Filtration Train Design For High-Solids Feed Streams

AUG 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Solids Filtration Technology Background and Objectives

Filtration technology for high-solids feed streams has evolved significantly over the past several decades, driven by increasing demands across various industries including mining, chemical processing, pharmaceutical manufacturing, and wastewater treatment. The historical development of this technology can be traced back to basic gravity filtration methods, which have progressively advanced to incorporate sophisticated pressure-driven and vacuum-assisted systems designed specifically to handle challenging high-solids content materials.

The evolution of high-solids filtration has been characterized by continuous improvements in filter media materials, equipment design, and process optimization. Early filtration systems struggled with issues such as rapid fouling, limited throughput, and high maintenance requirements when processing streams with solids content exceeding 5-10% by weight. Modern systems, by contrast, can effectively handle feeds with solids concentrations of 40% or higher while maintaining operational efficiency.

Recent technological advancements have focused on developing integrated filtration trains that combine multiple separation technologies in sequence to optimize the handling of high-solids streams. These developments have been largely driven by industrial needs for increased process efficiency, reduced operational costs, and stricter environmental regulations regarding waste disposal and water conservation.

The primary objective of high-solids filtration technology development is to design robust filtration trains capable of efficiently processing feed streams with high solids content while maximizing filtrate clarity, solids recovery, and operational uptime. Secondary objectives include minimizing energy consumption, reducing chemical additives, decreasing the physical footprint of filtration systems, and enhancing automation capabilities for reduced operator intervention.

Current technological trends in this field include the development of advanced ceramic and polymeric membrane materials with enhanced fouling resistance, the integration of real-time monitoring and control systems for optimized performance, and the implementation of hybrid processes that combine conventional filtration with emerging separation technologies such as forward osmosis or electrocoagulation.

The global market for high-solids filtration equipment has been growing steadily at approximately 5-7% annually, with particularly strong growth in regions with expanding industrial bases and increasing water scarcity concerns. This growth trajectory is expected to continue as industries worldwide face mounting pressure to improve resource efficiency and reduce environmental impact.

Looking forward, the field of high-solids filtration is moving toward more sustainable and adaptable solutions, with particular emphasis on modular designs that can be easily scaled and modified to accommodate changing feed characteristics and processing requirements. The integration of digital technologies, including machine learning algorithms for predictive maintenance and process optimization, represents a significant frontier in the ongoing evolution of filtration train design for high-solids applications.

The evolution of high-solids filtration has been characterized by continuous improvements in filter media materials, equipment design, and process optimization. Early filtration systems struggled with issues such as rapid fouling, limited throughput, and high maintenance requirements when processing streams with solids content exceeding 5-10% by weight. Modern systems, by contrast, can effectively handle feeds with solids concentrations of 40% or higher while maintaining operational efficiency.

Recent technological advancements have focused on developing integrated filtration trains that combine multiple separation technologies in sequence to optimize the handling of high-solids streams. These developments have been largely driven by industrial needs for increased process efficiency, reduced operational costs, and stricter environmental regulations regarding waste disposal and water conservation.

The primary objective of high-solids filtration technology development is to design robust filtration trains capable of efficiently processing feed streams with high solids content while maximizing filtrate clarity, solids recovery, and operational uptime. Secondary objectives include minimizing energy consumption, reducing chemical additives, decreasing the physical footprint of filtration systems, and enhancing automation capabilities for reduced operator intervention.

Current technological trends in this field include the development of advanced ceramic and polymeric membrane materials with enhanced fouling resistance, the integration of real-time monitoring and control systems for optimized performance, and the implementation of hybrid processes that combine conventional filtration with emerging separation technologies such as forward osmosis or electrocoagulation.

The global market for high-solids filtration equipment has been growing steadily at approximately 5-7% annually, with particularly strong growth in regions with expanding industrial bases and increasing water scarcity concerns. This growth trajectory is expected to continue as industries worldwide face mounting pressure to improve resource efficiency and reduce environmental impact.

Looking forward, the field of high-solids filtration is moving toward more sustainable and adaptable solutions, with particular emphasis on modular designs that can be easily scaled and modified to accommodate changing feed characteristics and processing requirements. The integration of digital technologies, including machine learning algorithms for predictive maintenance and process optimization, represents a significant frontier in the ongoing evolution of filtration train design for high-solids applications.

Market Analysis for High-Solids Filtration Systems

The global market for high-solids filtration systems has experienced significant growth in recent years, driven by increasing industrial demands for more efficient separation processes. The market size was valued at approximately $3.2 billion in 2022 and is projected to reach $4.7 billion by 2027, representing a compound annual growth rate of 8.1%. This growth trajectory is primarily fueled by expanding applications across various industries including mining, chemical processing, food and beverage, pharmaceuticals, and wastewater treatment.

In the mining sector, which accounts for nearly 28% of the total market share, high-solids filtration systems are essential for mineral processing operations where separating valuable minerals from waste materials is critical. The chemical processing industry follows closely, representing about 24% of the market, with applications focused on product recovery and waste minimization.

Regional analysis reveals that Asia-Pacific dominates the market with approximately 35% share, attributed to rapid industrialization in countries like China and India. North America and Europe collectively account for 45% of the market, with established industrial bases driving steady demand for advanced filtration technologies.

Customer requirements are increasingly centered around system efficiency, operational flexibility, and reduced environmental impact. End-users are demanding filtration systems capable of handling higher solid concentrations while maintaining throughput rates and filtrate quality. Additionally, there is growing emphasis on systems that minimize water consumption and reduce waste generation, aligning with global sustainability initiatives.

The competitive landscape features both established players and innovative startups. Major companies like Pall Corporation, Outotec, and Andritz hold significant market shares due to their comprehensive product portfolios and global presence. However, smaller specialized firms are gaining traction by offering niche solutions for specific high-solids applications.

Market trends indicate a shift toward automated filtration systems with integrated process control capabilities. The integration of IoT and AI technologies for predictive maintenance and performance optimization is becoming increasingly prevalent. Furthermore, modular and scalable system designs are gaining popularity as they offer flexibility to adapt to changing process requirements.

Regulatory factors are significantly influencing market dynamics, with stringent environmental regulations regarding industrial waste disposal and water usage driving adoption of more efficient filtration technologies. This regulatory landscape varies considerably across regions but generally trends toward more restrictive standards, creating both challenges and opportunities for filtration system manufacturers.

In the mining sector, which accounts for nearly 28% of the total market share, high-solids filtration systems are essential for mineral processing operations where separating valuable minerals from waste materials is critical. The chemical processing industry follows closely, representing about 24% of the market, with applications focused on product recovery and waste minimization.

Regional analysis reveals that Asia-Pacific dominates the market with approximately 35% share, attributed to rapid industrialization in countries like China and India. North America and Europe collectively account for 45% of the market, with established industrial bases driving steady demand for advanced filtration technologies.

Customer requirements are increasingly centered around system efficiency, operational flexibility, and reduced environmental impact. End-users are demanding filtration systems capable of handling higher solid concentrations while maintaining throughput rates and filtrate quality. Additionally, there is growing emphasis on systems that minimize water consumption and reduce waste generation, aligning with global sustainability initiatives.

The competitive landscape features both established players and innovative startups. Major companies like Pall Corporation, Outotec, and Andritz hold significant market shares due to their comprehensive product portfolios and global presence. However, smaller specialized firms are gaining traction by offering niche solutions for specific high-solids applications.

Market trends indicate a shift toward automated filtration systems with integrated process control capabilities. The integration of IoT and AI technologies for predictive maintenance and performance optimization is becoming increasingly prevalent. Furthermore, modular and scalable system designs are gaining popularity as they offer flexibility to adapt to changing process requirements.

Regulatory factors are significantly influencing market dynamics, with stringent environmental regulations regarding industrial waste disposal and water usage driving adoption of more efficient filtration technologies. This regulatory landscape varies considerably across regions but generally trends toward more restrictive standards, creating both challenges and opportunities for filtration system manufacturers.

Current Filtration Technologies and Challenges

Filtration technologies for high-solids feed streams have evolved significantly over the past decades, yet continue to face substantial challenges. Current industrial filtration systems typically employ a combination of methods arranged in sequence—known as filtration trains—to progressively remove solids of decreasing size from process streams. These systems are essential across numerous industries including mining, food processing, pharmaceuticals, and wastewater treatment.

Conventional filtration technologies for high-solids applications include coarse screening, hydrocyclones, settling tanks, clarifiers, and various pressure and vacuum filtration systems. Coarse screening serves as the initial stage, removing large particulates through physical barriers. Hydrocyclones leverage centrifugal forces to separate particles based on density differences, offering continuous operation capabilities but struggling with fine particle removal.

Pressure filtration systems, including filter presses and pressure leaf filters, provide high solids capture rates but operate in batch modes that limit throughput. Vacuum filtration technologies such as rotary drum filters and belt filters offer continuous operation advantages but typically achieve lower filtration efficiencies compared to pressure-based systems.

Membrane filtration technologies have gained prominence for their ability to remove fine particulates and dissolved solids. However, when applied to high-solids streams, these systems face rapid fouling and flux decline, necessitating frequent cleaning cycles that reduce operational efficiency and increase maintenance costs.

The primary technical challenges in high-solids filtration include membrane fouling, cake compressibility issues, and the trade-off between filtration efficiency and throughput. Membrane fouling occurs when particles accumulate on filter surfaces, creating resistance to flow and reducing separation efficiency. This phenomenon is particularly problematic in high-solids environments where fouling accelerates exponentially with solids concentration.

Cake compressibility presents another significant challenge, as the solid material accumulated on filter surfaces tends to compact under pressure, reducing permeability and filtration rates over time. This effect is especially pronounced in applications involving deformable particles or biological materials.

Energy consumption remains a critical constraint, with high-pressure differential requirements for processing viscous, solids-laden streams translating to substantial operational costs. Additionally, the handling and disposal of filter cake and backwash streams create secondary waste management challenges that must be addressed in comprehensive system designs.

Recent technological innovations have focused on self-cleaning filter designs, advanced anti-fouling materials, and hybrid systems that combine multiple separation mechanisms. Despite these advances, the development of filtration trains capable of efficiently handling high-solids feed streams while maintaining consistent performance over extended operational periods remains an active area of research and development.

Conventional filtration technologies for high-solids applications include coarse screening, hydrocyclones, settling tanks, clarifiers, and various pressure and vacuum filtration systems. Coarse screening serves as the initial stage, removing large particulates through physical barriers. Hydrocyclones leverage centrifugal forces to separate particles based on density differences, offering continuous operation capabilities but struggling with fine particle removal.

Pressure filtration systems, including filter presses and pressure leaf filters, provide high solids capture rates but operate in batch modes that limit throughput. Vacuum filtration technologies such as rotary drum filters and belt filters offer continuous operation advantages but typically achieve lower filtration efficiencies compared to pressure-based systems.

Membrane filtration technologies have gained prominence for their ability to remove fine particulates and dissolved solids. However, when applied to high-solids streams, these systems face rapid fouling and flux decline, necessitating frequent cleaning cycles that reduce operational efficiency and increase maintenance costs.

The primary technical challenges in high-solids filtration include membrane fouling, cake compressibility issues, and the trade-off between filtration efficiency and throughput. Membrane fouling occurs when particles accumulate on filter surfaces, creating resistance to flow and reducing separation efficiency. This phenomenon is particularly problematic in high-solids environments where fouling accelerates exponentially with solids concentration.

Cake compressibility presents another significant challenge, as the solid material accumulated on filter surfaces tends to compact under pressure, reducing permeability and filtration rates over time. This effect is especially pronounced in applications involving deformable particles or biological materials.

Energy consumption remains a critical constraint, with high-pressure differential requirements for processing viscous, solids-laden streams translating to substantial operational costs. Additionally, the handling and disposal of filter cake and backwash streams create secondary waste management challenges that must be addressed in comprehensive system designs.

Recent technological innovations have focused on self-cleaning filter designs, advanced anti-fouling materials, and hybrid systems that combine multiple separation mechanisms. Despite these advances, the development of filtration trains capable of efficiently handling high-solids feed streams while maintaining consistent performance over extended operational periods remains an active area of research and development.

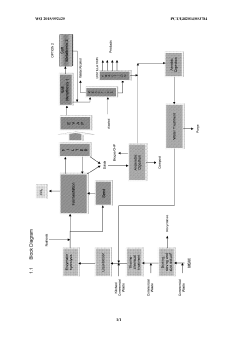

Current Filtration Train Design Approaches

01 Multi-stage filtration systems for high-solids streams

Multi-stage filtration systems are designed to handle high-solids feed streams by employing a series of filters with progressively finer filtration capabilities. These systems typically include primary filtration for larger particles, followed by secondary and tertiary stages to remove smaller particulates. This approach prevents rapid clogging of fine filters and extends the operational life of the filtration train while maintaining processing efficiency for streams with high solid content.- Multi-stage filtration systems for high-solids streams: Multi-stage filtration systems are designed to handle high-solids feed streams by employing a series of filters with progressively finer filtration capabilities. These systems typically start with coarse filtration to remove larger particles, followed by medium and fine filtration stages to capture smaller solids. This sequential approach prevents premature clogging of finer filters and extends the overall system lifespan while maintaining filtration efficiency for high-solids applications.

- Membrane filtration technologies for high-solids processing: Advanced membrane filtration technologies are specifically designed to handle high-solids feed streams across various industrial applications. These membranes utilize specialized materials and configurations to resist fouling while maintaining high flux rates. The technologies may include cross-flow filtration, dynamic membranes, or vibrating membrane systems that create turbulence to prevent solids accumulation on the membrane surface, thereby extending operational time between cleaning cycles.

- Pretreatment methods for high-solids filtration: Pretreatment processes are essential for optimizing the filtration of high-solids feed streams. These methods may include chemical conditioning, coagulation, flocculation, or physical pretreatment such as screening or sedimentation. By modifying the characteristics of the feed stream before it enters the main filtration system, these pretreatment approaches can significantly reduce filter fouling, increase throughput, and improve the overall efficiency of the filtration train.

- Backwashing and cleaning systems for high-solids filtration: Specialized backwashing and cleaning systems are critical for maintaining the performance of filtration trains processing high-solids feed streams. These systems employ various techniques such as reverse flow, air scouring, chemical cleaning, or ultrasonic vibration to dislodge accumulated solids from filter media. Automated cleaning sequences can be triggered based on differential pressure or time intervals, ensuring continuous operation and extending the service life of filtration equipment in challenging high-solids applications.

- Novel filter media for high-solids applications: Innovative filter media materials and designs have been developed specifically for high-solids feed streams. These advanced media may incorporate gradient density structures, composite materials, or surface modifications to enhance solids-holding capacity while maintaining flow rates. Some designs feature asymmetric pore structures or specialized surface treatments that resist adhesion of particulates, allowing for more efficient filtration of challenging high-solids streams across various industrial applications.

02 Membrane filtration technologies for high-solids processing

Advanced membrane filtration technologies are specifically designed for high-solids feed streams, utilizing specialized membrane materials and configurations that resist fouling. These systems may incorporate cross-flow filtration, where the feed flows tangentially across the membrane surface, reducing the accumulation of solids. Various membrane types including ceramic, polymeric, and composite membranes are employed based on the specific characteristics of the high-solids stream being processed.Expand Specific Solutions03 Pretreatment methods for high-solids filtration

Pretreatment processes are essential for optimizing the filtration of high-solids feed streams. These methods include chemical conditioning, coagulation, flocculation, and pH adjustment to modify the physical properties of suspended solids. Pretreatment can significantly improve filtration efficiency by aggregating fine particles into larger flocs that are more easily removed, reducing membrane fouling, and extending filter life in high-solids applications.Expand Specific Solutions04 Backwashing and cleaning systems for high-solids filtration

Specialized backwashing and cleaning systems are critical for maintaining the performance of filtration trains processing high-solids feed streams. These systems employ reverse flow, air scouring, chemical cleaning, and ultrasonic techniques to remove accumulated solids from filter media and membrane surfaces. Automated cleaning sequences can be programmed based on differential pressure or time intervals to ensure continuous operation without manual intervention in challenging high-solids environments.Expand Specific Solutions05 Hybrid filtration systems for complex high-solids streams

Hybrid filtration systems combine multiple filtration technologies to effectively process complex high-solids feed streams. These systems may integrate centrifugation, hydrocyclones, settling tanks, and various filter types in a single process train. By leveraging the strengths of different separation mechanisms, hybrid systems can handle varying particle sizes, densities, and concentrations, providing robust solutions for challenging industrial applications with high solid content and variable feed characteristics.Expand Specific Solutions

Key Industry Players and Manufacturers

The filtration train design for high-solids feed streams market is currently in a growth phase, characterized by increasing demand across industrial sectors requiring advanced separation technologies. The global market size is estimated to exceed $5 billion, driven by stringent environmental regulations and process efficiency requirements. From a technological maturity perspective, established players like Siemens AG, ExxonMobil, and Evoqua Water Technologies lead with comprehensive solutions, while specialized companies such as Hangzhou Cobetter Filtration and Sepro Membranes focus on niche innovations. The competitive landscape features both diversified industrial conglomerates (BASF, Shell) and specialized filtration technology providers, with increasing collaboration between academic institutions (Xi'an University of Architecture & Technology) and industry players to address complex high-solids separation challenges in energy, chemical, and water treatment applications.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil's high-solids filtration train design represents a sophisticated approach to handling challenging feed streams in petroleum refining and petrochemical applications. Their system employs a multi-barrier methodology beginning with their proprietary Induced Gas Flotation (IGF) technology that removes free and emulsified oils along with suspended solids through microbubble attachment and flotation. This is followed by their Advanced Walnut Shell Filter (AWSF) technology, which utilizes crushed walnut shells as a filtration medium capable of handling influent oil concentrations up to 1000 ppm and suspended solids up to 500 ppm while achieving effluent quality below 10 ppm TSS. For applications requiring finer filtration, ExxonMobil implements their Dual Media Filtration (DMF) system with proprietary media formulations that provide exceptional dirt-holding capacity while maintaining high flux rates. The final polishing stage incorporates their Enhanced Membrane Filtration (EMF) technology with specialized surface modifications that resist fouling from hydrocarbon contaminants. A distinguishing feature of their design is the implementation of their SMART-CYCLE™ automated backwash optimization system that uses predictive analytics to determine optimal cleaning intervals, reducing water consumption by up to 30% compared to time-based backwashing protocols.

Strengths: Exceptional performance with oily and hydrocarbon-contaminated high-solids streams. Integrated automation and predictive maintenance capabilities reduce operational costs and improve reliability. Weaknesses: Specialized media requirements increase replacement costs. System optimization requires significant process engineering expertise specific to hydrocarbon applications.

Hangzhou Cobetter Filtration Equipment Co., Ltd.

Technical Solution: Hangzhou Cobetter has developed a comprehensive high-solids filtration train specifically designed for challenging industrial applications. Their system employs a progressive filtration approach beginning with their patented self-cleaning strainers that can handle solids concentrations up to 5% by weight. The primary stage utilizes high-capacity bag filters with specially formulated media that resist blinding even with viscous fluids. For the intermediate stage, Cobetter implements their rotary drum vacuum filters with continuous belt cleaning mechanisms that maintain consistent performance with minimal operator intervention. The final polishing stage incorporates their multi-layer depth filtration technology using graded density media that provides particle retention down to 1 micron while maintaining high flow rates. A key innovation in their design is the implementation of ultrasonic vibration assistance on critical filter elements, which significantly reduces cake formation and extends filter run times by up to 300% compared to conventional designs. The entire system is monitored through their SmartFlow control platform that automatically adjusts operating parameters based on feed characteristics and desired output quality.

Strengths: Exceptional handling of viscous fluids and high solids content through multi-stage approach. Innovative ultrasonic anti-fouling technology significantly extends filter life and reduces maintenance frequency. Weaknesses: Higher energy consumption due to ultrasonic systems and multiple pumping stages. Requires more floor space compared to more compact filtration solutions.

Critical Patents and Innovations in High-Solids Filtration

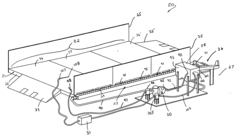

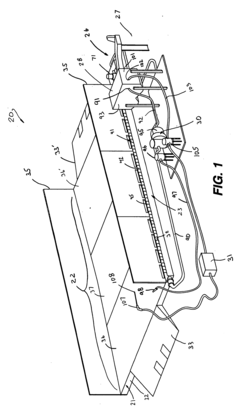

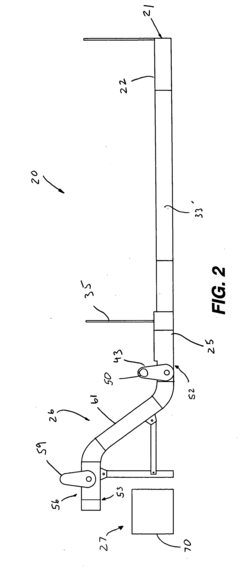

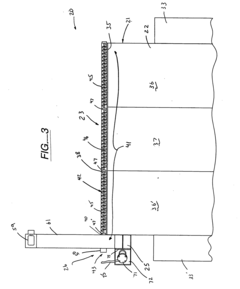

High solids closed-loop pressure washer system

PatentInactiveUS20050139243A1

Innovation

- A closed-loop pressure washing system with a support platform and collection device that separates and discards high solids contaminants using a drag conveyor and clarifying reservoir, allowing for the reuse of washing fluids, and incorporating a high-capacity fluid cannon and baffles for effective contaminant separation and recycling.

Manufacture of lactic acid

PatentWO2015092425A1

Innovation

- A novel fermentation method using a membrane bioreactor with microbial strains to produce substantially racemic lactic acid from biomass materials, including solids, allowing for efficient separation and recovery of D- and L-lactic acid enantiomers, enabling the production of PDLLA.

Energy Efficiency Considerations in Filtration Systems

Energy efficiency has become a critical consideration in the design and operation of filtration systems for high-solids feed streams. The energy consumption in filtration processes primarily stems from pumping requirements, mechanical separation mechanisms, and auxiliary equipment operation. For high-solids applications, these energy demands are particularly significant due to the increased resistance to flow and the need for more robust separation techniques.

Pumping energy represents the largest portion of energy consumption in most filtration systems. When dealing with high-solids content, the pressure drop across filtration media increases substantially, requiring higher pumping power. Recent advancements in pump design have focused on variable frequency drives (VFDs) that adjust power consumption based on real-time process requirements, achieving energy savings of 20-30% compared to conventional fixed-speed pumps.

Mechanical separation techniques such as centrifugation, which are often employed in high-solids filtration trains, are inherently energy-intensive. Innovations in centrifuge design have led to the development of high-efficiency rotors and improved bearing systems that reduce friction losses. These improvements have resulted in energy consumption reductions of up to 15% while maintaining separation efficiency.

Thermal energy considerations are also significant, particularly in applications requiring temperature control during filtration. Heat exchangers with enhanced surface designs have demonstrated improved thermal efficiency, reducing energy requirements for heating or cooling high-solids streams by approximately 25%. Additionally, waste heat recovery systems are increasingly being integrated into filtration trains to capture and repurpose thermal energy that would otherwise be lost.

Automation and control systems play a crucial role in optimizing energy efficiency. Advanced process control algorithms that continuously monitor filtration parameters and adjust operating conditions have shown energy savings of 10-15% across entire filtration trains. These systems are particularly valuable for high-solids applications where conditions can change rapidly, requiring dynamic adjustments to maintain optimal performance.

Membrane-based filtration technologies, while offering advantages in separation efficiency, often present energy challenges due to fouling issues with high-solids feeds. Recent developments in anti-fouling membrane materials and improved cleaning protocols have extended operational cycles between cleanings, reducing the energy associated with frequent backwashing and chemical cleaning procedures by up to 40%.

The integration of renewable energy sources into filtration systems represents an emerging trend in the industry. Solar-powered pumping systems and biogas generation from organic solids removed during filtration are being implemented in various applications, offering both environmental benefits and operational cost reductions over traditional energy sources.

Pumping energy represents the largest portion of energy consumption in most filtration systems. When dealing with high-solids content, the pressure drop across filtration media increases substantially, requiring higher pumping power. Recent advancements in pump design have focused on variable frequency drives (VFDs) that adjust power consumption based on real-time process requirements, achieving energy savings of 20-30% compared to conventional fixed-speed pumps.

Mechanical separation techniques such as centrifugation, which are often employed in high-solids filtration trains, are inherently energy-intensive. Innovations in centrifuge design have led to the development of high-efficiency rotors and improved bearing systems that reduce friction losses. These improvements have resulted in energy consumption reductions of up to 15% while maintaining separation efficiency.

Thermal energy considerations are also significant, particularly in applications requiring temperature control during filtration. Heat exchangers with enhanced surface designs have demonstrated improved thermal efficiency, reducing energy requirements for heating or cooling high-solids streams by approximately 25%. Additionally, waste heat recovery systems are increasingly being integrated into filtration trains to capture and repurpose thermal energy that would otherwise be lost.

Automation and control systems play a crucial role in optimizing energy efficiency. Advanced process control algorithms that continuously monitor filtration parameters and adjust operating conditions have shown energy savings of 10-15% across entire filtration trains. These systems are particularly valuable for high-solids applications where conditions can change rapidly, requiring dynamic adjustments to maintain optimal performance.

Membrane-based filtration technologies, while offering advantages in separation efficiency, often present energy challenges due to fouling issues with high-solids feeds. Recent developments in anti-fouling membrane materials and improved cleaning protocols have extended operational cycles between cleanings, reducing the energy associated with frequent backwashing and chemical cleaning procedures by up to 40%.

The integration of renewable energy sources into filtration systems represents an emerging trend in the industry. Solar-powered pumping systems and biogas generation from organic solids removed during filtration are being implemented in various applications, offering both environmental benefits and operational cost reductions over traditional energy sources.

Environmental Impact and Sustainability Factors

The environmental impact of filtration train design for high-solids feed streams extends far beyond operational efficiency, encompassing critical sustainability considerations that industries must address. Traditional filtration processes often consume substantial energy and water resources while generating significant waste streams. Modern filtration train designs increasingly incorporate closed-loop systems that recycle process water, reducing freshwater consumption by up to 60-70% compared to conventional systems. This water conservation aspect becomes particularly crucial in water-stressed regions where industrial operations face increasing regulatory and social pressure.

Waste minimization represents another pivotal environmental factor in filtration system design. Advanced filtration trains can achieve solid waste reduction of 15-30% through improved separation efficiency and filter cake dewatering techniques. The recovered solids often contain valuable materials that can be repurposed or sold as by-products, transforming waste streams into potential revenue sources while simultaneously reducing disposal requirements and associated environmental impacts.

Energy efficiency in filtration operations directly correlates with carbon footprint reduction. Recent innovations in pump design, pressure optimization, and automated control systems have demonstrated energy savings of 20-40% in high-solids filtration applications. The implementation of variable frequency drives and smart pressure sensors allows systems to dynamically adjust to changing feed characteristics, maintaining optimal performance while minimizing unnecessary energy expenditure.

Chemical usage in filtration processes presents both environmental challenges and opportunities for improvement. Coagulants and flocculants, while essential for many high-solids applications, can introduce additional contaminants into the environment if not properly managed. Emerging bio-based flocculants derived from agricultural waste products offer promising alternatives with reduced environmental toxicity and improved biodegradability profiles, though often at higher cost points than conventional options.

Lifecycle assessment (LCA) methodologies increasingly inform filtration train design decisions, with manufacturers and end-users collaborating to evaluate environmental impacts from raw material extraction through end-of-life disposal. This holistic approach reveals that approximately 60-80% of a filtration system's lifetime environmental impact occurs during the operational phase rather than manufacturing or disposal, emphasizing the importance of designing for operational sustainability. Forward-thinking organizations now incorporate environmental key performance indicators alongside traditional metrics like throughput and filtrate clarity when evaluating filtration system performance.

Waste minimization represents another pivotal environmental factor in filtration system design. Advanced filtration trains can achieve solid waste reduction of 15-30% through improved separation efficiency and filter cake dewatering techniques. The recovered solids often contain valuable materials that can be repurposed or sold as by-products, transforming waste streams into potential revenue sources while simultaneously reducing disposal requirements and associated environmental impacts.

Energy efficiency in filtration operations directly correlates with carbon footprint reduction. Recent innovations in pump design, pressure optimization, and automated control systems have demonstrated energy savings of 20-40% in high-solids filtration applications. The implementation of variable frequency drives and smart pressure sensors allows systems to dynamically adjust to changing feed characteristics, maintaining optimal performance while minimizing unnecessary energy expenditure.

Chemical usage in filtration processes presents both environmental challenges and opportunities for improvement. Coagulants and flocculants, while essential for many high-solids applications, can introduce additional contaminants into the environment if not properly managed. Emerging bio-based flocculants derived from agricultural waste products offer promising alternatives with reduced environmental toxicity and improved biodegradability profiles, though often at higher cost points than conventional options.

Lifecycle assessment (LCA) methodologies increasingly inform filtration train design decisions, with manufacturers and end-users collaborating to evaluate environmental impacts from raw material extraction through end-of-life disposal. This holistic approach reveals that approximately 60-80% of a filtration system's lifetime environmental impact occurs during the operational phase rather than manufacturing or disposal, emphasizing the importance of designing for operational sustainability. Forward-thinking organizations now incorporate environmental key performance indicators alongside traditional metrics like throughput and filtrate clarity when evaluating filtration system performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!