Drying Technologies Compared: Spray, Rotary, And Tray Dryers For Powders

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Powder Drying Technology Evolution and Objectives

Powder drying technology has evolved significantly over the past century, transforming from rudimentary methods to sophisticated industrial processes. The journey began in the early 1900s with simple tray drying techniques, which relied on natural air circulation and basic heating elements. By the 1920s, rotary dryers emerged as a more efficient alternative, offering continuous processing capabilities that revolutionized industrial production.

The 1940s marked a pivotal moment with the introduction of spray drying technology, initially developed for milk powder production during World War II. This innovation enabled the transformation of liquid solutions into powder form through atomization and hot air contact, dramatically increasing production efficiency and product quality.

The subsequent decades witnessed significant technological refinements across all drying platforms. Spray dryers evolved to incorporate multi-stage designs, improved atomization techniques, and advanced control systems. Rotary dryers saw enhancements in heat transfer efficiency, residence time control, and material handling capabilities. Even traditional tray dryers benefited from automation, improved airflow distribution, and precise temperature regulation.

Recent advancements have focused on energy efficiency, product quality optimization, and process control precision. Modern powder drying systems incorporate sophisticated sensors, real-time monitoring capabilities, and adaptive control algorithms that respond to variations in feed properties and environmental conditions. The integration of computational fluid dynamics (CFD) modeling has enabled manufacturers to optimize dryer designs and operating parameters without extensive physical testing.

The primary objectives driving powder drying technology development include maximizing energy efficiency, ensuring consistent product quality, increasing production throughput, and minimizing environmental impact. Energy consumption remains a critical concern, with manufacturers seeking solutions that reduce thermal energy requirements while maintaining product specifications. Quality considerations focus on particle size distribution, moisture content uniformity, and preservation of sensitive components.

Production efficiency objectives target reduced cycle times, minimized material handling, and increased automation. Environmental considerations have gained prominence, with emphasis on reducing emissions, minimizing waste, and implementing heat recovery systems. Additionally, flexibility has become increasingly important as manufacturers seek drying solutions capable of handling diverse formulations and adapting to changing market demands.

The evolution trajectory points toward more intelligent, adaptive systems that optimize performance based on real-time product and process data. Future developments will likely focus on hybrid drying technologies that combine the advantages of different approaches, along with continued improvements in energy utilization and product quality control.

The 1940s marked a pivotal moment with the introduction of spray drying technology, initially developed for milk powder production during World War II. This innovation enabled the transformation of liquid solutions into powder form through atomization and hot air contact, dramatically increasing production efficiency and product quality.

The subsequent decades witnessed significant technological refinements across all drying platforms. Spray dryers evolved to incorporate multi-stage designs, improved atomization techniques, and advanced control systems. Rotary dryers saw enhancements in heat transfer efficiency, residence time control, and material handling capabilities. Even traditional tray dryers benefited from automation, improved airflow distribution, and precise temperature regulation.

Recent advancements have focused on energy efficiency, product quality optimization, and process control precision. Modern powder drying systems incorporate sophisticated sensors, real-time monitoring capabilities, and adaptive control algorithms that respond to variations in feed properties and environmental conditions. The integration of computational fluid dynamics (CFD) modeling has enabled manufacturers to optimize dryer designs and operating parameters without extensive physical testing.

The primary objectives driving powder drying technology development include maximizing energy efficiency, ensuring consistent product quality, increasing production throughput, and minimizing environmental impact. Energy consumption remains a critical concern, with manufacturers seeking solutions that reduce thermal energy requirements while maintaining product specifications. Quality considerations focus on particle size distribution, moisture content uniformity, and preservation of sensitive components.

Production efficiency objectives target reduced cycle times, minimized material handling, and increased automation. Environmental considerations have gained prominence, with emphasis on reducing emissions, minimizing waste, and implementing heat recovery systems. Additionally, flexibility has become increasingly important as manufacturers seek drying solutions capable of handling diverse formulations and adapting to changing market demands.

The evolution trajectory points toward more intelligent, adaptive systems that optimize performance based on real-time product and process data. Future developments will likely focus on hybrid drying technologies that combine the advantages of different approaches, along with continued improvements in energy utilization and product quality control.

Market Analysis for Industrial Drying Solutions

The global industrial drying equipment market has demonstrated robust growth, valued at approximately $5.83 billion in 2022 and projected to reach $8.65 billion by 2030, representing a compound annual growth rate of 5.1%. This expansion is primarily driven by increasing demand across pharmaceutical, food processing, chemical, and agricultural sectors, where powder production forms a critical manufacturing component.

Spray dryers currently dominate the market share at 38%, followed by rotary dryers at 29% and tray dryers at 18%, with other technologies comprising the remaining 15%. This distribution reflects the versatility and efficiency advantages of spray drying technology, particularly in pharmaceutical and food industries where product quality and consistency are paramount.

Regional analysis reveals Asia-Pacific as the fastest-growing market, expanding at 6.7% annually, fueled by rapid industrialization in China and India. North America and Europe maintain significant market shares of 28% and 25% respectively, characterized by technology upgrades and automation integration in existing drying systems.

The food and beverage sector represents the largest application segment (34% market share), where powder production for instant foods, dairy products, and nutritional supplements drives demand. Pharmaceutical applications follow closely at 30%, with chemical processing at 22% and other industries comprising 14% of the market.

Customer demand patterns show increasing preference for energy-efficient drying solutions, with 76% of new installations featuring heat recovery systems or alternative energy sources. This trend aligns with tightening environmental regulations and rising energy costs across industrial sectors.

Price sensitivity varies significantly by region and application, with pharmaceutical customers prioritizing precision and consistency over initial capital expenditure, while food processors demonstrate greater price sensitivity balanced against operational efficiency requirements.

Market forecasts indicate specialized powder applications will grow at 7.3% annually through 2030, outpacing the overall market. This growth is particularly evident in advanced materials, specialty chemicals, and nutraceutical segments where product characteristics demand precise drying parameters.

Emerging economies present substantial growth opportunities, with Brazil, Indonesia, and Vietnam showing increased adoption rates for industrial drying technologies as their manufacturing sectors expand and modernize production facilities to meet international quality standards.

Spray dryers currently dominate the market share at 38%, followed by rotary dryers at 29% and tray dryers at 18%, with other technologies comprising the remaining 15%. This distribution reflects the versatility and efficiency advantages of spray drying technology, particularly in pharmaceutical and food industries where product quality and consistency are paramount.

Regional analysis reveals Asia-Pacific as the fastest-growing market, expanding at 6.7% annually, fueled by rapid industrialization in China and India. North America and Europe maintain significant market shares of 28% and 25% respectively, characterized by technology upgrades and automation integration in existing drying systems.

The food and beverage sector represents the largest application segment (34% market share), where powder production for instant foods, dairy products, and nutritional supplements drives demand. Pharmaceutical applications follow closely at 30%, with chemical processing at 22% and other industries comprising 14% of the market.

Customer demand patterns show increasing preference for energy-efficient drying solutions, with 76% of new installations featuring heat recovery systems or alternative energy sources. This trend aligns with tightening environmental regulations and rising energy costs across industrial sectors.

Price sensitivity varies significantly by region and application, with pharmaceutical customers prioritizing precision and consistency over initial capital expenditure, while food processors demonstrate greater price sensitivity balanced against operational efficiency requirements.

Market forecasts indicate specialized powder applications will grow at 7.3% annually through 2030, outpacing the overall market. This growth is particularly evident in advanced materials, specialty chemicals, and nutraceutical segments where product characteristics demand precise drying parameters.

Emerging economies present substantial growth opportunities, with Brazil, Indonesia, and Vietnam showing increased adoption rates for industrial drying technologies as their manufacturing sectors expand and modernize production facilities to meet international quality standards.

Current Capabilities and Limitations of Drying Technologies

Spray drying technology currently offers the highest throughput capacity among powder drying methods, capable of processing up to 100 tons per hour in large industrial installations. This technology excels in producing fine, homogeneous powders with particle sizes typically ranging from 10-200 microns and moisture content as low as 1-5%. The continuous operation capability represents a significant advantage for high-volume production environments, particularly in food, pharmaceutical, and chemical industries.

However, spray dryers face limitations in energy efficiency, with thermal efficiency typically ranging between 35-60%, significantly lower than some alternative technologies. The initial capital investment for spray drying systems is substantial, often 30-50% higher than comparable capacity rotary or tray systems, creating barriers to adoption for smaller manufacturers.

Rotary dryers demonstrate superior handling of heat-sensitive materials and materials with higher initial moisture content (up to 80%). These systems can process larger particles (0.5-10mm) and achieve throughput rates of 5-50 tons per hour, making them particularly suitable for minerals, fertilizers, and certain agricultural products. Their thermal efficiency typically ranges from 60-75%, representing a significant improvement over spray drying technology.

The limitations of rotary systems include less precise particle size control and potential for product degradation due to mechanical stress during tumbling. Additionally, rotary dryers require substantial floor space and present challenges in processing very fine powders due to potential dusting issues.

Tray dryers, while offering the lowest throughput capacity (typically 0.1-5 tons per batch), provide exceptional control over drying parameters and product quality. They excel in handling high-value, heat-sensitive materials requiring gentle processing conditions. The batch processing nature allows for complete traceability and quality control for each production lot, critical for pharmaceutical and specialty chemical applications.

The primary limitations of tray drying include labor-intensive operation, significant space requirements per unit of production, and longer processing cycles (typically 4-48 hours compared to minutes or hours for continuous systems). Energy efficiency varies widely between 40-70% depending on design and operation parameters.

Across all technologies, common challenges persist: energy consumption remains a significant operational cost (typically 15-40% of production costs), environmental considerations regarding emissions and waste heat utilization require attention, and scaling production while maintaining product quality presents ongoing engineering challenges. Recent technological advancements have focused on hybrid systems combining multiple drying principles to overcome individual limitations.

However, spray dryers face limitations in energy efficiency, with thermal efficiency typically ranging between 35-60%, significantly lower than some alternative technologies. The initial capital investment for spray drying systems is substantial, often 30-50% higher than comparable capacity rotary or tray systems, creating barriers to adoption for smaller manufacturers.

Rotary dryers demonstrate superior handling of heat-sensitive materials and materials with higher initial moisture content (up to 80%). These systems can process larger particles (0.5-10mm) and achieve throughput rates of 5-50 tons per hour, making them particularly suitable for minerals, fertilizers, and certain agricultural products. Their thermal efficiency typically ranges from 60-75%, representing a significant improvement over spray drying technology.

The limitations of rotary systems include less precise particle size control and potential for product degradation due to mechanical stress during tumbling. Additionally, rotary dryers require substantial floor space and present challenges in processing very fine powders due to potential dusting issues.

Tray dryers, while offering the lowest throughput capacity (typically 0.1-5 tons per batch), provide exceptional control over drying parameters and product quality. They excel in handling high-value, heat-sensitive materials requiring gentle processing conditions. The batch processing nature allows for complete traceability and quality control for each production lot, critical for pharmaceutical and specialty chemical applications.

The primary limitations of tray drying include labor-intensive operation, significant space requirements per unit of production, and longer processing cycles (typically 4-48 hours compared to minutes or hours for continuous systems). Energy efficiency varies widely between 40-70% depending on design and operation parameters.

Across all technologies, common challenges persist: energy consumption remains a significant operational cost (typically 15-40% of production costs), environmental considerations regarding emissions and waste heat utilization require attention, and scaling production while maintaining product quality presents ongoing engineering challenges. Recent technological advancements have focused on hybrid systems combining multiple drying principles to overcome individual limitations.

Comparative Analysis of Spray, Rotary, and Tray Drying Systems

01 Spray drying technology and efficiency improvements

Spray drying involves atomizing a liquid feed into fine droplets and exposing them to hot air, resulting in rapid moisture evaporation. Efficiency improvements in spray dryers include optimized atomization techniques, enhanced heat transfer mechanisms, and improved air flow patterns. Advanced spray dryer designs incorporate features like multi-stage drying, recirculation systems, and precise temperature control to maximize energy efficiency and product quality while minimizing drying time.- Spray drying technology and efficiency improvements: Spray drying technology involves atomizing liquid feed into fine droplets and drying them with hot air. Efficiency improvements in spray dryers focus on optimizing atomization techniques, controlling air flow patterns, and enhancing heat transfer. Advanced spray dryer designs incorporate features like multi-stage drying chambers, improved nozzle designs, and recirculation systems to reduce energy consumption and increase throughput. These innovations help achieve uniform particle size distribution and better product quality while minimizing energy usage.

- Rotary dryer efficiency optimization: Rotary dryers achieve efficiency through the tumbling action of material in a rotating drum while exposed to hot air. Efficiency optimization in rotary dryers involves improving flight designs for better material distribution, enhancing heat exchange surfaces, and implementing precise temperature control systems. Advanced rotary dryer systems incorporate variable speed drives, optimized drum angles, and improved sealing mechanisms to reduce heat losses. These improvements lead to more uniform drying, reduced energy consumption, and increased processing capacity.

- Tray dryer technology and energy efficiency: Tray dryers operate by placing materials on trays in enclosed chambers with controlled air circulation. Energy efficiency in tray dryers is achieved through improved air distribution systems, better insulation, and optimized loading patterns. Modern tray dryer designs incorporate multi-zone temperature control, variable air flow systems, and heat recovery mechanisms to reduce energy consumption. Enhanced tray designs with improved surface area and air contact facilitate faster and more uniform drying while maintaining product quality.

- Hybrid and combined drying systems: Hybrid drying systems integrate multiple drying technologies to leverage the advantages of each method. These systems may combine spray drying with fluidized bed finishing, rotary drying with microwave assistance, or tray drying with infrared heating. Combined approaches enable staged drying processes that optimize energy usage at different moisture content levels. These integrated systems achieve higher efficiency through synergistic effects, reducing overall energy consumption while improving product quality and processing time compared to single-technology approaches.

- Advanced control systems for drying efficiency: Advanced control systems significantly improve drying efficiency across all dryer types. These systems incorporate real-time moisture monitoring, adaptive control algorithms, and predictive modeling to optimize drying parameters. Smart sensors and IoT integration enable continuous monitoring of temperature, humidity, and product characteristics throughout the drying process. Automated control systems adjust operating parameters in response to changing conditions, ensuring optimal energy usage while maintaining product quality. These technologies reduce over-drying, minimize energy waste, and increase throughput across spray, rotary, and tray drying applications.

02 Rotary dryer design and performance optimization

Rotary dryers utilize rotating cylindrical shells with internal flights that lift and cascade material through a hot air stream. Performance optimization focuses on flight design, rotation speed, slope angle, and airflow configuration. Innovations include improved heat exchange surfaces, variable speed drives, and advanced sealing mechanisms to prevent heat loss. These enhancements contribute to higher thermal efficiency, reduced energy consumption, and more uniform drying of materials.Expand Specific Solutions03 Tray dryer technology and batch processing efficiency

Tray dryers consist of enclosed chambers with multiple trays where material is spread for drying using heated air circulation. Efficiency improvements include multi-zone temperature control, optimized air distribution systems, and enhanced tray designs for better product exposure. Advanced tray dryers incorporate features like programmable drying cycles, humidity control, and energy recovery systems to improve batch processing efficiency while maintaining product quality and reducing operating costs.Expand Specific Solutions04 Energy efficiency and heat recovery systems in drying technologies

Energy efficiency in drying technologies is enhanced through heat recovery systems that capture and reuse thermal energy from exhaust air. Innovations include heat exchangers, thermal wheels, and closed-loop systems that significantly reduce energy consumption. Advanced control systems optimize energy usage by adjusting operating parameters based on real-time monitoring of moisture content and temperature profiles. These approaches minimize heat losses and maximize the utilization of input energy across various dryer types.Expand Specific Solutions05 Hybrid and combined drying systems for enhanced efficiency

Hybrid drying systems integrate multiple drying technologies to leverage the advantages of each method while minimizing their limitations. Combinations such as microwave-assisted spray drying, solar-enhanced rotary drying, or multi-stage processes with different dryer types can significantly improve overall efficiency. These integrated approaches optimize moisture removal rates at different stages of the drying process, reduce energy consumption, and enhance product quality by applying the most suitable drying mechanism at each phase of moisture removal.Expand Specific Solutions

Leading Manufacturers and Technology Providers

The powder drying technology market is in a growth phase, characterized by increasing demand across pharmaceutical, food, and chemical industries. The global market size for industrial dryers is projected to reach significant value, driven by efficiency requirements and product quality demands. Technologically, spray drying dominates with advanced capabilities, while rotary and tray dryers serve specific applications. Leading players like GEA Systems, Glatt Ingenieurtechnik, and IMA Life have established mature spray drying technologies, while companies such as BASF, International Flavors & Fragrances, and Ajinomoto focus on application-specific innovations. Pharmaceutical specialists including CyDex and EirGen Pharma are advancing specialized drying techniques for sensitive compounds, indicating a trend toward customized solutions and energy-efficient designs in this competitive landscape.

GEA Systems North America LLC

Technical Solution: GEA has developed advanced spray drying technologies that utilize integrated fluid bed systems for enhanced powder properties. Their multi-stage drying approach combines conventional spray drying with fluid bed technology to optimize moisture content and particle characteristics. GEA's systems feature high-precision atomization using pressure nozzles or rotary atomizers that can achieve droplet sizes between 10-200 microns. Their designs incorporate computational fluid dynamics (CFD) modeling to optimize air flow patterns and heat transfer efficiency, resulting in uniform drying conditions throughout the chamber. GEA's spray dryers operate with inlet temperatures up to 220°C and can achieve evaporation rates of 25-30 kg water/m³ chamber volume per hour, significantly higher than conventional tray dryers.

Strengths: Superior energy efficiency with heat recovery systems reducing energy consumption by up to 20%; excellent particle size control; high production capacity (up to 80 tons/day). Weaknesses: Higher capital investment compared to simpler drying systems; requires specialized technical expertise for operation and maintenance.

Glatt Ingenieurtechnik GmbH

Technical Solution: Glatt specializes in fluid bed and spouted bed technologies that complement traditional drying methods. Their ProCell spouted bed technology represents an innovation in powder processing, combining drying with particle design capabilities. The system creates a controlled fluidization zone where particles are suspended in hot air streams, enabling simultaneous drying and coating/agglomeration. Glatt's multi-processor systems achieve moisture reduction from 40-60% to below 2% while maintaining particle integrity. Their continuous fluid bed dryers operate on a first-in-first-out principle, ensuring consistent residence time and uniform moisture content across batches. Glatt's systems incorporate PAT (Process Analytical Technology) tools for real-time monitoring of critical parameters including moisture content, particle size distribution, and bed temperature profiles.

Strengths: Exceptional particle engineering capabilities allowing simultaneous drying and functionalization; modular design enabling process flexibility; excellent for heat-sensitive materials with precise temperature control. Weaknesses: Higher complexity in process parameter optimization; requires more floor space than some competing technologies.

Technical Innovations in Modern Drying Equipment

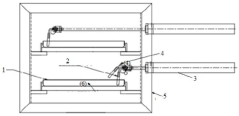

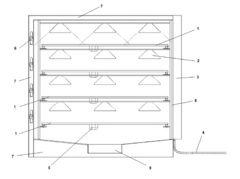

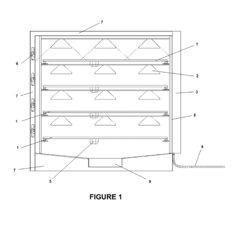

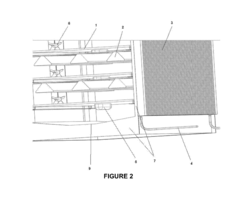

Heat sensitive material dryer consisting of racking system

PatentPendingIN202021044447A

Innovation

- A heat sensitive material dryer system featuring a tray with a scraper connected to a pneumatic arm and cylinder, allowing for automatic shaking under vacuum conditions, ensuring uniform material distribution and heat distribution, thereby enhancing evaporation speed and reducing cycle time.

Drier with solar radiation simulation

PatentActiveUS20180320966A1

Innovation

- A portable drier with a solar simulator that combines controlled infrared (IR) and ultraviolet (UV) rays to mimic ideal drying conditions, allowing for adjustable IR and UV settings for different products, ensuring vitamin D synthesis and minimizing chemical remnants, while maintaining hygienic and productive drying.

Energy Efficiency Considerations in Drying Operations

Energy efficiency represents a critical factor in industrial drying operations, directly impacting operational costs, environmental sustainability, and overall process economics. When comparing spray, rotary, and tray dryers for powder production, energy consumption patterns vary significantly based on design principles and operational parameters.

Spray dryers typically consume substantial thermal energy due to their high-temperature operation (150-300°C inlet temperatures) and the need to heat large volumes of air. However, modern spray drying systems have incorporated several efficiency improvements, including heat recovery systems that can recapture up to 30% of exhaust heat, multi-stage drying configurations, and optimized atomization techniques that reduce energy requirements by 15-25%.

Rotary dryers demonstrate moderate energy efficiency with thermal energy consumption ranging from 3,500-5,000 kJ/kg of water evaporated. Their efficiency advantage stems from excellent material-to-heating medium contact and the ability to operate continuously. Recent innovations include variable speed drives that adjust rotation based on moisture content, reducing energy consumption by 10-15%, and improved flight designs that optimize material cascading patterns.

Tray dryers, while simpler in design, typically exhibit lower energy efficiency with consumption rates of 4,500-6,000 kJ/kg of water evaporated. Their batch operation nature creates inherent inefficiencies during loading/unloading cycles. However, they remain advantageous for heat-sensitive materials requiring precise temperature control.

Across all technologies, several universal efficiency enhancement strategies have emerged. Heat pump drying systems can reduce energy consumption by 40-70% compared to conventional systems by recycling thermal energy. Advanced control systems utilizing real-time moisture sensing and predictive algorithms optimize drying parameters dynamically, reducing energy waste from over-drying.

Hybrid drying systems combining multiple technologies have shown promising results, with energy savings of 20-35%. For instance, combining microwave-assisted pre-drying with conventional methods reduces overall energy requirements while maintaining product quality. Waste heat recovery systems have become increasingly sophisticated, with plate heat exchangers and thermal wheels recovering up to 60% of exhaust heat.

The selection of appropriate drying technology must balance energy considerations with product requirements. For large-scale operations processing heat-stable powders, rotary dryers often provide the best energy-per-unit-product ratio. Conversely, spray dryers remain essential for heat-sensitive materials despite higher energy demands. Future developments in drying technology will likely focus on electrification, renewable energy integration, and advanced materials for improved heat transfer efficiency.

Spray dryers typically consume substantial thermal energy due to their high-temperature operation (150-300°C inlet temperatures) and the need to heat large volumes of air. However, modern spray drying systems have incorporated several efficiency improvements, including heat recovery systems that can recapture up to 30% of exhaust heat, multi-stage drying configurations, and optimized atomization techniques that reduce energy requirements by 15-25%.

Rotary dryers demonstrate moderate energy efficiency with thermal energy consumption ranging from 3,500-5,000 kJ/kg of water evaporated. Their efficiency advantage stems from excellent material-to-heating medium contact and the ability to operate continuously. Recent innovations include variable speed drives that adjust rotation based on moisture content, reducing energy consumption by 10-15%, and improved flight designs that optimize material cascading patterns.

Tray dryers, while simpler in design, typically exhibit lower energy efficiency with consumption rates of 4,500-6,000 kJ/kg of water evaporated. Their batch operation nature creates inherent inefficiencies during loading/unloading cycles. However, they remain advantageous for heat-sensitive materials requiring precise temperature control.

Across all technologies, several universal efficiency enhancement strategies have emerged. Heat pump drying systems can reduce energy consumption by 40-70% compared to conventional systems by recycling thermal energy. Advanced control systems utilizing real-time moisture sensing and predictive algorithms optimize drying parameters dynamically, reducing energy waste from over-drying.

Hybrid drying systems combining multiple technologies have shown promising results, with energy savings of 20-35%. For instance, combining microwave-assisted pre-drying with conventional methods reduces overall energy requirements while maintaining product quality. Waste heat recovery systems have become increasingly sophisticated, with plate heat exchangers and thermal wheels recovering up to 60% of exhaust heat.

The selection of appropriate drying technology must balance energy considerations with product requirements. For large-scale operations processing heat-stable powders, rotary dryers often provide the best energy-per-unit-product ratio. Conversely, spray dryers remain essential for heat-sensitive materials despite higher energy demands. Future developments in drying technology will likely focus on electrification, renewable energy integration, and advanced materials for improved heat transfer efficiency.

Quality Control Parameters for Dried Powder Products

Quality control is paramount in powder drying processes, as it directly impacts product consistency, safety, and market acceptance. The key parameters for quality control in dried powder products span physical, chemical, and microbiological attributes that must be systematically monitored throughout the production process.

Moisture content stands as the most critical parameter, with each industry having specific acceptable ranges. For pharmaceutical powders, moisture levels typically must remain below 5%, while food products may allow up to 12% depending on the specific application. Excessive moisture can lead to microbial growth, caking, and reduced shelf life, while insufficient moisture may affect flowability and product functionality.

Particle size distribution significantly influences powder behavior during subsequent processing and end-use performance. Spray dryers typically produce spherical particles ranging from 10-200 μm, while rotary dryers create more irregular particles between 50-500 μm. Tray dryers often yield the least uniform size distribution. Laser diffraction analysis and sieve analysis remain the standard methods for particle size measurement.

Bulk density and flowability are interrelated parameters that affect handling, packaging, and dosing precision. The Hausner ratio (tapped density/bulk density) provides valuable insights into powder flow characteristics, with values below 1.25 indicating excellent flow properties. Angle of repose measurements complement these assessments, with angles below 30° suggesting free-flowing powders.

Chemical stability parameters include active ingredient potency, oxidation markers, and pH levels. These are particularly crucial for pharmaceutical and nutritional products where bioactive components must maintain their efficacy throughout the product's shelf life. Spectroscopic methods like NIR and HPLC are commonly employed for real-time monitoring.

Microbiological quality parameters encompass total plate count, yeast and mold counts, and specific pathogen testing. The acceptable limits vary significantly by industry, with pharmaceutical products requiring near-sterile conditions while food products follow specific regulatory guidelines such as those established by the FDA or EFSA.

Organoleptic properties including color consistency, odor, and taste are essential for consumer acceptance, particularly in food and cosmetic applications. Colorimetric analysis using L*a*b* color space measurements provides objective color assessment, while trained sensory panels evaluate more subjective attributes.

Reconstitution properties, including wettability, dispersibility, and solubility, are critical for powders designed to be reconstituted before use. The time required for complete dissolution and the presence of undissolved particles serve as key indicators of product quality, especially for instant food products and pharmaceutical formulations.

Moisture content stands as the most critical parameter, with each industry having specific acceptable ranges. For pharmaceutical powders, moisture levels typically must remain below 5%, while food products may allow up to 12% depending on the specific application. Excessive moisture can lead to microbial growth, caking, and reduced shelf life, while insufficient moisture may affect flowability and product functionality.

Particle size distribution significantly influences powder behavior during subsequent processing and end-use performance. Spray dryers typically produce spherical particles ranging from 10-200 μm, while rotary dryers create more irregular particles between 50-500 μm. Tray dryers often yield the least uniform size distribution. Laser diffraction analysis and sieve analysis remain the standard methods for particle size measurement.

Bulk density and flowability are interrelated parameters that affect handling, packaging, and dosing precision. The Hausner ratio (tapped density/bulk density) provides valuable insights into powder flow characteristics, with values below 1.25 indicating excellent flow properties. Angle of repose measurements complement these assessments, with angles below 30° suggesting free-flowing powders.

Chemical stability parameters include active ingredient potency, oxidation markers, and pH levels. These are particularly crucial for pharmaceutical and nutritional products where bioactive components must maintain their efficacy throughout the product's shelf life. Spectroscopic methods like NIR and HPLC are commonly employed for real-time monitoring.

Microbiological quality parameters encompass total plate count, yeast and mold counts, and specific pathogen testing. The acceptable limits vary significantly by industry, with pharmaceutical products requiring near-sterile conditions while food products follow specific regulatory guidelines such as those established by the FDA or EFSA.

Organoleptic properties including color consistency, odor, and taste are essential for consumer acceptance, particularly in food and cosmetic applications. Colorimetric analysis using L*a*b* color space measurements provides objective color assessment, while trained sensory panels evaluate more subjective attributes.

Reconstitution properties, including wettability, dispersibility, and solubility, are critical for powders designed to be reconstituted before use. The time required for complete dissolution and the presence of undissolved particles serve as key indicators of product quality, especially for instant food products and pharmaceutical formulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!