Industrial Crystallization Best Practices: Seed, Cooling, And Purity Control

AUG 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Crystallization Technology Evolution and Objectives

Crystallization processes have evolved significantly since their industrial adoption in the 19th century. Initially, crystallization was primarily employed in the production of salt and sugar, utilizing rudimentary batch cooling techniques with limited control mechanisms. The early 20th century witnessed the introduction of mechanical agitation and basic temperature regulation, marking the first significant advancement in crystallization technology.

The mid-20th century brought forth substantial innovations with the development of continuous crystallization processes, enabling higher throughput and more consistent product quality. This period also saw the emergence of fundamental theories explaining nucleation and crystal growth mechanisms, providing a scientific foundation for process optimization.

The 1970s and 1980s represented a transformative era with the integration of computer-controlled systems for precise temperature manipulation and the introduction of sophisticated seeding techniques. These advancements allowed for enhanced control over crystal size distribution and morphology, critical parameters in determining final product characteristics.

Recent decades have witnessed revolutionary progress driven by advanced analytical technologies. In-situ process analytical tools (PAT) such as FBRM (Focused Beam Reflectance Measurement), ATR-FTIR (Attenuated Total Reflection-Fourier Transform Infrared Spectroscopy), and Raman spectroscopy now enable real-time monitoring of supersaturation levels, crystal size distribution, and polymorphic forms.

The current technological landscape is characterized by the integration of artificial intelligence and machine learning algorithms for predictive modeling and process optimization. These computational approaches facilitate the development of robust crystallization processes with reduced experimental burden and accelerated scale-up timelines.

The primary objectives of modern industrial crystallization technology center around achieving precise control over crystal attributes while maximizing process efficiency. Key goals include consistent production of crystals with predetermined size distribution, morphology, and polymorphic form, as these characteristics directly influence downstream processing efficiency and final product performance.

Additional objectives encompass minimizing impurity incorporation through selective crystallization techniques, reducing energy consumption through optimized cooling profiles, and developing continuous manufacturing platforms for enhanced productivity and reduced environmental impact.

Looking forward, the evolution of crystallization technology is expected to continue toward fully automated, self-optimizing systems capable of adapting to variations in raw material quality and process conditions. The integration of digital twins and advanced simulation tools will likely play a pivotal role in this progression, enabling virtual process development and optimization before physical implementation.

The mid-20th century brought forth substantial innovations with the development of continuous crystallization processes, enabling higher throughput and more consistent product quality. This period also saw the emergence of fundamental theories explaining nucleation and crystal growth mechanisms, providing a scientific foundation for process optimization.

The 1970s and 1980s represented a transformative era with the integration of computer-controlled systems for precise temperature manipulation and the introduction of sophisticated seeding techniques. These advancements allowed for enhanced control over crystal size distribution and morphology, critical parameters in determining final product characteristics.

Recent decades have witnessed revolutionary progress driven by advanced analytical technologies. In-situ process analytical tools (PAT) such as FBRM (Focused Beam Reflectance Measurement), ATR-FTIR (Attenuated Total Reflection-Fourier Transform Infrared Spectroscopy), and Raman spectroscopy now enable real-time monitoring of supersaturation levels, crystal size distribution, and polymorphic forms.

The current technological landscape is characterized by the integration of artificial intelligence and machine learning algorithms for predictive modeling and process optimization. These computational approaches facilitate the development of robust crystallization processes with reduced experimental burden and accelerated scale-up timelines.

The primary objectives of modern industrial crystallization technology center around achieving precise control over crystal attributes while maximizing process efficiency. Key goals include consistent production of crystals with predetermined size distribution, morphology, and polymorphic form, as these characteristics directly influence downstream processing efficiency and final product performance.

Additional objectives encompass minimizing impurity incorporation through selective crystallization techniques, reducing energy consumption through optimized cooling profiles, and developing continuous manufacturing platforms for enhanced productivity and reduced environmental impact.

Looking forward, the evolution of crystallization technology is expected to continue toward fully automated, self-optimizing systems capable of adapting to variations in raw material quality and process conditions. The integration of digital twins and advanced simulation tools will likely play a pivotal role in this progression, enabling virtual process development and optimization before physical implementation.

Market Demand for High-Purity Crystalline Products

The global market for high-purity crystalline products has experienced substantial growth over the past decade, driven primarily by increasing demands from pharmaceutical, electronics, and specialty chemical industries. These sectors require crystalline materials with exceptional purity levels to ensure product quality, performance, and regulatory compliance.

In the pharmaceutical industry, the demand for high-purity active pharmaceutical ingredients (APIs) continues to rise as regulatory bodies worldwide implement stricter quality standards. The FDA and EMA have progressively tightened specifications for impurity profiles, pushing manufacturers to achieve purity levels exceeding 99.9% in many cases. This regulatory pressure has created a market segment specifically focused on crystallization technologies that can consistently deliver pharmaceutical-grade crystals.

The electronics industry represents another significant market driver, particularly in semiconductor manufacturing where even trace impurities can dramatically impact device performance. The global semiconductor market, valued at approximately $556 billion in 2021, demands crystalline materials with impurity levels measured in parts per billion. As electronic devices continue to miniaturize while increasing in complexity, the requirements for crystal purity become increasingly stringent.

Specialty chemicals represent the third major market segment, encompassing applications in food additives, cosmetics, agrochemicals, and performance materials. Consumer preferences for "clean label" products have pushed manufacturers to seek higher purity ingredients, creating premium market opportunities for suppliers who can deliver crystalline products with minimal impurities and consistent physical properties.

Market analysis indicates regional variations in demand patterns. North America and Europe lead in pharmaceutical applications, while Asia-Pacific dominates in electronics-related crystalline materials. Emerging economies are showing accelerated growth rates in all segments as their manufacturing capabilities advance and domestic consumption increases.

Price sensitivity varies significantly across applications. Pharmaceutical manufacturers demonstrate willingness to pay premium prices for crystalline products that meet stringent regulatory requirements and reduce downstream processing costs. Electronics manufacturers prioritize consistency and reliability over price, while specialty chemical applications show more traditional price elasticity.

The market structure features a mix of large multinational corporations with integrated production capabilities and specialized medium-sized companies focusing on specific high-value crystalline products. Recent years have seen increased merger and acquisition activity as larger players seek to acquire specialized crystallization expertise and technologies.

Future market growth projections remain strong, with compound annual growth rates estimated between 5-7% for the next five years. This growth trajectory is supported by technological advancements in crystallization processes that enable higher purities, better yield, and more consistent crystal properties.

In the pharmaceutical industry, the demand for high-purity active pharmaceutical ingredients (APIs) continues to rise as regulatory bodies worldwide implement stricter quality standards. The FDA and EMA have progressively tightened specifications for impurity profiles, pushing manufacturers to achieve purity levels exceeding 99.9% in many cases. This regulatory pressure has created a market segment specifically focused on crystallization technologies that can consistently deliver pharmaceutical-grade crystals.

The electronics industry represents another significant market driver, particularly in semiconductor manufacturing where even trace impurities can dramatically impact device performance. The global semiconductor market, valued at approximately $556 billion in 2021, demands crystalline materials with impurity levels measured in parts per billion. As electronic devices continue to miniaturize while increasing in complexity, the requirements for crystal purity become increasingly stringent.

Specialty chemicals represent the third major market segment, encompassing applications in food additives, cosmetics, agrochemicals, and performance materials. Consumer preferences for "clean label" products have pushed manufacturers to seek higher purity ingredients, creating premium market opportunities for suppliers who can deliver crystalline products with minimal impurities and consistent physical properties.

Market analysis indicates regional variations in demand patterns. North America and Europe lead in pharmaceutical applications, while Asia-Pacific dominates in electronics-related crystalline materials. Emerging economies are showing accelerated growth rates in all segments as their manufacturing capabilities advance and domestic consumption increases.

Price sensitivity varies significantly across applications. Pharmaceutical manufacturers demonstrate willingness to pay premium prices for crystalline products that meet stringent regulatory requirements and reduce downstream processing costs. Electronics manufacturers prioritize consistency and reliability over price, while specialty chemical applications show more traditional price elasticity.

The market structure features a mix of large multinational corporations with integrated production capabilities and specialized medium-sized companies focusing on specific high-value crystalline products. Recent years have seen increased merger and acquisition activity as larger players seek to acquire specialized crystallization expertise and technologies.

Future market growth projections remain strong, with compound annual growth rates estimated between 5-7% for the next five years. This growth trajectory is supported by technological advancements in crystallization processes that enable higher purities, better yield, and more consistent crystal properties.

Current Challenges in Industrial Crystallization

Despite significant advancements in industrial crystallization technology, the field continues to face several critical challenges that impede optimal process efficiency and product quality. One of the most persistent issues is the difficulty in achieving consistent crystal size distribution (CSD). Variations in CSD directly impact downstream processes such as filtration, drying, and formulation, leading to inconsistent final product characteristics and manufacturing inefficiencies.

Temperature control during cooling crystallization remains problematic, particularly in large-scale operations where temperature gradients within crystallizers can cause localized supersaturation variations. These variations often result in uneven nucleation rates across the crystallizer volume, contributing to broad crystal size distributions and unpredictable crystal morphology. Even with advanced cooling systems, maintaining precise cooling profiles throughout industrial-scale equipment continues to challenge process engineers.

Seed quality and consistency present another significant hurdle. The industry lacks standardized methods for seed preparation and characterization, resulting in batch-to-batch variability. Seed aging, agglomeration, and degradation during storage further complicate matters, making reproducible crystallization outcomes difficult to achieve consistently across production campaigns.

Impurity incorporation and control represent perhaps the most complex challenge in industrial crystallization. Trace impurities can dramatically alter crystal growth kinetics, habit, and purity. The mechanisms by which impurities affect crystallization are often poorly understood at the molecular level, making it difficult to develop robust strategies for impurity rejection. This is particularly problematic in pharmaceutical and fine chemical industries where product purity requirements are exceptionally stringent.

Scale-up issues continue to plague industrial implementation of crystallization processes. Laboratory-optimized processes frequently perform differently at production scale due to differences in mixing patterns, heat transfer characteristics, and surface-to-volume ratios. These discrepancies often necessitate extensive and costly re-optimization at each scale.

Real-time monitoring and control systems, while advancing rapidly, still lack the precision and reliability needed for fully automated crystallization processes. Current process analytical technology (PAT) tools often suffer from calibration drift, fouling issues, and limited sensitivity to detect critical process events such as nucleation onset or polymorphic transformations.

Sustainability concerns are increasingly prominent, with traditional crystallization processes often requiring large volumes of solvents and significant energy inputs. Developing more environmentally friendly approaches while maintaining product quality and process economics represents a growing challenge for the industry.

Temperature control during cooling crystallization remains problematic, particularly in large-scale operations where temperature gradients within crystallizers can cause localized supersaturation variations. These variations often result in uneven nucleation rates across the crystallizer volume, contributing to broad crystal size distributions and unpredictable crystal morphology. Even with advanced cooling systems, maintaining precise cooling profiles throughout industrial-scale equipment continues to challenge process engineers.

Seed quality and consistency present another significant hurdle. The industry lacks standardized methods for seed preparation and characterization, resulting in batch-to-batch variability. Seed aging, agglomeration, and degradation during storage further complicate matters, making reproducible crystallization outcomes difficult to achieve consistently across production campaigns.

Impurity incorporation and control represent perhaps the most complex challenge in industrial crystallization. Trace impurities can dramatically alter crystal growth kinetics, habit, and purity. The mechanisms by which impurities affect crystallization are often poorly understood at the molecular level, making it difficult to develop robust strategies for impurity rejection. This is particularly problematic in pharmaceutical and fine chemical industries where product purity requirements are exceptionally stringent.

Scale-up issues continue to plague industrial implementation of crystallization processes. Laboratory-optimized processes frequently perform differently at production scale due to differences in mixing patterns, heat transfer characteristics, and surface-to-volume ratios. These discrepancies often necessitate extensive and costly re-optimization at each scale.

Real-time monitoring and control systems, while advancing rapidly, still lack the precision and reliability needed for fully automated crystallization processes. Current process analytical technology (PAT) tools often suffer from calibration drift, fouling issues, and limited sensitivity to detect critical process events such as nucleation onset or polymorphic transformations.

Sustainability concerns are increasingly prominent, with traditional crystallization processes often requiring large volumes of solvents and significant energy inputs. Developing more environmentally friendly approaches while maintaining product quality and process economics represents a growing challenge for the industry.

Seed Crystal Management Techniques and Protocols

01 Advanced crystallization techniques for purity control

Various advanced crystallization techniques can be employed to enhance purity control in industrial processes. These include controlled cooling crystallization, anti-solvent crystallization, and melt crystallization methods. By carefully controlling parameters such as temperature gradients, cooling rates, and solvent composition, manufacturers can significantly improve crystal purity and reduce impurity inclusion. These techniques often involve specialized equipment designed to maintain precise conditions throughout the crystallization process.- Advanced crystallization techniques for purity control: Various advanced crystallization techniques can be employed to enhance purity control in industrial processes. These include controlled cooling crystallization, anti-solvent crystallization, and melt crystallization methods. By carefully controlling parameters such as temperature gradients, cooling rates, and supersaturation levels, these techniques can significantly improve crystal purity and reduce impurity inclusion. Advanced monitoring systems allow for real-time adjustments to optimize crystal growth and minimize defects.

- Impurity removal strategies in crystallization processes: Effective impurity removal is crucial for achieving high-purity crystals in industrial applications. Techniques such as multi-stage crystallization, fractional crystallization, and selective adsorption can be implemented to separate target compounds from impurities. Washing protocols using specific solvents can remove surface impurities without dissolving the desired crystals. Additionally, seeding with high-purity crystals can promote selective crystallization of the target compound while excluding impurities.

- Process monitoring and control systems for crystallization: Advanced monitoring and control systems are essential for maintaining crystal purity in industrial processes. These systems utilize sensors for real-time measurement of parameters such as concentration, temperature, and crystal size distribution. Process analytical technologies (PAT) including in-situ spectroscopy, particle vision measurement, and ultrasonic techniques provide continuous feedback for process optimization. Automated control systems can make adjustments to maintain optimal crystallization conditions, resulting in consistent product purity.

- Equipment design for enhanced crystallization purity: Specialized equipment design plays a significant role in achieving high purity in industrial crystallization. Crystallizers with optimized geometry, improved mixing capabilities, and controlled flow patterns can minimize impurity incorporation. Features such as baffles, specialized agitators, and draft tubes help maintain uniform supersaturation and prevent localized concentration gradients. Novel crystallizer designs incorporate zones for nucleation, growth, and classification to better control crystal properties and purity.

- Solvent selection and optimization for purity control: The choice and optimization of solvents significantly impact crystal purity in industrial processes. Selecting appropriate solvents based on solubility differences between the target compound and impurities can enhance separation efficiency. Mixed solvent systems can be designed to manipulate supersaturation and crystal growth kinetics. Solvent purity itself is critical, as contaminants can be incorporated into the crystal lattice. Recycling and purification of process solvents help maintain consistent crystallization conditions and product quality.

02 In-process monitoring and control systems

Real-time monitoring and control systems play a crucial role in maintaining crystallization purity. These systems utilize sensors and analytical instruments to continuously measure critical parameters such as supersaturation, crystal size distribution, and solution composition. Advanced process analytical technology (PAT) enables immediate adjustments to process conditions when deviations are detected. Implementation of feedback control loops and automated systems helps maintain optimal crystallization conditions, resulting in consistent product purity across production batches.Expand Specific Solutions03 Impurity removal and purification methods

Various methods can be employed to remove impurities during or after the crystallization process. These include multi-stage crystallization, washing procedures, and selective adsorption techniques. Recrystallization from different solvents can effectively eliminate specific impurities based on their solubility profiles. Some processes incorporate activated carbon or ion-exchange resins to selectively capture impurities before crystallization. These purification methods can be combined in sequence to achieve progressively higher levels of product purity.Expand Specific Solutions04 Crystallization equipment design and optimization

The design and optimization of crystallization equipment significantly impacts product purity. Specialized crystallizers with features such as controlled agitation, uniform temperature distribution, and optimized flow patterns can minimize impurity incorporation. Equipment innovations include continuous crystallization systems, specialized scraped surface heat exchangers, and crystallizers with integrated filtration capabilities. Computational fluid dynamics and process modeling are increasingly used to optimize equipment design for specific crystallization applications, resulting in improved purity control.Expand Specific Solutions05 Seeding and nucleation control strategies

Controlling nucleation and crystal growth through strategic seeding is essential for purity control. By introducing high-quality seed crystals under carefully controlled conditions, manufacturers can direct the crystallization process toward desired crystal structures while minimizing impurity inclusion. Techniques include template-assisted crystallization, ultrasonic-assisted nucleation, and controlled secondary nucleation. The size, quantity, and quality of seed crystals significantly influence the final product purity. Advanced seeding strategies often involve precise temperature cycling and controlled supersaturation profiles.Expand Specific Solutions

Leading Companies in Crystallization Equipment and Solutions

Industrial crystallization is currently in a mature growth phase, with a global market size estimated at $3-4 billion and growing steadily at 5-7% annually. The competitive landscape features a mix of academic institutions and commercial players across different specialization areas. Leading academic institutions like Tianjin University and Dalian University of Technology are advancing fundamental research in crystallization processes, while pharmaceutical companies including Merck Sharp & Dohme, Novartis, and Shionogi Pharma focus on high-purity crystallization techniques for drug manufacturing. Industrial players such as Siemens AG, JGC Corp., and Mitsubishi Rayon have developed proprietary cooling crystallization technologies. The technology has reached commercial maturity in traditional applications, though innovations in seed crystal optimization, precise cooling control systems, and real-time purity monitoring represent emerging frontiers being pursued by companies like Ajinomoto and Baoshan Iron & Steel.

Merck Sharp & Dohme Corp.

Technical Solution: Merck has developed advanced crystallization platforms that integrate precise seed management systems with controlled cooling protocols. Their technology employs automated seed generation units that produce uniform crystal seeds with predetermined size distributions, critical for consistent crystal growth. The company's cooling crystallization approach utilizes proprietary temperature profile algorithms that adapt in real-time based on solution supersaturation measurements, enabling optimal crystal growth rates while minimizing impurity inclusion. For purity control, Merck implements multi-stage crystallization processes with intermediate washing steps and selective crystallization conditions that exploit solubility differences between the target compound and impurities. Their systems incorporate Process Analytical Technology (PAT) tools including in-line Raman spectroscopy and Focused Beam Reflectance Measurement (FBRM) for real-time monitoring of crystal properties and process optimization.

Strengths: Superior integration of PAT tools for real-time process control; highly automated systems reducing human error; excellent batch-to-batch consistency. Weaknesses: High capital investment requirements; complex validation processes for pharmaceutical applications; system complexity requires specialized operator training.

Siemens AG

Technical Solution: Siemens has developed an advanced industrial crystallization platform that integrates digital twin technology with precise process control systems. Their approach to seed management employs automated seed generation units with controlled primary nucleation environments, producing seeds with predetermined characteristics. These seeds are then introduced into the main crystallizer using precision dosing systems that ensure optimal seed loading. For cooling control, Siemens utilizes their SIMATIC PCS 7 control system with specialized crystallization modules that implement model-predictive control algorithms. These systems continuously adjust cooling rates based on real-time measurements of solution properties and crystal characteristics, maintaining the process within the optimal metastable zone. Purity control is achieved through a combination of selective crystallization conditions and advanced separation techniques integrated into the crystallization process. Their systems incorporate comprehensive PAT implementation including Raman spectroscopy, FBRM, and PVM, all integrated with their SIPAT (Siemens Process Analytical Technology) platform for real-time monitoring and control. The entire crystallization process is digitalized, with data analytics providing insights for continuous process improvement.

Strengths: Superior automation and digital integration capabilities; excellent scalability from lab to production; comprehensive data analytics for process optimization. Weaknesses: High initial investment costs; complex implementation requiring significant technical expertise; substantial customization needed for specific applications.

Cooling Profile Optimization and Control Strategies

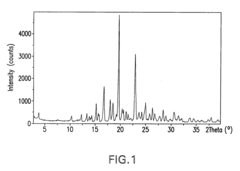

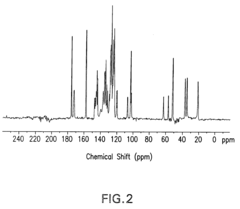

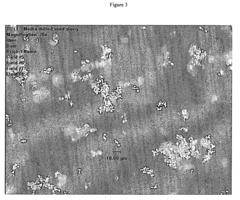

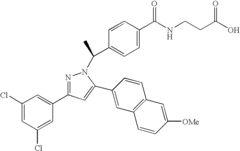

Process for the production of a crystalline glucagon receptor antagonist compound

PatentActiveUS20100184995A1

Innovation

- A process involving the generation of microseeds through wet milling and subsequent crystallization under ultrasonic energy to produce substantially uniform crystalline particles, eliminating the need for downstream dry milling and controlling particle size and purity.

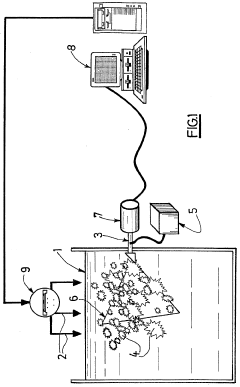

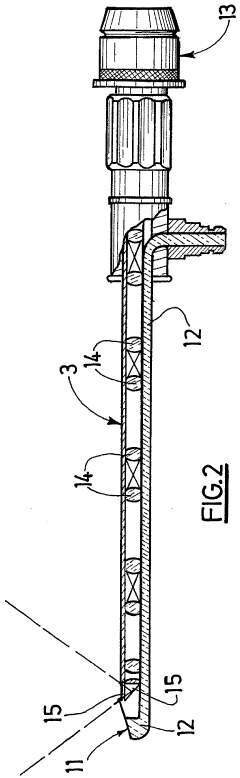

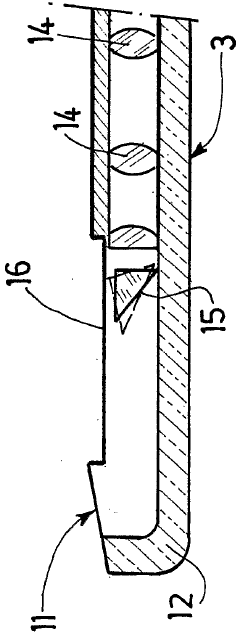

Method and device for continuously controlling a crystallisation process in a reaction medium

PatentWO2005019953A1

Innovation

- Implementing an image recording system within the reaction medium to capture and analyze crystal formation in real-time, using optical devices like endoscopes and microcomputers to process images and adjust operating conditions automatically, allowing for continuous monitoring and control of crystallization parameters like flow rates, cooling temperatures, and additive quantities.

Energy Efficiency in Industrial Crystallization Processes

Energy efficiency has become a critical consideration in industrial crystallization processes, driven by both economic imperatives and environmental regulations. Current industrial crystallization operations typically consume substantial energy, particularly in heating and cooling cycles, agitation systems, and downstream processing. Analysis of energy consumption patterns reveals that cooling crystallization processes often operate at efficiencies of only 40-60%, representing significant opportunities for optimization.

Advanced heat recovery systems have demonstrated potential to reduce energy consumption by 15-30% in industrial crystallization operations. These systems capture and repurpose thermal energy from exothermic crystallization reactions and cooling processes, creating closed-loop energy cycles that minimize waste. Implementation of variable frequency drives for agitation systems further reduces electrical consumption by adjusting power usage based on real-time crystallization kinetics.

Process intensification techniques specifically designed for crystallization have shown promising results in reducing energy footprints. Continuous crystallization processes, compared to traditional batch operations, can achieve energy savings of 20-45% while maintaining or improving product quality. Oscillatory baffled crystallizers represent an emerging technology that enhances mixing efficiency while reducing power requirements by up to 80% compared to conventional stirred tank crystallizers.

Seed crystal management strategies significantly impact energy efficiency. Optimized seeding protocols reduce the energy required for nucleation and growth phases, while precisely controlled cooling profiles minimize energy waste during supersaturation development. Studies indicate that implementing advanced seeding techniques can reduce overall process energy requirements by 10-25% while simultaneously improving crystal size distribution and purity.

Integration of real-time monitoring and control systems enables dynamic energy optimization throughout the crystallization process. Advanced PAT (Process Analytical Technology) tools allow for precise control of supersaturation levels, minimizing energy-intensive reprocessing due to quality deviations. Machine learning algorithms have demonstrated capability to reduce energy consumption by 8-17% through predictive control of crystallization parameters based on historical process data and real-time measurements.

Recent innovations in equipment design focus on thermal efficiency improvements. Novel crystallizer designs incorporating enhanced heat transfer surfaces have achieved cooling efficiency improvements of 25-40%. Additionally, selective application of ultrasonic energy to control nucleation events has shown potential to reduce overall energy requirements while improving crystal quality parameters.

Advanced heat recovery systems have demonstrated potential to reduce energy consumption by 15-30% in industrial crystallization operations. These systems capture and repurpose thermal energy from exothermic crystallization reactions and cooling processes, creating closed-loop energy cycles that minimize waste. Implementation of variable frequency drives for agitation systems further reduces electrical consumption by adjusting power usage based on real-time crystallization kinetics.

Process intensification techniques specifically designed for crystallization have shown promising results in reducing energy footprints. Continuous crystallization processes, compared to traditional batch operations, can achieve energy savings of 20-45% while maintaining or improving product quality. Oscillatory baffled crystallizers represent an emerging technology that enhances mixing efficiency while reducing power requirements by up to 80% compared to conventional stirred tank crystallizers.

Seed crystal management strategies significantly impact energy efficiency. Optimized seeding protocols reduce the energy required for nucleation and growth phases, while precisely controlled cooling profiles minimize energy waste during supersaturation development. Studies indicate that implementing advanced seeding techniques can reduce overall process energy requirements by 10-25% while simultaneously improving crystal size distribution and purity.

Integration of real-time monitoring and control systems enables dynamic energy optimization throughout the crystallization process. Advanced PAT (Process Analytical Technology) tools allow for precise control of supersaturation levels, minimizing energy-intensive reprocessing due to quality deviations. Machine learning algorithms have demonstrated capability to reduce energy consumption by 8-17% through predictive control of crystallization parameters based on historical process data and real-time measurements.

Recent innovations in equipment design focus on thermal efficiency improvements. Novel crystallizer designs incorporating enhanced heat transfer surfaces have achieved cooling efficiency improvements of 25-40%. Additionally, selective application of ultrasonic energy to control nucleation events has shown potential to reduce overall energy requirements while improving crystal quality parameters.

Scale-up Considerations for Crystallization Technologies

Scaling up crystallization processes from laboratory to industrial scale presents significant engineering challenges that must be addressed systematically. When transitioning from small-scale experiments to full production, parameters such as mixing efficiency, heat transfer rates, and mass transfer dynamics change dramatically. These variations can significantly impact crystal size distribution, morphology, and purity profiles if not properly managed.

Equipment selection becomes a critical factor in successful scale-up operations. While laboratory crystallizers may utilize simple jacketed vessels with magnetic stirring, industrial implementations require carefully designed crystallizers with optimized impeller configurations, baffling systems, and precise temperature control mechanisms. The geometry of industrial crystallizers must be designed to maintain uniform supersaturation throughout the vessel volume, preventing localized high supersaturation zones that could trigger unwanted nucleation events.

Heat transfer considerations represent another fundamental challenge during scale-up. As vessel size increases, the surface area-to-volume ratio decreases substantially, reducing relative heat transfer capacity. This necessitates the implementation of enhanced cooling systems, potentially including external heat exchangers, specialized cooling jackets, or internal cooling coils. The cooling rate must be carefully controlled to maintain the desired supersaturation profile throughout the batch cycle.

Mixing dynamics change profoundly with scale. Reynolds numbers increase significantly in larger vessels, altering flow patterns and potentially creating dead zones where crystallization behavior differs from the bulk solution. Computational fluid dynamics (CFD) modeling has become an essential tool for predicting these effects and optimizing impeller design and placement. Proper mixing ensures uniform temperature distribution, prevents particle sedimentation, and maintains consistent crystal growth conditions.

Seed introduction strategies must also be adapted during scale-up. The method of seed addition, seed loading rates, and seed quality control become increasingly important at industrial scale. Automated seed generation systems may be required to ensure consistent seed properties across production batches. The timing and rate of seed addition must be precisely controlled to achieve the desired crystal size distribution.

Process analytical technology (PAT) implementation becomes essential for monitoring and controlling large-scale crystallization. In-situ measurement techniques such as focused beam reflectance measurement (FBRM), particle vision measurement (PVM), and attenuated total reflectance Fourier transform infrared spectroscopy (ATR-FTIR) provide real-time data on crystal properties and solution composition. These technologies enable feedback control systems that can adjust process parameters dynamically to maintain optimal crystallization conditions despite scale-up challenges.

Equipment selection becomes a critical factor in successful scale-up operations. While laboratory crystallizers may utilize simple jacketed vessels with magnetic stirring, industrial implementations require carefully designed crystallizers with optimized impeller configurations, baffling systems, and precise temperature control mechanisms. The geometry of industrial crystallizers must be designed to maintain uniform supersaturation throughout the vessel volume, preventing localized high supersaturation zones that could trigger unwanted nucleation events.

Heat transfer considerations represent another fundamental challenge during scale-up. As vessel size increases, the surface area-to-volume ratio decreases substantially, reducing relative heat transfer capacity. This necessitates the implementation of enhanced cooling systems, potentially including external heat exchangers, specialized cooling jackets, or internal cooling coils. The cooling rate must be carefully controlled to maintain the desired supersaturation profile throughout the batch cycle.

Mixing dynamics change profoundly with scale. Reynolds numbers increase significantly in larger vessels, altering flow patterns and potentially creating dead zones where crystallization behavior differs from the bulk solution. Computational fluid dynamics (CFD) modeling has become an essential tool for predicting these effects and optimizing impeller design and placement. Proper mixing ensures uniform temperature distribution, prevents particle sedimentation, and maintains consistent crystal growth conditions.

Seed introduction strategies must also be adapted during scale-up. The method of seed addition, seed loading rates, and seed quality control become increasingly important at industrial scale. Automated seed generation systems may be required to ensure consistent seed properties across production batches. The timing and rate of seed addition must be precisely controlled to achieve the desired crystal size distribution.

Process analytical technology (PAT) implementation becomes essential for monitoring and controlling large-scale crystallization. In-situ measurement techniques such as focused beam reflectance measurement (FBRM), particle vision measurement (PVM), and attenuated total reflectance Fourier transform infrared spectroscopy (ATR-FTIR) provide real-time data on crystal properties and solution composition. These technologies enable feedback control systems that can adjust process parameters dynamically to maintain optimal crystallization conditions despite scale-up challenges.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!