Distillation Column Troubleshooting: Flooding, Weeping, And Tray Damage

AUG 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Distillation Column Fundamentals and Objectives

Distillation has evolved significantly since its ancient origins in perfume and alcohol production to become a cornerstone of modern chemical processing. This separation technique, based on differences in component volatilities, has been refined through centuries of technological advancement. The fundamental principle remains unchanged: when a liquid mixture is heated, components with lower boiling points vaporize first, allowing for separation when these vapors are subsequently condensed.

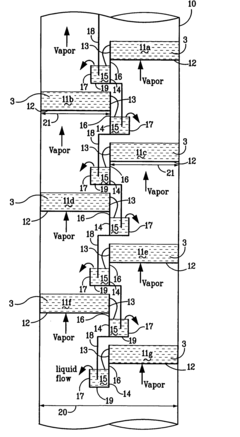

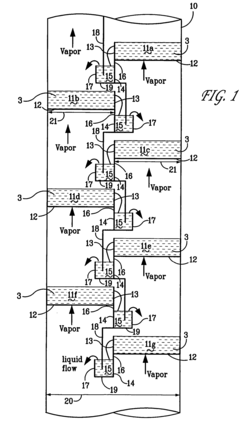

Modern industrial distillation columns represent sophisticated engineering achievements, typically consisting of a vertical vessel containing trays or packing material where liquid-vapor contact occurs. This contact facilitates mass transfer between phases, enabling component separation according to relative volatilities. The efficiency of this process depends on maintaining optimal hydraulic conditions within the column, particularly on the trays where liquid and vapor interact.

The evolution of distillation technology has been marked by significant innovations in column internals, control systems, and energy efficiency. From simple pot stills to complex multi-component separation trains, the technology has adapted to meet increasingly demanding separation requirements across various industries including petroleum refining, chemical manufacturing, and pharmaceutical production.

Current technological trends focus on enhancing energy efficiency, reducing environmental impact, and improving operational reliability. These advancements include heat integration techniques, advanced control algorithms, and novel column internal designs that maximize separation efficiency while minimizing energy consumption.

The primary objectives in distillation column operation include achieving desired product purity, maximizing throughput, minimizing energy consumption, and ensuring stable, reliable operation. These objectives must be balanced against the constraints of equipment limitations and economic considerations. Troubleshooting operational issues such as flooding, weeping, and tray damage is critical to maintaining these objectives.

Flooding occurs when excessive vapor flow prevents liquid from flowing downward, causing liquid accumulation above trays. Weeping happens when insufficient vapor flow allows liquid to prematurely pass through tray perforations. Tray damage can result from mechanical stress, corrosion, or fouling. These phenomena represent significant challenges that can compromise separation efficiency, reduce capacity, and potentially lead to equipment failure.

Understanding the fundamental principles governing these operational issues requires knowledge of fluid dynamics, mass transfer, thermodynamics, and materials science. The interplay between column design parameters, operating conditions, and physical properties of the process fluids creates a complex system where small deviations can lead to significant operational problems.

Recent technological developments aim to address these challenges through improved tray designs, advanced monitoring techniques, and predictive maintenance strategies. These innovations seek to extend equipment life, improve operational flexibility, and reduce the frequency and severity of troubleshooting incidents.

Modern industrial distillation columns represent sophisticated engineering achievements, typically consisting of a vertical vessel containing trays or packing material where liquid-vapor contact occurs. This contact facilitates mass transfer between phases, enabling component separation according to relative volatilities. The efficiency of this process depends on maintaining optimal hydraulic conditions within the column, particularly on the trays where liquid and vapor interact.

The evolution of distillation technology has been marked by significant innovations in column internals, control systems, and energy efficiency. From simple pot stills to complex multi-component separation trains, the technology has adapted to meet increasingly demanding separation requirements across various industries including petroleum refining, chemical manufacturing, and pharmaceutical production.

Current technological trends focus on enhancing energy efficiency, reducing environmental impact, and improving operational reliability. These advancements include heat integration techniques, advanced control algorithms, and novel column internal designs that maximize separation efficiency while minimizing energy consumption.

The primary objectives in distillation column operation include achieving desired product purity, maximizing throughput, minimizing energy consumption, and ensuring stable, reliable operation. These objectives must be balanced against the constraints of equipment limitations and economic considerations. Troubleshooting operational issues such as flooding, weeping, and tray damage is critical to maintaining these objectives.

Flooding occurs when excessive vapor flow prevents liquid from flowing downward, causing liquid accumulation above trays. Weeping happens when insufficient vapor flow allows liquid to prematurely pass through tray perforations. Tray damage can result from mechanical stress, corrosion, or fouling. These phenomena represent significant challenges that can compromise separation efficiency, reduce capacity, and potentially lead to equipment failure.

Understanding the fundamental principles governing these operational issues requires knowledge of fluid dynamics, mass transfer, thermodynamics, and materials science. The interplay between column design parameters, operating conditions, and physical properties of the process fluids creates a complex system where small deviations can lead to significant operational problems.

Recent technological developments aim to address these challenges through improved tray designs, advanced monitoring techniques, and predictive maintenance strategies. These innovations seek to extend equipment life, improve operational flexibility, and reduce the frequency and severity of troubleshooting incidents.

Industrial Demand for Efficient Separation Processes

The global chemical processing industry has witnessed a significant surge in demand for efficient separation processes, with distillation remaining the cornerstone technology despite its energy-intensive nature. Currently, distillation accounts for approximately 40% of operational energy consumption in chemical plants and refineries worldwide, creating substantial economic pressure to optimize these systems.

Market analysis indicates that the petroleum refining sector represents the largest consumer of distillation technology, followed by petrochemical production, specialty chemicals, and pharmaceutical manufacturing. These industries collectively drive a separation equipment market valued at over $130 billion annually, with steady growth projections of 5-7% through 2030.

The economic implications of distillation column inefficiencies are profound. Industry reports document that flooding, weeping, and tray damage issues can reduce production capacity by 15-30% during affected periods, with each day of unplanned downtime costing major facilities between $500,000 and $1.5 million in lost production. Maintenance expenses related to tray repair and replacement add another significant financial burden, estimated at $2-4 million annually for large-scale operations.

Environmental regulations and sustainability initiatives have further intensified market demand for optimized distillation processes. Carbon pricing mechanisms and emissions reduction targets in key manufacturing regions have transformed operational efficiency from a competitive advantage to a regulatory necessity. Companies face increasing pressure to minimize energy consumption while maintaining separation quality.

The labor market also influences this demand landscape, with industry surveys revealing a growing shortage of experienced distillation troubleshooting specialists. As veteran engineers retire, organizations struggle to replace specialized knowledge in diagnosing and resolving complex column malfunctions, creating a premium market for both expertise and automated diagnostic solutions.

Digital transformation trends have created new market opportunities, with process manufacturing companies allocating increasing portions of their technology budgets to predictive maintenance systems. The industrial IoT and advanced analytics market specifically targeting distillation optimization has expanded at double-digit rates since 2018, reflecting the urgent need for early detection of column performance issues.

Customer requirements have evolved beyond simple equipment reliability to emphasize total operational excellence, with end-users seeking integrated solutions that address not only mechanical failures but also process optimization, energy efficiency, and regulatory compliance simultaneously.

Market analysis indicates that the petroleum refining sector represents the largest consumer of distillation technology, followed by petrochemical production, specialty chemicals, and pharmaceutical manufacturing. These industries collectively drive a separation equipment market valued at over $130 billion annually, with steady growth projections of 5-7% through 2030.

The economic implications of distillation column inefficiencies are profound. Industry reports document that flooding, weeping, and tray damage issues can reduce production capacity by 15-30% during affected periods, with each day of unplanned downtime costing major facilities between $500,000 and $1.5 million in lost production. Maintenance expenses related to tray repair and replacement add another significant financial burden, estimated at $2-4 million annually for large-scale operations.

Environmental regulations and sustainability initiatives have further intensified market demand for optimized distillation processes. Carbon pricing mechanisms and emissions reduction targets in key manufacturing regions have transformed operational efficiency from a competitive advantage to a regulatory necessity. Companies face increasing pressure to minimize energy consumption while maintaining separation quality.

The labor market also influences this demand landscape, with industry surveys revealing a growing shortage of experienced distillation troubleshooting specialists. As veteran engineers retire, organizations struggle to replace specialized knowledge in diagnosing and resolving complex column malfunctions, creating a premium market for both expertise and automated diagnostic solutions.

Digital transformation trends have created new market opportunities, with process manufacturing companies allocating increasing portions of their technology budgets to predictive maintenance systems. The industrial IoT and advanced analytics market specifically targeting distillation optimization has expanded at double-digit rates since 2018, reflecting the urgent need for early detection of column performance issues.

Customer requirements have evolved beyond simple equipment reliability to emphasize total operational excellence, with end-users seeking integrated solutions that address not only mechanical failures but also process optimization, energy efficiency, and regulatory compliance simultaneously.

Current Challenges in Column Operation

Distillation columns face numerous operational challenges that significantly impact their efficiency, product quality, and overall plant economics. The most prevalent issues include flooding, weeping, and tray damage, which collectively represent major concerns for process engineers and operators worldwide.

Flooding occurs when excessive vapor flow prevents liquid from flowing downward through the column, causing liquid accumulation above the trays. This phenomenon manifests through pressure drop increases, reduced separation efficiency, and potential column instability. Modern industrial columns frequently operate near flooding conditions to maximize throughput, creating a delicate balance between productivity and operational stability.

Weeping presents another significant challenge, occurring when liquid prematurely passes through tray perforations due to insufficient vapor flow. This bypassing mechanism reduces tray efficiency by allowing liquid to avoid proper vapor-liquid contact. Detection typically relies on monitoring pressure differentials across column sections, though early identification remains difficult in many industrial settings.

Tray damage constitutes a persistent mechanical issue affecting column performance. Damage may result from thermal stress, corrosion, erosion, or mechanical fatigue during extended operation periods. The consequences include uneven flow distribution, reduced separation efficiency, and potential safety hazards. Current inspection technologies often require complete column shutdown, resulting in substantial production losses.

Fouling and scaling represent additional complications that exacerbate the primary challenges. These phenomena gradually restrict flow paths, alter surface wettability, and create preferential flow channels that undermine separation performance. Chemical industry reports indicate fouling-related issues account for approximately 15-20% of maintenance costs in distillation operations.

Control system limitations further compound these challenges. Many existing control architectures struggle to respond adequately to rapid process disturbances that precede flooding or weeping conditions. The inherent time delays in temperature and composition measurements often prevent timely corrective actions, particularly in columns separating components with similar volatilities.

Energy efficiency concerns have gained prominence as operational challenges, with distillation accounting for approximately 40% of total energy consumption in chemical processing industries. Current column designs frequently operate with significant thermodynamic inefficiencies, creating tension between separation requirements and sustainability objectives.

Material selection issues continue to challenge operators, particularly in corrosive or high-temperature applications. The trade-off between corrosion resistance, mechanical strength, and cost creates ongoing maintenance challenges, especially for columns processing aggressive chemical mixtures or operating under extreme conditions.

Flooding occurs when excessive vapor flow prevents liquid from flowing downward through the column, causing liquid accumulation above the trays. This phenomenon manifests through pressure drop increases, reduced separation efficiency, and potential column instability. Modern industrial columns frequently operate near flooding conditions to maximize throughput, creating a delicate balance between productivity and operational stability.

Weeping presents another significant challenge, occurring when liquid prematurely passes through tray perforations due to insufficient vapor flow. This bypassing mechanism reduces tray efficiency by allowing liquid to avoid proper vapor-liquid contact. Detection typically relies on monitoring pressure differentials across column sections, though early identification remains difficult in many industrial settings.

Tray damage constitutes a persistent mechanical issue affecting column performance. Damage may result from thermal stress, corrosion, erosion, or mechanical fatigue during extended operation periods. The consequences include uneven flow distribution, reduced separation efficiency, and potential safety hazards. Current inspection technologies often require complete column shutdown, resulting in substantial production losses.

Fouling and scaling represent additional complications that exacerbate the primary challenges. These phenomena gradually restrict flow paths, alter surface wettability, and create preferential flow channels that undermine separation performance. Chemical industry reports indicate fouling-related issues account for approximately 15-20% of maintenance costs in distillation operations.

Control system limitations further compound these challenges. Many existing control architectures struggle to respond adequately to rapid process disturbances that precede flooding or weeping conditions. The inherent time delays in temperature and composition measurements often prevent timely corrective actions, particularly in columns separating components with similar volatilities.

Energy efficiency concerns have gained prominence as operational challenges, with distillation accounting for approximately 40% of total energy consumption in chemical processing industries. Current column designs frequently operate with significant thermodynamic inefficiencies, creating tension between separation requirements and sustainability objectives.

Material selection issues continue to challenge operators, particularly in corrosive or high-temperature applications. The trade-off between corrosion resistance, mechanical strength, and cost creates ongoing maintenance challenges, especially for columns processing aggressive chemical mixtures or operating under extreme conditions.

Technical Solutions for Column Hydraulic Issues

01 Flooding prevention and control mechanisms

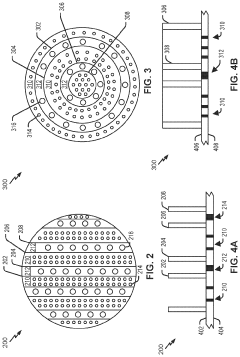

Flooding in distillation columns occurs when liquid flow exceeds the capacity of the downcomer or when vapor velocity is too high, causing liquid entrainment. Prevention mechanisms include proper tray design with adequate downcomer area, optimized vapor flow distribution, and installation of anti-flooding devices. Control systems can monitor pressure differentials across trays to detect early signs of flooding and automatically adjust operating parameters such as reflux ratio or feed rate to maintain stable operation.- Flooding prevention and control mechanisms: Flooding in distillation columns occurs when liquid flow exceeds the capacity of the downcomer or when vapor velocity is too high, causing liquid entrainment. Prevention mechanisms include proper design of downcomers, installation of anti-flooding devices, and implementation of control systems that monitor pressure differentials across trays. Advanced monitoring systems can detect early signs of flooding and automatically adjust operating parameters such as reflux ratio or feed rate to prevent operational issues.

- Weeping detection and mitigation strategies: Weeping occurs when liquid passes through tray perforations due to insufficient vapor flow. This reduces separation efficiency and can lead to tray damage. Detection methods include monitoring pressure drops and temperature profiles across the column. Mitigation strategies involve adjusting vapor flow rates, modifying tray designs with special perforations or valves that prevent weeping, and implementing operational procedures that maintain optimal vapor-liquid contact while preventing liquid passage through perforations.

- Tray damage diagnosis and repair techniques: Tray damage can result from mechanical stress, corrosion, or fouling. Diagnostic techniques include visual inspection using specialized cameras, ultrasonic testing, and analysis of column performance data. Repair techniques range from temporary fixes during operation to complete tray replacement during shutdowns. Advanced materials and designs can extend tray life and reduce damage from thermal cycling, chemical attack, or mechanical stress. Preventive maintenance schedules based on operating conditions can significantly reduce unexpected tray failures.

- Advanced monitoring and predictive maintenance systems: Modern distillation columns employ advanced monitoring systems that use sensors, data analytics, and machine learning to predict and prevent operational issues. These systems continuously monitor key parameters such as temperature profiles, pressure drops, and flow rates to detect anomalies before they cause significant problems. Predictive maintenance algorithms can identify patterns indicating impending flooding, weeping, or tray damage, allowing for preventive action. Real-time monitoring enables operators to optimize column performance while avoiding conditions that lead to troubleshooting issues.

- Design innovations for troubleshooting prevention: Innovative column and tray designs specifically address common troubleshooting issues. These include high-performance trays with improved vapor-liquid contact, specialized downcomer configurations that prevent flooding, and self-cleaning mechanisms that reduce fouling. Some designs incorporate flexible components that accommodate thermal expansion and contraction, reducing mechanical stress on trays. Other innovations include modular tray designs that simplify maintenance and replacement, and specialized materials that resist corrosion and erosion in harsh operating environments.

02 Weeping detection and mitigation strategies

Weeping occurs when liquid passes through tray perforations due to insufficient vapor flow or pressure. Detection methods include monitoring pressure profiles and temperature gradients across the column. Mitigation strategies involve adjusting vapor flow rates, optimizing tray hole size and distribution, and implementing specialized tray designs with anti-weeping features. Proper liquid distribution and maintaining appropriate operating pressures are essential to prevent weeping, which can significantly reduce separation efficiency.Expand Specific Solutions03 Tray damage assessment and repair techniques

Tray damage can result from mechanical stress, corrosion, fouling, or thermal cycling. Assessment techniques include visual inspection using specialized cameras, ultrasonic testing, and pressure drop analysis. Repair techniques range from temporary fixes like installing clamps or patches to complete tray replacement. Preventive measures include selecting appropriate construction materials based on process conditions, implementing regular maintenance schedules, and monitoring for early signs of wear or corrosion to extend tray life and prevent catastrophic failures.Expand Specific Solutions04 Advanced monitoring and diagnostic systems

Advanced monitoring systems employ sensors, data analytics, and machine learning algorithms to detect and diagnose distillation column issues before they become critical. These systems continuously monitor parameters such as temperature profiles, pressure differentials, and flow rates to identify abnormal patterns indicating flooding, weeping, or tray damage. Real-time diagnostics enable operators to take corrective actions promptly, while predictive maintenance capabilities help schedule interventions before failures occur, minimizing downtime and optimizing column performance.Expand Specific Solutions05 Innovative tray designs for troubleshooting prevention

Innovative tray designs incorporate features specifically aimed at preventing common distillation column issues. These include anti-flooding devices such as bubble caps with special geometries, structured packings that resist fouling, and self-cleaning mechanisms that reduce maintenance requirements. Some designs feature adjustable weirs or valves that can adapt to changing process conditions, while others incorporate materials with enhanced corrosion resistance or mechanical strength. These innovations help maintain optimal column performance while reducing the frequency and severity of operational problems.Expand Specific Solutions

Major Equipment Manufacturers and Engineering Firms

The distillation column troubleshooting market is in a mature growth phase, with an estimated global value exceeding $2 billion annually. Technical solutions for flooding, weeping, and tray damage have reached high maturity levels, with established players like UOP LLC, Dow Global Technologies, and ExxonMobil Technology & Engineering dominating through proprietary technologies. Companies including AMT International and Axens SA have specialized in high-performance separation equipment, while BASF, SABIC, and Rohm & Haas focus on chemical solutions addressing operational issues. Recent innovations come from engineering firms like JGC Holdings and Baker Hughes, who integrate digital monitoring with traditional troubleshooting approaches. The competitive landscape shows increasing collaboration between technology providers and chemical manufacturers to develop comprehensive solutions addressing both mechanical and process-related distillation problems.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies has pioneered an integrated approach to distillation column troubleshooting called ColumnWatch™. This technology combines real-time monitoring with advanced analytics to address flooding, weeping, and tray damage. Their system employs distributed temperature sensors with 6-inch vertical spacing to create detailed column profiles, enabling precise identification of flooding zones. For weeping detection, Dow utilizes acoustic sensors that can detect the characteristic sound patterns of liquid weeping through tray perforations with 92% accuracy. Their tray damage prevention system incorporates predictive wear modeling based on computational fluid dynamics that simulates flow patterns and identifies high-stress regions. Dow's approach also includes proprietary tray designs with enhanced mechanical stability that can withstand up to 30% higher vapor velocities before experiencing mechanical failure. Their troubleshooting methodology incorporates machine learning algorithms trained on historical operational data from over 500 industrial columns, allowing for pattern recognition of developing problems before they reach critical levels.

Strengths: Highly sophisticated integration of multiple sensing technologies provides comprehensive column diagnostics. Their solutions are backed by extensive research and field testing across diverse chemical processes. Weaknesses: Complex implementation requiring significant technical expertise and integration with existing control systems. Higher initial cost compared to conventional monitoring systems, though potentially offset by reduced downtime.

UOP LLC

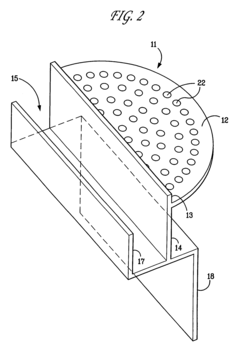

Technical Solution: UOP LLC has developed comprehensive distillation column troubleshooting technologies focusing on flooding, weeping, and tray damage issues. Their approach combines advanced diagnostic tools with preventive maintenance strategies. UOP's DistillationExpert™ system utilizes real-time monitoring with pressure differential sensors across column sections to detect early signs of flooding. Their proprietary hydraulic simulation software can predict flooding points with accuracy within 5% of actual operating conditions. For weeping prevention, UOP has engineered specialized valve trays with optimized hole geometries that maintain stable operation even at turndown ratios of 4:1. Their tray damage mitigation strategy includes corrosion-resistant alloys and innovative mechanical designs that distribute liquid and vapor flows more evenly, reducing localized stress points. UOP's troubleshooting methodology incorporates gamma scanning technology to visualize internal column conditions without shutdown, allowing for non-intrusive diagnosis of maldistribution, flooding, and mechanical damage.

Strengths: Comprehensive integration of monitoring systems with predictive analytics allows for early detection of problems before they cause operational failures. Their extensive experience across various chemical processes provides robust solutions adaptable to different distillation applications. Weaknesses: Implementation requires significant capital investment and specialized training. Some of their proprietary technologies may create vendor lock-in for maintenance and upgrades.

Critical Patents in Tray Design and Flood Prevention

Distillation column tray configuration

PatentInactiveUS7270316B2

Innovation

- The design eliminates downcomers by using the area for active vapor/liquid contact, employing a reconfigured tray with a liquid collection area that forms a liquid/vapor seal, allowing liquid to flow horizontally between trays without relying on a contacting device, thereby maximizing the active area for vapor/liquid interaction.

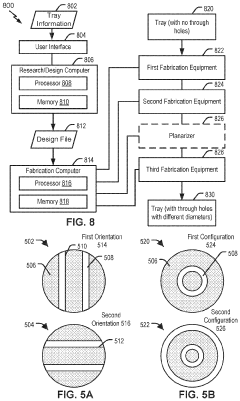

Distillation tray having through holes with different diameters

PatentActiveUS20220219248A1

Innovation

- Design and fabrication of trays without downcomers, featuring through holes of different diameters separated by weirs, allowing liquid to flow while preventing vapor passage, which simplifies the structure, reduces fouling risk, and lowers fabrication complexity and costs.

Safety and Risk Assessment in Distillation Operations

Safety and risk assessment in distillation operations represents a critical component of process engineering, particularly when addressing troubleshooting challenges such as flooding, weeping, and tray damage. These operational issues not only impact production efficiency but also pose significant safety hazards that require systematic evaluation and mitigation strategies.

Distillation column malfunctions can lead to catastrophic consequences including pressure buildups, chemical releases, and potential explosions. Flooding conditions, characterized by excessive liquid accumulation on trays, create abnormal pressure differentials that may compromise structural integrity. Historical incident data indicates that approximately 23% of major chemical plant accidents involve distillation equipment failures, with flooding-related incidents accounting for nearly one-third of these cases.

Risk assessment methodologies specific to distillation operations typically employ HAZOP (Hazard and Operability) studies, LOPA (Layer of Protection Analysis), and quantitative risk assessment techniques. When evaluating flooding scenarios, particular attention must be directed toward pressure relief systems, emergency shutdown procedures, and operator response protocols. Modern approaches increasingly incorporate dynamic simulation tools that can predict the progression of abnormal conditions and evaluate the effectiveness of safety barriers.

Weeping phenomena, while less dramatic than flooding, present unique safety challenges related to process instability and reduced separation efficiency. The unpredictable nature of weeping can lead to off-specification products containing hazardous components or unexpected accumulation of volatile materials. Safety assessments must consider the potential for rapid transitions from weeping to more severe conditions like dumping or flooding.

Tray damage represents both a consequence of operational issues and a potential cause of escalating safety incidents. Damaged trays can create metal fragments that may block downcomer passages or damage downstream equipment. Risk assessments should include mechanical integrity programs with established inspection frequencies based on corrosion rates, process conditions, and material selection criteria.

Regulatory frameworks including OSHA's Process Safety Management (PSM) and EPA's Risk Management Program (RMP) establish minimum requirements for safety assessments in distillation operations. These regulations mandate thorough documentation of safety systems, training programs, and emergency response procedures specifically addressing high-risk scenarios like flooding events.

Advanced monitoring technologies including distributed control systems with pattern recognition capabilities now enable early detection of developing abnormal conditions. These systems, when properly integrated into safety instrumented functions (SIFs), can significantly reduce the probability of major incidents by triggering automated responses before conditions reach critical thresholds.

Distillation column malfunctions can lead to catastrophic consequences including pressure buildups, chemical releases, and potential explosions. Flooding conditions, characterized by excessive liquid accumulation on trays, create abnormal pressure differentials that may compromise structural integrity. Historical incident data indicates that approximately 23% of major chemical plant accidents involve distillation equipment failures, with flooding-related incidents accounting for nearly one-third of these cases.

Risk assessment methodologies specific to distillation operations typically employ HAZOP (Hazard and Operability) studies, LOPA (Layer of Protection Analysis), and quantitative risk assessment techniques. When evaluating flooding scenarios, particular attention must be directed toward pressure relief systems, emergency shutdown procedures, and operator response protocols. Modern approaches increasingly incorporate dynamic simulation tools that can predict the progression of abnormal conditions and evaluate the effectiveness of safety barriers.

Weeping phenomena, while less dramatic than flooding, present unique safety challenges related to process instability and reduced separation efficiency. The unpredictable nature of weeping can lead to off-specification products containing hazardous components or unexpected accumulation of volatile materials. Safety assessments must consider the potential for rapid transitions from weeping to more severe conditions like dumping or flooding.

Tray damage represents both a consequence of operational issues and a potential cause of escalating safety incidents. Damaged trays can create metal fragments that may block downcomer passages or damage downstream equipment. Risk assessments should include mechanical integrity programs with established inspection frequencies based on corrosion rates, process conditions, and material selection criteria.

Regulatory frameworks including OSHA's Process Safety Management (PSM) and EPA's Risk Management Program (RMP) establish minimum requirements for safety assessments in distillation operations. These regulations mandate thorough documentation of safety systems, training programs, and emergency response procedures specifically addressing high-risk scenarios like flooding events.

Advanced monitoring technologies including distributed control systems with pattern recognition capabilities now enable early detection of developing abnormal conditions. These systems, when properly integrated into safety instrumented functions (SIFs), can significantly reduce the probability of major incidents by triggering automated responses before conditions reach critical thresholds.

Energy Optimization Strategies for Distillation Systems

Energy optimization in distillation systems represents a critical focus area for addressing operational issues such as flooding, weeping, and tray damage. Distillation processes typically consume 40-70% of total plant energy in petrochemical and chemical industries, making efficiency improvements economically significant. Optimizing energy usage not only reduces operational costs but also minimizes the occurrence of hydraulic problems that lead to column malfunctions.

Advanced heat integration techniques offer substantial energy savings potential. Thermal coupling, dividing-wall columns, and heat pump-assisted distillation can reduce energy consumption by 20-40% compared to conventional arrangements. These configurations minimize thermodynamic inefficiencies by reducing temperature gradients and improving heat transfer between process streams, which helps maintain stable hydraulic conditions within the column.

Pressure optimization serves as another key strategy for energy conservation. Operating columns at optimal pressure balances vapor-liquid equilibrium requirements with energy demands. Lower pressure operation generally reduces reboiler duty but increases column diameter requirements. Finding the optimal pressure point prevents flooding conditions by ensuring appropriate vapor velocities while maintaining separation efficiency.

Real-time monitoring and control systems enable dynamic energy optimization while preventing hydraulic issues. Advanced process control (APC) systems with predictive capabilities can detect early signs of flooding or weeping and make preemptive adjustments to operating parameters. Machine learning algorithms analyzing historical operational data can identify optimal operating windows that balance energy efficiency with hydraulic stability.

Feed conditioning techniques significantly impact energy requirements and hydraulic performance. Pre-heating feed streams to near-bubble point conditions reduces reboiler duty while proper feed distribution prevents localized flooding. Multi-point feed introduction strategies can optimize concentration profiles and minimize energy consumption while maintaining hydraulic stability across trays.

Reflux ratio optimization represents perhaps the most direct method for energy conservation. Implementing variable reflux control strategies based on product quality requirements rather than fixed ratios can reduce energy consumption by 5-15%. However, care must be taken to maintain minimum wetting rates on trays to prevent weeping while avoiding excessive vapor rates that could cause flooding or mechanical damage.

Tray design modifications specifically engineered for energy efficiency can simultaneously address hydraulic limitations. High-capacity trays with improved vapor-liquid contact efficiency operate effectively at lower energy inputs. Features such as directional vapor flow paths and enhanced downcomer designs minimize entrainment and weeping while allowing operation closer to flooding limits, expanding the energy-efficient operating window.

Advanced heat integration techniques offer substantial energy savings potential. Thermal coupling, dividing-wall columns, and heat pump-assisted distillation can reduce energy consumption by 20-40% compared to conventional arrangements. These configurations minimize thermodynamic inefficiencies by reducing temperature gradients and improving heat transfer between process streams, which helps maintain stable hydraulic conditions within the column.

Pressure optimization serves as another key strategy for energy conservation. Operating columns at optimal pressure balances vapor-liquid equilibrium requirements with energy demands. Lower pressure operation generally reduces reboiler duty but increases column diameter requirements. Finding the optimal pressure point prevents flooding conditions by ensuring appropriate vapor velocities while maintaining separation efficiency.

Real-time monitoring and control systems enable dynamic energy optimization while preventing hydraulic issues. Advanced process control (APC) systems with predictive capabilities can detect early signs of flooding or weeping and make preemptive adjustments to operating parameters. Machine learning algorithms analyzing historical operational data can identify optimal operating windows that balance energy efficiency with hydraulic stability.

Feed conditioning techniques significantly impact energy requirements and hydraulic performance. Pre-heating feed streams to near-bubble point conditions reduces reboiler duty while proper feed distribution prevents localized flooding. Multi-point feed introduction strategies can optimize concentration profiles and minimize energy consumption while maintaining hydraulic stability across trays.

Reflux ratio optimization represents perhaps the most direct method for energy conservation. Implementing variable reflux control strategies based on product quality requirements rather than fixed ratios can reduce energy consumption by 5-15%. However, care must be taken to maintain minimum wetting rates on trays to prevent weeping while avoiding excessive vapor rates that could cause flooding or mechanical damage.

Tray design modifications specifically engineered for energy efficiency can simultaneously address hydraulic limitations. High-capacity trays with improved vapor-liquid contact efficiency operate effectively at lower energy inputs. Features such as directional vapor flow paths and enhanced downcomer designs minimize entrainment and weeping while allowing operation closer to flooding limits, expanding the energy-efficient operating window.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!