Choosing Separation Methods For Biomolecule Purification: A Decision Matrix

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biomolecule Purification Technology Background and Objectives

Biomolecule purification represents a cornerstone technology in modern biotechnology, pharmaceuticals, and life sciences. The evolution of separation methods for biomolecules traces back to the early 20th century with rudimentary techniques such as precipitation and crystallization. Over subsequent decades, significant advancements emerged with the development of chromatography by Tswett in 1906, followed by electrophoresis in the 1930s, and the revolutionary introduction of affinity chromatography in the 1960s.

The technological trajectory has consistently moved toward achieving higher purity, improved yield, reduced processing time, and enhanced scalability. Recent years have witnessed remarkable innovations in membrane-based separations, continuous processing systems, and the integration of computational modeling for process optimization. These developments reflect the industry's response to increasing demands for more efficient and cost-effective purification solutions.

The primary objective of biomolecule purification technology is to isolate target molecules with specified purity while maintaining their biological activity. This fundamental goal has become increasingly challenging as the complexity and diversity of biomolecules under investigation continue to expand. Modern purification technologies must address not only traditional proteins but also advanced modalities such as monoclonal antibodies, nucleic acids, virus-like particles, and cell-based therapeutics.

Current technological trends indicate a shift toward multi-modal approaches that combine different separation principles to achieve superior results. The integration of high-throughput screening methodologies has accelerated the development and optimization of purification protocols. Additionally, the emergence of single-use technologies has transformed manufacturing flexibility while addressing concerns related to cross-contamination and validation requirements.

The field is experiencing a paradigm shift from empirical approaches toward knowledge-based design principles. This transition is facilitated by advances in computational tools that enable the prediction of separation behavior based on molecular properties. Machine learning algorithms are increasingly employed to optimize purification parameters and predict process outcomes, reducing development timelines and resources required.

Looking forward, the technological roadmap for biomolecule purification aims to establish robust decision frameworks that guide the selection of appropriate separation methods based on specific molecular characteristics, process requirements, and economic considerations. The development of a comprehensive decision matrix represents a critical step toward standardizing purification strategy development across the biopharmaceutical industry, potentially reducing time-to-market for novel therapeutics and enhancing overall process economics.

The technological trajectory has consistently moved toward achieving higher purity, improved yield, reduced processing time, and enhanced scalability. Recent years have witnessed remarkable innovations in membrane-based separations, continuous processing systems, and the integration of computational modeling for process optimization. These developments reflect the industry's response to increasing demands for more efficient and cost-effective purification solutions.

The primary objective of biomolecule purification technology is to isolate target molecules with specified purity while maintaining their biological activity. This fundamental goal has become increasingly challenging as the complexity and diversity of biomolecules under investigation continue to expand. Modern purification technologies must address not only traditional proteins but also advanced modalities such as monoclonal antibodies, nucleic acids, virus-like particles, and cell-based therapeutics.

Current technological trends indicate a shift toward multi-modal approaches that combine different separation principles to achieve superior results. The integration of high-throughput screening methodologies has accelerated the development and optimization of purification protocols. Additionally, the emergence of single-use technologies has transformed manufacturing flexibility while addressing concerns related to cross-contamination and validation requirements.

The field is experiencing a paradigm shift from empirical approaches toward knowledge-based design principles. This transition is facilitated by advances in computational tools that enable the prediction of separation behavior based on molecular properties. Machine learning algorithms are increasingly employed to optimize purification parameters and predict process outcomes, reducing development timelines and resources required.

Looking forward, the technological roadmap for biomolecule purification aims to establish robust decision frameworks that guide the selection of appropriate separation methods based on specific molecular characteristics, process requirements, and economic considerations. The development of a comprehensive decision matrix represents a critical step toward standardizing purification strategy development across the biopharmaceutical industry, potentially reducing time-to-market for novel therapeutics and enhancing overall process economics.

Market Analysis of Biomolecule Purification Demands

The global biomolecule purification market has experienced substantial growth, reaching approximately $6.7 billion in 2022 and projected to expand at a CAGR of 8.2% through 2030. This growth is primarily driven by increasing demand for biopharmaceuticals, advancements in biotechnology research, and expanding applications in personalized medicine.

Biopharmaceuticals represent the largest segment within the biomolecule purification market, accounting for over 40% of market share. Monoclonal antibodies dominate this category, with global sales exceeding $200 billion annually. The COVID-19 pandemic significantly accelerated market growth, creating unprecedented demand for vaccine production and therapeutic antibodies, which required sophisticated purification technologies.

Geographically, North America leads the market with approximately 35% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is witnessing the fastest growth rate due to increasing investment in biotechnology infrastructure, particularly in China, India, and South Korea. These countries are rapidly developing their biomanufacturing capabilities, creating substantial demand for purification technologies.

Industry segments driving purification demand include pharmaceutical companies (45%), biotechnology firms (30%), academic and research institutions (15%), and contract manufacturing organizations (10%). The pharmaceutical sector's dominance stems from stringent regulatory requirements for product purity, particularly for injectable biologics where impurity levels must typically remain below 0.001%.

Chromatography techniques currently dominate the purification methods market, with affinity chromatography accounting for approximately 40% of all purification processes. However, membrane-based separation technologies are gaining traction, growing at nearly 10% annually due to their scalability and cost-effectiveness for certain applications.

End-user requirements are evolving toward more efficient purification solutions that can handle complex biomolecules while reducing processing time and costs. There is increasing demand for continuous purification processes rather than traditional batch methods, as continuous processing can improve yield by 15-20% while reducing buffer consumption by up to 40%.

Regulatory considerations significantly influence market dynamics, with FDA and EMA guidelines requiring comprehensive validation of purification processes. This has created demand for purification technologies that offer better process analytical technology (PAT) integration and real-time monitoring capabilities, allowing manufacturers to implement Quality by Design (QbD) approaches.

Biopharmaceuticals represent the largest segment within the biomolecule purification market, accounting for over 40% of market share. Monoclonal antibodies dominate this category, with global sales exceeding $200 billion annually. The COVID-19 pandemic significantly accelerated market growth, creating unprecedented demand for vaccine production and therapeutic antibodies, which required sophisticated purification technologies.

Geographically, North America leads the market with approximately 35% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is witnessing the fastest growth rate due to increasing investment in biotechnology infrastructure, particularly in China, India, and South Korea. These countries are rapidly developing their biomanufacturing capabilities, creating substantial demand for purification technologies.

Industry segments driving purification demand include pharmaceutical companies (45%), biotechnology firms (30%), academic and research institutions (15%), and contract manufacturing organizations (10%). The pharmaceutical sector's dominance stems from stringent regulatory requirements for product purity, particularly for injectable biologics where impurity levels must typically remain below 0.001%.

Chromatography techniques currently dominate the purification methods market, with affinity chromatography accounting for approximately 40% of all purification processes. However, membrane-based separation technologies are gaining traction, growing at nearly 10% annually due to their scalability and cost-effectiveness for certain applications.

End-user requirements are evolving toward more efficient purification solutions that can handle complex biomolecules while reducing processing time and costs. There is increasing demand for continuous purification processes rather than traditional batch methods, as continuous processing can improve yield by 15-20% while reducing buffer consumption by up to 40%.

Regulatory considerations significantly influence market dynamics, with FDA and EMA guidelines requiring comprehensive validation of purification processes. This has created demand for purification technologies that offer better process analytical technology (PAT) integration and real-time monitoring capabilities, allowing manufacturers to implement Quality by Design (QbD) approaches.

Current Separation Methods and Technical Challenges

Biomolecule purification represents a critical step in biopharmaceutical manufacturing, diagnostic reagent production, and research applications. The landscape of separation methods has evolved significantly over the past decades, with several established techniques dominating the field. Currently, chromatography-based methods constitute the backbone of industrial-scale biomolecule purification, with affinity chromatography, ion exchange chromatography, size exclusion chromatography, and hydrophobic interaction chromatography being the most widely implemented approaches.

Affinity chromatography offers exceptional selectivity through specific ligand-target interactions, making it particularly valuable for antibody purification using Protein A resins. However, this method faces challenges related to ligand leaching, high resin costs, and limited reusability cycles. Ion exchange chromatography, while more economical and robust, struggles with selectivity in complex biological mixtures and salt gradient optimization requirements.

Size exclusion chromatography provides gentle separation conditions that preserve biomolecule activity but suffers from limited throughput, dilution effects, and resolution constraints when handling molecules of similar sizes. Hydrophobic interaction chromatography offers complementary selectivity to ion exchange but requires careful optimization of salt conditions and faces challenges with hydrophobic biomolecules that may irreversibly bind to the stationary phase.

Emerging technologies like membrane chromatography address some throughput limitations but currently lack the resolution of traditional column chromatography. Similarly, aqueous two-phase extraction systems offer scalability advantages but struggle with reproducibility and predictability across different biomolecule classes.

The technical challenges facing current separation methods cluster around several key areas. Scalability remains problematic, with laboratory-scale purification protocols often failing to translate efficiently to production scales. This scale-up challenge is particularly acute for high-value, low-volume biopharmaceuticals where process economics are critical.

Selectivity limitations persist across all platforms, especially when purifying biomolecules with similar physicochemical properties or from complex biological matrices. This challenge intensifies with the increasing complexity of modern biotherapeutics like bispecific antibodies and fusion proteins.

Process robustness represents another significant hurdle, with many current methods exhibiting sensitivity to minor variations in feed composition, buffer conditions, or operating parameters. This sensitivity complicates validation efforts and increases manufacturing risks.

Additionally, sustainability concerns are gaining prominence, with traditional separation methods often requiring substantial water usage, generating significant waste streams, and consuming large quantities of single-use plastics. The industry faces mounting pressure to develop more environmentally responsible purification technologies that maintain performance while reducing resource consumption and waste generation.

Affinity chromatography offers exceptional selectivity through specific ligand-target interactions, making it particularly valuable for antibody purification using Protein A resins. However, this method faces challenges related to ligand leaching, high resin costs, and limited reusability cycles. Ion exchange chromatography, while more economical and robust, struggles with selectivity in complex biological mixtures and salt gradient optimization requirements.

Size exclusion chromatography provides gentle separation conditions that preserve biomolecule activity but suffers from limited throughput, dilution effects, and resolution constraints when handling molecules of similar sizes. Hydrophobic interaction chromatography offers complementary selectivity to ion exchange but requires careful optimization of salt conditions and faces challenges with hydrophobic biomolecules that may irreversibly bind to the stationary phase.

Emerging technologies like membrane chromatography address some throughput limitations but currently lack the resolution of traditional column chromatography. Similarly, aqueous two-phase extraction systems offer scalability advantages but struggle with reproducibility and predictability across different biomolecule classes.

The technical challenges facing current separation methods cluster around several key areas. Scalability remains problematic, with laboratory-scale purification protocols often failing to translate efficiently to production scales. This scale-up challenge is particularly acute for high-value, low-volume biopharmaceuticals where process economics are critical.

Selectivity limitations persist across all platforms, especially when purifying biomolecules with similar physicochemical properties or from complex biological matrices. This challenge intensifies with the increasing complexity of modern biotherapeutics like bispecific antibodies and fusion proteins.

Process robustness represents another significant hurdle, with many current methods exhibiting sensitivity to minor variations in feed composition, buffer conditions, or operating parameters. This sensitivity complicates validation efforts and increases manufacturing risks.

Additionally, sustainability concerns are gaining prominence, with traditional separation methods often requiring substantial water usage, generating significant waste streams, and consuming large quantities of single-use plastics. The industry faces mounting pressure to develop more environmentally responsible purification technologies that maintain performance while reducing resource consumption and waste generation.

Comparative Analysis of Current Separation Methods

01 Chromatography-based separation methods

Various chromatography techniques are employed for biomolecule purification, including affinity chromatography, ion exchange chromatography, and size exclusion chromatography. These methods separate biomolecules based on different properties such as binding affinity, charge, or molecular size. Decision matrices for selecting appropriate chromatography methods consider factors like target molecule properties, required purity, scale of operation, and cost-effectiveness.- Chromatography-based separation methods: Chromatography techniques are widely used for biomolecule purification, including affinity chromatography, ion exchange chromatography, and size exclusion chromatography. These methods separate biomolecules based on their specific binding properties, charge characteristics, or molecular size. Decision matrices for chromatography-based methods typically consider factors such as binding capacity, selectivity, resolution, and scalability to determine the most suitable technique for specific biomolecule purification applications.

- Membrane-based separation technologies: Membrane-based separation technologies, including ultrafiltration, microfiltration, and tangential flow filtration, are effective methods for biomolecule purification. These techniques separate molecules based on size, using semi-permeable membranes with specific pore sizes. Decision matrices for membrane-based separations evaluate parameters such as membrane material, pore size, flux rate, fouling resistance, and process economics to optimize purification efficiency and product yield.

- Precipitation and crystallization methods: Precipitation and crystallization are separation methods that exploit differences in solubility of biomolecules under varying conditions. These techniques involve altering solution parameters such as pH, temperature, ionic strength, or adding specific precipitating agents to selectively separate target biomolecules. Decision matrices for these methods consider factors like precipitation efficiency, purity of the precipitated product, scalability, and downstream processing compatibility to determine optimal conditions for biomolecule purification.

- Automated decision support systems for purification method selection: Automated decision support systems employ algorithms and computational models to assist in selecting optimal purification strategies for biomolecules. These systems integrate multiple parameters including biomolecule properties, purification objectives, available resources, and process constraints to generate decision matrices. By analyzing complex datasets and applying machine learning techniques, these systems can recommend the most suitable separation methods, process parameters, and purification sequences for specific biomolecule purification challenges.

- Multi-parameter optimization for purification process development: Multi-parameter optimization approaches involve systematic evaluation of multiple variables affecting biomolecule purification processes. These methods utilize experimental design techniques, statistical analysis, and modeling to develop comprehensive decision matrices that guide purification strategy selection. Key parameters typically include yield, purity, activity retention, process time, cost, and scalability. By simultaneously optimizing these parameters, researchers can develop robust purification processes that meet specific requirements for different biomolecule applications.

02 Membrane-based separation techniques

Membrane-based separation techniques such as ultrafiltration, microfiltration, and diafiltration are widely used for biomolecule purification. These methods separate molecules based on size, using semi-permeable membranes with specific pore sizes. Decision matrices for membrane selection consider parameters like molecular weight cut-off, membrane material compatibility, fouling resistance, and process integration capabilities.Expand Specific Solutions03 Precipitation and crystallization methods

Precipitation and crystallization techniques are employed for biomolecule purification by manipulating solution conditions to induce solid formation. These methods utilize changes in pH, temperature, ionic strength, or addition of precipitating agents to separate target biomolecules. Decision matrices for these techniques evaluate factors such as biomolecule stability, recovery yield, scalability, and downstream processing compatibility.Expand Specific Solutions04 Automated purification systems and decision support tools

Automated systems and computational tools assist in biomolecule purification by optimizing separation parameters and process conditions. These systems incorporate decision matrices that evaluate multiple variables simultaneously to determine optimal purification strategies. They may include machine learning algorithms, statistical models, and expert systems that analyze experimental data and predict purification outcomes based on biomolecule properties and process constraints.Expand Specific Solutions05 Multi-modal and integrated purification approaches

Multi-modal and integrated purification approaches combine multiple separation techniques in sequence or parallel to achieve higher purity and yield. These strategies utilize decision matrices to determine the optimal combination and sequence of separation methods based on the specific biomolecule characteristics and purification requirements. The integration of different techniques can overcome limitations of individual methods and provide more efficient purification processes.Expand Specific Solutions

Leading Companies in Biomolecule Purification Industry

The biomolecule purification separation methods market is currently in a growth phase, with increasing demand driven by biopharmaceutical development and personalized medicine. The global market is estimated at $8-10 billion annually, expanding at 10-12% CAGR. Technologically, the field shows varying maturity levels across different separation techniques. Industry leaders like Cytiva (formerly GE Healthcare Life Sciences) and Sartorius Stedim Biotech dominate chromatography solutions, while Eppendorf and QIAGEN excel in centrifugation technologies. Companies including Thermo Fisher Scientific (Pierce Biotechnology) and FUJIFILM are advancing membrane-based separation methods. Emerging players like Seer are disrupting the market with novel proteomics approaches. Academic institutions (Oxford, Max Planck) continue contributing fundamental research, while biopharmaceutical manufacturers (Biogen, Boehringer Ingelheim) drive application-specific innovations to optimize their production processes.

Eppendorf SE

Technical Solution: Eppendorf has developed an integrated approach to biomolecule purification focusing on sample preparation, handling, and processing technologies. Their epMotion automated liquid handling systems enable precise and reproducible biomolecule purification workflows with minimal user intervention. For protein purification, Eppendorf offers the Protein LoBind consumables that significantly reduce protein adsorption to vessel surfaces, improving recovery rates especially for low-concentration samples. Their centrifugation technology, including the Centrifuge 5920 R with temperature control capabilities, provides gentle separation conditions critical for maintaining biomolecule integrity during purification[9]. Eppendorf's decision matrix for separation method selection incorporates factors such as biomolecule stability, required purity, throughput requirements, and available instrumentation. Their approach emphasizes workflow integration, with compatible consumables and instruments designed to work together seamlessly. For nucleic acid purification, they've developed specialized kits that utilize magnetic bead technology for high-yield, high-purity extraction. Eppendorf's technology particularly excels in maintaining sample integrity throughout the purification process, with temperature-controlled environments and low-binding materials[10].

Strengths: Comprehensive ecosystem of compatible instruments and consumables that work together seamlessly. Superior sample preservation through temperature control and low-binding materials. High precision automation reduces operator variability and increases reproducibility. Weaknesses: Less specialized in large-scale bioprocessing compared to dedicated bioprocess companies. Their technologies focus more on research-scale applications rather than production-scale purification. Higher cost for premium consumables compared to standard laboratory plasticware.

Cytiva BioProcess R&D AB

Technical Solution: Cytiva's biomolecule purification technology centers on their advanced chromatography platforms, particularly the ÄKTA systems. These systems utilize multiple separation principles including size exclusion, ion exchange, hydrophobic interaction, and affinity chromatography in an integrated workflow. Their Process Intensification approach combines traditional chromatography with modern membrane adsorbers and multimodal resins to reduce purification steps while maintaining yield and purity. Cytiva has developed Fibro technology, a cellulose-based chromatography material with an open pore structure that allows for significantly faster mass transfer rates compared to traditional bead-based resins[1]. This enables processing times of minutes rather than hours while maintaining separation efficiency. Their decision matrices incorporate factors such as target molecule properties, required purity, scale, throughput requirements, and economic considerations to guide method selection[2].

Strengths: Industry-leading expertise in bioprocessing with comprehensive platform solutions that address the entire purification workflow. Their Fibro technology offers breakthrough cycle times and productivity improvements. Weaknesses: Higher capital investment required for complete systems, and some proprietary technologies may create vendor lock-in. Complex systems may require specialized training and technical support.

Key Patents and Innovations in Separation Technology

Biomolecule separation using apatite

PatentWO2016009221A1

Innovation

- The method employs a differential transit rate separation technique using an apatite matrix, where the biomolecule of interest and contaminant species do not adsorb to the matrix, allowing for their separation through bulk flow-through without desorption, utilizing a buffered solution throughout the process to maintain consistency.

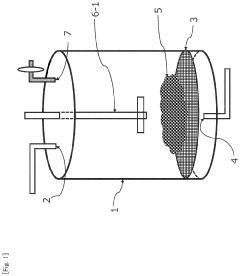

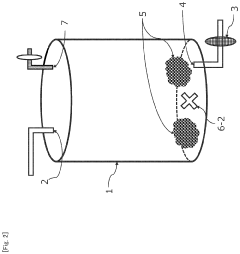

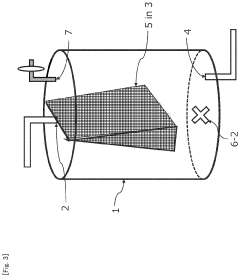

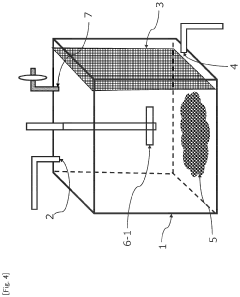

Product for biomolecule purification

PatentPendingUS20240173646A1

Innovation

- A container equipped with a filter and an adsorbent or aggregating agent, such as water-insoluble inorganic compounds or resins, that selectively adsorbs or aggregates impurities, allowing for efficient separation and purification of target biomolecules by capturing impurities and allowing the biomolecules to pass through.

Regulatory Compliance in Biopharmaceutical Purification

Regulatory compliance represents a critical dimension in the selection of separation methods for biomolecule purification, particularly in the biopharmaceutical industry where stringent standards govern product development and manufacturing processes. The regulatory landscape is dominated by key authorities including the FDA (Food and Drug Administration), EMA (European Medicines Agency), and ICH (International Council for Harmonisation), each establishing comprehensive guidelines that directly impact purification strategy decisions.

These regulatory frameworks mandate specific requirements for process validation, documentation, and quality control that must be integrated into separation method selection. For instance, FDA's Quality by Design (QbD) approach necessitates thorough understanding of critical quality attributes (CQAs) and how separation parameters affect them, influencing the choice between chromatography techniques, filtration methods, or precipitation approaches.

Current Good Manufacturing Practices (cGMP) compliance introduces additional considerations when evaluating separation technologies. Methods must demonstrate consistent reproducibility, scalability, and robustness under cGMP conditions. This often favors well-established techniques with extensive validation history, such as protein A chromatography for monoclonal antibody purification, over newer but less validated approaches.

Regulatory expectations regarding impurity profiles significantly impact separation method selection. Residual host cell proteins (HCPs), DNA, endotoxins, and leachables must be reduced to acceptable levels, with different separation techniques offering varying capabilities for specific impurity removal. The decision matrix must therefore incorporate each method's demonstrated effectiveness in meeting regulatory impurity thresholds.

Documentation requirements represent another regulatory dimension affecting separation choices. Methods requiring extensive validation documentation may present implementation challenges despite technical advantages. The regulatory burden associated with novel separation technologies often delays their adoption in favor of conventional approaches with established regulatory acceptance.

Global regulatory harmonization efforts through ICH guidelines have streamlined some aspects of compliance, yet regional variations persist. Separation strategies must account for these differences when products target multiple markets, potentially necessitating redundant purification steps to satisfy diverse regulatory requirements.

Risk assessment frameworks mandated by regulatory authorities must be incorporated into separation method selection. Techniques with higher process risks may require additional controls or alternative approaches to achieve regulatory acceptance, directly influencing the decision matrix weightings for different separation options.

These regulatory frameworks mandate specific requirements for process validation, documentation, and quality control that must be integrated into separation method selection. For instance, FDA's Quality by Design (QbD) approach necessitates thorough understanding of critical quality attributes (CQAs) and how separation parameters affect them, influencing the choice between chromatography techniques, filtration methods, or precipitation approaches.

Current Good Manufacturing Practices (cGMP) compliance introduces additional considerations when evaluating separation technologies. Methods must demonstrate consistent reproducibility, scalability, and robustness under cGMP conditions. This often favors well-established techniques with extensive validation history, such as protein A chromatography for monoclonal antibody purification, over newer but less validated approaches.

Regulatory expectations regarding impurity profiles significantly impact separation method selection. Residual host cell proteins (HCPs), DNA, endotoxins, and leachables must be reduced to acceptable levels, with different separation techniques offering varying capabilities for specific impurity removal. The decision matrix must therefore incorporate each method's demonstrated effectiveness in meeting regulatory impurity thresholds.

Documentation requirements represent another regulatory dimension affecting separation choices. Methods requiring extensive validation documentation may present implementation challenges despite technical advantages. The regulatory burden associated with novel separation technologies often delays their adoption in favor of conventional approaches with established regulatory acceptance.

Global regulatory harmonization efforts through ICH guidelines have streamlined some aspects of compliance, yet regional variations persist. Separation strategies must account for these differences when products target multiple markets, potentially necessitating redundant purification steps to satisfy diverse regulatory requirements.

Risk assessment frameworks mandated by regulatory authorities must be incorporated into separation method selection. Techniques with higher process risks may require additional controls or alternative approaches to achieve regulatory acceptance, directly influencing the decision matrix weightings for different separation options.

Cost-Efficiency Analysis of Separation Technologies

The economic implications of biomolecule purification technologies represent a critical factor in industrial decision-making processes. When evaluating separation methods such as chromatography, filtration, precipitation, and centrifugation, organizations must consider both direct costs and indirect economic impacts that affect the overall production economics.

Initial capital expenditure varies significantly across separation technologies. High-performance liquid chromatography (HPLC) systems typically require substantial investment, with costs ranging from $50,000 to $500,000 depending on scale and specifications. Membrane filtration systems generally present lower initial investments, particularly at smaller scales, though ultrafiltration and nanofiltration technologies may approach chromatography costs at industrial scales.

Operational expenses constitute another crucial dimension in the cost-efficiency matrix. Chromatographic methods incur significant costs through resin replacement, buffer consumption, and cleaning validation. Recent market analysis indicates that chromatography resins can represent 50-80% of downstream processing costs in biopharmaceutical production. Tangential flow filtration, while requiring membrane replacement, typically demonstrates 30-40% lower operational costs compared to equivalent chromatographic processes.

Scale-up economics must be carefully assessed when selecting separation technologies. Precipitation methods often exhibit favorable scale-up cost profiles, with costs increasing approximately linearly with volume. Conversely, chromatographic methods frequently demonstrate less favorable scale-up economics, with costs increasing exponentially beyond certain processing volumes. This relationship becomes particularly relevant for commercial-scale biopharmaceutical manufacturing.

Process yield represents a frequently overlooked economic factor. Higher-resolution separation methods like affinity chromatography may command premium prices but can deliver superior product recovery rates—often exceeding 90%—thereby justifying their implementation through reduced product loss. Comparative studies indicate that a 5% improvement in recovery yield can offset a 15-20% increase in separation technology costs for high-value biomolecules.

Regulatory compliance costs vary substantially across separation technologies. Chromatographic methods typically face more rigorous validation requirements, particularly for clinical and commercial applications. Documentation, testing, and validation expenses can add 15-25% to the overall implementation costs of these technologies, whereas simpler mechanical separation methods may incur significantly lower regulatory overhead.

Time-to-market considerations introduce temporal economic factors into the decision matrix. Technologies requiring extensive development and optimization phases generate substantial opportunity costs through delayed market entry. Recent industry analyses suggest that each month of delay in biopharmaceutical product launch represents approximately 3-5% of lifetime product revenue loss, emphasizing the economic value of separation technologies that enable rapid process development.

Initial capital expenditure varies significantly across separation technologies. High-performance liquid chromatography (HPLC) systems typically require substantial investment, with costs ranging from $50,000 to $500,000 depending on scale and specifications. Membrane filtration systems generally present lower initial investments, particularly at smaller scales, though ultrafiltration and nanofiltration technologies may approach chromatography costs at industrial scales.

Operational expenses constitute another crucial dimension in the cost-efficiency matrix. Chromatographic methods incur significant costs through resin replacement, buffer consumption, and cleaning validation. Recent market analysis indicates that chromatography resins can represent 50-80% of downstream processing costs in biopharmaceutical production. Tangential flow filtration, while requiring membrane replacement, typically demonstrates 30-40% lower operational costs compared to equivalent chromatographic processes.

Scale-up economics must be carefully assessed when selecting separation technologies. Precipitation methods often exhibit favorable scale-up cost profiles, with costs increasing approximately linearly with volume. Conversely, chromatographic methods frequently demonstrate less favorable scale-up economics, with costs increasing exponentially beyond certain processing volumes. This relationship becomes particularly relevant for commercial-scale biopharmaceutical manufacturing.

Process yield represents a frequently overlooked economic factor. Higher-resolution separation methods like affinity chromatography may command premium prices but can deliver superior product recovery rates—often exceeding 90%—thereby justifying their implementation through reduced product loss. Comparative studies indicate that a 5% improvement in recovery yield can offset a 15-20% increase in separation technology costs for high-value biomolecules.

Regulatory compliance costs vary substantially across separation technologies. Chromatographic methods typically face more rigorous validation requirements, particularly for clinical and commercial applications. Documentation, testing, and validation expenses can add 15-25% to the overall implementation costs of these technologies, whereas simpler mechanical separation methods may incur significantly lower regulatory overhead.

Time-to-market considerations introduce temporal economic factors into the decision matrix. Technologies requiring extensive development and optimization phases generate substantial opportunity costs through delayed market entry. Recent industry analyses suggest that each month of delay in biopharmaceutical product launch represents approximately 3-5% of lifetime product revenue loss, emphasizing the economic value of separation technologies that enable rapid process development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!