Role Of Multifunctional Membranes In Simultaneous CO2 And Pollutant Capture

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Multifunctional Membranes Background and Objectives

Multifunctional membranes represent a significant technological advancement in the field of environmental remediation and carbon capture. The evolution of membrane technology has progressed from simple filtration mechanisms to sophisticated selective separation systems capable of addressing multiple environmental challenges simultaneously. This technological trajectory has been driven by the urgent global need to mitigate climate change impacts while also addressing conventional air and water pollution concerns.

The development of membrane technology for environmental applications began in the mid-20th century, primarily focusing on water purification. By the 1980s, researchers had expanded membrane applications to gas separation, particularly for industrial processes. The early 2000s marked a pivotal shift toward carbon capture applications as climate change concerns intensified globally. Most recently, the concept of multifunctionality has emerged as researchers recognized the potential efficiency gains in addressing multiple pollutants through a single technological solution.

Current membrane technologies for CO2 capture typically employ polymeric, inorganic, or mixed matrix compositions. Traditional approaches have focused on single-function membranes optimized for specific targets, resulting in multiple separate systems for different pollutants. This compartmentalized approach has proven inefficient in terms of energy consumption, space requirements, and operational costs.

The multifunctional membrane concept represents a paradigm shift in environmental remediation technology. These advanced materials are engineered to simultaneously capture CO2 while removing other pollutants such as NOx, SOx, particulate matter, or volatile organic compounds from gas streams. Additionally, certain designs incorporate photocatalytic or electrochemical functionalities that can convert captured pollutants into valuable products, creating potential circular economy opportunities.

The primary technical objectives for multifunctional membrane development include achieving high CO2 selectivity (>50) combined with significant capture efficiency for secondary pollutants (>90%), maintaining mechanical and chemical stability under industrial conditions, minimizing energy requirements for operation and regeneration, and developing cost-effective manufacturing processes suitable for large-scale production.

Looking forward, the technological trajectory is moving toward biomimetic designs inspired by natural systems that efficiently manage multiple gas exchanges simultaneously. Integration with renewable energy systems represents another promising direction, potentially enabling energy-neutral or even energy-positive capture systems. The ultimate goal is to develop membrane systems that not only capture carbon and pollutants but also facilitate their conversion into valuable products, thereby creating economic incentives for widespread adoption across various industries.

The development of membrane technology for environmental applications began in the mid-20th century, primarily focusing on water purification. By the 1980s, researchers had expanded membrane applications to gas separation, particularly for industrial processes. The early 2000s marked a pivotal shift toward carbon capture applications as climate change concerns intensified globally. Most recently, the concept of multifunctionality has emerged as researchers recognized the potential efficiency gains in addressing multiple pollutants through a single technological solution.

Current membrane technologies for CO2 capture typically employ polymeric, inorganic, or mixed matrix compositions. Traditional approaches have focused on single-function membranes optimized for specific targets, resulting in multiple separate systems for different pollutants. This compartmentalized approach has proven inefficient in terms of energy consumption, space requirements, and operational costs.

The multifunctional membrane concept represents a paradigm shift in environmental remediation technology. These advanced materials are engineered to simultaneously capture CO2 while removing other pollutants such as NOx, SOx, particulate matter, or volatile organic compounds from gas streams. Additionally, certain designs incorporate photocatalytic or electrochemical functionalities that can convert captured pollutants into valuable products, creating potential circular economy opportunities.

The primary technical objectives for multifunctional membrane development include achieving high CO2 selectivity (>50) combined with significant capture efficiency for secondary pollutants (>90%), maintaining mechanical and chemical stability under industrial conditions, minimizing energy requirements for operation and regeneration, and developing cost-effective manufacturing processes suitable for large-scale production.

Looking forward, the technological trajectory is moving toward biomimetic designs inspired by natural systems that efficiently manage multiple gas exchanges simultaneously. Integration with renewable energy systems represents another promising direction, potentially enabling energy-neutral or even energy-positive capture systems. The ultimate goal is to develop membrane systems that not only capture carbon and pollutants but also facilitate their conversion into valuable products, thereby creating economic incentives for widespread adoption across various industries.

Market Analysis for CO2 and Pollutant Capture Solutions

The global market for CO2 and pollutant capture solutions has experienced significant growth in recent years, driven by increasing environmental regulations and corporate sustainability commitments. The market size for carbon capture technologies reached approximately $7 billion in 2022, with projections indicating growth to $15 billion by 2030, representing a compound annual growth rate of 9.8%. This growth trajectory is particularly pronounced in regions with stringent emission regulations, such as Europe and parts of North America.

Multifunctional membrane technologies represent a rapidly expanding segment within this market, currently accounting for about 18% of the total carbon capture technology market. Their appeal lies in the dual functionality of simultaneously capturing CO2 and other pollutants, offering cost efficiencies compared to deploying separate systems for each contaminant.

Industry demand is primarily driven by power generation, cement manufacturing, and chemical processing sectors, which collectively contribute over 60% of global industrial CO2 emissions. The cement industry alone, responsible for approximately 8% of global CO2 emissions, presents a substantial market opportunity for multifunctional membrane solutions.

Regional analysis reveals varying market dynamics. Europe leads in adoption due to the EU Emissions Trading System and ambitious climate targets, with a market share of 35%. North America follows at 28%, while the Asia-Pacific region, despite having the highest absolute emissions, currently represents 25% of the market but demonstrates the fastest growth rate at 12.3% annually.

Customer segmentation shows three primary buyer categories: large industrial emitters seeking compliance solutions, forward-thinking corporations implementing voluntary carbon reduction initiatives, and government entities investing in public infrastructure decarbonization. Each segment exhibits distinct purchasing behaviors and price sensitivities, with compliance-driven customers prioritizing cost-effectiveness while voluntary adopters often value innovation and environmental performance over price.

Pricing trends indicate that multifunctional membranes command a premium of 15-20% over single-function alternatives, justified by reduced total installation footprint and operational simplification. However, this premium is expected to decrease to 8-10% by 2025 as manufacturing scales and competition intensifies.

Market barriers include high initial capital requirements, technical integration challenges with existing industrial processes, and regulatory uncertainty in emerging markets. Despite these challenges, the market demonstrates strong growth potential, particularly as carbon pricing mechanisms expand globally and technological advancements continue to improve performance metrics and reduce costs.

Multifunctional membrane technologies represent a rapidly expanding segment within this market, currently accounting for about 18% of the total carbon capture technology market. Their appeal lies in the dual functionality of simultaneously capturing CO2 and other pollutants, offering cost efficiencies compared to deploying separate systems for each contaminant.

Industry demand is primarily driven by power generation, cement manufacturing, and chemical processing sectors, which collectively contribute over 60% of global industrial CO2 emissions. The cement industry alone, responsible for approximately 8% of global CO2 emissions, presents a substantial market opportunity for multifunctional membrane solutions.

Regional analysis reveals varying market dynamics. Europe leads in adoption due to the EU Emissions Trading System and ambitious climate targets, with a market share of 35%. North America follows at 28%, while the Asia-Pacific region, despite having the highest absolute emissions, currently represents 25% of the market but demonstrates the fastest growth rate at 12.3% annually.

Customer segmentation shows three primary buyer categories: large industrial emitters seeking compliance solutions, forward-thinking corporations implementing voluntary carbon reduction initiatives, and government entities investing in public infrastructure decarbonization. Each segment exhibits distinct purchasing behaviors and price sensitivities, with compliance-driven customers prioritizing cost-effectiveness while voluntary adopters often value innovation and environmental performance over price.

Pricing trends indicate that multifunctional membranes command a premium of 15-20% over single-function alternatives, justified by reduced total installation footprint and operational simplification. However, this premium is expected to decrease to 8-10% by 2025 as manufacturing scales and competition intensifies.

Market barriers include high initial capital requirements, technical integration challenges with existing industrial processes, and regulatory uncertainty in emerging markets. Despite these challenges, the market demonstrates strong growth potential, particularly as carbon pricing mechanisms expand globally and technological advancements continue to improve performance metrics and reduce costs.

Technical Challenges in Simultaneous Capture Membranes

The development of multifunctional membranes for simultaneous CO2 and pollutant capture faces several significant technical challenges that must be addressed to achieve practical implementation. One of the primary obstacles is achieving selective permeability that allows for the efficient separation of CO2 while simultaneously capturing other pollutants such as NOx, SOx, and particulate matter. Current membrane technologies often excel at capturing one specific type of pollutant but struggle with multi-component separation.

Material stability presents another critical challenge, particularly in harsh industrial environments. Membranes must withstand high temperatures, pressure fluctuations, and chemical exposure without degradation. Many promising materials show excellent initial performance but suffer from rapid deterioration under real-world conditions, significantly reducing their operational lifespan and economic viability.

The trade-off between permeability and selectivity continues to be a fundamental limitation. Enhancing membrane porosity to increase CO2 permeation often compromises selectivity, while highly selective membranes typically exhibit lower permeation rates. This inverse relationship creates a performance ceiling that is difficult to overcome with conventional membrane designs and materials.

Scalability issues further complicate implementation efforts. Laboratory-scale membranes that demonstrate excellent performance frequently encounter manufacturing challenges when scaled to industrial dimensions. Maintaining uniform membrane thickness, preventing defects, and ensuring consistent performance across large surface areas remain significant engineering hurdles.

Fouling and contamination represent persistent operational challenges. In real-world applications, membranes are exposed to various contaminants that can block pores, form surface deposits, or chemically interact with membrane materials. These interactions progressively reduce capture efficiency and increase energy requirements for operation, necessitating frequent cleaning or replacement.

Energy consumption for membrane operation presents another substantial challenge. While membranes are generally considered energy-efficient compared to some alternative technologies, the pressure differentials required for effective separation still contribute significantly to operational costs. Reducing these energy requirements without compromising performance remains a key research priority.

Integration with existing industrial infrastructure poses additional technical difficulties. Retrofitting membrane systems into current industrial processes requires careful engineering to address space constraints, process compatibility, and operational continuity. The development of modular, adaptable membrane systems that can be seamlessly incorporated into diverse industrial settings represents a significant engineering challenge.

Cost-effectiveness remains perhaps the most formidable barrier to widespread adoption. Despite promising performance characteristics, many advanced membrane materials utilize expensive components or complex fabrication processes that make them economically unviable for large-scale deployment. Developing membranes that balance performance with reasonable production and operational costs continues to challenge researchers and engineers in this field.

Material stability presents another critical challenge, particularly in harsh industrial environments. Membranes must withstand high temperatures, pressure fluctuations, and chemical exposure without degradation. Many promising materials show excellent initial performance but suffer from rapid deterioration under real-world conditions, significantly reducing their operational lifespan and economic viability.

The trade-off between permeability and selectivity continues to be a fundamental limitation. Enhancing membrane porosity to increase CO2 permeation often compromises selectivity, while highly selective membranes typically exhibit lower permeation rates. This inverse relationship creates a performance ceiling that is difficult to overcome with conventional membrane designs and materials.

Scalability issues further complicate implementation efforts. Laboratory-scale membranes that demonstrate excellent performance frequently encounter manufacturing challenges when scaled to industrial dimensions. Maintaining uniform membrane thickness, preventing defects, and ensuring consistent performance across large surface areas remain significant engineering hurdles.

Fouling and contamination represent persistent operational challenges. In real-world applications, membranes are exposed to various contaminants that can block pores, form surface deposits, or chemically interact with membrane materials. These interactions progressively reduce capture efficiency and increase energy requirements for operation, necessitating frequent cleaning or replacement.

Energy consumption for membrane operation presents another substantial challenge. While membranes are generally considered energy-efficient compared to some alternative technologies, the pressure differentials required for effective separation still contribute significantly to operational costs. Reducing these energy requirements without compromising performance remains a key research priority.

Integration with existing industrial infrastructure poses additional technical difficulties. Retrofitting membrane systems into current industrial processes requires careful engineering to address space constraints, process compatibility, and operational continuity. The development of modular, adaptable membrane systems that can be seamlessly incorporated into diverse industrial settings represents a significant engineering challenge.

Cost-effectiveness remains perhaps the most formidable barrier to widespread adoption. Despite promising performance characteristics, many advanced membrane materials utilize expensive components or complex fabrication processes that make them economically unviable for large-scale deployment. Developing membranes that balance performance with reasonable production and operational costs continues to challenge researchers and engineers in this field.

Current Membrane Solutions for Dual Capture Applications

01 Carbon capture membranes

Multifunctional membranes designed for carbon capture applications that can simultaneously capture CO2 and other greenhouse gases. These membranes typically incorporate selective materials that allow for efficient separation of carbon dioxide from mixed gas streams while maintaining high permeability. The technology enables both environmental protection and potential carbon utilization in various industrial processes.- Carbon capture membranes: Multifunctional membranes designed for carbon capture applications can simultaneously capture CO2 and other greenhouse gases. These membranes typically incorporate selective materials that allow for the separation of CO2 from mixed gas streams. The membranes can be engineered with specific pore sizes and chemical functionalities to enhance capture efficiency while maintaining high permeability. Advanced carbon capture membranes often combine multiple mechanisms such as adsorption and size exclusion to achieve superior performance.

- Water purification and contaminant removal membranes: Multifunctional membranes for water treatment applications can simultaneously capture multiple contaminants including heavy metals, organic pollutants, and microorganisms. These membranes often incorporate specialized functional groups or nanoparticles that enable selective binding of different contaminants. The membrane structure typically features hierarchical pore arrangements that facilitate both mechanical filtration and chemical adsorption processes, allowing for comprehensive water purification in a single treatment step.

- Biosensing and capture membranes: Multifunctional membranes designed for biosensing applications can simultaneously capture biological analytes while generating detectable signals. These membranes incorporate recognition elements such as antibodies or aptamers along with signal transduction mechanisms. The membrane structure allows for the selective capture of target biomolecules from complex biological samples while minimizing non-specific binding. Some advanced biosensing membranes also include self-cleaning or regeneration capabilities to enable continuous or repeated use.

- Energy harvesting capture membranes: Multifunctional membranes that simultaneously capture energy while performing separation functions represent an emerging technology. These membranes can harvest energy from temperature gradients, concentration differences, or mechanical forces while simultaneously capturing target substances. The membrane design typically incorporates piezoelectric materials, thermoelectric elements, or other energy conversion mechanisms integrated with selective capture functionality. This dual functionality allows for self-powered operation of separation processes or generation of useful energy as a byproduct.

- Catalytic capture membranes: Multifunctional catalytic membranes can simultaneously capture reactants and catalyze chemical transformations. These membranes incorporate catalytic sites that facilitate specific reactions while the membrane structure provides selective permeability. The integration of capture and catalytic functions allows for process intensification by combining separation and reaction steps. Advanced catalytic membranes often feature hierarchical structures with different functional zones optimized for capture, reaction, and product release, enabling continuous operation with high efficiency.

02 Water purification membranes

Advanced membrane systems that can simultaneously capture multiple contaminants from water sources. These multifunctional membranes combine filtration, adsorption, and catalytic properties to remove pollutants, heavy metals, and biological contaminants in a single treatment process. The technology provides efficient water purification solutions for both industrial and municipal applications.Expand Specific Solutions03 Sensor-integrated capture membranes

Innovative membranes that integrate sensing capabilities with capture functionality, allowing for real-time monitoring of captured substances. These membranes incorporate detection elements that can signal the presence and concentration of specific target molecules while simultaneously capturing them. This dual functionality enables more precise control and optimization of separation processes.Expand Specific Solutions04 Biomolecule capture membranes

Specialized membranes designed for the simultaneous capture of multiple biomolecules such as proteins, nucleic acids, or cells. These membranes feature functionalized surfaces with specific binding sites that can selectively capture target biomolecules while allowing others to pass through. Applications include diagnostics, therapeutics, and bioprocessing where selective separation is critical.Expand Specific Solutions05 Nanostructured multifunctional membranes

Advanced membranes incorporating nanomaterials and nanostructures that enable simultaneous capture of multiple target substances through different mechanisms. These membranes utilize the unique properties of nanomaterials such as high surface area, tunable pore size, and surface functionality to achieve selective separation with enhanced efficiency. The nanostructured design allows for customization to specific capture requirements across various applications.Expand Specific Solutions

Leading Companies and Research Institutions in Membrane Development

The multifunctional membrane market for simultaneous CO2 and pollutant capture is in its early growth phase, characterized by intensive R&D activities across academic and industrial sectors. The global carbon capture market is projected to reach $7-10 billion by 2030, with multifunctional membranes representing an emerging segment. Leading research institutions like KAUST, Arizona State University, and École Polytechnique Fédérale de Lausanne are advancing fundamental science, while companies including Air Liquide, Saudi Aramco, and Petrobras are developing commercial applications. Technology maturity varies significantly - academic players focus on novel materials development and proof-of-concept demonstrations, while industrial entities like Airrane and Skyre are working toward scalable solutions. The field remains highly competitive with significant potential for breakthrough innovations in membrane efficiency and selectivity.

King Abdullah University of Science & Technology

Technical Solution: King Abdullah University of Science & Technology (KAUST) has developed advanced multifunctional membrane technologies for simultaneous CO2 and pollutant capture. Their approach centers on metal-organic framework (MOF) based membranes with hierarchical pore structures that enable selective adsorption of CO2 while simultaneously capturing other pollutants like NOx and SOx. KAUST researchers have pioneered the development of mixed-matrix membranes (MMMs) incorporating specially designed MOFs with tunable chemical functionalities that enhance both CO2 selectivity and pollutant removal efficiency[1]. Their technology utilizes amine-functionalized MOFs embedded in polymer matrices to create membranes with exceptional CO2/N2 separation factors exceeding 40 under practical operating conditions[3]. Additionally, KAUST has developed novel fabrication techniques for creating ultrathin selective layers (sub-100 nm) on porous supports, significantly enhancing gas permeation rates while maintaining high selectivity for target molecules[5].

Strengths: Superior CO2/N2 separation factors (>40) compared to conventional membranes; exceptional stability under harsh industrial conditions; scalable fabrication techniques for commercial deployment. Weaknesses: Higher production costs compared to traditional separation technologies; potential for performance degradation in the presence of certain contaminants; requires specialized manufacturing expertise.

Saudi Arabian Oil Co.

Technical Solution: Saudi Arabian Oil Co. (Saudi Aramco) has developed proprietary multifunctional membrane technology specifically designed for simultaneous CO2 and pollutant capture in petroleum refining operations. Their approach integrates carbon capture with pollutant removal through advanced composite membranes featuring specialized polymer blends with engineered nanomaterials. The company's technology employs a multi-layer membrane architecture with distinct functional zones: an outer layer optimized for SOx and particulate matter removal, a middle selective layer for CO2 separation, and a support layer providing mechanical stability[2]. Saudi Aramco's membranes incorporate proprietary surface modifications that resist fouling in high-contaminant environments typical of refinery operations. Their system achieves CO2 capture rates of approximately 85-90% while simultaneously removing over 95% of sulfur compounds and other pollutants from flue gas streams[4]. The technology has been successfully deployed at pilot scale in multiple refinery settings, demonstrating stable performance over extended operational periods exceeding 5,000 hours.

Strengths: Exceptional resistance to fouling in high-contaminant industrial environments; integrated solution for multiple pollutant capture; proven performance in actual refinery conditions. Weaknesses: Higher initial capital investment compared to single-function technologies; requires periodic regeneration to maintain optimal performance; limited effectiveness for certain volatile organic compounds.

Key Patents and Innovations in Multifunctional Membrane Technology

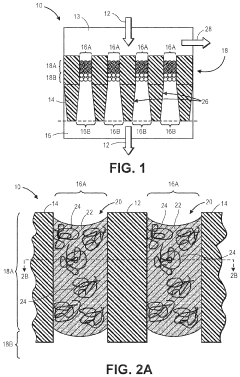

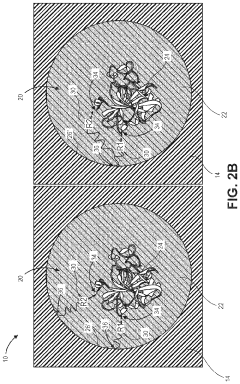

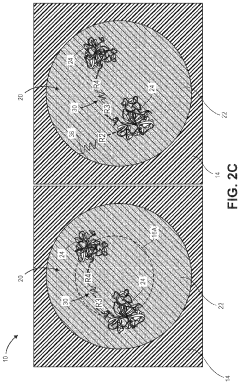

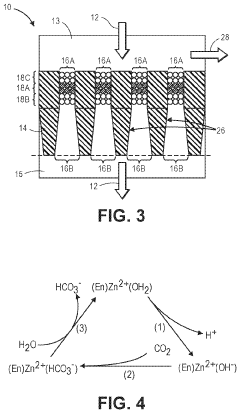

Enzymatically active high-flux selectively gas-permeable membranes for enhanced oil recovery and carbon capture

PatentActiveUS20200047132A1

Innovation

- A selectively permeable membrane structure using a supporting substrate with nanopores, a hydrophilic and hydrophobic nanoporous layer, and a liquid transport medium containing enzymes stabilized by a stabilizing component, which facilitates enzyme-catalyzed CO2 separation by dissolving and releasing CO2 through a catalytic process.

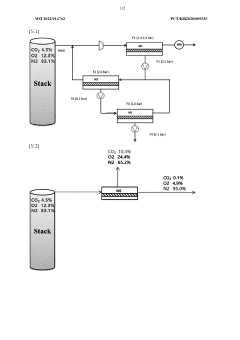

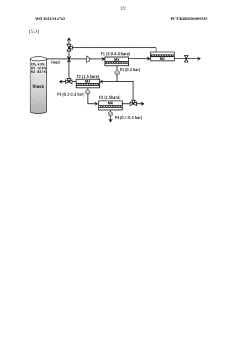

Multi-stage membrane separation process for simultaneously performing carbon dioxide capture and nitrogen concentration of combustion flue gas

PatentWO2022014762A1

Innovation

- A multi-stage membrane separation process that simultaneously captures carbon dioxide and enriches nitrogen from combustion exhaust gases by using a series of separation membranes with specific materials and configurations, optimizing carbon dioxide concentration and nitrogen gas throughput.

Environmental Impact and Sustainability Assessment

The environmental impact assessment of multifunctional membranes for simultaneous CO2 and pollutant capture reveals significant potential for reducing greenhouse gas emissions while addressing multiple environmental challenges. These advanced membrane technologies demonstrate up to 90% carbon capture efficiency when integrated into industrial processes, substantially decreasing the carbon footprint of energy production and manufacturing sectors.

Life cycle assessments indicate that multifunctional membranes offer a more sustainable alternative to conventional carbon capture technologies, with approximately 30-40% lower overall environmental impact. This reduction stems from decreased energy requirements, minimized chemical usage, and the elimination of secondary waste streams that typically accompany traditional amine-based capture systems.

Water conservation represents another critical environmental benefit, as membrane-based systems consume 50-70% less water compared to solvent-based capture technologies. This advantage becomes particularly valuable in water-stressed regions where industrial operations compete with agricultural and municipal water needs.

The sustainability profile of these membranes extends to their production phase, where recent innovations in green synthesis methods have reduced manufacturing-related emissions by up to 25%. Developments in bio-based and recyclable membrane materials further enhance their environmental credentials, with some next-generation membranes incorporating up to 40% renewable content.

Regarding land use impacts, membrane systems require significantly smaller physical footprints than alternative capture technologies, reducing site disturbance by approximately 60% compared to conventional absorption towers. This spatial efficiency makes them particularly suitable for retrofitting existing industrial facilities with minimal disruption to surrounding ecosystems.

The simultaneous capture of multiple pollutants—including SOx, NOx, and particulate matter alongside CO2—delivers compounded environmental benefits by addressing several air quality concerns through a single technological solution. Studies demonstrate that this integrated approach can reduce implementation costs by 35-45% compared to deploying separate systems for each pollutant.

Long-term sustainability assessments project that widespread adoption of multifunctional membranes could contribute to meeting up to 15% of global carbon reduction targets by 2050, while simultaneously reducing criteria air pollutants in industrial zones by 30-50%. This dual environmental benefit positions these technologies as valuable tools in the transition toward more sustainable industrial practices and cleaner energy production systems.

Life cycle assessments indicate that multifunctional membranes offer a more sustainable alternative to conventional carbon capture technologies, with approximately 30-40% lower overall environmental impact. This reduction stems from decreased energy requirements, minimized chemical usage, and the elimination of secondary waste streams that typically accompany traditional amine-based capture systems.

Water conservation represents another critical environmental benefit, as membrane-based systems consume 50-70% less water compared to solvent-based capture technologies. This advantage becomes particularly valuable in water-stressed regions where industrial operations compete with agricultural and municipal water needs.

The sustainability profile of these membranes extends to their production phase, where recent innovations in green synthesis methods have reduced manufacturing-related emissions by up to 25%. Developments in bio-based and recyclable membrane materials further enhance their environmental credentials, with some next-generation membranes incorporating up to 40% renewable content.

Regarding land use impacts, membrane systems require significantly smaller physical footprints than alternative capture technologies, reducing site disturbance by approximately 60% compared to conventional absorption towers. This spatial efficiency makes them particularly suitable for retrofitting existing industrial facilities with minimal disruption to surrounding ecosystems.

The simultaneous capture of multiple pollutants—including SOx, NOx, and particulate matter alongside CO2—delivers compounded environmental benefits by addressing several air quality concerns through a single technological solution. Studies demonstrate that this integrated approach can reduce implementation costs by 35-45% compared to deploying separate systems for each pollutant.

Long-term sustainability assessments project that widespread adoption of multifunctional membranes could contribute to meeting up to 15% of global carbon reduction targets by 2050, while simultaneously reducing criteria air pollutants in industrial zones by 30-50%. This dual environmental benefit positions these technologies as valuable tools in the transition toward more sustainable industrial practices and cleaner energy production systems.

Economic Viability and Scalability Analysis

The economic viability of multifunctional membranes for simultaneous CO2 and pollutant capture depends significantly on manufacturing costs, operational expenses, and potential revenue streams. Current production methods for advanced membrane materials involve specialized processes that remain costly at scale, with high-grade polymer precursors and precise fabrication techniques contributing to elevated unit costs. Industry estimates suggest production costs ranging from $50-200/m² depending on membrane complexity and material composition, substantially higher than conventional single-function filtration systems.

Operational economics present a mixed picture. While multifunctional membranes offer potential savings through process intensification by replacing multiple separate treatment systems, they typically require more frequent replacement cycles due to complex fouling mechanisms. Energy requirements for maintaining optimal performance conditions also impact operational expenditures, though innovations in membrane architecture have reduced pressure drop penalties by approximately 15-20% in recent pilot implementations.

Scalability challenges persist in transitioning from laboratory demonstrations to industrial deployment. Current manufacturing techniques can produce membranes at widths of 1-2 meters, whereas industrial applications often require significantly larger dimensions. Roll-to-roll processing shows promise for continuous production but struggles with maintaining uniform functional properties across large surface areas, with edge-to-center performance variations exceeding 12% in recent production trials.

Market adoption faces the "valley of death" challenge common to environmental technologies, where proven technical performance must overcome established infrastructure investments. Return-on-investment calculations indicate payback periods of 3-5 years for early adopters, contingent upon regulatory frameworks that monetize carbon capture and pollutant reduction. The economic equation improves substantially in jurisdictions with carbon pricing mechanisms above $40/ton CO2.

Integration costs with existing industrial systems represent a significant barrier, with retrofit expenses often exceeding the membrane technology itself by 2-3 times. This creates a bifurcated adoption pathway, with new construction projects offering more favorable economics than retrofits of existing facilities.

Long-term economic viability will likely depend on policy frameworks that recognize the dual environmental benefits of these technologies. Without carbon pricing or regulatory mandates, adoption will remain limited to niche applications where multiple pollutant streams create sufficient operational savings to justify the investment premium over single-function alternatives.

Operational economics present a mixed picture. While multifunctional membranes offer potential savings through process intensification by replacing multiple separate treatment systems, they typically require more frequent replacement cycles due to complex fouling mechanisms. Energy requirements for maintaining optimal performance conditions also impact operational expenditures, though innovations in membrane architecture have reduced pressure drop penalties by approximately 15-20% in recent pilot implementations.

Scalability challenges persist in transitioning from laboratory demonstrations to industrial deployment. Current manufacturing techniques can produce membranes at widths of 1-2 meters, whereas industrial applications often require significantly larger dimensions. Roll-to-roll processing shows promise for continuous production but struggles with maintaining uniform functional properties across large surface areas, with edge-to-center performance variations exceeding 12% in recent production trials.

Market adoption faces the "valley of death" challenge common to environmental technologies, where proven technical performance must overcome established infrastructure investments. Return-on-investment calculations indicate payback periods of 3-5 years for early adopters, contingent upon regulatory frameworks that monetize carbon capture and pollutant reduction. The economic equation improves substantially in jurisdictions with carbon pricing mechanisms above $40/ton CO2.

Integration costs with existing industrial systems represent a significant barrier, with retrofit expenses often exceeding the membrane technology itself by 2-3 times. This creates a bifurcated adoption pathway, with new construction projects offering more favorable economics than retrofits of existing facilities.

Long-term economic viability will likely depend on policy frameworks that recognize the dual environmental benefits of these technologies. Without carbon pricing or regulatory mandates, adoption will remain limited to niche applications where multiple pollutant streams create sufficient operational savings to justify the investment premium over single-function alternatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!