Role Of High-Free-Volume Polymers In Ultra-Permeable Membranes

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Free-Volume Polymers Background and Objectives

High-free-volume polymers have emerged as a revolutionary class of materials in membrane technology over the past three decades. These polymers are characterized by their unique molecular architecture featuring large interconnected free volume elements, which facilitate enhanced gas and liquid transport properties. The concept of free volume in polymer science dates back to the 1950s, but significant breakthroughs in synthesizing polymers with intentionally designed high free volume only materialized in the 1990s with the development of polymers of intrinsic microporosity (PIMs).

The evolution of high-free-volume polymers has been driven by the increasing global demand for energy-efficient separation processes. Traditional membrane materials face a fundamental limitation known as the permeability-selectivity trade-off, as articulated in Robeson's upper bound relationship. High-free-volume polymers represent a paradigm shift in this context, potentially transcending these established performance limitations by offering unprecedented combinations of permeability and selectivity.

Key milestones in this field include the development of thermally rearranged (TR) polymers, PIMs, and substituted polyacetylenes. Each of these polymer families employs different molecular design strategies to create and maintain high free volume elements within the polymer matrix. The contorted molecular structures in PIMs, the thermal conversion process in TR polymers, and the sterically hindered rotation in substituted polyacetylenes all contribute to their exceptional transport properties.

The primary technical objective in this field is to develop membrane materials that simultaneously achieve high permeability and selectivity for targeted separation applications. This includes gas separations (CO2/CH4, O2/N2, H2/CO2), water purification, and emerging applications in organic solvent nanofiltration. Secondary objectives involve addressing the aging phenomena inherent to high-free-volume polymers, enhancing their mechanical stability, and developing scalable manufacturing processes.

Current research trends focus on hybrid approaches combining high-free-volume polymers with other materials such as metal-organic frameworks (MOFs), graphene derivatives, and inorganic nanoparticles to create mixed matrix membranes with synergistic properties. Additionally, there is growing interest in understanding the fundamental structure-property relationships that govern transport in these materials through advanced characterization techniques and molecular simulation.

The technological trajectory suggests a continued expansion of the free volume concept into new polymer architectures, including block copolymers, crosslinked networks, and stimuli-responsive systems. These developments aim to create the next generation of ultra-permeable membranes with unprecedented separation performance, addressing critical global challenges in energy, water, and environmental sustainability.

The evolution of high-free-volume polymers has been driven by the increasing global demand for energy-efficient separation processes. Traditional membrane materials face a fundamental limitation known as the permeability-selectivity trade-off, as articulated in Robeson's upper bound relationship. High-free-volume polymers represent a paradigm shift in this context, potentially transcending these established performance limitations by offering unprecedented combinations of permeability and selectivity.

Key milestones in this field include the development of thermally rearranged (TR) polymers, PIMs, and substituted polyacetylenes. Each of these polymer families employs different molecular design strategies to create and maintain high free volume elements within the polymer matrix. The contorted molecular structures in PIMs, the thermal conversion process in TR polymers, and the sterically hindered rotation in substituted polyacetylenes all contribute to their exceptional transport properties.

The primary technical objective in this field is to develop membrane materials that simultaneously achieve high permeability and selectivity for targeted separation applications. This includes gas separations (CO2/CH4, O2/N2, H2/CO2), water purification, and emerging applications in organic solvent nanofiltration. Secondary objectives involve addressing the aging phenomena inherent to high-free-volume polymers, enhancing their mechanical stability, and developing scalable manufacturing processes.

Current research trends focus on hybrid approaches combining high-free-volume polymers with other materials such as metal-organic frameworks (MOFs), graphene derivatives, and inorganic nanoparticles to create mixed matrix membranes with synergistic properties. Additionally, there is growing interest in understanding the fundamental structure-property relationships that govern transport in these materials through advanced characterization techniques and molecular simulation.

The technological trajectory suggests a continued expansion of the free volume concept into new polymer architectures, including block copolymers, crosslinked networks, and stimuli-responsive systems. These developments aim to create the next generation of ultra-permeable membranes with unprecedented separation performance, addressing critical global challenges in energy, water, and environmental sustainability.

Market Analysis for Ultra-Permeable Membrane Applications

The global market for ultra-permeable membranes has experienced significant growth in recent years, driven by increasing water scarcity concerns and stringent environmental regulations. The market value reached approximately $3.5 billion in 2022 and is projected to grow at a CAGR of 7.8% through 2030, potentially reaching $6.2 billion by the end of the forecast period.

Water treatment applications currently dominate the market, accounting for nearly 65% of the total demand. This segment includes desalination, wastewater treatment, and industrial water purification. The desalination sector specifically has shown remarkable growth due to freshwater shortages in arid regions, with major investments in countries like Saudi Arabia, UAE, Israel, and Australia.

Industrial gas separation represents the fastest-growing application segment, with an estimated growth rate of 9.2% annually. This is primarily driven by the need for more efficient carbon capture technologies and hydrogen purification processes in the emerging hydrogen economy. The pharmaceutical and food & beverage industries are also increasingly adopting ultra-permeable membranes for separation processes.

Geographically, Asia-Pacific leads the market with approximately 38% share, followed by North America (27%) and Europe (22%). China and India are experiencing the highest growth rates due to rapid industrialization, urbanization, and increasing water treatment infrastructure investments.

The healthcare sector presents an emerging opportunity for ultra-permeable membranes, particularly in hemodialysis and controlled drug delivery systems. High-free-volume polymers enable the development of more efficient biomedical membranes with enhanced biocompatibility and selective permeability.

End-user industries are increasingly demanding membranes with higher flux rates, better selectivity, and longer operational lifespans. This has created a premium segment within the market where high-performance membranes command price premiums of 30-40% over conventional alternatives.

Cost remains a significant barrier to wider adoption, particularly in developing economies. The average cost of high-free-volume polymer membranes is approximately 2-3 times higher than conventional membranes, limiting penetration in price-sensitive markets. However, the total cost of ownership analysis often favors ultra-permeable membranes due to their higher efficiency and longer service life.

Sustainability considerations are reshaping market dynamics, with growing demand for membranes manufactured using environmentally friendly processes and materials. This trend aligns with the inherent sustainability benefits of membrane-based separation processes, which typically consume less energy than conventional separation methods.

Water treatment applications currently dominate the market, accounting for nearly 65% of the total demand. This segment includes desalination, wastewater treatment, and industrial water purification. The desalination sector specifically has shown remarkable growth due to freshwater shortages in arid regions, with major investments in countries like Saudi Arabia, UAE, Israel, and Australia.

Industrial gas separation represents the fastest-growing application segment, with an estimated growth rate of 9.2% annually. This is primarily driven by the need for more efficient carbon capture technologies and hydrogen purification processes in the emerging hydrogen economy. The pharmaceutical and food & beverage industries are also increasingly adopting ultra-permeable membranes for separation processes.

Geographically, Asia-Pacific leads the market with approximately 38% share, followed by North America (27%) and Europe (22%). China and India are experiencing the highest growth rates due to rapid industrialization, urbanization, and increasing water treatment infrastructure investments.

The healthcare sector presents an emerging opportunity for ultra-permeable membranes, particularly in hemodialysis and controlled drug delivery systems. High-free-volume polymers enable the development of more efficient biomedical membranes with enhanced biocompatibility and selective permeability.

End-user industries are increasingly demanding membranes with higher flux rates, better selectivity, and longer operational lifespans. This has created a premium segment within the market where high-performance membranes command price premiums of 30-40% over conventional alternatives.

Cost remains a significant barrier to wider adoption, particularly in developing economies. The average cost of high-free-volume polymer membranes is approximately 2-3 times higher than conventional membranes, limiting penetration in price-sensitive markets. However, the total cost of ownership analysis often favors ultra-permeable membranes due to their higher efficiency and longer service life.

Sustainability considerations are reshaping market dynamics, with growing demand for membranes manufactured using environmentally friendly processes and materials. This trend aligns with the inherent sustainability benefits of membrane-based separation processes, which typically consume less energy than conventional separation methods.

Current Status and Technical Challenges in Membrane Technology

Membrane technology has witnessed significant advancements in recent decades, with high-free-volume polymers emerging as a critical component in ultra-permeable membrane development. Currently, the global membrane market is experiencing robust growth, valued at approximately $5.4 billion in 2020 and projected to reach $8.3 billion by 2026, with a CAGR of 7.9%. This growth is primarily driven by increasing water scarcity, stringent environmental regulations, and industrial demand for efficient separation processes.

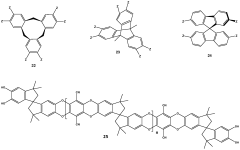

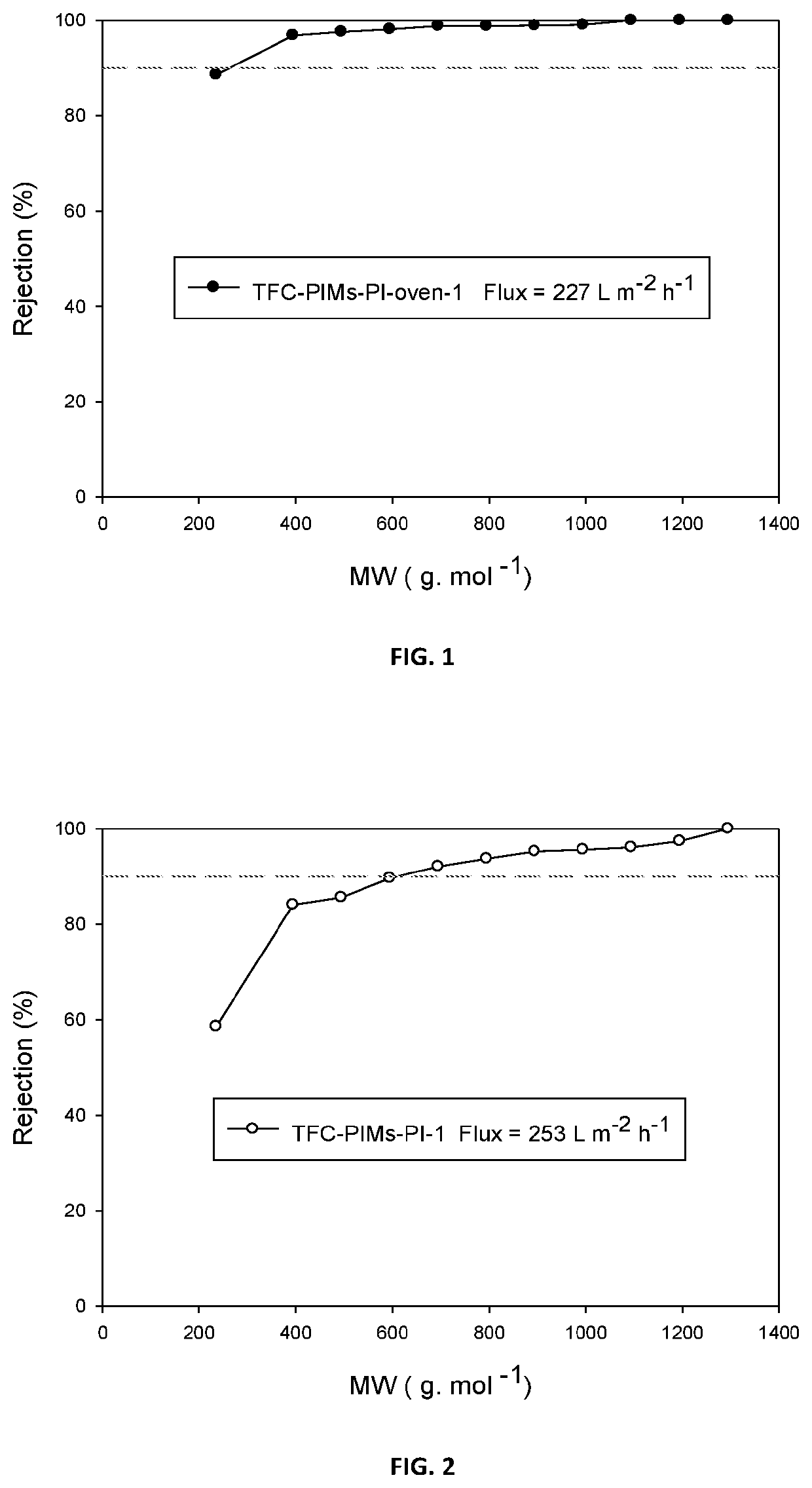

The state-of-the-art in membrane technology features several key developments. Polymers of intrinsic microporosity (PIMs) represent a breakthrough in creating high-free-volume structures that facilitate enhanced gas and liquid permeation. These materials exhibit permeability coefficients 10-100 times higher than conventional polymers while maintaining reasonable selectivity. Thermally rearranged (TR) polymers have also gained prominence, offering exceptional chemical stability and separation performance through controlled thermal treatment processes.

Despite these advances, significant technical challenges persist. Physical aging remains a critical issue, as high-free-volume polymers tend to undergo time-dependent performance degradation due to the collapse of free volume elements. This phenomenon can reduce permeability by 30-50% within the first year of operation, severely limiting membrane lifespan and reliability in industrial applications.

Plasticization resistance presents another major hurdle, particularly in gas separation applications involving CO2 and hydrocarbon mixtures. When exposed to these components at high pressures, many high-free-volume polymers experience swelling and loss of selectivity, compromising separation efficiency. Current research indicates that crosslinking strategies can mitigate this effect but often at the cost of reduced permeability.

Scalable manufacturing represents a substantial challenge in transitioning from laboratory success to commercial viability. The complex synthesis procedures for advanced high-free-volume polymers often involve expensive precursors and multi-step reactions that are difficult to scale. Additionally, forming these materials into defect-free thin-film composite membranes with consistent properties remains technically demanding.

Geographically, membrane technology development shows distinct patterns. North America and Europe lead in fundamental research and patent filings related to high-free-volume polymers, with approximately 45% and 30% of publications respectively. However, Asia, particularly China, Japan, and South Korea, has rapidly increased research output, accounting for about 22% of publications in 2020, up from just 8% in 2010, and demonstrating growing manufacturing capabilities for commercial membrane products.

The integration of nanotechnology with high-free-volume polymers represents both an opportunity and a challenge, as researchers work to develop mixed matrix membranes that combine the processability of polymers with the enhanced separation properties of nanomaterials.

The state-of-the-art in membrane technology features several key developments. Polymers of intrinsic microporosity (PIMs) represent a breakthrough in creating high-free-volume structures that facilitate enhanced gas and liquid permeation. These materials exhibit permeability coefficients 10-100 times higher than conventional polymers while maintaining reasonable selectivity. Thermally rearranged (TR) polymers have also gained prominence, offering exceptional chemical stability and separation performance through controlled thermal treatment processes.

Despite these advances, significant technical challenges persist. Physical aging remains a critical issue, as high-free-volume polymers tend to undergo time-dependent performance degradation due to the collapse of free volume elements. This phenomenon can reduce permeability by 30-50% within the first year of operation, severely limiting membrane lifespan and reliability in industrial applications.

Plasticization resistance presents another major hurdle, particularly in gas separation applications involving CO2 and hydrocarbon mixtures. When exposed to these components at high pressures, many high-free-volume polymers experience swelling and loss of selectivity, compromising separation efficiency. Current research indicates that crosslinking strategies can mitigate this effect but often at the cost of reduced permeability.

Scalable manufacturing represents a substantial challenge in transitioning from laboratory success to commercial viability. The complex synthesis procedures for advanced high-free-volume polymers often involve expensive precursors and multi-step reactions that are difficult to scale. Additionally, forming these materials into defect-free thin-film composite membranes with consistent properties remains technically demanding.

Geographically, membrane technology development shows distinct patterns. North America and Europe lead in fundamental research and patent filings related to high-free-volume polymers, with approximately 45% and 30% of publications respectively. However, Asia, particularly China, Japan, and South Korea, has rapidly increased research output, accounting for about 22% of publications in 2020, up from just 8% in 2010, and demonstrating growing manufacturing capabilities for commercial membrane products.

The integration of nanotechnology with high-free-volume polymers represents both an opportunity and a challenge, as researchers work to develop mixed matrix membranes that combine the processability of polymers with the enhanced separation properties of nanomaterials.

Current Technical Solutions for Enhanced Membrane Permeability

01 Polymers of intrinsic microporosity (PIMs) for gas separation

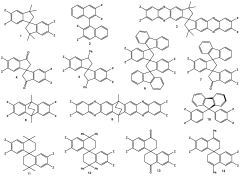

High-free-volume polymers known as PIMs feature rigid and contorted molecular structures that prevent efficient chain packing, creating interconnected free volume elements. These polymers demonstrate exceptional gas permeability and selectivity, making them valuable for membrane-based gas separation applications. Their unique molecular architecture allows for enhanced diffusion of specific gases while maintaining good selectivity, offering improved performance over conventional polymeric membranes.- Polymers of intrinsic microporosity (PIMs) for gas separation: High-free-volume polymers known as PIMs (Polymers of Intrinsic Microporosity) feature rigid and contorted molecular structures that cannot pack efficiently, creating interconnected micropores. These polymers exhibit exceptional gas permeability and selectivity, making them ideal for membrane-based gas separation applications. Their unique molecular architecture allows for enhanced transport of specific gases while maintaining good mechanical properties and processability.

- Thermally rearranged polymers with enhanced permeability: Thermally rearranged (TR) polymers represent a class of high-free-volume materials that undergo structural transformation upon thermal treatment. This rearrangement creates a rigid backbone structure with increased free volume and enhanced permeability characteristics. These polymers demonstrate excellent separation performance for various gas pairs and liquid mixtures, with improved resistance to plasticization and physical aging compared to conventional membrane materials.

- Functionalized high-free-volume polymers for selective permeability: Incorporating functional groups into high-free-volume polymer structures allows for tailored permeability and selectivity properties. These functionalized polymers can be designed with specific chemical moieties that enhance interactions with target molecules, improving separation efficiency. The strategic placement of functional groups can create preferential transport pathways while maintaining the advantageous free volume characteristics of the base polymer structure.

- Composite membranes with high-free-volume polymer components: Composite membranes incorporating high-free-volume polymers combine the exceptional permeability characteristics of these polymers with the mechanical stability of support materials. These multi-layer structures can be optimized for specific separation applications by controlling the thickness and composition of each layer. The synergistic combination of different materials enables membranes with enhanced permeability, selectivity, and durability for gas separation, water purification, and other membrane-based processes.

- Novel high-free-volume polymer synthesis methods: Advanced synthesis techniques for high-free-volume polymers focus on creating materials with controlled microstructure and optimized permeability properties. These methods include novel polymerization approaches, post-synthesis modifications, and processing techniques that enhance free volume characteristics. By precisely controlling reaction conditions and monomer selection, polymers with tailored pore size distributions, interconnectivity, and surface chemistry can be developed for specific permeability applications.

02 Thermally rearranged polymers with enhanced permeability

Thermally rearranged (TR) polymers represent a class of high-free-volume materials that undergo structural transformation upon thermal treatment. This rearrangement creates additional free volume and enhances gas transport properties. These polymers exhibit excellent permeability for various gases while maintaining good selectivity, particularly for CO2 separation applications. The thermal rearrangement process can be controlled to optimize the balance between permeability and selectivity for specific separation needs.Expand Specific Solutions03 Perfluorinated and fluoropolymer membranes for enhanced permeability

Fluorinated and perfluorinated high-free-volume polymers offer exceptional chemical resistance and thermal stability while providing enhanced gas permeability. These materials feature weak intermolecular forces and rigid structures that prevent efficient chain packing, resulting in high free volume. Their unique properties make them particularly suitable for aggressive environments where conventional polymers would degrade. Applications include gas separation, vapor recovery, and chemical processing where both permeability and chemical resistance are required.Expand Specific Solutions04 Nanocomposite high-free-volume polymer membranes

Incorporating nanoparticles into high-free-volume polymer matrices creates nanocomposite membranes with enhanced permeability and selectivity. These nanocomposites combine the processability of polymers with the superior separation properties of inorganic materials. The nanoparticles can disrupt polymer chain packing, creating additional free volume, or provide alternative transport pathways. Various nanofillers including metal-organic frameworks, silica, and carbon nanotubes can be used to tailor membrane performance for specific separation applications.Expand Specific Solutions05 High-free-volume polymers for sensing and electronic applications

Beyond separation membranes, high-free-volume polymers find applications in sensing technologies and electronic devices. Their porous structure allows for rapid diffusion of analytes, making them excellent materials for chemical sensors. Additionally, these polymers can be used as low-dielectric constant materials in microelectronics, where their high free volume reduces signal interference. The controlled porosity also makes them suitable for applications in optoelectronics, where refractive index can be precisely tuned.Expand Specific Solutions

Key Industry Players and Research Institutions

The ultra-permeable membrane market is currently in a growth phase, with increasing demand driven by industrial separation needs and environmental concerns. The high-free-volume polymer technology represents a critical innovation area, with market size projected to reach significant expansion in the coming years. Technical maturity varies across players, with established companies like Dow Global Technologies, Air Products & Chemicals, and ExxonMobil leading commercial applications, while academic institutions such as King Abdullah University of Science & Technology and University of California contribute fundamental research breakthroughs. Research organizations like Commonwealth Scientific & Industrial Research Organisation and Membrane Technology & Research are bridging the gap between theoretical advances and practical implementations. Companies like Toray Industries and Celanese are advancing material science aspects, positioning themselves as key innovators in this emerging field.

King Abdullah University of Science & Technology

Technical Solution: KAUST has developed pioneering research in polymers of intrinsic microporosity (PIMs) for ultra-permeable membrane applications. Their approach focuses on creating rigid, contorted molecular structures that cannot pack efficiently, resulting in high free volume elements. KAUST researchers have successfully incorporated β-cyclodextrin-based monomers into PIM structures, creating interconnected microporous networks with exceptional gas transport properties. Their latest generation of membranes utilizes post-synthetic modification techniques including thermal oxidation and chemical crosslinking to further enhance free volume distribution. Performance data shows oxygen permeability exceeding 2000 Barrer while maintaining O₂/N₂ selectivity above 4.5, positioning these materials well above the Robeson upper bound. KAUST has also pioneered mixed-matrix membranes incorporating nanoporous fillers within high-free-volume polymer matrices to create synergistic transport pathways[2][5].

Strengths: Cutting-edge fundamental research capabilities; innovative molecular design approaches; strong international collaboration network; access to advanced characterization facilities. Weaknesses: Limited industrial-scale manufacturing experience; some materials show aging and plasticization issues; relatively early stage in technology readiness level compared to established commercial players.

Dow Global Technologies LLC

Technical Solution: Dow has developed a comprehensive platform of high-free-volume polymer membranes based on their proprietary FILMTEC™ technology. Their approach focuses on block copolymer architectures that combine rigid, high-free-volume segments with flexible, processable domains. Dow's innovation lies in their ability to precisely control free volume distribution through advanced polymerization techniques and post-processing treatments. Their ultra-permeable membranes incorporate thermally rearranged aromatic polymers with controlled microporosity, achieving water permeability exceeding 4 L/m²·h·bar while maintaining excellent salt rejection. For gas separation applications, Dow has pioneered fluorinated polymers with bulky side groups that disrupt chain packing, creating permanent free volume elements that enhance gas transport. Recent developments include hybrid materials combining high-free-volume polymers with engineered fillers to create preferential transport pathways[4][6].

Strengths: Extensive manufacturing infrastructure and scale-up capabilities; comprehensive polymer chemistry expertise; established market presence and distribution channels; robust quality control systems. Weaknesses: More conservative innovation approach compared to specialized startups; focus primarily on water treatment applications rather than broader membrane markets; potential regulatory constraints on some fluorinated materials.

Critical Patents and Innovations in Polymer Membrane Design

Membranes for separation

PatentWO2013057492A1

Innovation

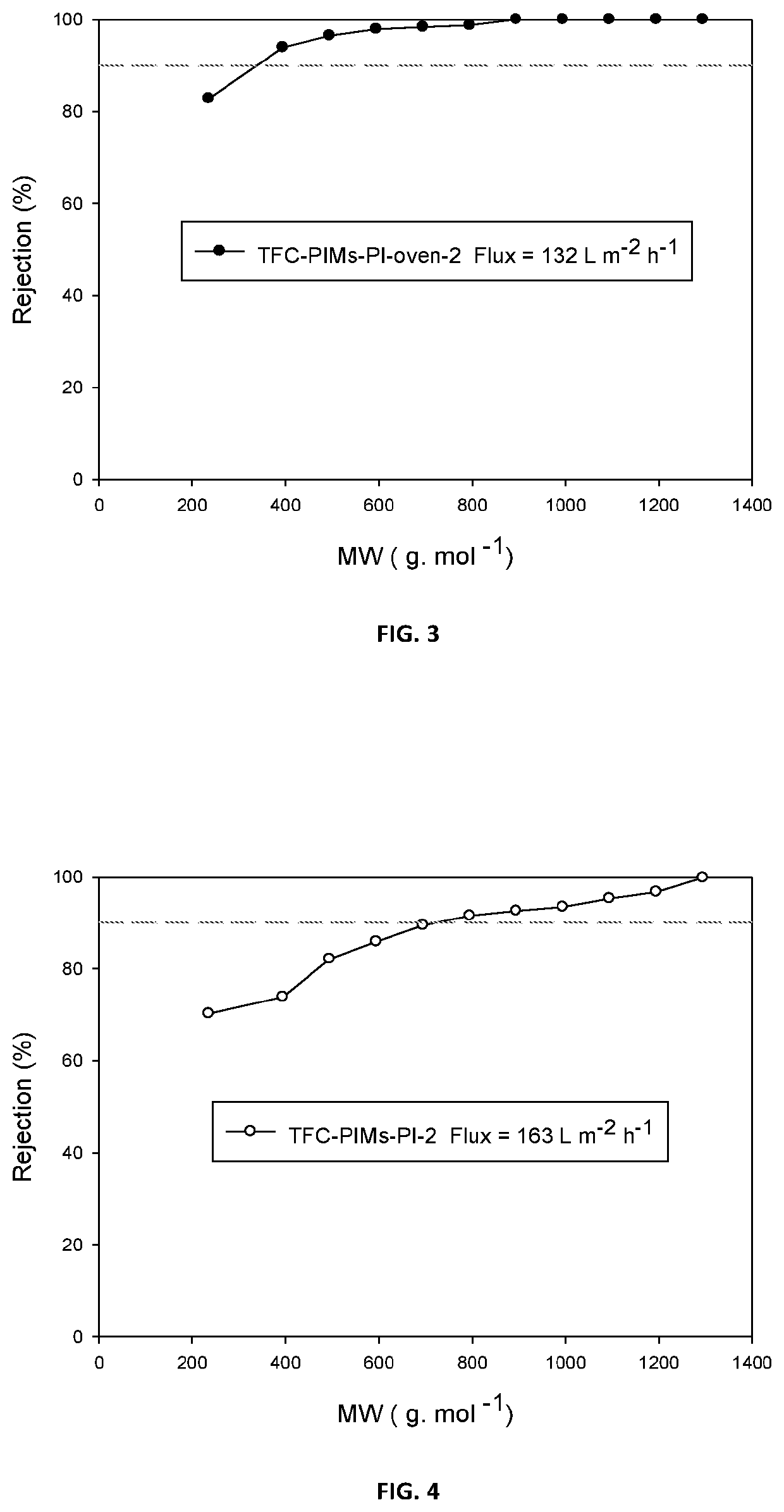

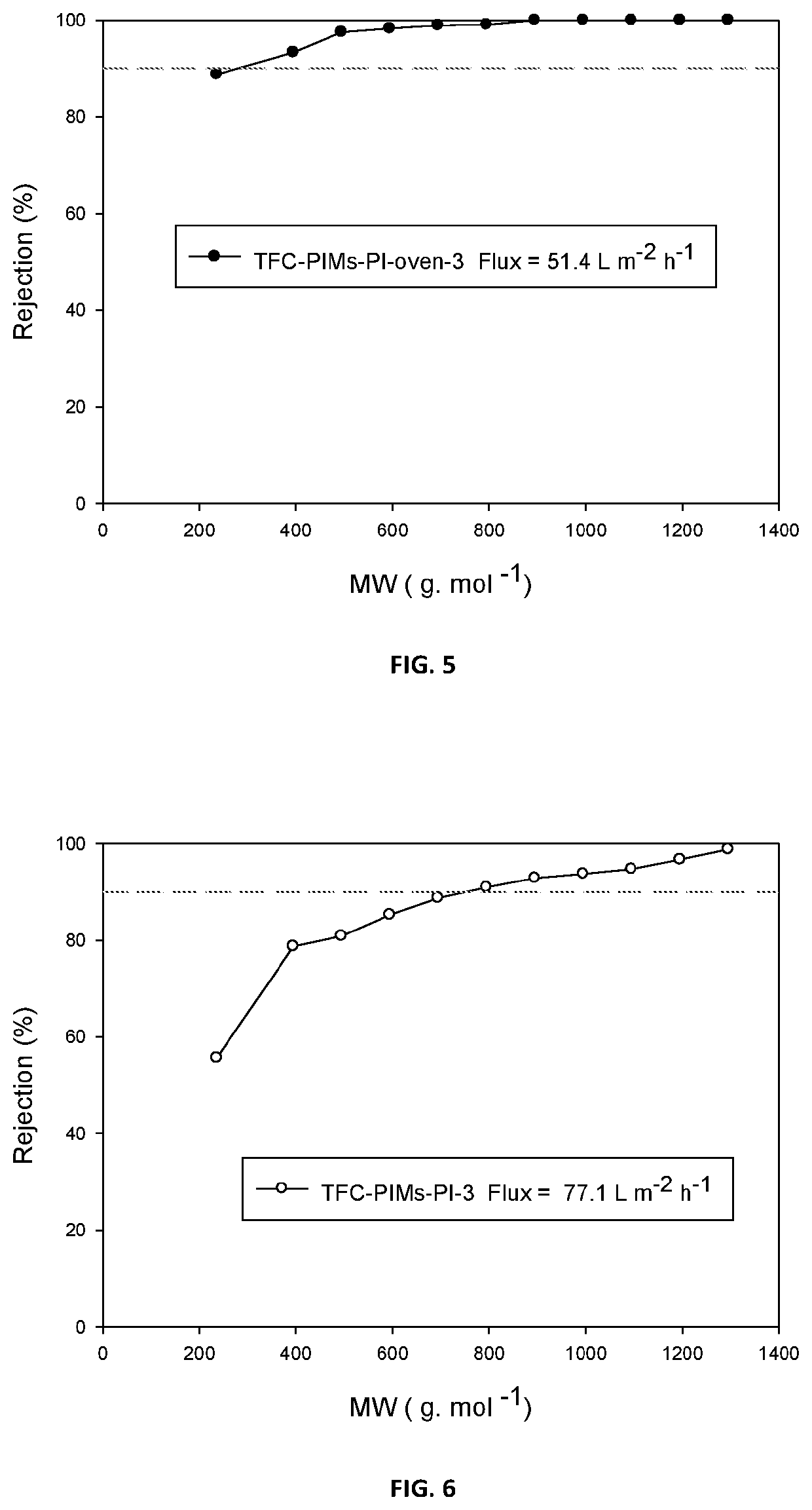

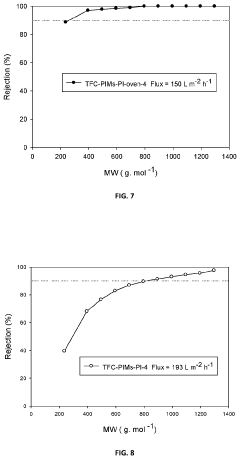

- Development of thin film composite membranes with a separating layer formed by interfacial polymerization using network polymers with intrinsic microporosity, where at least one monomer possesses concavity, and treatment with activating solvents to enhance membrane flux and stability, allowing for effective nanofiltration in organic solvents.

Composite membranes having intrinsic microporosity

PatentActiveUS20200094198A1

Innovation

- Development of thin film composite membranes with a separating layer formed by interfacial polymerization using network polymers with intrinsic microporosity, where at least one monomer possesses concavity, and treatment with activating solvents to enhance membrane flux and selectivity, along with curing to improve properties such as selectivity.

Sustainability and Environmental Impact Assessment

The integration of high-free-volume polymers in ultra-permeable membranes represents a significant advancement in sustainable separation technologies. These innovative materials offer substantial environmental benefits through reduced energy consumption in separation processes, which traditionally account for 10-15% of global energy usage. By enhancing permeability without sacrificing selectivity, these membranes enable more efficient gas separation, water purification, and chemical processing with lower operational energy requirements.

Life cycle assessment (LCA) studies indicate that ultra-permeable membranes based on high-free-volume polymers can reduce the carbon footprint of industrial separation processes by 30-45% compared to conventional technologies. This reduction stems primarily from decreased energy demands during operation, though considerations must include the environmental impact of polymer synthesis and membrane manufacturing processes, which often involve solvent usage and energy-intensive fabrication steps.

Water purification applications demonstrate particularly promising sustainability metrics. Ultra-permeable membranes incorporating polymers of intrinsic microporosity (PIMs) and thermally rearranged (TR) polymers show potential to reduce the energy consumption of desalination and wastewater treatment by up to 50%, addressing critical global challenges in water scarcity and pollution. The extended operational lifetime of these membranes—often 1.5-2 times longer than conventional alternatives—further enhances their environmental value proposition through reduced replacement frequency and associated material waste.

Chemical compatibility and resistance to fouling represent additional environmental advantages. High-free-volume polymers can be engineered to minimize chemical cleaning requirements, reducing the discharge of potentially harmful cleaning agents into aquatic ecosystems. Several studies have documented 40-60% reductions in cleaning chemical usage compared to traditional membrane technologies.

End-of-life considerations remain an area requiring further research and development. Current high-free-volume polymer membranes present recycling challenges due to their complex compositions and modifications. Emerging research focuses on developing biodegradable variants and recycling protocols to address this sustainability gap, with preliminary studies suggesting potential for up to 70% material recovery through specialized solvent-based recycling processes.

The scalability of manufacturing processes for these advanced membranes will significantly influence their ultimate environmental impact. Current laboratory-scale production methods often involve environmentally concerning solvents and energy-intensive steps. Industry partnerships are actively developing greener synthesis routes, including aqueous-based processing and solvent recovery systems, which could reduce the environmental footprint of manufacturing by an estimated 35-50%.

Life cycle assessment (LCA) studies indicate that ultra-permeable membranes based on high-free-volume polymers can reduce the carbon footprint of industrial separation processes by 30-45% compared to conventional technologies. This reduction stems primarily from decreased energy demands during operation, though considerations must include the environmental impact of polymer synthesis and membrane manufacturing processes, which often involve solvent usage and energy-intensive fabrication steps.

Water purification applications demonstrate particularly promising sustainability metrics. Ultra-permeable membranes incorporating polymers of intrinsic microporosity (PIMs) and thermally rearranged (TR) polymers show potential to reduce the energy consumption of desalination and wastewater treatment by up to 50%, addressing critical global challenges in water scarcity and pollution. The extended operational lifetime of these membranes—often 1.5-2 times longer than conventional alternatives—further enhances their environmental value proposition through reduced replacement frequency and associated material waste.

Chemical compatibility and resistance to fouling represent additional environmental advantages. High-free-volume polymers can be engineered to minimize chemical cleaning requirements, reducing the discharge of potentially harmful cleaning agents into aquatic ecosystems. Several studies have documented 40-60% reductions in cleaning chemical usage compared to traditional membrane technologies.

End-of-life considerations remain an area requiring further research and development. Current high-free-volume polymer membranes present recycling challenges due to their complex compositions and modifications. Emerging research focuses on developing biodegradable variants and recycling protocols to address this sustainability gap, with preliminary studies suggesting potential for up to 70% material recovery through specialized solvent-based recycling processes.

The scalability of manufacturing processes for these advanced membranes will significantly influence their ultimate environmental impact. Current laboratory-scale production methods often involve environmentally concerning solvents and energy-intensive steps. Industry partnerships are actively developing greener synthesis routes, including aqueous-based processing and solvent recovery systems, which could reduce the environmental footprint of manufacturing by an estimated 35-50%.

Scalability and Manufacturing Considerations

The scalability of high-free-volume polymer membranes represents a critical challenge in transitioning from laboratory-scale demonstrations to commercial-scale production. Current manufacturing processes for these ultra-permeable membranes often involve complex solvent casting techniques that are difficult to scale while maintaining consistent pore structure and free volume distribution. The precision required in controlling polymer chain packing during membrane formation becomes increasingly challenging at larger scales.

Industrial implementation of high-free-volume polymer membranes faces several manufacturing hurdles. The synthesis of polymers with intrinsic microporosity (PIMs) and thermally rearranged (TR) polymers typically requires specialized monomers and carefully controlled reaction conditions. These requirements translate to higher production costs and potential supply chain vulnerabilities when scaling to industrial volumes. Additionally, the solvent systems used in membrane casting often involve volatile organic compounds that present both environmental concerns and regulatory compliance issues at manufacturing scale.

Roll-to-roll processing represents a promising approach for continuous production of high-free-volume polymer membranes. However, this technique requires careful optimization of solution viscosity, casting speed, and environmental conditions to ensure uniform membrane formation. Recent advances in controlled evaporation techniques have improved thickness uniformity, but maintaining consistent free volume distribution across large membrane areas remains problematic.

Quality control presents another significant challenge in scaled production. Nanoscale defects that may be inconsequential in laboratory samples can create critical failure points in industrial-scale membranes. Advanced characterization techniques such as positron annihilation lifetime spectroscopy (PALS) provide valuable insights into free volume distribution but are difficult to implement as in-line quality control measures in high-throughput manufacturing environments.

Cost considerations also significantly impact scalability. The specialized monomers required for high-free-volume polymers often come with substantial price premiums compared to conventional membrane materials. Economic viability at commercial scale will likely require either cost reduction through manufacturing innovation or the development of applications where performance advantages justify premium pricing. Recent research into bio-based precursors for high-free-volume polymers shows promise for reducing raw material costs.

Module design and membrane housing systems must also evolve to fully capitalize on the enhanced permeability of these materials. Current industrial membrane modules are optimized for conventional polymers and may not effectively harness the performance advantages of high-free-volume materials. Computational fluid dynamics modeling suggests that redesigned flow patterns could significantly improve efficiency when using ultra-permeable membranes in industrial separation processes.

Industrial implementation of high-free-volume polymer membranes faces several manufacturing hurdles. The synthesis of polymers with intrinsic microporosity (PIMs) and thermally rearranged (TR) polymers typically requires specialized monomers and carefully controlled reaction conditions. These requirements translate to higher production costs and potential supply chain vulnerabilities when scaling to industrial volumes. Additionally, the solvent systems used in membrane casting often involve volatile organic compounds that present both environmental concerns and regulatory compliance issues at manufacturing scale.

Roll-to-roll processing represents a promising approach for continuous production of high-free-volume polymer membranes. However, this technique requires careful optimization of solution viscosity, casting speed, and environmental conditions to ensure uniform membrane formation. Recent advances in controlled evaporation techniques have improved thickness uniformity, but maintaining consistent free volume distribution across large membrane areas remains problematic.

Quality control presents another significant challenge in scaled production. Nanoscale defects that may be inconsequential in laboratory samples can create critical failure points in industrial-scale membranes. Advanced characterization techniques such as positron annihilation lifetime spectroscopy (PALS) provide valuable insights into free volume distribution but are difficult to implement as in-line quality control measures in high-throughput manufacturing environments.

Cost considerations also significantly impact scalability. The specialized monomers required for high-free-volume polymers often come with substantial price premiums compared to conventional membrane materials. Economic viability at commercial scale will likely require either cost reduction through manufacturing innovation or the development of applications where performance advantages justify premium pricing. Recent research into bio-based precursors for high-free-volume polymers shows promise for reducing raw material costs.

Module design and membrane housing systems must also evolve to fully capitalize on the enhanced permeability of these materials. Current industrial membrane modules are optimized for conventional polymers and may not effectively harness the performance advantages of high-free-volume materials. Computational fluid dynamics modeling suggests that redesigned flow patterns could significantly improve efficiency when using ultra-permeable membranes in industrial separation processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!