How Hybrid Inorganic-Organic Membranes Improve Long-Term Durability

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hybrid Membrane Technology Evolution and Objectives

Hybrid inorganic-organic membranes represent a significant evolution in separation technology, combining the mechanical and thermal stability of inorganic materials with the flexibility and processability of organic polymers. The development of these hybrid structures began in the 1990s as researchers sought to overcome the inherent limitations of purely organic or inorganic membranes. Early iterations focused primarily on simple blending techniques, but technological advancements have led to more sophisticated approaches including sol-gel processes, in-situ polymerization, and layer-by-layer assembly methods.

The evolution of hybrid membrane technology has been driven by increasing demands for membranes that can withstand harsh operating conditions while maintaining separation efficiency. Traditional polymeric membranes, while cost-effective and easy to process, often suffer from performance degradation under elevated temperatures, high pressures, and exposure to aggressive chemicals. Conversely, purely inorganic membranes exhibit excellent stability but are typically brittle and difficult to manufacture at scale.

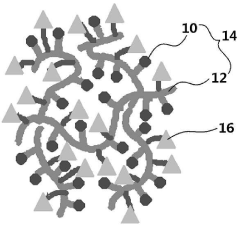

A significant milestone in hybrid membrane development occurred in the early 2000s with the introduction of mixed matrix membranes (MMMs), incorporating inorganic fillers within organic polymer matrices. This approach has since expanded to include more complex architectures such as surface-modified nanoparticles, metal-organic frameworks (MOFs), and covalent organic frameworks (COFs) as the inorganic components.

The primary objective of hybrid membrane technology is to achieve synergistic properties that exceed those of the individual components. Specifically, these membranes aim to deliver enhanced mechanical strength, improved chemical resistance, superior thermal stability, and extended operational lifetimes while maintaining or improving separation performance metrics such as permeability and selectivity.

Recent research has increasingly focused on tailoring the interface between organic and inorganic components, recognizing this boundary as critical to overall membrane performance and durability. Advanced characterization techniques, including atomic force microscopy, X-ray photoelectron spectroscopy, and molecular dynamics simulations, have enabled researchers to better understand and optimize these interfaces at the nanoscale.

The technological trajectory is now moving toward "smart" hybrid membranes with stimuli-responsive properties, self-healing capabilities, and precisely engineered nanostructures. These innovations aim to address persistent challenges in membrane technology, particularly the trade-off between permeability and selectivity, and the degradation of performance over extended operational periods.

As environmental regulations become more stringent and industrial processes more demanding, the development of hybrid membranes with enhanced long-term durability has emerged as a critical research priority, with potential applications spanning water purification, gas separation, energy storage, and biomedical devices.

The evolution of hybrid membrane technology has been driven by increasing demands for membranes that can withstand harsh operating conditions while maintaining separation efficiency. Traditional polymeric membranes, while cost-effective and easy to process, often suffer from performance degradation under elevated temperatures, high pressures, and exposure to aggressive chemicals. Conversely, purely inorganic membranes exhibit excellent stability but are typically brittle and difficult to manufacture at scale.

A significant milestone in hybrid membrane development occurred in the early 2000s with the introduction of mixed matrix membranes (MMMs), incorporating inorganic fillers within organic polymer matrices. This approach has since expanded to include more complex architectures such as surface-modified nanoparticles, metal-organic frameworks (MOFs), and covalent organic frameworks (COFs) as the inorganic components.

The primary objective of hybrid membrane technology is to achieve synergistic properties that exceed those of the individual components. Specifically, these membranes aim to deliver enhanced mechanical strength, improved chemical resistance, superior thermal stability, and extended operational lifetimes while maintaining or improving separation performance metrics such as permeability and selectivity.

Recent research has increasingly focused on tailoring the interface between organic and inorganic components, recognizing this boundary as critical to overall membrane performance and durability. Advanced characterization techniques, including atomic force microscopy, X-ray photoelectron spectroscopy, and molecular dynamics simulations, have enabled researchers to better understand and optimize these interfaces at the nanoscale.

The technological trajectory is now moving toward "smart" hybrid membranes with stimuli-responsive properties, self-healing capabilities, and precisely engineered nanostructures. These innovations aim to address persistent challenges in membrane technology, particularly the trade-off between permeability and selectivity, and the degradation of performance over extended operational periods.

As environmental regulations become more stringent and industrial processes more demanding, the development of hybrid membranes with enhanced long-term durability has emerged as a critical research priority, with potential applications spanning water purification, gas separation, energy storage, and biomedical devices.

Market Demand Analysis for Durable Membrane Solutions

The global membrane market has witnessed significant growth in recent years, driven primarily by increasing demand for water treatment solutions across industrial, municipal, and residential sectors. The market for durable membrane solutions specifically is projected to reach $12 billion by 2028, growing at a CAGR of 7.2% from 2023. This growth trajectory underscores the critical need for membranes with enhanced longevity and performance characteristics.

Water scarcity remains a paramount global challenge, with the United Nations estimating that by 2025, nearly 1.8 billion people will live in regions with absolute water scarcity. This crisis has intensified the demand for advanced water purification and desalination technologies, where hybrid inorganic-organic membranes offer substantial advantages over conventional solutions.

Industrial sectors, particularly oil and gas, chemical processing, and pharmaceuticals, represent major market segments driving demand for durable membrane solutions. These industries require membranes capable of withstanding harsh operating conditions, including exposure to aggressive chemicals, high temperatures, and mechanical stress. Current conventional polymeric membranes typically demonstrate operational lifespans of 3-5 years, necessitating frequent replacements that increase operational costs and production downtime.

The healthcare and pharmaceutical industries have emerged as significant growth sectors for specialized membrane applications. With stringent regulatory requirements and the need for ultra-pure filtration systems, these sectors demand membranes with exceptional chemical stability and consistent performance over extended periods. Market research indicates that pharmaceutical companies are willing to pay premium prices for membrane solutions that can demonstrate validated long-term durability.

Environmental regulations worldwide have become increasingly stringent regarding industrial wastewater discharge and drinking water quality standards. The European Union's Water Framework Directive and similar regulations in North America and Asia have created substantial market pull for advanced membrane technologies capable of meeting these elevated standards consistently over time.

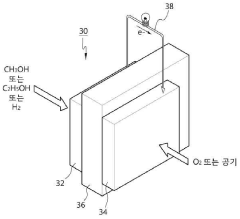

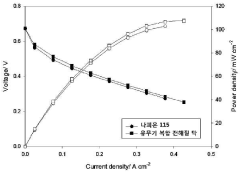

The renewable energy sector, particularly in fuel cell applications, represents an emerging market for durable membrane solutions. As hydrogen energy initiatives gain momentum globally, the demand for stable, long-lasting membranes for proton exchange membrane fuel cells has increased substantially, with market forecasts suggesting a 22% annual growth rate in this specific application segment through 2030.

Cost considerations remain paramount in market adoption decisions. While initial investment in hybrid inorganic-organic membranes may be 30-40% higher than conventional alternatives, the total cost of ownership analysis reveals significant advantages when factoring in extended operational lifespans, reduced maintenance requirements, and improved process efficiency. Market surveys indicate that industrial end-users increasingly prioritize lifecycle costs over initial acquisition expenses.

Water scarcity remains a paramount global challenge, with the United Nations estimating that by 2025, nearly 1.8 billion people will live in regions with absolute water scarcity. This crisis has intensified the demand for advanced water purification and desalination technologies, where hybrid inorganic-organic membranes offer substantial advantages over conventional solutions.

Industrial sectors, particularly oil and gas, chemical processing, and pharmaceuticals, represent major market segments driving demand for durable membrane solutions. These industries require membranes capable of withstanding harsh operating conditions, including exposure to aggressive chemicals, high temperatures, and mechanical stress. Current conventional polymeric membranes typically demonstrate operational lifespans of 3-5 years, necessitating frequent replacements that increase operational costs and production downtime.

The healthcare and pharmaceutical industries have emerged as significant growth sectors for specialized membrane applications. With stringent regulatory requirements and the need for ultra-pure filtration systems, these sectors demand membranes with exceptional chemical stability and consistent performance over extended periods. Market research indicates that pharmaceutical companies are willing to pay premium prices for membrane solutions that can demonstrate validated long-term durability.

Environmental regulations worldwide have become increasingly stringent regarding industrial wastewater discharge and drinking water quality standards. The European Union's Water Framework Directive and similar regulations in North America and Asia have created substantial market pull for advanced membrane technologies capable of meeting these elevated standards consistently over time.

The renewable energy sector, particularly in fuel cell applications, represents an emerging market for durable membrane solutions. As hydrogen energy initiatives gain momentum globally, the demand for stable, long-lasting membranes for proton exchange membrane fuel cells has increased substantially, with market forecasts suggesting a 22% annual growth rate in this specific application segment through 2030.

Cost considerations remain paramount in market adoption decisions. While initial investment in hybrid inorganic-organic membranes may be 30-40% higher than conventional alternatives, the total cost of ownership analysis reveals significant advantages when factoring in extended operational lifespans, reduced maintenance requirements, and improved process efficiency. Market surveys indicate that industrial end-users increasingly prioritize lifecycle costs over initial acquisition expenses.

Current Challenges in Hybrid Inorganic-Organic Membrane Development

Despite significant advancements in hybrid inorganic-organic membrane technology, several critical challenges continue to impede their widespread industrial adoption and long-term performance. The integration of disparate materials—inorganic components for stability and organic components for flexibility and functionality—creates inherent interface compatibility issues that remain difficult to resolve completely.

One of the most persistent challenges is the degradation of membrane performance over time. Hybrid membranes often experience a decline in separation efficiency and selectivity after prolonged exposure to harsh operating conditions. This degradation stems from multiple factors, including chemical instability at the organic-inorganic interfaces, mechanical stress-induced microcracks, and gradual leaching of organic components.

Thermal stability presents another significant hurdle. While inorganic components typically exhibit excellent thermal resistance, the organic portions may degrade at elevated temperatures, compromising the overall membrane integrity. This thermal mismatch creates internal stresses during temperature fluctuations, leading to delamination and performance deterioration over multiple thermal cycles.

Chemical resistance remains problematic in aggressive environments. Although hybrid membranes theoretically combine the best properties of both material classes, they still demonstrate vulnerability to certain chemical attacks. Organic components are particularly susceptible to oxidation, hydrolysis, and solvent-induced swelling, while some inorganic materials may dissolve in extreme pH conditions.

Manufacturing scalability constitutes a major technical barrier. Laboratory-scale synthesis methods often yield high-performance membranes, but translating these processes to industrial production introduces consistency and quality control challenges. The precise control of interfacial chemistry required for optimal hybrid membrane performance is difficult to maintain in large-scale manufacturing environments.

Fouling resistance represents another unresolved challenge. Despite improvements over purely organic or inorganic membranes, hybrid membranes still suffer from performance decline due to surface fouling and internal pore blockage. The development of anti-fouling surfaces that maintain separation performance remains an active research area.

Cost-effectiveness issues further complicate commercial viability. The complex synthesis procedures, specialized precursors, and multi-step fabrication processes significantly increase production costs compared to conventional membrane materials. This economic barrier limits adoption in price-sensitive applications despite superior technical performance.

Reproducibility and quality control challenges persist across different production batches. The complex interplay between organic and inorganic components creates sensitivity to minor variations in synthesis conditions, resulting in inconsistent membrane properties and performance metrics between manufacturing runs.

One of the most persistent challenges is the degradation of membrane performance over time. Hybrid membranes often experience a decline in separation efficiency and selectivity after prolonged exposure to harsh operating conditions. This degradation stems from multiple factors, including chemical instability at the organic-inorganic interfaces, mechanical stress-induced microcracks, and gradual leaching of organic components.

Thermal stability presents another significant hurdle. While inorganic components typically exhibit excellent thermal resistance, the organic portions may degrade at elevated temperatures, compromising the overall membrane integrity. This thermal mismatch creates internal stresses during temperature fluctuations, leading to delamination and performance deterioration over multiple thermal cycles.

Chemical resistance remains problematic in aggressive environments. Although hybrid membranes theoretically combine the best properties of both material classes, they still demonstrate vulnerability to certain chemical attacks. Organic components are particularly susceptible to oxidation, hydrolysis, and solvent-induced swelling, while some inorganic materials may dissolve in extreme pH conditions.

Manufacturing scalability constitutes a major technical barrier. Laboratory-scale synthesis methods often yield high-performance membranes, but translating these processes to industrial production introduces consistency and quality control challenges. The precise control of interfacial chemistry required for optimal hybrid membrane performance is difficult to maintain in large-scale manufacturing environments.

Fouling resistance represents another unresolved challenge. Despite improvements over purely organic or inorganic membranes, hybrid membranes still suffer from performance decline due to surface fouling and internal pore blockage. The development of anti-fouling surfaces that maintain separation performance remains an active research area.

Cost-effectiveness issues further complicate commercial viability. The complex synthesis procedures, specialized precursors, and multi-step fabrication processes significantly increase production costs compared to conventional membrane materials. This economic barrier limits adoption in price-sensitive applications despite superior technical performance.

Reproducibility and quality control challenges persist across different production batches. The complex interplay between organic and inorganic components creates sensitivity to minor variations in synthesis conditions, resulting in inconsistent membrane properties and performance metrics between manufacturing runs.

State-of-the-Art Hybrid Membrane Durability Solutions

01 Composite membrane structures for enhanced durability

Hybrid inorganic-organic membranes can be designed with composite structures that enhance their long-term durability. These structures typically involve multiple layers or components that work together to resist degradation. The composite approach allows for the combination of different materials with complementary properties, such as organic polymers for flexibility and inorganic components for stability. This structural design helps to prevent mechanical failure and extends the operational lifetime of the membrane under various environmental conditions.- Composite membrane structures for enhanced durability: Hybrid inorganic-organic membranes can be designed with composite structures that enhance their long-term durability. These structures typically involve multiple layers or components that work together to resist degradation. The composite approach allows for the combination of the mechanical strength of inorganic materials with the flexibility of organic components, resulting in membranes that maintain performance over extended periods under harsh operating conditions.

- Chemical stabilization techniques for hybrid membranes: Various chemical stabilization techniques can be employed to improve the long-term durability of hybrid inorganic-organic membranes. These include cross-linking of organic components, surface modification of inorganic particles, and incorporation of stabilizing additives. Such techniques help prevent chemical degradation, maintain membrane integrity, and extend service life by reducing susceptibility to chemical attack, hydrolysis, and other degradation mechanisms.

- Thermal and mechanical stability enhancements: Improving the thermal and mechanical stability of hybrid inorganic-organic membranes is crucial for their long-term durability. This can be achieved through the incorporation of thermally resistant inorganic components, optimization of organic-inorganic interfaces, and development of stress-resistant membrane architectures. These enhancements allow the membranes to withstand thermal cycling, mechanical stress, and pressure fluctuations without significant performance degradation over time.

- Environmental resistance and aging prevention: Hybrid inorganic-organic membranes can be formulated to resist environmental factors that accelerate aging and degradation. This includes resistance to humidity, UV radiation, oxidation, and microbial attack. Specialized additives, protective coatings, and optimized material compositions can be incorporated to prevent membrane fouling, maintain hydrophobicity/hydrophilicity balance, and ensure consistent performance in various environmental conditions over extended periods.

- Testing and prediction methods for long-term durability: Advanced testing protocols and predictive models have been developed to evaluate and forecast the long-term durability of hybrid inorganic-organic membranes. These include accelerated aging tests, real-time monitoring systems, and computational models that simulate degradation mechanisms. Such methods help in understanding failure modes, optimizing membrane compositions, and establishing reliable lifetime predictions for different operating conditions and applications.

02 Chemical modification techniques for stability improvement

Chemical modification of hybrid membranes can significantly improve their long-term durability. These techniques include cross-linking between organic and inorganic components, surface functionalization, and the incorporation of stabilizing additives. Such modifications create stronger chemical bonds within the membrane structure, reducing susceptibility to chemical degradation, hydrolysis, and oxidation. These approaches help maintain membrane performance over extended periods, even when exposed to harsh operating environments or aggressive chemical species.Expand Specific Solutions03 Thermal and mechanical stability enhancements

Improving the thermal and mechanical stability of hybrid inorganic-organic membranes is crucial for their long-term durability. This can be achieved through the incorporation of thermally resistant inorganic components, reinforcement with nanoparticles or fibers, and optimized processing techniques. These enhancements allow the membranes to withstand temperature fluctuations, mechanical stress, and pressure variations without compromising their structural integrity or separation performance over time.Expand Specific Solutions04 Resistance to fouling and chemical degradation

Developing hybrid membranes with enhanced resistance to fouling and chemical degradation is essential for long-term durability. This can be achieved through the incorporation of anti-fouling agents, hydrophilic/hydrophobic balance optimization, and the use of chemically resistant materials. These features help prevent the accumulation of contaminants on the membrane surface and protect against degradation from exposure to acids, bases, oxidants, and other aggressive chemicals, thereby extending the operational lifetime and reducing maintenance requirements.Expand Specific Solutions05 Advanced testing and performance prediction methods

Advanced testing protocols and performance prediction methods are critical for evaluating and ensuring the long-term durability of hybrid inorganic-organic membranes. These include accelerated aging tests, real-time monitoring systems, computational modeling, and lifetime prediction algorithms. Such approaches enable researchers and manufacturers to assess membrane performance under various conditions, identify potential failure mechanisms, and optimize membrane formulations for specific applications, ultimately leading to more durable and reliable membrane systems.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Hybrid Membranes

The hybrid inorganic-organic membrane technology market is currently in a growth phase, characterized by increasing adoption across water treatment, gas separation, and energy storage applications. The global market size is projected to expand significantly due to rising demand for durable separation technologies. From a technical maturity perspective, research institutions like Fraunhofer-Gesellschaft, CSIC, and CEA are leading fundamental research, while industrial players including 3M, Sumitomo Chemical, and LG Energy Solution are commercializing applications. University collaborations (University of California, Georgia Tech) are bridging the gap between theoretical advances and practical implementations. The competitive landscape shows a balanced distribution between established chemical companies developing proprietary formulations and research institutions focusing on novel material combinations to enhance membrane durability, with Asian manufacturers increasingly gaining market share through cost-effective production methods.

Fraunhofer-Gesellschaft eV

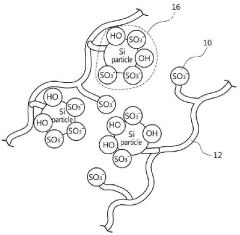

Technical Solution: Fraunhofer has developed advanced hybrid inorganic-organic membranes using sol-gel technology that incorporates silica nanoparticles into polymer matrices. Their approach involves controlled hydrolysis and condensation of metal alkoxides (typically silicon-based) within organic polymer networks to create interpenetrating networks. The resulting membranes exhibit significantly enhanced mechanical stability and chemical resistance compared to conventional polymer membranes. Fraunhofer's technology employs functionalized silica precursors that form covalent bonds with the organic polymer chains, preventing phase separation and ensuring homogeneous distribution of the inorganic components. This creates a synergistic effect where the inorganic phase provides structural rigidity and thermal stability while the organic phase contributes flexibility and processability. Their membranes have demonstrated up to 3x longer operational lifetimes in harsh chemical environments and elevated temperatures compared to conventional membranes.

Strengths: Superior mechanical stability and chemical resistance in harsh environments; excellent thermal stability up to 200°C; highly customizable through precursor selection. Weaknesses: Higher production costs compared to conventional membranes; complex manufacturing process requiring precise control of reaction conditions; potential brittleness at high inorganic content.

3M Innovative Properties Co.

Technical Solution: 3M has pioneered hybrid membrane technology through their proprietary "Mixed Matrix Membrane" (MMM) platform that combines organic polymers with inorganic fillers to enhance durability. Their approach utilizes specially functionalized zeolites, metal-organic frameworks (MOFs), and ceramic nanoparticles that are chemically modified to improve compatibility with the polymer matrix. 3M's technology employs surface modification techniques to create strong interfacial bonding between the organic and inorganic components, preventing agglomeration and ensuring uniform dispersion. The company has developed proprietary coupling agents that act as molecular bridges between the two phases, resulting in membranes with exceptional long-term stability. Their hybrid membranes demonstrate significantly reduced plasticization and physical aging effects, maintaining separation performance over extended periods. 3M's manufacturing process incorporates controlled phase inversion techniques that optimize the membrane microstructure for specific applications, resulting in up to 40% longer service life in industrial separation processes.

Strengths: Exceptional resistance to plasticization and physical aging; scalable manufacturing processes suitable for industrial production; extensive application expertise across multiple industries. Weaknesses: Higher initial cost compared to conventional membranes; potential for decreased flux rates in some applications; limited performance in extremely high-temperature environments.

Key Patents and Innovations in Hybrid Membrane Technology

Inorganic-organic hybrid membrane for ionic interchange, preparation thereof and use in electrochemical devices

PatentWO2009000963A1

Innovation

- Development of hybrid organic-inorganic ion exchange membranes composed of a crosslinked natural rubber latex matrix and an inorganic proton conductor, which provides excellent mechanical properties, flexibility, and proton conductivity similar to Nafion, while being environmentally friendly and cost-effective.

Organic-inorganic hybrid electrolyte membrane, method for fabricating the same and fuel cell

PatentInactiveKR1020110119264A

Innovation

- An organic-inorganic composite electrolyte membrane is developed with ion exchange groups chemically bonded between a polymer and inorganic particles, using a sol-gel reaction to integrate ion-conductive silica particles, ensuring they are selectively positioned in ion transport channels.

Environmental Impact and Sustainability Considerations

The adoption of hybrid inorganic-organic membranes represents a significant advancement in sustainable materials science. These membranes typically require less energy during manufacturing compared to conventional polymeric or ceramic alternatives, resulting in a reduced carbon footprint across their production lifecycle. Life Cycle Assessment (LCA) studies indicate that the extended durability of hybrid membranes translates directly into environmental benefits through decreased replacement frequency and associated resource consumption.

From a waste management perspective, hybrid membranes offer notable advantages. Their enhanced resistance to degradation means fewer membrane replacements and consequently less waste generation in industrial applications. However, this durability presents a double-edged sword for end-of-life considerations, as the strong chemical bonds between organic and inorganic components can complicate recycling processes. Current research is exploring selective dissolution methods to separate these components for more effective material recovery.

Water conservation represents another critical environmental benefit of these hybrid systems. In water treatment applications, the improved fouling resistance and chemical stability of hybrid membranes enable more efficient filtration with reduced cleaning chemical requirements. This translates to lower environmental discharge of potentially harmful cleaning agents and extended operational periods between maintenance cycles.

The raw material sourcing for hybrid membranes also merits consideration in sustainability assessments. While some inorganic components may involve energy-intensive mining operations, research is increasingly focused on incorporating bio-based organic precursors and sustainably sourced silica derivatives. These developments align with circular economy principles and reduce dependence on petroleum-based feedstocks.

Energy efficiency during operation constitutes a significant sustainability advantage. The optimized pore structures and surface properties of hybrid membranes often enable lower operating pressures in filtration systems, resulting in reduced energy consumption throughout their service life. This operational efficiency can substantially offset the initial environmental impact of membrane production, particularly in energy-intensive applications like desalination.

Toxicity considerations remain an active area of investigation. While hybrid membranes generally exhibit lower leaching of potentially harmful components compared to conventional alternatives, the long-term environmental fate of nanoscale inorganic particles potentially released during service requires continued monitoring and assessment to ensure environmental safety across the complete product lifecycle.

From a waste management perspective, hybrid membranes offer notable advantages. Their enhanced resistance to degradation means fewer membrane replacements and consequently less waste generation in industrial applications. However, this durability presents a double-edged sword for end-of-life considerations, as the strong chemical bonds between organic and inorganic components can complicate recycling processes. Current research is exploring selective dissolution methods to separate these components for more effective material recovery.

Water conservation represents another critical environmental benefit of these hybrid systems. In water treatment applications, the improved fouling resistance and chemical stability of hybrid membranes enable more efficient filtration with reduced cleaning chemical requirements. This translates to lower environmental discharge of potentially harmful cleaning agents and extended operational periods between maintenance cycles.

The raw material sourcing for hybrid membranes also merits consideration in sustainability assessments. While some inorganic components may involve energy-intensive mining operations, research is increasingly focused on incorporating bio-based organic precursors and sustainably sourced silica derivatives. These developments align with circular economy principles and reduce dependence on petroleum-based feedstocks.

Energy efficiency during operation constitutes a significant sustainability advantage. The optimized pore structures and surface properties of hybrid membranes often enable lower operating pressures in filtration systems, resulting in reduced energy consumption throughout their service life. This operational efficiency can substantially offset the initial environmental impact of membrane production, particularly in energy-intensive applications like desalination.

Toxicity considerations remain an active area of investigation. While hybrid membranes generally exhibit lower leaching of potentially harmful components compared to conventional alternatives, the long-term environmental fate of nanoscale inorganic particles potentially released during service requires continued monitoring and assessment to ensure environmental safety across the complete product lifecycle.

Scalability and Industrial Implementation Challenges

The transition from laboratory-scale success to industrial implementation of hybrid inorganic-organic membranes faces significant challenges that must be addressed to realize their commercial potential. Manufacturing scalability represents the primary hurdle, as current production methods often involve complex multi-step processes that work effectively for small membrane areas but become problematic at industrial scales. Techniques such as interfacial polymerization and layer-by-layer assembly, while precise for laboratory samples, encounter consistency issues when scaled to several square meters of membrane surface.

Cost considerations further complicate industrial adoption, with specialized precursors and complex fabrication protocols driving production expenses beyond economically viable thresholds. The integration of organic and inorganic components requires precise control over reaction conditions that becomes increasingly difficult to maintain in large-scale production environments. Additionally, quality control becomes exponentially more challenging as production volumes increase, necessitating the development of new in-line monitoring technologies.

Equipment modification presents another substantial barrier, as existing membrane manufacturing infrastructure is primarily designed for conventional polymeric membranes. Retrofitting these systems for hybrid membrane production requires significant capital investment and technical adjustments that many manufacturers hesitate to undertake without clear return-on-investment projections.

Regulatory compliance adds complexity to the implementation pathway, particularly for membranes intended for water treatment or food processing applications. Hybrid membranes must undergo rigorous safety assessments to ensure no leaching of potentially harmful components occurs during operation, a process that can delay market entry by several years.

The knowledge gap between academic research and industrial practice further impedes implementation. While laboratory researchers focus on performance metrics, industrial engineers must prioritize practical considerations such as membrane module design, backwashing protocols, and compatibility with existing treatment trains. This disconnect often results in promising laboratory technologies failing to translate to practical applications.

Addressing these challenges requires collaborative efforts between material scientists, chemical engineers, and industry partners to develop scalable synthesis routes, standardized quality control protocols, and cost-effective production methods. Pilot-scale demonstration projects represent a critical stepping stone, allowing for the identification and resolution of scale-up issues before full industrial implementation.

Cost considerations further complicate industrial adoption, with specialized precursors and complex fabrication protocols driving production expenses beyond economically viable thresholds. The integration of organic and inorganic components requires precise control over reaction conditions that becomes increasingly difficult to maintain in large-scale production environments. Additionally, quality control becomes exponentially more challenging as production volumes increase, necessitating the development of new in-line monitoring technologies.

Equipment modification presents another substantial barrier, as existing membrane manufacturing infrastructure is primarily designed for conventional polymeric membranes. Retrofitting these systems for hybrid membrane production requires significant capital investment and technical adjustments that many manufacturers hesitate to undertake without clear return-on-investment projections.

Regulatory compliance adds complexity to the implementation pathway, particularly for membranes intended for water treatment or food processing applications. Hybrid membranes must undergo rigorous safety assessments to ensure no leaching of potentially harmful components occurs during operation, a process that can delay market entry by several years.

The knowledge gap between academic research and industrial practice further impedes implementation. While laboratory researchers focus on performance metrics, industrial engineers must prioritize practical considerations such as membrane module design, backwashing protocols, and compatibility with existing treatment trains. This disconnect often results in promising laboratory technologies failing to translate to practical applications.

Addressing these challenges requires collaborative efforts between material scientists, chemical engineers, and industry partners to develop scalable synthesis routes, standardized quality control protocols, and cost-effective production methods. Pilot-scale demonstration projects represent a critical stepping stone, allowing for the identification and resolution of scale-up issues before full industrial implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!