Membrane Filtration Versus Distillation: Energy, Purity, And Cost Trade-Offs

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Filtration Technologies Background and Objectives

Membrane filtration and distillation represent two fundamental approaches to separation processes that have evolved significantly over the past century. Filtration technologies date back to ancient civilizations, with rudimentary sand and cloth filters, while modern membrane filtration emerged in the mid-20th century with the development of synthetic polymer membranes. Distillation, conversely, has been practiced since antiquity for alcohol production and perfumery, with industrial applications expanding dramatically during the industrial revolution.

The technological trajectory of membrane filtration has accelerated dramatically since the 1960s, with the invention of asymmetric cellulose acetate membranes by Loeb and Sourirajan marking a pivotal moment. This innovation enabled practical reverse osmosis applications and catalyzed development across the spectrum of membrane technologies including microfiltration, ultrafiltration, nanofiltration, and reverse osmosis. Each of these technologies operates on different principles of size exclusion and offers varying degrees of separation capability.

Distillation technology has similarly progressed from simple pot stills to sophisticated multi-stage fractional distillation columns with advanced heat integration systems. Modern distillation incorporates vacuum operation, azeotropic distillation, and reactive distillation to overcome thermodynamic limitations and enhance energy efficiency. The development of computational modeling tools has further optimized these processes, allowing for precise design and control.

The primary objective of this technical research report is to conduct a comprehensive comparative analysis of membrane filtration and distillation technologies across three critical dimensions: energy consumption, product purity, and economic considerations. We aim to establish quantitative benchmarks for each technology across various application scenarios, identifying the specific conditions under which each approach demonstrates optimal performance.

Additionally, this report seeks to map the technological evolution pathways for both separation methods, with particular emphasis on recent innovations that may disrupt traditional trade-off relationships. These include developments in anti-fouling membrane materials, novel membrane geometries, advanced distillation internals, and hybrid separation systems that combine elements of both approaches.

The ultimate goal is to provide decision-makers with a structured framework for technology selection based on application-specific requirements, resource constraints, and sustainability objectives. This framework will incorporate both established performance metrics and emerging considerations such as carbon footprint, water usage, and adaptability to renewable energy sources, reflecting the increasing importance of environmental factors in technology deployment decisions.

The technological trajectory of membrane filtration has accelerated dramatically since the 1960s, with the invention of asymmetric cellulose acetate membranes by Loeb and Sourirajan marking a pivotal moment. This innovation enabled practical reverse osmosis applications and catalyzed development across the spectrum of membrane technologies including microfiltration, ultrafiltration, nanofiltration, and reverse osmosis. Each of these technologies operates on different principles of size exclusion and offers varying degrees of separation capability.

Distillation technology has similarly progressed from simple pot stills to sophisticated multi-stage fractional distillation columns with advanced heat integration systems. Modern distillation incorporates vacuum operation, azeotropic distillation, and reactive distillation to overcome thermodynamic limitations and enhance energy efficiency. The development of computational modeling tools has further optimized these processes, allowing for precise design and control.

The primary objective of this technical research report is to conduct a comprehensive comparative analysis of membrane filtration and distillation technologies across three critical dimensions: energy consumption, product purity, and economic considerations. We aim to establish quantitative benchmarks for each technology across various application scenarios, identifying the specific conditions under which each approach demonstrates optimal performance.

Additionally, this report seeks to map the technological evolution pathways for both separation methods, with particular emphasis on recent innovations that may disrupt traditional trade-off relationships. These include developments in anti-fouling membrane materials, novel membrane geometries, advanced distillation internals, and hybrid separation systems that combine elements of both approaches.

The ultimate goal is to provide decision-makers with a structured framework for technology selection based on application-specific requirements, resource constraints, and sustainability objectives. This framework will incorporate both established performance metrics and emerging considerations such as carbon footprint, water usage, and adaptability to renewable energy sources, reflecting the increasing importance of environmental factors in technology deployment decisions.

Market Analysis for Water Purification Solutions

The global water purification market is experiencing robust growth, driven by increasing water scarcity, rising pollution levels, and growing awareness of health impacts from contaminated water. Currently valued at approximately $30 billion, the market is projected to reach $44 billion by 2025, representing a compound annual growth rate of 7.1%.

Membrane filtration and distillation technologies collectively dominate nearly 65% of the industrial water treatment sector. Membrane filtration has seen accelerated adoption in recent years, capturing 38% of the market share due to its lower energy requirements and operational flexibility. Distillation technologies, while more established, maintain a 27% market share primarily in applications requiring extremely high purity levels.

Regional analysis reveals distinct market preferences. North America and Europe favor membrane technologies due to stringent environmental regulations and energy efficiency concerns. The Asia-Pacific region represents the fastest-growing market for both technologies, with China and India investing heavily in water infrastructure development. Middle Eastern countries continue to be the strongest market for distillation technologies, particularly thermal desalination, due to their energy resources and acute freshwater scarcity.

End-user segmentation shows that municipal water treatment accounts for 41% of the market, followed by industrial applications at 32%, and residential solutions at 27%. Within industrial applications, pharmaceuticals, food and beverage, and semiconductor manufacturing represent the highest-value segments due to their ultra-pure water requirements.

Customer demand patterns indicate a growing preference for hybrid systems that combine membrane filtration with other purification methods to optimize both energy consumption and water purity. The market also shows increasing interest in modular, scalable solutions that can be deployed in decentralized settings, particularly in developing regions with limited infrastructure.

Price sensitivity varies significantly across market segments. Municipal projects typically prioritize total lifecycle costs, while industrial users often place premium value on reliability and purity guarantees. The residential market remains highly price-sensitive, with consumers increasingly seeking solutions that balance affordability with effectiveness.

Emerging market opportunities include point-of-use systems for developing regions, specialized solutions for emerging contaminants (such as PFAS and microplastics), and smart water purification systems incorporating IoT capabilities for remote monitoring and predictive maintenance. These segments are expected to grow at above-market rates of 9-12% annually over the next five years.

Membrane filtration and distillation technologies collectively dominate nearly 65% of the industrial water treatment sector. Membrane filtration has seen accelerated adoption in recent years, capturing 38% of the market share due to its lower energy requirements and operational flexibility. Distillation technologies, while more established, maintain a 27% market share primarily in applications requiring extremely high purity levels.

Regional analysis reveals distinct market preferences. North America and Europe favor membrane technologies due to stringent environmental regulations and energy efficiency concerns. The Asia-Pacific region represents the fastest-growing market for both technologies, with China and India investing heavily in water infrastructure development. Middle Eastern countries continue to be the strongest market for distillation technologies, particularly thermal desalination, due to their energy resources and acute freshwater scarcity.

End-user segmentation shows that municipal water treatment accounts for 41% of the market, followed by industrial applications at 32%, and residential solutions at 27%. Within industrial applications, pharmaceuticals, food and beverage, and semiconductor manufacturing represent the highest-value segments due to their ultra-pure water requirements.

Customer demand patterns indicate a growing preference for hybrid systems that combine membrane filtration with other purification methods to optimize both energy consumption and water purity. The market also shows increasing interest in modular, scalable solutions that can be deployed in decentralized settings, particularly in developing regions with limited infrastructure.

Price sensitivity varies significantly across market segments. Municipal projects typically prioritize total lifecycle costs, while industrial users often place premium value on reliability and purity guarantees. The residential market remains highly price-sensitive, with consumers increasingly seeking solutions that balance affordability with effectiveness.

Emerging market opportunities include point-of-use systems for developing regions, specialized solutions for emerging contaminants (such as PFAS and microplastics), and smart water purification systems incorporating IoT capabilities for remote monitoring and predictive maintenance. These segments are expected to grow at above-market rates of 9-12% annually over the next five years.

Current Challenges in Separation Technologies

Separation technologies face significant challenges in today's industrial landscape, particularly when comparing membrane filtration and distillation processes. Energy consumption remains a primary concern, with distillation typically requiring substantial thermal energy to achieve phase changes, while membrane filtration generally consumes less energy but faces limitations in throughput capacity and membrane durability under harsh conditions.

Purity achievement presents another critical challenge. Distillation excels at producing high-purity separations for certain applications, but struggles with azeotropic mixtures where components cannot be completely separated regardless of repeated distillation. Membrane technologies, while advancing rapidly, still encounter difficulties with fouling and concentration polarization that compromise separation efficiency and product purity over operational cycles.

Cost considerations create complex trade-off scenarios that industries must navigate. Distillation systems generally require higher initial capital investment but may offer longer operational lifespans. Membrane systems typically have lower upfront costs but higher replacement frequencies and maintenance requirements, creating challenges in total cost of ownership calculations across different operational timeframes.

Scale-up capabilities differ significantly between these technologies. Distillation benefits from decades of engineering experience in large-scale implementations, while membrane technologies often face challenges in maintaining consistent performance when scaled from laboratory to industrial applications. This creates barriers to adoption for membrane technologies despite their potential advantages.

Environmental impact considerations are increasingly constraining technology selection. Distillation's high energy consumption contributes to larger carbon footprints, while membrane technologies may involve specialized materials with their own environmental concerns regarding production and disposal. Regulatory frameworks are evolving to address these impacts, creating compliance challenges for both approaches.

Integration with existing infrastructure presents significant hurdles, particularly for facilities designed around traditional distillation processes. Retrofitting for membrane technologies often requires substantial modifications to process control systems, piping configurations, and operational protocols, creating resistance to adoption despite potential benefits.

Material limitations constrain both technologies. Membrane materials struggle with chemical compatibility, temperature tolerance, and mechanical stability under industrial conditions. Distillation equipment faces corrosion, scaling, and efficiency losses that require specialized materials and designs, particularly for aggressive separation environments.

These multifaceted challenges necessitate careful evaluation of separation technology selection based on specific application requirements, available resources, and long-term operational goals rather than universal solutions.

Purity achievement presents another critical challenge. Distillation excels at producing high-purity separations for certain applications, but struggles with azeotropic mixtures where components cannot be completely separated regardless of repeated distillation. Membrane technologies, while advancing rapidly, still encounter difficulties with fouling and concentration polarization that compromise separation efficiency and product purity over operational cycles.

Cost considerations create complex trade-off scenarios that industries must navigate. Distillation systems generally require higher initial capital investment but may offer longer operational lifespans. Membrane systems typically have lower upfront costs but higher replacement frequencies and maintenance requirements, creating challenges in total cost of ownership calculations across different operational timeframes.

Scale-up capabilities differ significantly between these technologies. Distillation benefits from decades of engineering experience in large-scale implementations, while membrane technologies often face challenges in maintaining consistent performance when scaled from laboratory to industrial applications. This creates barriers to adoption for membrane technologies despite their potential advantages.

Environmental impact considerations are increasingly constraining technology selection. Distillation's high energy consumption contributes to larger carbon footprints, while membrane technologies may involve specialized materials with their own environmental concerns regarding production and disposal. Regulatory frameworks are evolving to address these impacts, creating compliance challenges for both approaches.

Integration with existing infrastructure presents significant hurdles, particularly for facilities designed around traditional distillation processes. Retrofitting for membrane technologies often requires substantial modifications to process control systems, piping configurations, and operational protocols, creating resistance to adoption despite potential benefits.

Material limitations constrain both technologies. Membrane materials struggle with chemical compatibility, temperature tolerance, and mechanical stability under industrial conditions. Distillation equipment faces corrosion, scaling, and efficiency losses that require specialized materials and designs, particularly for aggressive separation environments.

These multifaceted challenges necessitate careful evaluation of separation technology selection based on specific application requirements, available resources, and long-term operational goals rather than universal solutions.

Comparative Analysis of Membrane vs Distillation

01 Energy efficiency in membrane filtration and distillation

Various technologies have been developed to improve energy efficiency in membrane filtration and distillation processes. These include heat recovery systems, energy-efficient membrane materials, and optimized process configurations that reduce energy consumption. Advanced designs incorporate waste heat utilization and energy integration between process steps, significantly lowering operational costs while maintaining separation performance.- Energy efficiency in membrane filtration and distillation: Various technologies have been developed to improve energy efficiency in membrane filtration and distillation processes. These include heat recovery systems, energy-efficient membrane designs, and optimized operating conditions. By reducing energy consumption, these innovations help lower operational costs while maintaining filtration performance. Advanced energy recovery devices and thermal integration techniques further enhance efficiency by capturing and reusing energy that would otherwise be lost during the process.

- Purity enhancement techniques: Specialized membrane materials and configurations have been developed to achieve higher purity levels in filtration and distillation processes. These include multi-stage filtration systems, advanced membrane compositions, and hybrid processes that combine different separation mechanisms. Such techniques enable the removal of specific contaminants and achieve higher product purity, which is crucial for applications requiring ultra-pure water or other substances. The purity enhancement is achieved without significantly increasing energy requirements or operational costs.

- Cost optimization strategies: Various approaches have been developed to optimize the cost-effectiveness of membrane filtration and distillation systems. These include the use of lower-cost membrane materials, modular system designs that allow for scalability, and maintenance-reducing technologies that extend membrane life. Additionally, process intensification techniques help reduce capital and operational expenses by increasing throughput per unit area of membrane. These innovations make membrane-based separation more economically viable for a wider range of applications.

- Hybrid membrane-distillation systems: Hybrid systems that combine membrane filtration with distillation processes offer advantages in terms of energy efficiency, product purity, and operational costs. These integrated approaches leverage the strengths of each technology while mitigating their individual limitations. For example, membrane distillation can operate at lower temperatures than conventional distillation while achieving similar separation efficiency. Such hybrid configurations are particularly beneficial for treating complex feed streams or when both high purity and energy efficiency are required simultaneously.

- Novel membrane materials and configurations: Research has led to the development of innovative membrane materials and configurations that improve filtration performance while addressing energy, purity, and cost concerns. These include nanocomposite membranes, biomimetic membranes, and specialized surface modifications that enhance selectivity and flux. Advanced membrane configurations, such as hollow fiber and spiral-wound designs, optimize the surface area-to-volume ratio and flow dynamics. These innovations contribute to higher throughput, better rejection of contaminants, and longer membrane lifetimes, ultimately improving the overall efficiency of filtration and distillation processes.

02 Purity enhancement techniques

Innovations in membrane technology focus on achieving higher purity levels in filtration and distillation processes. These include multi-stage filtration systems, specialized membrane materials with selective permeability, and hybrid processes combining different separation mechanisms. These techniques enable the removal of specific contaminants and achieve higher product purity while optimizing resource utilization.Expand Specific Solutions03 Cost reduction strategies

Cost-effective approaches for membrane filtration and distillation include the development of durable membrane materials with extended operational lifespans, modular system designs that allow for scalability, and simplified maintenance procedures. Process intensification techniques reduce capital investment while automated control systems optimize operational parameters to minimize resource consumption and maintenance requirements.Expand Specific Solutions04 Hybrid and integrated systems

Hybrid systems combining membrane filtration with distillation processes offer synergistic benefits in terms of energy efficiency, product purity, and operational costs. These integrated approaches leverage the strengths of each technology while mitigating their individual limitations. Examples include membrane distillation, forward osmosis coupled with thermal processes, and electrochemically assisted membrane systems that enhance separation efficiency while reducing energy requirements.Expand Specific Solutions05 Novel membrane materials and configurations

Advanced membrane materials and innovative configurations significantly impact energy consumption, achievable purity, and overall process economics. These include nanocomposite membranes, biomimetic materials, 3D-printed membrane structures, and specialized surface modifications that enhance selectivity and flux. Novel membrane configurations such as hollow fiber, spiral-wound, and sheet arrangements optimize surface area and flow dynamics, improving separation efficiency while reducing footprint and energy requirements.Expand Specific Solutions

Leading Companies in Filtration Industry

The membrane filtration versus distillation technology landscape is currently in a growth phase, with the global market expected to reach $8-10 billion by 2025. Membrane technologies are gaining momentum due to their lower energy consumption, while distillation maintains dominance in applications requiring high purity. Leading players represent diverse specializations: academic institutions (MIT, KAUST, Nanyang Technological University) drive fundamental research; industrial giants (Siemens AG, LG Chem, Toray Industries) focus on commercial applications; and specialized companies (Aquatech International, Whitefox Technologies, Milton Roy) develop niche solutions. The competitive landscape is characterized by increasing collaboration between research institutions and industry partners to address energy-efficiency challenges while maintaining separation performance.

King Abdullah University of Science & Technology

Technical Solution: KAUST has pioneered advanced membrane technologies specifically designed for water treatment in extreme environments. Their research focuses on developing thermally resistant mixed matrix membranes (MMMs) that incorporate metal-organic frameworks (MOFs) and other nanomaterials to enhance separation performance. These membranes demonstrate exceptional chlorine resistance (>10,000 ppm-hours) and thermal stability (up to 90°C), making them suitable for challenging industrial wastewater treatment applications[1]. KAUST has also developed innovative membrane distillation (MD) configurations, particularly multi-stage vacuum membrane distillation systems that operate at significantly lower temperatures than conventional thermal distillation. Their pilot studies demonstrate that these systems can achieve 98% water recovery from high-salinity brines while consuming approximately 30-40% less energy than multi-stage flash distillation[3]. Additionally, KAUST has pioneered solar-powered membrane distillation systems that utilize renewable energy to further reduce operational costs in regions with abundant sunlight.

Strengths: Exceptional performance in high-salinity environments; lower energy requirements compared to conventional distillation; innovative integration with renewable energy sources; excellent fouling resistance. Weaknesses: Higher manufacturing costs for specialized membranes; technology still scaling from pilot to full commercial implementation; potential challenges in regions with limited solar resources.

Massachusetts Institute of Technology

Technical Solution: MIT has developed advanced membrane filtration technologies focusing on forward osmosis (FO) and pressure retarded osmosis (PRO) systems. Their research includes novel thin-film composite membranes with engineered surface chemistry that significantly reduces fouling while maintaining high flux rates. MIT's approach integrates nanotechnology with membrane science, creating nanostructured membranes with precisely controlled pore sizes (1-10 nm) that enable selective filtration of specific contaminants while allowing water molecules to pass through[1]. They've also pioneered temperature-responsive membranes that can self-clean when exposed to temperature changes, addressing one of the major operational challenges in membrane filtration. MIT's research demonstrates that their optimized membrane systems can achieve up to 30% energy savings compared to conventional distillation processes for seawater desalination applications[3], while maintaining comparable output water purity levels.

Strengths: Superior energy efficiency with documented 30% reduction in energy consumption compared to distillation; advanced anti-fouling properties extending operational lifetime; scalable manufacturing processes. Weaknesses: Higher initial capital costs; potential limitations in handling extremely high-salinity feeds; membrane replacement requirements over time.

Key Patents in Separation Technology

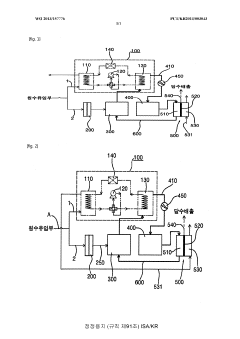

Membrane filtering apparatus using heat pump

PatentWO2013157776A1

Innovation

- A membrane filtration device integrating a heat pump to absorb thermal energy from influent water, using forward osmosis and membrane distillation to separate fresh water, reducing heating power and eliminating the need for separate cooling, with recirculation of induction solution and fresh water to minimize heat loss and extend membrane lifespan.

Method and device for the purification, especially desalination, of water

PatentWO2004101444A9

Innovation

- A membrane distillation process using a hydrophobic membrane in conjunction with a thicker, less conductive hydrophilic membrane, where a vapor pressure difference is generated by pumping action to drive water condensation in the hydrophilic membrane pores, reducing energy consumption and preventing saltwater from filling the hydrophobic membrane pores.

Environmental Impact Assessment

The environmental impact of water treatment technologies has become increasingly important in decision-making processes for industrial and municipal applications. When comparing membrane filtration and distillation technologies, their environmental footprints differ significantly across multiple dimensions.

Membrane filtration systems generally demonstrate lower energy consumption compared to distillation processes, resulting in reduced greenhouse gas emissions when powered by conventional energy sources. Modern ultrafiltration and reverse osmosis systems operate at 3-10 kWh per cubic meter of treated water, while thermal distillation methods typically require 15-100 kWh per cubic meter, depending on configuration and scale.

Chemical usage patterns also differ substantially between these technologies. Distillation processes often require fewer chemical inputs for routine operation but may need aggressive cleaning agents during maintenance cycles. Membrane systems regularly utilize antiscalants, disinfectants, and cleaning chemicals that can potentially impact aquatic ecosystems if discharge management is inadequate.

Waste stream characteristics present another environmental consideration. Membrane processes generate concentrated reject streams containing the removed contaminants, which require proper management to prevent environmental contamination. Distillation produces brine with different compositional characteristics, often at higher temperatures, potentially creating thermal pollution concerns in receiving water bodies.

The carbon footprint analysis reveals that membrane filtration typically produces 0.5-2 kg CO2 equivalent per cubic meter of treated water, while distillation systems generate 2-8 kg CO2 equivalent, depending on energy source and system efficiency. However, when renewable energy sources power distillation systems, this gap narrows significantly.

Life cycle assessment studies indicate that membrane technologies generally have lower environmental impacts in categories such as acidification potential and eutrophication. However, membrane manufacturing processes involve petrochemical derivatives with their own environmental burdens, and membrane disposal presents end-of-life challenges due to limited recycling options.

Water recovery rates also influence environmental sustainability, with modern membrane systems achieving 75-85% recovery compared to distillation's 30-50%. Higher recovery rates translate to reduced raw water extraction needs, benefiting source water ecosystems, particularly in water-stressed regions.

Recent technological innovations are improving the environmental profiles of both technologies, with energy recovery devices for membrane systems and renewable energy integration for distillation processes showing promising reductions in overall environmental impact.

Membrane filtration systems generally demonstrate lower energy consumption compared to distillation processes, resulting in reduced greenhouse gas emissions when powered by conventional energy sources. Modern ultrafiltration and reverse osmosis systems operate at 3-10 kWh per cubic meter of treated water, while thermal distillation methods typically require 15-100 kWh per cubic meter, depending on configuration and scale.

Chemical usage patterns also differ substantially between these technologies. Distillation processes often require fewer chemical inputs for routine operation but may need aggressive cleaning agents during maintenance cycles. Membrane systems regularly utilize antiscalants, disinfectants, and cleaning chemicals that can potentially impact aquatic ecosystems if discharge management is inadequate.

Waste stream characteristics present another environmental consideration. Membrane processes generate concentrated reject streams containing the removed contaminants, which require proper management to prevent environmental contamination. Distillation produces brine with different compositional characteristics, often at higher temperatures, potentially creating thermal pollution concerns in receiving water bodies.

The carbon footprint analysis reveals that membrane filtration typically produces 0.5-2 kg CO2 equivalent per cubic meter of treated water, while distillation systems generate 2-8 kg CO2 equivalent, depending on energy source and system efficiency. However, when renewable energy sources power distillation systems, this gap narrows significantly.

Life cycle assessment studies indicate that membrane technologies generally have lower environmental impacts in categories such as acidification potential and eutrophication. However, membrane manufacturing processes involve petrochemical derivatives with their own environmental burdens, and membrane disposal presents end-of-life challenges due to limited recycling options.

Water recovery rates also influence environmental sustainability, with modern membrane systems achieving 75-85% recovery compared to distillation's 30-50%. Higher recovery rates translate to reduced raw water extraction needs, benefiting source water ecosystems, particularly in water-stressed regions.

Recent technological innovations are improving the environmental profiles of both technologies, with energy recovery devices for membrane systems and renewable energy integration for distillation processes showing promising reductions in overall environmental impact.

Scalability and Implementation Considerations

Scaling membrane filtration and distillation technologies presents distinct challenges that significantly impact their industrial adoption. Membrane filtration systems demonstrate superior modularity, allowing for incremental capacity expansion through the addition of membrane modules. This characteristic makes membrane technologies particularly suitable for decentralized applications and facilities with space constraints or fluctuating production demands. The footprint advantage becomes especially pronounced in large-scale operations, where membrane systems typically require 50-70% less floor space than equivalent distillation installations.

Implementation complexity varies substantially between these technologies. Distillation systems demand extensive infrastructure including boilers, condensers, and complex control systems, resulting in longer installation timeframes—typically 12-18 months for industrial-scale units. Conversely, membrane filtration systems can often be deployed within 3-6 months, offering faster operational readiness and return on investment. This implementation agility provides strategic advantages for businesses facing rapid market changes or seasonal production requirements.

Operational scalability considerations extend beyond physical installation to include staffing requirements and expertise levels. Distillation operations generally necessitate specialized technical personnel with thermodynamic process expertise, whereas membrane systems can often be managed with less specialized training after initial setup. This staffing differential translates to approximately 30-40% lower operational labor costs for membrane systems at comparable production scales.

Infrastructure dependencies represent another critical implementation factor. Distillation's substantial energy requirements often necessitate dedicated utility infrastructure upgrades, including steam generation capacity and cooling systems. Membrane filtration's more modest energy profile typically allows implementation within existing utility frameworks, though specialized pre-treatment systems may be required to protect membrane integrity and longevity.

Regulatory compliance pathways differ significantly between technologies. Distillation benefits from well-established regulatory frameworks across industries, while membrane technologies may face more variable approval processes depending on application context. This regulatory familiarity can accelerate implementation timelines for distillation in highly regulated sectors like pharmaceuticals, despite the technology's greater physical complexity.

Scaling considerations must also account for non-linear cost relationships. Distillation exhibits favorable economies of scale, with capital costs increasing at approximately 0.6 power of capacity increase (following the six-tenths rule). Membrane systems demonstrate more linear scaling, potentially disadvantaging very large installations where distillation's economies of scale become pronounced. This economic inflection point typically occurs at processing volumes exceeding 500,000 liters per day, depending on specific separation requirements.

Implementation complexity varies substantially between these technologies. Distillation systems demand extensive infrastructure including boilers, condensers, and complex control systems, resulting in longer installation timeframes—typically 12-18 months for industrial-scale units. Conversely, membrane filtration systems can often be deployed within 3-6 months, offering faster operational readiness and return on investment. This implementation agility provides strategic advantages for businesses facing rapid market changes or seasonal production requirements.

Operational scalability considerations extend beyond physical installation to include staffing requirements and expertise levels. Distillation operations generally necessitate specialized technical personnel with thermodynamic process expertise, whereas membrane systems can often be managed with less specialized training after initial setup. This staffing differential translates to approximately 30-40% lower operational labor costs for membrane systems at comparable production scales.

Infrastructure dependencies represent another critical implementation factor. Distillation's substantial energy requirements often necessitate dedicated utility infrastructure upgrades, including steam generation capacity and cooling systems. Membrane filtration's more modest energy profile typically allows implementation within existing utility frameworks, though specialized pre-treatment systems may be required to protect membrane integrity and longevity.

Regulatory compliance pathways differ significantly between technologies. Distillation benefits from well-established regulatory frameworks across industries, while membrane technologies may face more variable approval processes depending on application context. This regulatory familiarity can accelerate implementation timelines for distillation in highly regulated sectors like pharmaceuticals, despite the technology's greater physical complexity.

Scaling considerations must also account for non-linear cost relationships. Distillation exhibits favorable economies of scale, with capital costs increasing at approximately 0.6 power of capacity increase (following the six-tenths rule). Membrane systems demonstrate more linear scaling, potentially disadvantaging very large installations where distillation's economies of scale become pronounced. This economic inflection point typically occurs at processing volumes exceeding 500,000 liters per day, depending on specific separation requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!