Scale-Up Guide For Membrane Systems: Fouling, Backwash, And Flux Decline

AUG 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Membrane Technology Evolution and Scaling Objectives

Membrane technology has evolved significantly over the past several decades, transforming from laboratory curiosities to industrial workhorses across multiple sectors. The journey began in the 1960s with the development of the first asymmetric cellulose acetate membranes by Loeb and Sourirajan, which revolutionized water desalination through reverse osmosis. This breakthrough laid the foundation for modern membrane separation processes that now extend beyond water treatment to pharmaceuticals, food processing, and chemical manufacturing.

The 1980s witnessed the emergence of more robust polymeric membranes with enhanced chemical resistance and thermal stability, enabling broader industrial applications. By the 1990s, ceramic and inorganic membranes gained prominence for their exceptional durability in harsh environments. The early 2000s marked the integration of nanotechnology with membrane science, introducing nanofiltration membranes and nanocomposite materials that offered unprecedented selectivity and flux rates.

Recent advancements have focused on addressing the persistent challenges of membrane fouling and flux decline. Innovations include the development of anti-fouling surface modifications, self-cleaning membranes, and biomimetic designs inspired by natural filtration systems. These improvements have significantly extended membrane operational lifespans and reduced maintenance requirements, making membrane systems more economically viable for large-scale applications.

The primary objective in scaling membrane systems is to maintain consistent performance metrics when transitioning from laboratory or pilot scale to full industrial implementation. This includes preserving separation efficiency, flux rates, and selectivity while managing the increased complexity of larger systems. Scaling objectives must account for the non-linear relationship between membrane surface area and system performance, particularly as fouling dynamics change with scale.

Critical scaling considerations include optimizing hydrodynamic conditions to minimize concentration polarization and fouling propensity. Engineers must design appropriate backwash protocols that can be effectively implemented across larger membrane arrays without compromising membrane integrity or system efficiency. Additionally, scaling objectives encompass the development of predictive models that accurately forecast flux decline patterns in industrial-scale operations, enabling proactive maintenance scheduling.

The evolution of membrane technology continues to be driven by the dual imperatives of enhancing performance while reducing operational costs. Future scaling objectives will likely focus on energy efficiency, sustainable materials, and intelligent monitoring systems that leverage machine learning for real-time optimization of membrane operations. These advancements will be crucial for expanding membrane technology into emerging applications such as resource recovery from waste streams and advanced separations in biorefineries.

The 1980s witnessed the emergence of more robust polymeric membranes with enhanced chemical resistance and thermal stability, enabling broader industrial applications. By the 1990s, ceramic and inorganic membranes gained prominence for their exceptional durability in harsh environments. The early 2000s marked the integration of nanotechnology with membrane science, introducing nanofiltration membranes and nanocomposite materials that offered unprecedented selectivity and flux rates.

Recent advancements have focused on addressing the persistent challenges of membrane fouling and flux decline. Innovations include the development of anti-fouling surface modifications, self-cleaning membranes, and biomimetic designs inspired by natural filtration systems. These improvements have significantly extended membrane operational lifespans and reduced maintenance requirements, making membrane systems more economically viable for large-scale applications.

The primary objective in scaling membrane systems is to maintain consistent performance metrics when transitioning from laboratory or pilot scale to full industrial implementation. This includes preserving separation efficiency, flux rates, and selectivity while managing the increased complexity of larger systems. Scaling objectives must account for the non-linear relationship between membrane surface area and system performance, particularly as fouling dynamics change with scale.

Critical scaling considerations include optimizing hydrodynamic conditions to minimize concentration polarization and fouling propensity. Engineers must design appropriate backwash protocols that can be effectively implemented across larger membrane arrays without compromising membrane integrity or system efficiency. Additionally, scaling objectives encompass the development of predictive models that accurately forecast flux decline patterns in industrial-scale operations, enabling proactive maintenance scheduling.

The evolution of membrane technology continues to be driven by the dual imperatives of enhancing performance while reducing operational costs. Future scaling objectives will likely focus on energy efficiency, sustainable materials, and intelligent monitoring systems that leverage machine learning for real-time optimization of membrane operations. These advancements will be crucial for expanding membrane technology into emerging applications such as resource recovery from waste streams and advanced separations in biorefineries.

Market Demand for Advanced Membrane Filtration Systems

The global membrane filtration market has experienced significant growth in recent years, driven by increasing water scarcity concerns, stringent environmental regulations, and growing industrial demand for efficient separation technologies. The market for advanced membrane systems is projected to reach $19.6 billion by 2025, with a compound annual growth rate of 7.2% from 2020 to 2025.

Water treatment applications represent the largest segment of the membrane filtration market, accounting for approximately 40% of the total demand. This is primarily due to the growing need for clean water in both developed and developing regions, coupled with increasingly strict regulations on water quality and discharge standards. Municipal water treatment facilities are increasingly adopting membrane technologies to replace conventional treatment methods due to their higher efficiency and smaller footprint.

Industrial applications constitute another significant market segment, particularly in food and beverage, pharmaceuticals, and chemical processing. These industries require high-purity water and efficient separation processes, driving the adoption of advanced membrane systems. The food and beverage industry alone accounts for 25% of the industrial membrane market, with dairy processing being a major application area.

Healthcare and pharmaceutical sectors show the fastest growth rate in membrane technology adoption, with an estimated 9.5% annual growth. This is attributed to the increasing demand for purified water in drug manufacturing and the growing emphasis on quality control in pharmaceutical processes. Biopharmaceutical manufacturing, in particular, relies heavily on membrane filtration for protein separation and purification.

Geographically, North America and Europe currently dominate the market with a combined share of 55%, primarily due to early adoption and stringent environmental regulations. However, the Asia-Pacific region is expected to witness the highest growth rate of 8.7% annually, driven by rapid industrialization, urbanization, and increasing water treatment needs in countries like China and India.

A key market trend is the growing demand for membrane systems that effectively address fouling, backwashing, and flux decline issues. End-users are increasingly seeking solutions that minimize operational downtime and maintenance costs associated with membrane cleaning and replacement. This has created a specific market segment for anti-fouling membranes and advanced backwash systems, estimated to be worth $3.2 billion globally.

Energy efficiency has emerged as another critical factor driving market demand. Industries are seeking membrane systems that can operate at lower pressures while maintaining high flux rates, thereby reducing energy consumption and operational costs. This trend is particularly evident in desalination applications, where energy costs represent a significant portion of operational expenses.

Water treatment applications represent the largest segment of the membrane filtration market, accounting for approximately 40% of the total demand. This is primarily due to the growing need for clean water in both developed and developing regions, coupled with increasingly strict regulations on water quality and discharge standards. Municipal water treatment facilities are increasingly adopting membrane technologies to replace conventional treatment methods due to their higher efficiency and smaller footprint.

Industrial applications constitute another significant market segment, particularly in food and beverage, pharmaceuticals, and chemical processing. These industries require high-purity water and efficient separation processes, driving the adoption of advanced membrane systems. The food and beverage industry alone accounts for 25% of the industrial membrane market, with dairy processing being a major application area.

Healthcare and pharmaceutical sectors show the fastest growth rate in membrane technology adoption, with an estimated 9.5% annual growth. This is attributed to the increasing demand for purified water in drug manufacturing and the growing emphasis on quality control in pharmaceutical processes. Biopharmaceutical manufacturing, in particular, relies heavily on membrane filtration for protein separation and purification.

Geographically, North America and Europe currently dominate the market with a combined share of 55%, primarily due to early adoption and stringent environmental regulations. However, the Asia-Pacific region is expected to witness the highest growth rate of 8.7% annually, driven by rapid industrialization, urbanization, and increasing water treatment needs in countries like China and India.

A key market trend is the growing demand for membrane systems that effectively address fouling, backwashing, and flux decline issues. End-users are increasingly seeking solutions that minimize operational downtime and maintenance costs associated with membrane cleaning and replacement. This has created a specific market segment for anti-fouling membranes and advanced backwash systems, estimated to be worth $3.2 billion globally.

Energy efficiency has emerged as another critical factor driving market demand. Industries are seeking membrane systems that can operate at lower pressures while maintaining high flux rates, thereby reducing energy consumption and operational costs. This trend is particularly evident in desalination applications, where energy costs represent a significant portion of operational expenses.

Current Challenges in Large-Scale Membrane Operations

Despite significant advancements in membrane technology, large-scale membrane operations face several persistent challenges that limit their efficiency and economic viability. Membrane fouling remains the most critical issue, occurring when particles, colloids, organic matter, and microorganisms accumulate on membrane surfaces or within pores. This phenomenon manifests differently across scales, with large systems experiencing more complex fouling patterns due to uneven flow distribution and concentration polarization effects that are less pronounced in laboratory settings.

Flux decline, directly related to fouling, presents a major operational challenge in industrial applications. While laboratory systems might maintain stable flux for hours, industrial-scale operations often experience gradual performance deterioration over weeks or months, necessitating more frequent cleaning cycles and reducing overall productivity. This scale-dependent behavior is inadequately addressed in current design methodologies.

Backwashing and cleaning protocols that prove effective at bench scale frequently fail to deliver comparable results in full-scale operations. The challenge lies in achieving uniform cleaning agent distribution throughout large membrane modules, particularly in configurations with complex flow patterns. Additionally, the economics of cleaning chemicals usage becomes significantly more impactful at industrial scale, requiring optimization strategies that balance effectiveness with cost considerations.

Energy consumption represents another scale-dependent challenge, with pumping requirements increasing non-linearly with system size due to pressure drop considerations across larger membrane arrays. This creates a complex optimization problem where membrane configuration, module arrangement, and operating parameters must be carefully balanced to minimize energy consumption while maintaining performance.

Operational control systems face increased complexity in large installations, where multiple membrane trains operate in parallel with varying fouling rates and performance characteristics. Developing robust control algorithms that can manage such heterogeneous conditions remains difficult, particularly when incorporating predictive maintenance capabilities to optimize cleaning cycles.

Material limitations also become more apparent at scale, with mechanical integrity and chemical resistance issues emerging during long-term operation that may not be evident in short-duration laboratory tests. The mechanical stress on membranes in large housings, combined with repeated cleaning cycles, can accelerate aging and failure mechanisms that are rarely captured in accelerated testing protocols.

Finally, the economic viability of large membrane systems depends heavily on optimizing the balance between capital expenditure and operational costs, with scale-up decisions significantly impacting this balance. Current design approaches often fail to accurately predict how performance parameters will translate across scales, leading to suboptimal system configurations and unexpected operational challenges.

Flux decline, directly related to fouling, presents a major operational challenge in industrial applications. While laboratory systems might maintain stable flux for hours, industrial-scale operations often experience gradual performance deterioration over weeks or months, necessitating more frequent cleaning cycles and reducing overall productivity. This scale-dependent behavior is inadequately addressed in current design methodologies.

Backwashing and cleaning protocols that prove effective at bench scale frequently fail to deliver comparable results in full-scale operations. The challenge lies in achieving uniform cleaning agent distribution throughout large membrane modules, particularly in configurations with complex flow patterns. Additionally, the economics of cleaning chemicals usage becomes significantly more impactful at industrial scale, requiring optimization strategies that balance effectiveness with cost considerations.

Energy consumption represents another scale-dependent challenge, with pumping requirements increasing non-linearly with system size due to pressure drop considerations across larger membrane arrays. This creates a complex optimization problem where membrane configuration, module arrangement, and operating parameters must be carefully balanced to minimize energy consumption while maintaining performance.

Operational control systems face increased complexity in large installations, where multiple membrane trains operate in parallel with varying fouling rates and performance characteristics. Developing robust control algorithms that can manage such heterogeneous conditions remains difficult, particularly when incorporating predictive maintenance capabilities to optimize cleaning cycles.

Material limitations also become more apparent at scale, with mechanical integrity and chemical resistance issues emerging during long-term operation that may not be evident in short-duration laboratory tests. The mechanical stress on membranes in large housings, combined with repeated cleaning cycles, can accelerate aging and failure mechanisms that are rarely captured in accelerated testing protocols.

Finally, the economic viability of large membrane systems depends heavily on optimizing the balance between capital expenditure and operational costs, with scale-up decisions significantly impacting this balance. Current design approaches often fail to accurately predict how performance parameters will translate across scales, leading to suboptimal system configurations and unexpected operational challenges.

Established Scale-Up Methodologies for Membrane Systems

01 Fouling prevention and monitoring in membrane systems

Membrane fouling is a critical issue in filtration systems that leads to decreased performance and increased operational costs. Various technologies have been developed to prevent and monitor fouling, including advanced sensors that detect early signs of fouling, specialized coatings that reduce adhesion of foulants, and optimized operational parameters that minimize fouling potential. These preventive approaches help maintain membrane performance and extend the service life of filtration systems.- Fouling prevention and monitoring techniques: Various techniques are employed to prevent and monitor membrane fouling, which is a major cause of flux decline in membrane systems. These include real-time monitoring systems that detect early signs of fouling, advanced sensor technologies that measure parameters like pressure differential and flow rates, and preventive treatments that can be applied to membrane surfaces to reduce fouling propensity. These approaches help maintain optimal membrane performance and extend operational lifetimes.

- Backwash optimization strategies: Optimizing backwash procedures is critical for maintaining membrane performance. This includes determining optimal backwash frequency, duration, and intensity based on feed water quality and membrane characteristics. Advanced backwash systems may incorporate pulsed backwashing, air scouring, or chemical-enhanced backwashing to more effectively remove foulants from membrane surfaces. Properly designed backwash protocols can significantly reduce flux decline and extend intervals between chemical cleanings.

- Novel membrane materials and surface modifications: Development of new membrane materials and surface modifications aims to reduce fouling propensity and improve flux recovery. These innovations include hydrophilic coatings, antimicrobial surface treatments, and nanocomposite materials that resist organic and biological fouling. Some membranes incorporate self-cleaning mechanisms or responsive surfaces that change properties under different conditions. These advanced materials help maintain higher flux rates over longer operational periods.

- Chemical cleaning and maintenance protocols: Effective chemical cleaning protocols are essential for restoring membrane performance after fouling occurs. This includes selection of appropriate cleaning agents based on foulant type (organic, inorganic, or biological), optimization of cleaning frequency and duration, and development of multi-stage cleaning sequences. Proper maintenance protocols also include integrity testing and performance monitoring to assess cleaning effectiveness and membrane condition over time.

- Hydrodynamic optimization and flux control: Hydrodynamic optimization involves controlling flow patterns, turbulence, and pressure conditions to minimize fouling and flux decline. Techniques include cross-flow velocity adjustment, feed spacer design improvements, and implementation of variable flux operation. Advanced control systems can dynamically adjust operating parameters based on feed water quality and membrane condition. These approaches help maintain sustainable flux rates and reduce energy consumption while extending membrane life.

02 Backwash techniques and optimization

Backwashing is a crucial process for removing accumulated foulants from membrane surfaces. Advanced backwash techniques include pulsed backwashing, air-assisted backwashing, and chemically enhanced backwashing. Optimization of backwash parameters such as frequency, duration, pressure, and flow rate significantly improves cleaning efficiency while minimizing water consumption and system downtime. These optimized backwash strategies help restore membrane permeability and maintain consistent filtration performance.Expand Specific Solutions03 Flux decline management strategies

Flux decline in membrane systems occurs due to fouling, concentration polarization, and membrane degradation. Management strategies include implementing critical flux operation, where systems operate below the threshold where rapid fouling occurs, flux stepping techniques that gradually increase filtration rates, and relaxation periods that allow for foulant diffusion away from the membrane surface. These approaches help maintain sustainable flux rates and extend operational cycles between intensive cleaning procedures.Expand Specific Solutions04 Novel membrane materials and surface modifications

Innovative membrane materials and surface modifications have been developed to address fouling and flux decline issues. These include hydrophilic polymer blends that reduce organic fouling, nanocomposite membranes with embedded particles that provide antimicrobial properties, and surface grafting techniques that create anti-fouling layers. These advanced materials demonstrate improved resistance to various foulants while maintaining high permeability, resulting in more stable flux rates and extended operational lifetimes.Expand Specific Solutions05 Integrated cleaning and maintenance systems

Integrated cleaning and maintenance systems combine multiple approaches to address membrane fouling and flux decline. These systems incorporate automated cleaning sequences, real-time monitoring and adjustment of operational parameters, and predictive maintenance algorithms. Some designs feature built-in cleaning mechanisms that can be activated without system shutdown, while others utilize specialized cleaning agents formulated for specific foulant types. These integrated approaches minimize manual intervention and optimize system performance throughout the membrane lifecycle.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Membrane Technology

The membrane systems market for water treatment is currently in a growth phase, characterized by increasing adoption across industrial and municipal sectors. The market size is expanding steadily, driven by water scarcity concerns and stringent environmental regulations. Technologically, membrane fouling and flux decline remain critical challenges, with varying degrees of maturity in solutions. Leading players like Evoqua Water Technologies, Siemens Water Technologies, and IDE Technologies have developed advanced backwash techniques and anti-fouling membranes, while academic institutions such as MIT, KAUST, and Sichuan University are pioneering next-generation membrane materials. Companies including H2O Innovation and Ecolab are focusing on specialized chemical treatments to extend membrane life and optimize performance, creating a competitive landscape where technological differentiation is key to market leadership.

Evoqua Water Technologies LLC

Technical Solution: Evoqua's membrane fouling management system employs a multi-barrier approach combining pretreatment, advanced membrane chemistry, and automated cleaning protocols. Their proprietary MemCor® membrane systems utilize PVDF hollow fiber membranes with outside-in filtration that allows for more effective backwashing. The system incorporates real-time monitoring with predictive analytics to detect early signs of fouling and automatically adjust operational parameters. Their membrane aeration system creates turbulence at the membrane surface to reduce cake layer formation, while their automated chemical cleaning sequence alternates between acidic and alkaline cleaners to address both organic and inorganic foulants[1]. Evoqua's scale-up methodology includes pilot testing followed by modular expansion, allowing systems to grow from 0.1 MGD to over 100 MGD while maintaining consistent flux rates and recovery percentages.

Strengths: Superior backwash efficiency with outside-in filtration allowing for higher recovery rates; advanced predictive analytics for early fouling detection; modular design enabling seamless scale-up. Weaknesses: Higher initial capital investment compared to conventional systems; proprietary technology creates potential vendor lock-in; requires more sophisticated operator training.

Ecolab USA, Inc.

Technical Solution: Ecolab has developed a comprehensive membrane management program called "Membrane Performance Enhancement Technology" (MPET) specifically addressing fouling, backwash optimization, and flux maintenance during scale-up. Their approach integrates specialized membrane-compatible chemistry with advanced monitoring systems and service protocols. The MPET system utilizes proprietary anti-scalants and dispersants formulated to prevent specific foulants based on feed water analysis. Their membrane cleaning protocols incorporate a sequential cleaning approach with customized chemical formulations targeting organic, inorganic, and biological fouling mechanisms. Ecolab's real-time monitoring system tracks key performance indicators including normalized flux, differential pressure, and salt passage to detect early signs of fouling[3]. For backwash optimization, they've developed an adaptive backwash controller that adjusts frequency, duration, and intensity based on membrane performance data. During scale-up, Ecolab implements a phased approach with intermediate testing to validate performance parameters before full-scale implementation, ensuring consistent flux rates across expanded systems.

Strengths: Customized chemical solutions for specific fouling challenges; comprehensive service approach combining chemistry, equipment, and expertise; data-driven optimization of cleaning protocols. Weaknesses: Reliance on proprietary chemicals may increase operational costs; requires ongoing service relationship; complex monitoring systems require specialized technical support.

Critical Fouling Mechanisms and Backwash Optimization Techniques

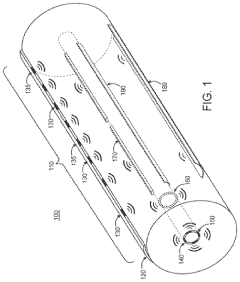

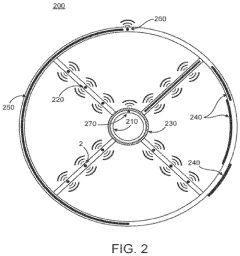

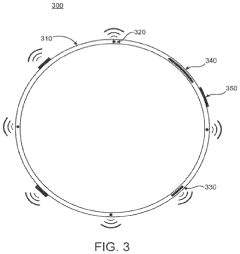

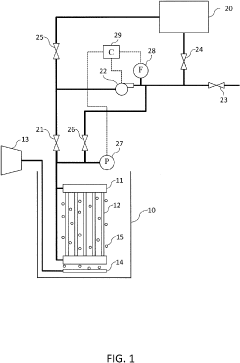

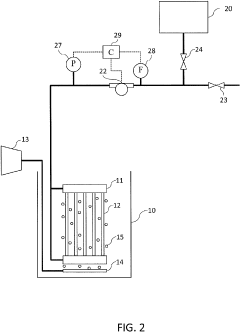

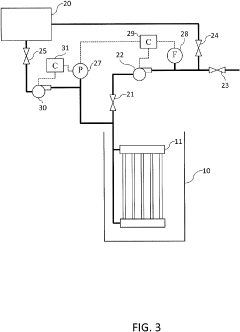

Methods and apparatuses for reducing membrane fouling, scaling, and concentration polarization using ultrasound wave energy (USWE)

PatentActiveUS10799835B2

Innovation

- The use of Ultrasound Wave Energy (USWE) is employed to mitigate fouling and concentration polarization through mechanisms such as cavitation, acoustic streaming, and particle charge interactions, by integrating ultrasound generating devices with membranes in systems that include pulsing or continuous wave energy delivery and reflective layers to enhance signal permeation and duration.

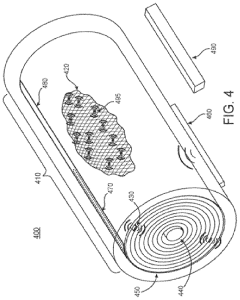

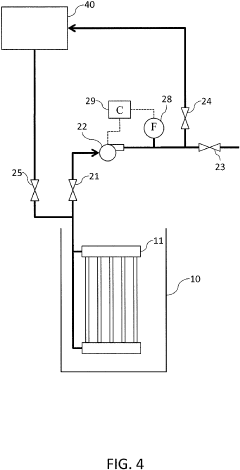

Biological and algae harvesting and cultivation systems and methods

PatentActiveUS20230242865A1

Innovation

- The implementation of a dead-end filtration system with a gravity-driven siphon system and optimized backwash sequences that reduce backwashing periods and intervals, allowing for higher algae concentrations without the use of flocculants or coagulants, and utilizing multistage filtration with variable flux and area to enhance flux and reduce costs.

Sustainability Aspects of Scaled Membrane Operations

The sustainability of scaled membrane operations represents a critical dimension in the evolution of membrane technology implementation. As membrane systems scale up from laboratory to industrial applications, their environmental footprint and resource efficiency become increasingly significant considerations. The sustainability profile of these systems encompasses multiple interconnected factors including energy consumption, chemical usage, water recovery rates, and waste generation.

Energy efficiency stands as a paramount concern in scaled membrane operations. Larger systems typically require substantial pumping energy to maintain transmembrane pressure and overcome fouling resistance. Advanced energy recovery devices (ERDs) have emerged as essential components in modern large-scale installations, with pressure exchangers and turbochargers recovering up to 60-80% of the energy in concentrate streams. This represents a significant improvement from earlier generations of membrane systems where energy recovery was minimal or non-existent.

Water conservation through optimized backwash protocols demonstrates another crucial sustainability aspect. Traditional backwash approaches often utilize 5-15% of product water, representing a substantial loss in system efficiency. Recent innovations in backwash timing algorithms and directional flushing have reduced this consumption to 2-7% in well-designed systems, significantly improving the water footprint of membrane operations.

Chemical consumption for membrane cleaning and maintenance presents both environmental and economic challenges in scaled operations. The industry has witnessed a gradual shift from aggressive cleaning chemicals (strong acids and bases) toward environmentally benign alternatives. Enzymatic cleaners and biodegradable surfactants have gained traction, reducing the environmental impact of discharge streams while maintaining effective fouling control. This transition has been particularly evident in food processing and pharmaceutical applications where discharge regulations are stringent.

Membrane lifetime extension represents perhaps the most underappreciated sustainability aspect. Modern membrane materials and optimized operating protocols have extended typical membrane lifespans from 3-5 years to 7-10 years in many applications. This extension dramatically reduces the embodied energy and material consumption associated with membrane manufacturing and replacement cycles.

Carbon footprint analysis of scaled membrane operations reveals that operational energy typically accounts for 60-80% of lifecycle emissions, with membrane manufacturing and replacement contributing 10-25%, and chemical usage representing the remainder. This distribution highlights the importance of energy efficiency measures in sustainability improvement strategies, particularly as systems scale to industrial capacities.

Energy efficiency stands as a paramount concern in scaled membrane operations. Larger systems typically require substantial pumping energy to maintain transmembrane pressure and overcome fouling resistance. Advanced energy recovery devices (ERDs) have emerged as essential components in modern large-scale installations, with pressure exchangers and turbochargers recovering up to 60-80% of the energy in concentrate streams. This represents a significant improvement from earlier generations of membrane systems where energy recovery was minimal or non-existent.

Water conservation through optimized backwash protocols demonstrates another crucial sustainability aspect. Traditional backwash approaches often utilize 5-15% of product water, representing a substantial loss in system efficiency. Recent innovations in backwash timing algorithms and directional flushing have reduced this consumption to 2-7% in well-designed systems, significantly improving the water footprint of membrane operations.

Chemical consumption for membrane cleaning and maintenance presents both environmental and economic challenges in scaled operations. The industry has witnessed a gradual shift from aggressive cleaning chemicals (strong acids and bases) toward environmentally benign alternatives. Enzymatic cleaners and biodegradable surfactants have gained traction, reducing the environmental impact of discharge streams while maintaining effective fouling control. This transition has been particularly evident in food processing and pharmaceutical applications where discharge regulations are stringent.

Membrane lifetime extension represents perhaps the most underappreciated sustainability aspect. Modern membrane materials and optimized operating protocols have extended typical membrane lifespans from 3-5 years to 7-10 years in many applications. This extension dramatically reduces the embodied energy and material consumption associated with membrane manufacturing and replacement cycles.

Carbon footprint analysis of scaled membrane operations reveals that operational energy typically accounts for 60-80% of lifecycle emissions, with membrane manufacturing and replacement contributing 10-25%, and chemical usage representing the remainder. This distribution highlights the importance of energy efficiency measures in sustainability improvement strategies, particularly as systems scale to industrial capacities.

Economic Analysis of Membrane System Scale-Up

The economic analysis of membrane system scale-up represents a critical component in the decision-making process for implementing large-scale membrane filtration systems. When transitioning from pilot-scale to full-scale operations, the economic implications become increasingly complex and multifaceted, requiring thorough evaluation of both capital expenditures (CAPEX) and operational expenditures (OPEX).

Initial investment costs for scaled-up membrane systems include not only the membrane modules themselves but also supporting infrastructure such as pumping systems, pretreatment facilities, cleaning systems, and control instrumentation. These costs typically follow non-linear scaling relationships, with economies of scale becoming evident as system size increases. Research indicates that membrane system costs often scale according to a power law relationship with an exponent ranging from 0.6 to 0.8, rather than linearly.

Operational costs are significantly influenced by fouling phenomena and the resulting flux decline. As membrane systems scale up, the economic impact of fouling becomes more pronounced, necessitating more frequent cleaning cycles and potentially shorter membrane lifespans. Energy consumption represents a substantial portion of operational expenses, primarily associated with maintaining transmembrane pressure and executing backwash procedures. Studies have shown that optimized backwash protocols can reduce energy consumption by 15-30% compared to standard approaches.

Membrane replacement costs constitute another significant economic factor in scaled-up systems. The frequency of replacement is directly correlated with fouling severity and the effectiveness of cleaning regimes. Advanced anti-fouling membranes may command premium prices but often demonstrate superior economic performance over their operational lifetime due to sustained higher flux rates and reduced cleaning requirements.

Labor costs for system monitoring and maintenance increase with scale but not proportionally, as automation and control systems enable efficient management of larger installations. However, specialized technical expertise becomes increasingly valuable as system complexity grows, potentially adding to personnel expenses.

Return on investment (ROI) calculations must account for the time-dependent performance degradation typical in membrane systems. Financial models should incorporate flux decline rates, which typically follow non-linear patterns with rapid initial decline followed by more gradual long-term reduction. Sensitivity analysis reveals that even small improvements in fouling resistance can yield substantial economic benefits when applied at industrial scale.

Risk assessment in economic analysis should consider the potential for catastrophic fouling events, which can temporarily halt production and incur significant recovery costs. Redundancy in design and robust cleaning protocols serve as insurance against such occurrences, justifying their additional expense through risk mitigation.

Initial investment costs for scaled-up membrane systems include not only the membrane modules themselves but also supporting infrastructure such as pumping systems, pretreatment facilities, cleaning systems, and control instrumentation. These costs typically follow non-linear scaling relationships, with economies of scale becoming evident as system size increases. Research indicates that membrane system costs often scale according to a power law relationship with an exponent ranging from 0.6 to 0.8, rather than linearly.

Operational costs are significantly influenced by fouling phenomena and the resulting flux decline. As membrane systems scale up, the economic impact of fouling becomes more pronounced, necessitating more frequent cleaning cycles and potentially shorter membrane lifespans. Energy consumption represents a substantial portion of operational expenses, primarily associated with maintaining transmembrane pressure and executing backwash procedures. Studies have shown that optimized backwash protocols can reduce energy consumption by 15-30% compared to standard approaches.

Membrane replacement costs constitute another significant economic factor in scaled-up systems. The frequency of replacement is directly correlated with fouling severity and the effectiveness of cleaning regimes. Advanced anti-fouling membranes may command premium prices but often demonstrate superior economic performance over their operational lifetime due to sustained higher flux rates and reduced cleaning requirements.

Labor costs for system monitoring and maintenance increase with scale but not proportionally, as automation and control systems enable efficient management of larger installations. However, specialized technical expertise becomes increasingly valuable as system complexity grows, potentially adding to personnel expenses.

Return on investment (ROI) calculations must account for the time-dependent performance degradation typical in membrane systems. Financial models should incorporate flux decline rates, which typically follow non-linear patterns with rapid initial decline followed by more gradual long-term reduction. Sensitivity analysis reveals that even small improvements in fouling resistance can yield substantial economic benefits when applied at industrial scale.

Risk assessment in economic analysis should consider the potential for catastrophic fouling events, which can temporarily halt production and incur significant recovery costs. Redundancy in design and robust cleaning protocols serve as insurance against such occurrences, justifying their additional expense through risk mitigation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!