Advanced Ceramic Membranes For High-Temperature Carbon Capture Applications

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ceramic Membrane Technology Background and Objectives

Ceramic membranes have emerged as a promising technology for carbon capture applications, particularly in high-temperature environments where traditional separation methods face significant limitations. The development of these advanced materials traces back to the 1980s when researchers began exploring porous ceramic structures for filtration purposes. Over the subsequent decades, ceramic membrane technology has evolved from simple filtration media to sophisticated separation systems capable of molecular-level selectivity.

The evolution of ceramic membranes has been driven by increasing environmental concerns and stringent regulations regarding carbon emissions. Early ceramic membranes suffered from low permeability and insufficient selectivity, but continuous research has led to remarkable improvements in material composition, pore structure control, and surface functionalization techniques. The field has witnessed a paradigm shift from conventional alumina-based membranes to advanced perovskite, fluorite, and mixed ionic-electronic conducting (MIEC) ceramic membranes that offer superior performance at elevated temperatures.

Current technological trends point toward the development of multi-functional ceramic membranes that combine high CO2 selectivity with excellent thermal and chemical stability. Research is increasingly focused on nanostructured ceramic materials that can maintain structural integrity and separation efficiency at temperatures exceeding 500°C, which is critical for integration with power generation and industrial processes where carbon capture is most needed.

The primary objective of advanced ceramic membrane technology for carbon capture is to achieve economically viable separation of CO2 from flue gases and process streams at high temperatures (400-900°C). This would eliminate the energy-intensive cooling steps required by conventional carbon capture technologies, thereby significantly reducing the overall energy penalty associated with carbon capture processes.

Additional technical goals include developing membranes with CO2 permeance exceeding 1×10^-6 mol·m^-2·s^-1·Pa^-1 and CO2/N2 selectivity greater than 100 under realistic operating conditions. Researchers aim to create membrane systems with operational lifespans of at least 5 years in harsh industrial environments, resistant to contaminants such as SOx, NOx, and particulate matter.

The long-term vision encompasses the seamless integration of ceramic membrane technology into existing industrial infrastructure, enabling a transition toward carbon-neutral operations without compromising production efficiency. This includes developing modular and scalable membrane systems that can be retrofitted to existing facilities or incorporated into new plant designs, providing a versatile solution for various industrial sectors including power generation, cement production, and steel manufacturing.

The evolution of ceramic membranes has been driven by increasing environmental concerns and stringent regulations regarding carbon emissions. Early ceramic membranes suffered from low permeability and insufficient selectivity, but continuous research has led to remarkable improvements in material composition, pore structure control, and surface functionalization techniques. The field has witnessed a paradigm shift from conventional alumina-based membranes to advanced perovskite, fluorite, and mixed ionic-electronic conducting (MIEC) ceramic membranes that offer superior performance at elevated temperatures.

Current technological trends point toward the development of multi-functional ceramic membranes that combine high CO2 selectivity with excellent thermal and chemical stability. Research is increasingly focused on nanostructured ceramic materials that can maintain structural integrity and separation efficiency at temperatures exceeding 500°C, which is critical for integration with power generation and industrial processes where carbon capture is most needed.

The primary objective of advanced ceramic membrane technology for carbon capture is to achieve economically viable separation of CO2 from flue gases and process streams at high temperatures (400-900°C). This would eliminate the energy-intensive cooling steps required by conventional carbon capture technologies, thereby significantly reducing the overall energy penalty associated with carbon capture processes.

Additional technical goals include developing membranes with CO2 permeance exceeding 1×10^-6 mol·m^-2·s^-1·Pa^-1 and CO2/N2 selectivity greater than 100 under realistic operating conditions. Researchers aim to create membrane systems with operational lifespans of at least 5 years in harsh industrial environments, resistant to contaminants such as SOx, NOx, and particulate matter.

The long-term vision encompasses the seamless integration of ceramic membrane technology into existing industrial infrastructure, enabling a transition toward carbon-neutral operations without compromising production efficiency. This includes developing modular and scalable membrane systems that can be retrofitted to existing facilities or incorporated into new plant designs, providing a versatile solution for various industrial sectors including power generation, cement production, and steel manufacturing.

Carbon Capture Market Analysis and Growth Projections

The global carbon capture market is experiencing significant growth, driven by increasing environmental regulations and the urgent need to reduce greenhouse gas emissions. As of 2023, the carbon capture, utilization, and storage (CCUS) market was valued at approximately $7.5 billion, with projections indicating a compound annual growth rate (CAGR) of 15.2% through 2030, potentially reaching $20.3 billion by the end of the decade.

High-temperature carbon capture applications represent a particularly promising segment within this market. Industrial sectors including cement production, steel manufacturing, and power generation collectively account for over 40% of global CO2 emissions, with most of these processes operating at temperatures exceeding 400°C. This creates substantial demand for advanced materials like ceramic membranes that can function effectively in these harsh environments.

The Asia-Pacific region is emerging as the fastest-growing market for carbon capture technologies, with China and India making substantial investments in decarbonization technologies for their expanding industrial sectors. North America currently leads in market share, accounting for approximately 35% of the global market, largely due to established carbon capture infrastructure and favorable government policies including tax incentives like the 45Q tax credit in the United States.

European nations are also significant players, with the EU's commitment to carbon neutrality by 2050 driving adoption. The European Carbon Capture and Storage Demonstration Project Network has allocated €1.8 billion specifically for developing next-generation capture technologies, including ceramic membrane systems.

Market analysis reveals that cost remains the primary barrier to widespread adoption, with current carbon capture technologies adding 25-70% to operational expenses in most industrial applications. Advanced ceramic membranes show potential to reduce these costs by up to 40% compared to conventional amine-based systems, particularly in high-temperature applications where traditional technologies struggle with degradation issues.

Investor confidence in the carbon capture sector has grown substantially, with venture capital funding increasing from $336 million in 2020 to over $1.1 billion in 2022. Strategic partnerships between technology developers and industrial end-users are becoming increasingly common, accelerating commercialization pathways for promising technologies like advanced ceramic membranes.

Government policies continue to be a critical market driver, with carbon pricing mechanisms now covering approximately 23% of global emissions. The implementation of carbon border adjustment mechanisms by major economies is expected to further stimulate demand for effective carbon capture solutions across global supply chains, creating additional market opportunities for high-temperature capture technologies.

High-temperature carbon capture applications represent a particularly promising segment within this market. Industrial sectors including cement production, steel manufacturing, and power generation collectively account for over 40% of global CO2 emissions, with most of these processes operating at temperatures exceeding 400°C. This creates substantial demand for advanced materials like ceramic membranes that can function effectively in these harsh environments.

The Asia-Pacific region is emerging as the fastest-growing market for carbon capture technologies, with China and India making substantial investments in decarbonization technologies for their expanding industrial sectors. North America currently leads in market share, accounting for approximately 35% of the global market, largely due to established carbon capture infrastructure and favorable government policies including tax incentives like the 45Q tax credit in the United States.

European nations are also significant players, with the EU's commitment to carbon neutrality by 2050 driving adoption. The European Carbon Capture and Storage Demonstration Project Network has allocated €1.8 billion specifically for developing next-generation capture technologies, including ceramic membrane systems.

Market analysis reveals that cost remains the primary barrier to widespread adoption, with current carbon capture technologies adding 25-70% to operational expenses in most industrial applications. Advanced ceramic membranes show potential to reduce these costs by up to 40% compared to conventional amine-based systems, particularly in high-temperature applications where traditional technologies struggle with degradation issues.

Investor confidence in the carbon capture sector has grown substantially, with venture capital funding increasing from $336 million in 2020 to over $1.1 billion in 2022. Strategic partnerships between technology developers and industrial end-users are becoming increasingly common, accelerating commercialization pathways for promising technologies like advanced ceramic membranes.

Government policies continue to be a critical market driver, with carbon pricing mechanisms now covering approximately 23% of global emissions. The implementation of carbon border adjustment mechanisms by major economies is expected to further stimulate demand for effective carbon capture solutions across global supply chains, creating additional market opportunities for high-temperature capture technologies.

High-Temperature Ceramic Membrane State-of-the-Art

Ceramic membranes for high-temperature carbon capture applications have evolved significantly over the past two decades. Initially developed for gas separation in industrial processes, these membranes have been increasingly optimized for carbon capture operations at elevated temperatures, typically ranging from 400°C to 800°C. The fundamental advantage of ceramic membranes lies in their exceptional thermal stability and chemical resistance compared to polymeric alternatives.

Current state-of-the-art ceramic membranes primarily fall into three categories: oxygen transport membranes (OTMs), proton-conducting membranes, and mixed ionic-electronic conducting (MIEC) membranes. OTMs, typically composed of perovskite-type oxides, have demonstrated oxygen flux rates exceeding 10 ml·min⁻¹·cm⁻² at temperatures above 800°C, representing a significant advancement over earlier generations that achieved only 1-2 ml·min⁻¹·cm⁻².

Proton-conducting ceramic membranes, often based on doped barium cerates and zirconates, have shown remarkable CO₂ separation factors exceeding 1000 in laboratory conditions. These materials exhibit proton conductivity in the range of 10⁻² to 10⁻¹ S·cm⁻¹ at operating temperatures between 600-700°C, enabling efficient hydrogen separation which indirectly facilitates carbon capture processes.

MIEC membranes represent the cutting edge of ceramic membrane technology, combining both ionic and electronic conductivity in a single material. Recent developments have produced membranes with CO₂ permeance values of 10⁻⁷ to 10⁻⁶ mol·m⁻²·s⁻¹·Pa⁻¹ at temperatures above 700°C, while maintaining selectivity factors above 100 for CO₂/N₂ separation.

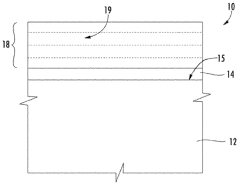

Manufacturing techniques have also advanced considerably. Traditional extrusion and slip casting methods have been supplemented by advanced techniques such as phase inversion, tape casting, and 3D printing. These newer fabrication approaches have enabled the production of asymmetric membrane structures with thin selective layers (5-20 μm) supported on porous substrates, dramatically improving both flux and mechanical stability.

Stability remains a critical challenge, with the most advanced membranes now demonstrating continuous operation for up to 5,000 hours under simulated flue gas conditions. This represents a five-fold improvement compared to membranes available a decade ago, which typically failed after 1,000 hours due to chemical degradation or mechanical failure.

Recent innovations include dual-phase composite membranes that combine a ceramic ion-conducting phase with a molten carbonate phase, achieving unprecedented CO₂ permeation rates exceeding 1.0 ml·min⁻¹·cm⁻² at 650°C. Additionally, surface modification techniques using catalytic coatings have enhanced both permeability and selectivity by facilitating surface exchange reactions that often limit overall membrane performance.

Current state-of-the-art ceramic membranes primarily fall into three categories: oxygen transport membranes (OTMs), proton-conducting membranes, and mixed ionic-electronic conducting (MIEC) membranes. OTMs, typically composed of perovskite-type oxides, have demonstrated oxygen flux rates exceeding 10 ml·min⁻¹·cm⁻² at temperatures above 800°C, representing a significant advancement over earlier generations that achieved only 1-2 ml·min⁻¹·cm⁻².

Proton-conducting ceramic membranes, often based on doped barium cerates and zirconates, have shown remarkable CO₂ separation factors exceeding 1000 in laboratory conditions. These materials exhibit proton conductivity in the range of 10⁻² to 10⁻¹ S·cm⁻¹ at operating temperatures between 600-700°C, enabling efficient hydrogen separation which indirectly facilitates carbon capture processes.

MIEC membranes represent the cutting edge of ceramic membrane technology, combining both ionic and electronic conductivity in a single material. Recent developments have produced membranes with CO₂ permeance values of 10⁻⁷ to 10⁻⁶ mol·m⁻²·s⁻¹·Pa⁻¹ at temperatures above 700°C, while maintaining selectivity factors above 100 for CO₂/N₂ separation.

Manufacturing techniques have also advanced considerably. Traditional extrusion and slip casting methods have been supplemented by advanced techniques such as phase inversion, tape casting, and 3D printing. These newer fabrication approaches have enabled the production of asymmetric membrane structures with thin selective layers (5-20 μm) supported on porous substrates, dramatically improving both flux and mechanical stability.

Stability remains a critical challenge, with the most advanced membranes now demonstrating continuous operation for up to 5,000 hours under simulated flue gas conditions. This represents a five-fold improvement compared to membranes available a decade ago, which typically failed after 1,000 hours due to chemical degradation or mechanical failure.

Recent innovations include dual-phase composite membranes that combine a ceramic ion-conducting phase with a molten carbonate phase, achieving unprecedented CO₂ permeation rates exceeding 1.0 ml·min⁻¹·cm⁻² at 650°C. Additionally, surface modification techniques using catalytic coatings have enhanced both permeability and selectivity by facilitating surface exchange reactions that often limit overall membrane performance.

Current High-Temperature Carbon Separation Solutions

01 Ceramic membrane compositions for carbon capture

Advanced ceramic membranes with specific compositions are designed for efficient carbon capture. These membranes typically incorporate materials such as metal oxides, zeolites, and perovskites that provide high selectivity for CO2 molecules. The composition can be tailored to enhance permeability and separation efficiency while maintaining structural integrity under high-temperature and high-pressure conditions typical in carbon capture applications.- Ceramic membrane compositions for carbon capture: Advanced ceramic membranes with specific material compositions enhance carbon capture efficiency. These membranes typically incorporate materials such as zeolites, perovskites, or metal oxides that provide selective permeability for CO2 molecules. The composition can be engineered to optimize properties like porosity, thermal stability, and chemical resistance, which are crucial for effective carbon capture applications in industrial settings.

- Structural design of ceramic membranes: The structural design of ceramic membranes plays a critical role in carbon capture performance. Innovations include multi-layered configurations, hollow fiber structures, and asymmetric designs that maximize surface area while maintaining mechanical integrity. These structural enhancements improve gas separation efficiency by providing optimized pathways for CO2 transport while blocking other gases, resulting in higher selectivity and permeability for carbon capture applications.

- Surface modification techniques for ceramic membranes: Surface modification of ceramic membranes enhances carbon capture capabilities through functionalization with specific chemical groups or coatings. Techniques include grafting of amine-containing compounds, incorporation of metal-organic frameworks, or deposition of thin selective layers. These modifications create active sites that interact preferentially with CO2 molecules, improving selectivity and adsorption capacity while maintaining the mechanical and thermal stability advantages of the ceramic substrate.

- Integration of ceramic membranes in carbon capture systems: Integration strategies for ceramic membranes in carbon capture systems focus on optimizing operational parameters and system configurations. This includes designing appropriate module housings, flow patterns, and process conditions to maximize CO2 separation efficiency. Advanced integration approaches incorporate membrane units into hybrid systems with other capture technologies, pressure swing adsorption units, or pre-treatment processes to handle real-world gas streams with varying compositions and impurities.

- Performance enhancement methods for ceramic membranes: Various methods are employed to enhance the performance of ceramic membranes for carbon capture. These include doping with catalytic elements, creating hierarchical pore structures, and incorporating composite materials to improve selectivity and permeability. Other approaches focus on reducing membrane thickness while maintaining mechanical strength, developing self-healing capabilities, or engineering defect-free surfaces. These enhancements aim to address challenges such as membrane fouling, chemical stability, and long-term durability under industrial carbon capture conditions.

02 Membrane structure optimization for enhanced CO2 separation

The structural design of ceramic membranes plays a crucial role in carbon capture efficiency. Advanced membranes feature optimized pore sizes, controlled porosity, and engineered surface areas to maximize CO2 adsorption and transport. Multi-layer structures with gradient porosity and asymmetric configurations are developed to balance permeability and selectivity requirements, while maintaining mechanical strength under industrial operating conditions.Expand Specific Solutions03 Surface functionalization techniques for ceramic membranes

Surface modification of ceramic membranes enhances their carbon capture capabilities. Functionalization techniques include grafting of amine groups, incorporation of metal-organic frameworks, and deposition of catalytic materials on the membrane surface. These modifications increase CO2 adsorption capacity, improve selectivity, and facilitate faster transport of captured carbon through the membrane structure, resulting in higher overall capture efficiency.Expand Specific Solutions04 Hybrid ceramic-polymer membrane systems

Hybrid membrane systems combining ceramic materials with polymers offer advantages for carbon capture applications. These composite membranes leverage the thermal and chemical stability of ceramics with the processability and cost-effectiveness of polymers. The synergistic combination results in membranes with enhanced CO2 permeability, improved mechanical properties, and better resistance to fouling and degradation in industrial carbon capture environments.Expand Specific Solutions05 Manufacturing processes for advanced ceramic membranes

Innovative manufacturing techniques are crucial for producing high-performance ceramic membranes for carbon capture. These processes include sol-gel synthesis, phase inversion, tape casting, and advanced sintering methods. Emerging fabrication approaches such as 3D printing and freeze casting enable precise control over membrane architecture. These manufacturing innovations allow for scalable production of ceramic membranes with consistent properties and optimized performance for industrial carbon capture applications.Expand Specific Solutions

Leading Organizations in Advanced Ceramic Membrane Development

Advanced ceramic membranes for high-temperature carbon capture applications are in an early growth phase, with market size expanding due to increasing global decarbonization efforts. The technology is approaching commercial maturity, with key players demonstrating varied levels of development. Research institutions like Nanjing Tech University, Dalian Institute of Chemical Physics, and Rice University are advancing fundamental membrane science, while industrial players including DuPont, Air Liquide, and ExxonMobil are focusing on scalable solutions. Energy companies such as PETRONAS, Korea Gas, and Petrobras are investing in field applications, indicating growing commercial interest. The competitive landscape shows a balanced ecosystem of academic innovation and industrial implementation, with collaboration between sectors accelerating technology readiness for widespread carbon capture deployment.

Dalian Institute of Chemical Physics Chinese Academy of Sci

Technical Solution: Dalian Institute of Chemical Physics (DICP) has developed advanced ceramic membrane technology specifically for high-temperature carbon capture applications. Their approach focuses on mixed ionic-electronic conducting (MIEC) ceramic membranes, particularly oxygen transport membranes (OTMs) based on perovskite-type materials. These membranes operate at temperatures between 700-900°C and can selectively separate oxygen from air, which is crucial for oxyfuel combustion and other carbon capture processes. DICP has pioneered the development of Ba0.5Sr0.5Co0.8Fe0.2O3-δ (BSCF) membranes with enhanced stability and oxygen permeation flux exceeding 10 ml·min-1·cm-2 at 900°C[1]. Their technology includes innovative membrane fabrication methods such as phase-inversion tape casting to create asymmetric structures with thin selective layers supported on porous substrates, significantly improving both flux and mechanical strength. DICP has also developed dual-phase ceramic membranes combining ionic and electronic conducting phases to overcome the stability limitations of single-phase materials in CO2-rich environments typical in carbon capture applications[2].

Strengths: Superior oxygen permeation flux and excellent high-temperature stability in harsh environments. Their dual-phase membrane design effectively addresses the chemical stability issues in CO2-rich atmospheres. Weaknesses: Manufacturing complexity of asymmetric structures increases production costs, and the technology still faces challenges with long-term mechanical stability under thermal cycling conditions typical in industrial carbon capture processes.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed proprietary ceramic membrane technology for high-temperature carbon capture focusing on carbonate dual-phase membranes (CDPMs). Their approach utilizes a composite structure consisting of molten carbonate phases infiltrated into porous ceramic supports, typically made of yttria-stabilized zirconia or similar materials. These membranes operate at temperatures between 600-900°C and facilitate selective CO2 transport through a combination of carbonate ion (CO3²⁻) transport and oxygen ion (O²⁻) counter-transport mechanisms. ExxonMobil's innovation lies in their membrane architecture optimization, which achieves CO2 permeation rates exceeding 1.0 ml·min⁻¹·cm⁻² at 900°C while maintaining structural integrity in the presence of contaminants like SOx and NOx[3]. Their technology incorporates specialized surface catalysts to enhance CO2 conversion at the membrane interfaces and utilizes proprietary ceramic support structures with engineered porosity gradients to maximize mechanical strength while minimizing mass transfer resistance. ExxonMobil has demonstrated this technology at pilot scale, integrating it with their existing refinery and petrochemical processes to achieve carbon capture rates above 90% with lower energy penalties compared to conventional amine scrubbing[4].

Strengths: High CO2 selectivity and permeability at elevated temperatures, with demonstrated integration into existing industrial processes. Their membrane design shows excellent tolerance to common flue gas contaminants. Weaknesses: The molten carbonate phase can cause long-term stability issues through gradual leakage, and the technology requires precise temperature control to maintain the optimal molten state of the carbonate phase, increasing operational complexity.

Key Patents and Innovations in Ceramic Membrane Technology

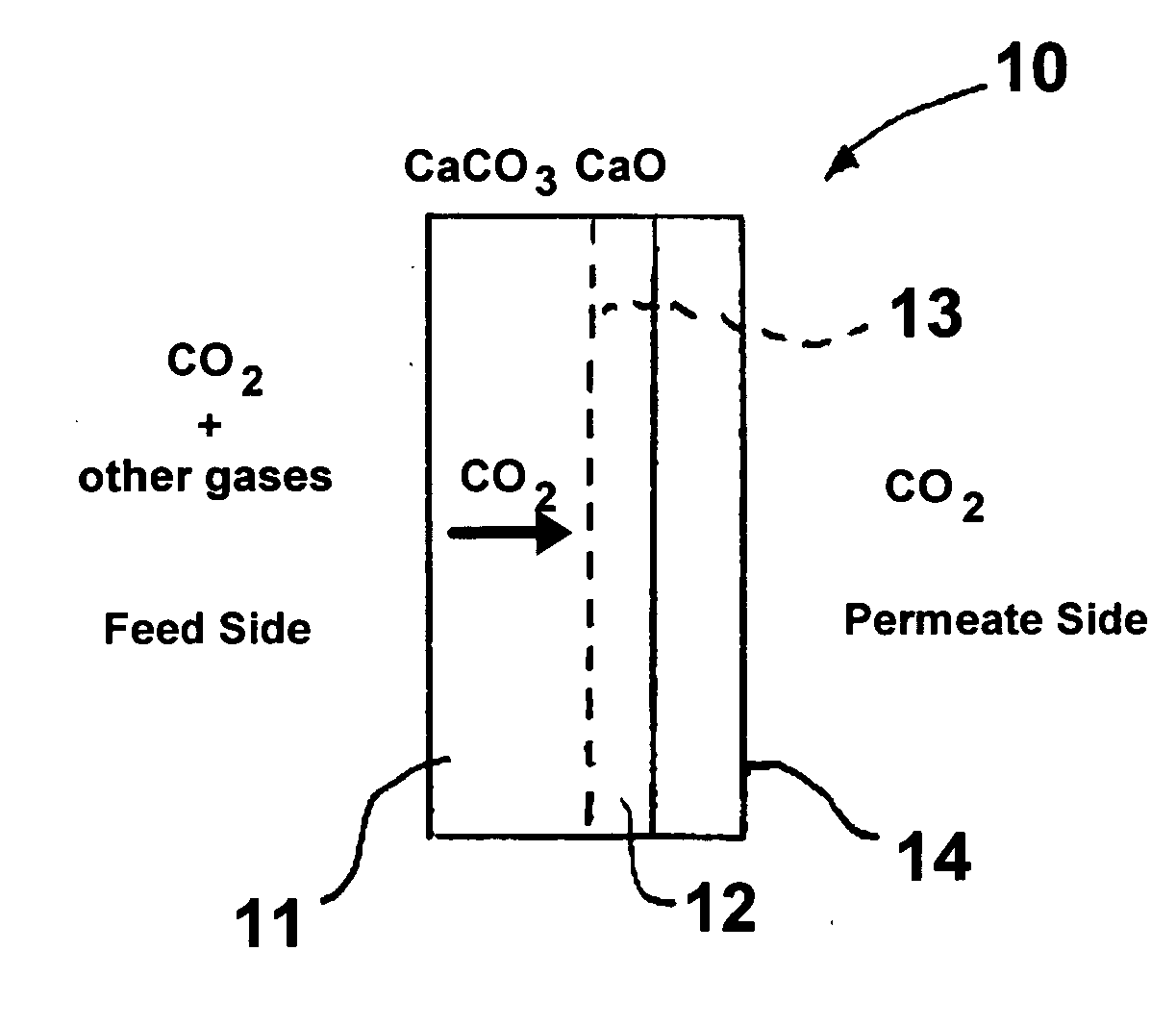

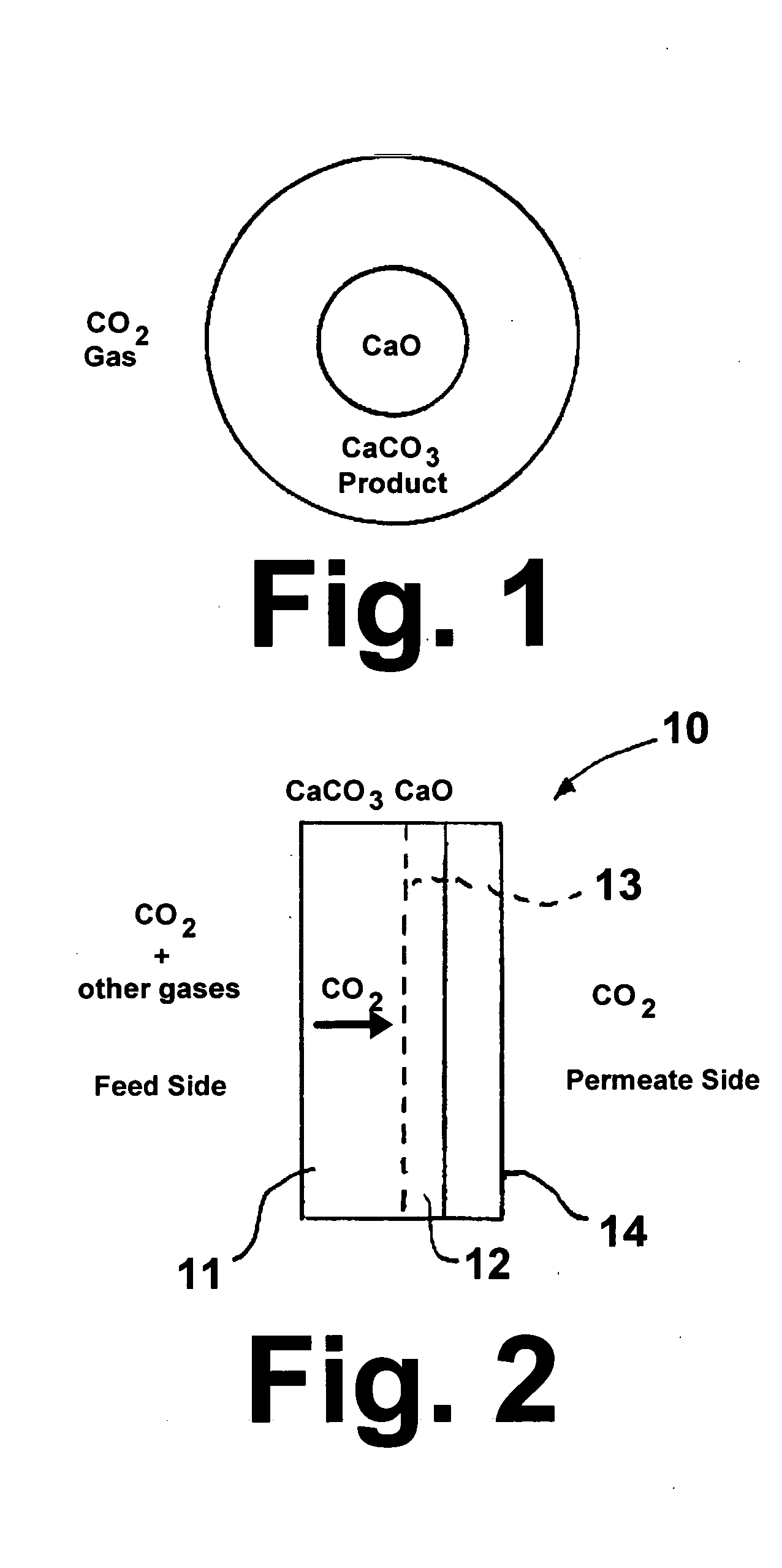

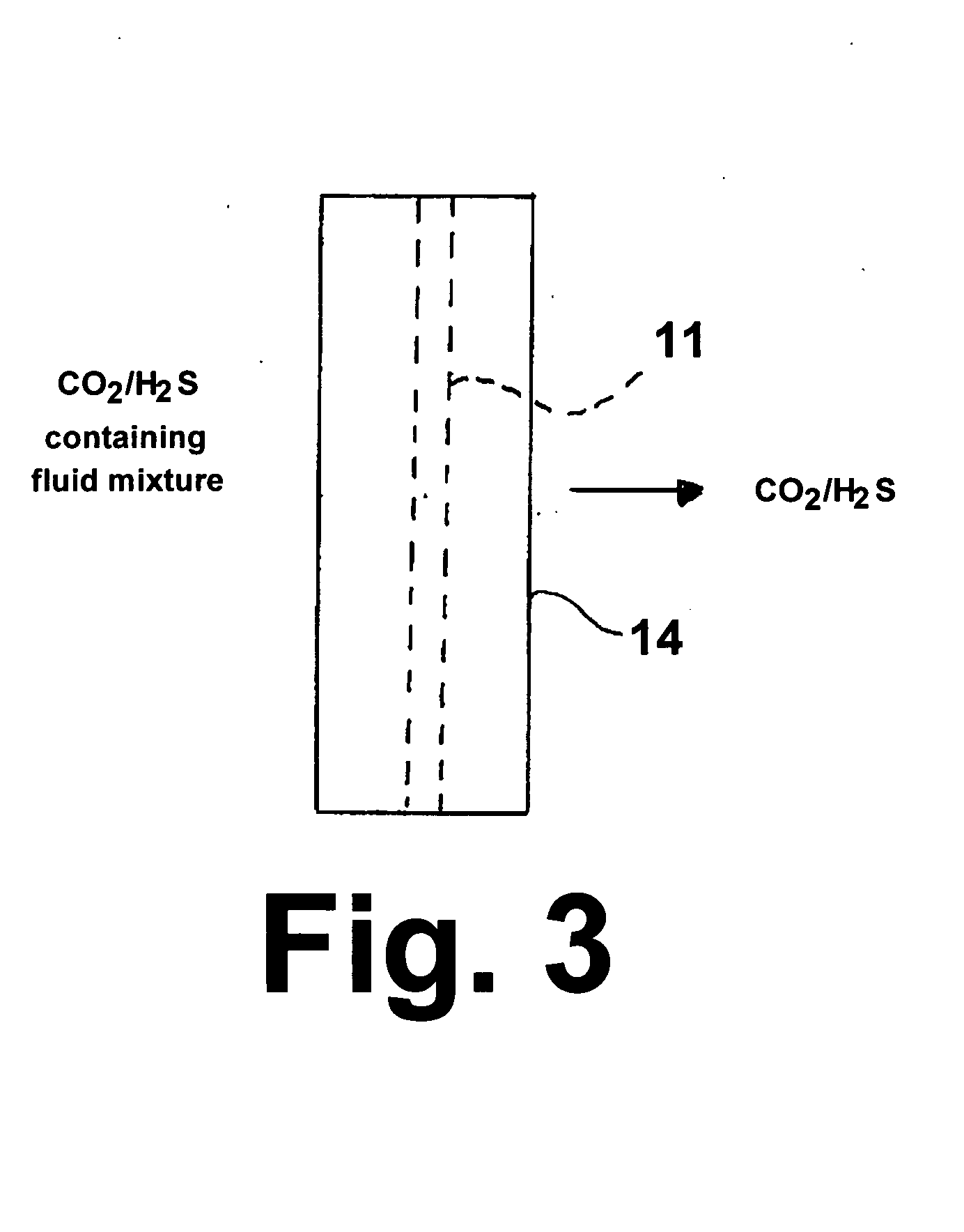

High-temperature membrane for CO2 and/or H2S separation

PatentInactiveUS20070240570A1

Innovation

- A nonporous metal carbonate membrane, comprising metals like Ca, Mg, Ba, and Sr, is used for selective separation of CO2 and H2S at high temperatures, allowing only carbonate and sulfide ions to diffuse through while excluding other gases, achieving 100% selectivity and high diffusion flux.

Ceramic composites with an intermediate layer having a carbon sink material for high temperature applications

PatentActiveUS11655194B2

Innovation

- A carbon-sink intermediate layer is introduced between the ceramic substrate and the EBC, inhibiting the accumulation of free carbon and preventing the formation of carbon oxides, thus eliminating the need for a silicon bond coating and allowing for higher operational temperatures by reacting with free carbon to form stable carbides.

Environmental Policy Impact on Carbon Capture Technologies

Environmental policies worldwide have become increasingly stringent regarding carbon emissions, creating a significant impact on the development and deployment of carbon capture technologies, particularly advanced ceramic membranes for high-temperature applications. The Paris Agreement of 2015 marked a pivotal moment, establishing global commitments to limit temperature increases and reduce greenhouse gas emissions, thereby accelerating research funding and industrial interest in carbon capture solutions.

In the United States, policies such as the 45Q tax credit provide substantial financial incentives for carbon capture projects, offering up to $50 per metric ton of CO2 permanently sequestered. The Inflation Reduction Act of 2022 further enhanced these incentives, increasing credit values and lowering capture thresholds, making ceramic membrane technologies more economically viable for industrial implementation.

The European Union's Emissions Trading System (EU ETS) has created a carbon market that directly influences technology adoption decisions. With carbon prices reaching record levels of over €90 per ton in 2023, industries face mounting pressure to implement effective carbon capture solutions. The EU Innovation Fund specifically allocates resources for breakthrough technologies like advanced ceramic membranes that can operate efficiently in high-temperature industrial environments.

China's inclusion of carbon neutrality goals in its 14th Five-Year Plan (2021-2025) has similarly catalyzed government support for carbon capture research, with particular emphasis on technologies applicable to the country's coal-dominated energy sector. This policy direction has accelerated ceramic membrane development through increased funding and pilot project opportunities.

Regulatory frameworks addressing technical standards and safety requirements for carbon capture technologies have evolved significantly. These frameworks now increasingly recognize the unique properties of ceramic membranes, such as their durability under extreme conditions and chemical stability, providing clearer pathways for certification and commercial deployment.

Environmental justice considerations are also shaping policy approaches to carbon capture. Regulations increasingly require assessment of local environmental impacts beyond CO2 reduction, including potential effects on air quality and water resources, factors where ceramic membranes often demonstrate advantages over alternative technologies due to their clean operation and minimal chemical requirements.

Looking forward, policy trends indicate movement toward technology-neutral performance standards rather than prescriptive requirements, potentially benefiting ceramic membrane technologies that can demonstrate superior efficiency metrics in high-temperature industrial applications. This shift aligns with the growing recognition that diverse technological approaches will be necessary to achieve ambitious climate targets across different industrial sectors.

In the United States, policies such as the 45Q tax credit provide substantial financial incentives for carbon capture projects, offering up to $50 per metric ton of CO2 permanently sequestered. The Inflation Reduction Act of 2022 further enhanced these incentives, increasing credit values and lowering capture thresholds, making ceramic membrane technologies more economically viable for industrial implementation.

The European Union's Emissions Trading System (EU ETS) has created a carbon market that directly influences technology adoption decisions. With carbon prices reaching record levels of over €90 per ton in 2023, industries face mounting pressure to implement effective carbon capture solutions. The EU Innovation Fund specifically allocates resources for breakthrough technologies like advanced ceramic membranes that can operate efficiently in high-temperature industrial environments.

China's inclusion of carbon neutrality goals in its 14th Five-Year Plan (2021-2025) has similarly catalyzed government support for carbon capture research, with particular emphasis on technologies applicable to the country's coal-dominated energy sector. This policy direction has accelerated ceramic membrane development through increased funding and pilot project opportunities.

Regulatory frameworks addressing technical standards and safety requirements for carbon capture technologies have evolved significantly. These frameworks now increasingly recognize the unique properties of ceramic membranes, such as their durability under extreme conditions and chemical stability, providing clearer pathways for certification and commercial deployment.

Environmental justice considerations are also shaping policy approaches to carbon capture. Regulations increasingly require assessment of local environmental impacts beyond CO2 reduction, including potential effects on air quality and water resources, factors where ceramic membranes often demonstrate advantages over alternative technologies due to their clean operation and minimal chemical requirements.

Looking forward, policy trends indicate movement toward technology-neutral performance standards rather than prescriptive requirements, potentially benefiting ceramic membrane technologies that can demonstrate superior efficiency metrics in high-temperature industrial applications. This shift aligns with the growing recognition that diverse technological approaches will be necessary to achieve ambitious climate targets across different industrial sectors.

Techno-Economic Assessment of Ceramic Membrane Implementation

The implementation of advanced ceramic membranes for carbon capture requires careful economic analysis to determine viability across different industrial settings. Initial capital expenditure for ceramic membrane systems ranges from $500-1,500 per square meter of membrane area, significantly higher than conventional polymer-based alternatives ($100-300/m²). However, this premium is offset by superior durability in high-temperature environments, with ceramic membranes demonstrating operational lifespans of 5-7 years compared to 1-2 years for polymeric options.

Operational expenditure analysis reveals that ceramic membrane systems can achieve 15-30% lower energy consumption for carbon separation processes when operating at elevated temperatures (500-900°C). This translates to estimated annual energy savings of $0.5-2.0 million for a medium-sized industrial facility capturing 100,000 tons of CO₂ annually. Maintenance costs remain relatively stable at approximately 3-5% of capital investment per year, compared to 7-10% for conventional systems operating in similar harsh conditions.

Scale-up economics demonstrate favorable trends, with production costs potentially decreasing by 30-40% when manufacturing volumes increase tenfold. Current production methods remain semi-specialized, but industry projections suggest standardization opportunities could emerge within 3-5 years as demand increases, further reducing unit costs by an estimated 15-25%.

Integration expenses with existing industrial infrastructure represent a significant consideration. Retrofitting existing facilities with ceramic membrane systems typically adds 20-35% to base installation costs, though this premium decreases to 10-15% for new construction projects designed with high-temperature carbon capture capabilities from inception.

Return on investment calculations indicate payback periods of 4-6 years for most industrial applications, with cement and steel manufacturing showing the most favorable economics due to their inherently high-temperature processes. Power generation applications demonstrate longer payback periods (6-8 years) but remain economically viable when carbon pricing exceeds $40-50 per ton.

Sensitivity analysis reveals that membrane performance degradation rates and carbon pricing mechanisms represent the most significant variables affecting long-term economic viability. A 10% improvement in membrane durability can reduce lifetime costs by approximately 7-12%, while carbon price fluctuations of $20/ton can shift payback periods by 1-2 years in either direction.

Operational expenditure analysis reveals that ceramic membrane systems can achieve 15-30% lower energy consumption for carbon separation processes when operating at elevated temperatures (500-900°C). This translates to estimated annual energy savings of $0.5-2.0 million for a medium-sized industrial facility capturing 100,000 tons of CO₂ annually. Maintenance costs remain relatively stable at approximately 3-5% of capital investment per year, compared to 7-10% for conventional systems operating in similar harsh conditions.

Scale-up economics demonstrate favorable trends, with production costs potentially decreasing by 30-40% when manufacturing volumes increase tenfold. Current production methods remain semi-specialized, but industry projections suggest standardization opportunities could emerge within 3-5 years as demand increases, further reducing unit costs by an estimated 15-25%.

Integration expenses with existing industrial infrastructure represent a significant consideration. Retrofitting existing facilities with ceramic membrane systems typically adds 20-35% to base installation costs, though this premium decreases to 10-15% for new construction projects designed with high-temperature carbon capture capabilities from inception.

Return on investment calculations indicate payback periods of 4-6 years for most industrial applications, with cement and steel manufacturing showing the most favorable economics due to their inherently high-temperature processes. Power generation applications demonstrate longer payback periods (6-8 years) but remain economically viable when carbon pricing exceeds $40-50 per ton.

Sensitivity analysis reveals that membrane performance degradation rates and carbon pricing mechanisms represent the most significant variables affecting long-term economic viability. A 10% improvement in membrane durability can reduce lifetime costs by approximately 7-12%, while carbon price fluctuations of $20/ton can shift payback periods by 1-2 years in either direction.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!