates significant process redesign and additional capital investment.

Economic viability remains a fundamental concern as solvent costs, waste disposal expenses, and energy prices continue to rise. Traditional separation methods frequently involve trade-offs between separation efficiency, processing time, and operational costs. The economic equation becomes particularly challenging when considering the total lifecycle costs of solvent-based processes, including environmental compliance and waste management.

Cross-contamination between product streams and solvent residues in final products creates quality control issues across pharmaceutical, food, and chemical industries. Increasingly stringent product purity requirements demand more sophisticated separation techniques that minimize solvent residues while maintaining throughput rates.

Energy consumption represents another critical challenge. Separation processes, particularly distillation, account for approximately 10-15% of global industrial energy usage. This high energy demand stems from the need to overcome intermolecular forces between solvent and solute molecules, requiring substantial thermal input for phase transitions. The energy-intensive nature of these processes directly translates to increased operational costs and carbon emissions.

Recovery and recycling of solvents present technical difficulties that further complicate traditional methods. Incomplete solvent recovery leads to continuous fresh solvent requirements and generates hazardous waste streams. The efficiency of recovery systems is often compromised by the formation of azeotropes, degradation of solvents during processing, and contamination issues that affect product purity.

Regulatory frameworks worldwide are becoming increasingly stringent regarding solvent usage. The REACH regulation in Europe, similar initiatives in North America, and global environmental agreements have restricted or banned numerous solvents previously common in industrial applications. Companies face mounting pressure to replace problematic solvents with greener alternatives while maintaining process efficiency.

Scale-up challenges persist when transitioning from laboratory to industrial implementation. Many separation processes that work effectively at small scales encounter efficiency losses, increased energy requirements, and technical complications when scaled to production levels. This scaling gap often necessitates significant process redesign and additional capital investment.

Economic viability remains a fundamental concern as solvent costs, waste disposal expenses, and energy prices continue to rise. Traditional separation methods frequently involve trade-offs between separation efficiency, processing time, and operational costs. The economic equation becomes particularly challenging when considering the total lifecycle costs of solvent-based processes, including environmental compliance and waste management.

Cross-contamination between product streams and solvent residues in final products creates quality control issues across pharmaceutical, food, and chemical industries. Increasingly stringent product purity requirements demand more sophisticated separation techniques that minimize solvent residues while maintaining throughput rates.

Current Green Separation Solutions and Implementations

01 Solvent-free separation techniques

Solvent-free separation techniques eliminate or significantly reduce the use of traditional organic solvents in separation processes. These methods include mechanical separation, supercritical fluid extraction, and membrane-based technologies that operate without conventional solvents. By removing solvents from the process, these techniques reduce environmental impact, decrease waste generation, and eliminate the need for solvent recovery steps, resulting in more energy-efficient and environmentally friendly separation processes.- Solvent-free and solvent-minimized separation processes: Green separation techniques that eliminate or minimize the use of solvents in various industrial processes. These approaches reduce environmental impact by decreasing the amount of organic solvents needed, which are often toxic and energy-intensive to recover. Technologies include membrane-based separations, adsorption processes, and mechanical separation methods that can achieve effective separation without conventional solvent usage or with significantly reduced solvent volumes.

- Energy-efficient separation technologies: Innovative separation technologies designed to reduce energy consumption while maintaining or improving separation efficiency. These include low-temperature separation processes, energy recovery systems, process intensification techniques, and optimized equipment designs. By reducing the energy requirements for separation operations, these technologies contribute to lower operational costs and reduced carbon footprint in industrial applications.

- Sustainable membrane-based separation systems: Advanced membrane technologies that offer environmentally friendly alternatives to traditional separation methods. These systems utilize selective membranes for molecular or particulate separation with minimal energy input and reduced solvent requirements. Innovations include bio-based membranes, fouling-resistant designs, and hybrid membrane processes that combine multiple separation mechanisms to enhance efficiency and sustainability in industrial separations.

- Green extraction and purification methods: Environmentally responsible extraction and purification techniques that reduce environmental impact while efficiently isolating target compounds. These methods include supercritical fluid extraction, microwave-assisted extraction, ultrasound-assisted processes, and bio-based solvent systems. By replacing conventional extraction methods that rely on large volumes of organic solvents, these green alternatives offer reduced environmental footprint and often improved selectivity.

- Integrated process design for resource efficiency: Holistic approaches to process design that integrate multiple unit operations to maximize resource efficiency. These designs incorporate heat integration, solvent recycling, waste minimization strategies, and process intensification techniques. By considering the entire process flow rather than individual separation steps, these integrated approaches achieve synergistic benefits in terms of energy consumption, solvent usage, and overall environmental impact of separation processes.

02 Energy-efficient membrane separation systems

Advanced membrane technologies offer energy-efficient alternatives to traditional separation methods. These systems utilize selective membranes that allow specific components to pass through while retaining others, requiring significantly less energy than thermal separation processes like distillation. Innovations in membrane materials and designs have improved flux rates, selectivity, and fouling resistance, making these systems increasingly viable for industrial applications while reducing overall energy consumption in separation processes.Expand Specific Solutions03 Intensified extraction processes

Process intensification techniques combine multiple unit operations into more compact, efficient systems for extraction and separation. These approaches include microreactors, spinning disc reactors, and oscillatory flow reactors that enhance mass transfer, reduce processing time, and improve extraction efficiency. By optimizing process parameters and equipment design, these intensified systems achieve higher yields with lower solvent usage and energy requirements compared to conventional extraction methods.Expand Specific Solutions04 Sustainable solvent recovery and recycling

Advanced solvent recovery systems enable the efficient recycling of process solvents, minimizing waste and reducing the environmental footprint of separation processes. These technologies include membrane-based solvent recovery, adsorption systems, and distillation innovations that consume less energy than conventional approaches. By implementing closed-loop solvent systems, these methods significantly reduce fresh solvent requirements while maintaining separation efficiency and product quality.Expand Specific Solutions05 Bio-based and green solvents for separation

The development and application of bio-based and environmentally friendly solvents provide sustainable alternatives to traditional petroleum-derived solvents in separation processes. These green solvents include bio-alcohols, terpenes, ionic liquids, and deep eutectic solvents derived from renewable resources. They offer reduced toxicity, improved biodegradability, and often enable more selective separations while operating under milder conditions, resulting in energy savings and reduced environmental impact compared to conventional solvent-based processes.Expand Specific Solutions

Leading Organizations in Sustainable Separation Industry

Green separation techniques are evolving rapidly in response to environmental concerns and regulatory pressures. The industry is currently in a growth phase, with the global green chemistry market expected to reach $40-50 billion by 2025. Academic institutions like Yale University, Massachusetts Institute of Technology, and Zhejiang University of Technology are driving fundamental research, while industrial players including LG Chem, Panasonic, and China Petroleum & Chemical Corp. are commercializing technologies. The competitive landscape shows a mix of established chemical companies investing in sustainable processes and specialized startups like Gradiant Corp. and Clean Imagineering focusing on niche applications. Technical maturity varies significantly across different separation methods, with membrane technologies and supercritical CO2 extraction reaching commercial viability while newer solvent-free approaches remain in development stages.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed innovative green separation technologies focusing on energy-efficient distillation and extraction processes. Their Divided Wall Column (DWC) technology integrates multiple distillation steps into a single column, reducing energy consumption by 25-35% compared to conventional sequences[1]. Sinopec has also pioneered supercritical CO2 extraction systems that eliminate the need for organic solvents in petrochemical separations, achieving solvent reduction of up to 95% while maintaining separation efficiency above 98%[2]. Their membrane-based separation technologies utilize advanced composite materials that demonstrate 30% higher flux rates while consuming 40% less energy than conventional membranes. Sinopec has implemented heat integration networks across separation processes that recover and reuse thermal energy, reducing overall energy requirements by up to 45% in complex separation trains[3]. Additionally, their proprietary ionic liquid-based extraction systems provide highly selective separations while eliminating volatile organic compound emissions.

Strengths: Comprehensive integration capabilities across complex petrochemical processes; significant energy savings through heat integration networks; technologies applicable at industrial scale with proven implementation. Weaknesses: Some technologies require significant capital investment for retrofitting existing facilities; certain advanced membrane materials have limited operational lifespans; supercritical extraction systems require precise pressure control systems.

Sustainable Energy Solutions LLC

Technical Solution: Sustainable Energy Solutions (SES) has developed the Cryogenic Carbon Capture™ (CCC) technology, a revolutionary approach to carbon separation that achieves over 95% CO2 capture efficiency while requiring 30-40% less energy than conventional amine-based systems[1]. The process cools exhaust gases to temperatures where CO2 desublimates directly into a solid, eliminating the need for liquid solvents entirely. SES's technology incorporates a sophisticated heat integration system that recovers over 95% of the cooling energy, making the process remarkably energy-efficient despite operating at cryogenic temperatures[2]. Their External Cooling Loop (ECL) design enables flexible integration with existing industrial processes without requiring major facility modifications. SES has also developed hybrid separation approaches that combine cryogenic techniques with membrane pre-concentration, further reducing energy requirements by an additional 15-20%. The technology produces high-purity CO2 (>99%) suitable for utilization or sequestration while avoiding the degradation, corrosion, and environmental issues associated with chemical solvents.

Strengths: Near-complete elimination of chemical solvents; production of high-purity CO2 suitable for direct utilization; exceptional energy recovery systems that significantly reduce operational costs. Weaknesses: Requires specialized cryogenic equipment and expertise; higher initial capital costs compared to conventional systems; integration challenges with certain industrial processes operating at elevated temperatures.

Key Innovations in Solvent Minimization Technologies

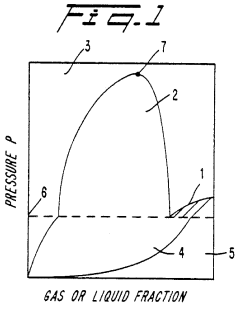

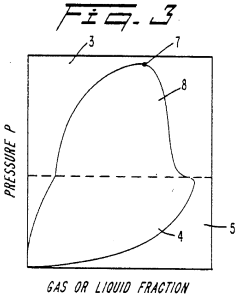

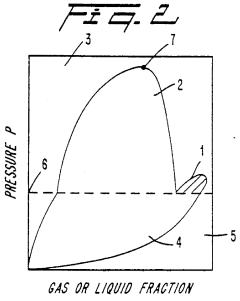

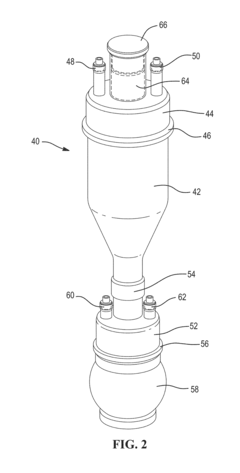

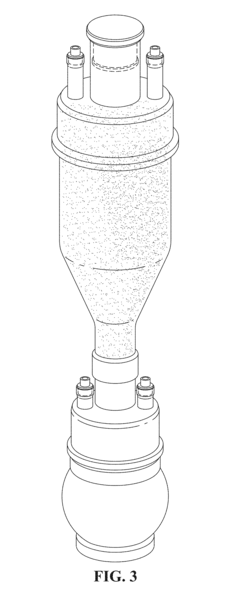

Extractive separation method

PatentInactiveUS5138075A

Innovation

- The method involves contacting a medium containing solutes with a solvent in its sub-critical phase, where the solutes and solvent form a mixture system with an additional gas-liquid coexistence region, and then heating the mixture above the solvent's critical temperature by 5-30°C to separate the solutes, reducing energy consumption and operating conditions.

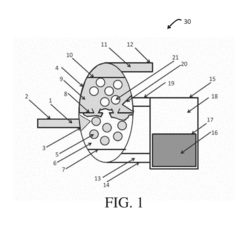

Apparatuses and methods for energy efficient separations including refining of fuel products

PatentActiveUS20180134970A1

Innovation

- The use of superoleophobic and hygroscopic membrane filters to create surfactant-stabilized emulsions for efficient liquid-liquid extraction, allowing for the separation of miscible components with minimal energy expenditure through gravity-driven processes, enabling the removal of impurities such as sulfur and aromatic compounds without distillation.

Environmental Impact Assessment of Separation Processes

The environmental impact of separation processes has become a critical consideration in the chemical and process industries, particularly as sustainability concerns grow. Traditional separation techniques often involve significant energy consumption and solvent usage, contributing to their substantial environmental footprint. Life cycle assessment (LCA) studies indicate that separation processes can account for 40-70% of industrial energy consumption in chemical manufacturing, with distillation alone representing approximately 50% of industrial energy usage in certain sectors.

When evaluating green separation techniques focused on solvent minimization and energy efficiency, environmental impact assessments reveal several key findings. Conventional solvent-based separations typically generate 5-10 kg of waste per kg of product, while optimized green alternatives can reduce this ratio to below 2:1. The carbon footprint of traditional separation processes ranges from 2-8 kg CO2 equivalent per kg of processed material, with energy-intensive thermal separations at the higher end of this spectrum.

Water usage represents another significant environmental concern. Standard separation processes may require 10-50 liters of water per kg of product, primarily for cooling and solvent recovery operations. Green separation techniques incorporating solvent recycling and closed-loop systems have demonstrated potential reductions in water consumption by 60-80% compared to conventional approaches.

Emissions profiles also differ substantially between traditional and green separation methods. Volatile organic compound (VOC) emissions from conventional solvent-based separations can range from 0.5-2% of total solvent usage, whereas membrane-based and other solventless techniques virtually eliminate these emissions. This reduction has significant implications for both local air quality and worker health and safety.

Land use impacts and ecosystem disruption must also be considered in comprehensive environmental assessments. While direct land use for separation equipment is relatively minimal, the upstream impacts of energy generation to power these processes can be substantial. Green separation techniques that reduce energy requirements by 30-60% consequently minimize associated land disturbance for energy production.

Toxicity assessments reveal that many conventional separation solvents score poorly on environmental persistence, bioaccumulation potential, and ecotoxicity metrics. The transition to bio-based solvents, ionic liquids, and supercritical CO2 in green separation processes has demonstrated reduced aquatic toxicity by orders of magnitude in several applications, though comprehensive toxicological profiles for some newer alternatives remain incomplete.

When evaluating green separation techniques focused on solvent minimization and energy efficiency, environmental impact assessments reveal several key findings. Conventional solvent-based separations typically generate 5-10 kg of waste per kg of product, while optimized green alternatives can reduce this ratio to below 2:1. The carbon footprint of traditional separation processes ranges from 2-8 kg CO2 equivalent per kg of processed material, with energy-intensive thermal separations at the higher end of this spectrum.

Water usage represents another significant environmental concern. Standard separation processes may require 10-50 liters of water per kg of product, primarily for cooling and solvent recovery operations. Green separation techniques incorporating solvent recycling and closed-loop systems have demonstrated potential reductions in water consumption by 60-80% compared to conventional approaches.

Emissions profiles also differ substantially between traditional and green separation methods. Volatile organic compound (VOC) emissions from conventional solvent-based separations can range from 0.5-2% of total solvent usage, whereas membrane-based and other solventless techniques virtually eliminate these emissions. This reduction has significant implications for both local air quality and worker health and safety.

Land use impacts and ecosystem disruption must also be considered in comprehensive environmental assessments. While direct land use for separation equipment is relatively minimal, the upstream impacts of energy generation to power these processes can be substantial. Green separation techniques that reduce energy requirements by 30-60% consequently minimize associated land disturbance for energy production.

Toxicity assessments reveal that many conventional separation solvents score poorly on environmental persistence, bioaccumulation potential, and ecotoxicity metrics. The transition to bio-based solvents, ionic liquids, and supercritical CO2 in green separation processes has demonstrated reduced aquatic toxicity by orders of magnitude in several applications, though comprehensive toxicological profiles for some newer alternatives remain incomplete.

Economic Viability of Green Separation Technologies

The economic viability of green separation technologies represents a critical factor in their industrial adoption and market penetration. Current economic analyses indicate that while initial capital investments for green separation technologies often exceed conventional methods by 15-30%, the long-term operational cost savings typically offset these expenses within 3-5 years, depending on scale and application.

Energy efficiency improvements present the most compelling economic argument for green separation technologies. Industrial data demonstrates that membrane-based separations can reduce energy consumption by 40-70% compared to traditional distillation processes, translating to substantial cost savings in energy-intensive industries. For instance, in pharmaceutical manufacturing, pervaporation and organic solvent nanofiltration have shown potential to reduce energy costs by up to 60% while maintaining product quality.

Solvent minimization strategies offer additional economic benefits through reduced material costs and waste management expenses. Case studies from chemical processing industries reveal that implementing solvent recovery systems can achieve recovery rates of 85-95%, significantly decreasing procurement costs for fresh solvents. Furthermore, the reduction in hazardous waste disposal costs—which can range from $50-300 per ton depending on solvent classification—provides substantial financial incentives.

Regulatory compliance represents another economic dimension favoring green separation technologies. As environmental regulations become increasingly stringent worldwide, companies implementing these technologies gain competitive advantages through avoided compliance costs and penalties. The economic value of regulatory preparedness is estimated at 5-8% of operational costs in chemical and pharmaceutical sectors.

Market differentiation through sustainability credentials offers premium pricing opportunities. Consumer goods manufacturers implementing green separation processes in their supply chains have documented price premiums of 3-7% for environmentally responsible products, particularly in European and North American markets where consumer environmental awareness is high.

Return on investment (ROI) analyses across various industries indicate that green separation technologies typically achieve ROI rates of 15-25% when accounting for all economic factors, including energy savings, material recovery, waste reduction, regulatory compliance, and market positioning benefits. These figures compare favorably with the 10-15% ROI threshold typically required for major capital investments in process industries.

The economic landscape for green separation technologies continues to improve as technological maturation drives down implementation costs and as carbon pricing mechanisms increasingly monetize environmental externalities, further enhancing the comparative economic advantage of these sustainable approaches.

Energy efficiency improvements present the most compelling economic argument for green separation technologies. Industrial data demonstrates that membrane-based separations can reduce energy consumption by 40-70% compared to traditional distillation processes, translating to substantial cost savings in energy-intensive industries. For instance, in pharmaceutical manufacturing, pervaporation and organic solvent nanofiltration have shown potential to reduce energy costs by up to 60% while maintaining product quality.

Solvent minimization strategies offer additional economic benefits through reduced material costs and waste management expenses. Case studies from chemical processing industries reveal that implementing solvent recovery systems can achieve recovery rates of 85-95%, significantly decreasing procurement costs for fresh solvents. Furthermore, the reduction in hazardous waste disposal costs—which can range from $50-300 per ton depending on solvent classification—provides substantial financial incentives.

Regulatory compliance represents another economic dimension favoring green separation technologies. As environmental regulations become increasingly stringent worldwide, companies implementing these technologies gain competitive advantages through avoided compliance costs and penalties. The economic value of regulatory preparedness is estimated at 5-8% of operational costs in chemical and pharmaceutical sectors.

Market differentiation through sustainability credentials offers premium pricing opportunities. Consumer goods manufacturers implementing green separation processes in their supply chains have documented price premiums of 3-7% for environmentally responsible products, particularly in European and North American markets where consumer environmental awareness is high.

Return on investment (ROI) analyses across various industries indicate that green separation technologies typically achieve ROI rates of 15-25% when accounting for all economic factors, including energy savings, material recovery, waste reduction, regulatory compliance, and market positioning benefits. These figures compare favorably with the 10-15% ROI threshold typically required for major capital investments in process industries.

The economic landscape for green separation technologies continues to improve as technological maturation drives down implementation costs and as carbon pricing mechanisms increasingly monetize environmental externalities, further enhancing the comparative economic advantage of these sustainable approaches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!