Development Of Facilitated Transport Membranes For Post-Combustion Capture

SEP 3, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Facilitated Transport Membranes Background and Objectives

Facilitated transport membranes (FTMs) represent a significant advancement in the field of carbon capture technologies, emerging as a promising solution for post-combustion CO2 separation. The development of these membranes dates back to the 1970s, when researchers first explored the concept of carrier-mediated transport to enhance gas separation performance. Over the decades, this technology has evolved from theoretical concepts to practical applications, driven by the increasing global focus on reducing greenhouse gas emissions.

The fundamental principle behind FTMs involves the incorporation of carrier molecules that selectively and reversibly react with CO2, facilitating its transport across the membrane while restricting the passage of other gases. This mechanism allows FTMs to overcome the traditional permeability-selectivity trade-off that limits conventional polymeric membranes, potentially achieving both high permeance and high selectivity simultaneously.

The evolution of FTM technology has been marked by several key developments. Early research focused primarily on liquid membranes containing mobile carriers, which demonstrated excellent selectivity but suffered from stability issues. The field then progressed toward fixed-carrier membranes, where the carrier molecules are immobilized within a polymer matrix, offering improved mechanical stability and operational longevity.

Recent technological advances have focused on novel carrier molecules, innovative polymer matrices, and composite structures that combine the advantages of different materials. The integration of nanomaterials and the development of mixed matrix membranes represent cutting-edge approaches that have significantly enhanced the performance of FTMs in laboratory settings.

The primary objective of current FTM development is to create membrane systems that can efficiently capture CO2 from post-combustion flue gases under realistic operating conditions. This includes addressing challenges such as the presence of contaminants (SOx, NOx, water vapor), the relatively low CO2 partial pressure in flue gas, and the need for long-term stability under continuous operation.

Additional technical goals include reducing the energy penalty associated with carbon capture, minimizing membrane fouling and plasticization, and developing scalable manufacturing processes that can transition laboratory successes to industrial applications. Researchers are also focusing on enhancing the CO2/N2 selectivity while maintaining high CO2 permeance, as this combination is crucial for economic viability.

The development trajectory of FTMs is increasingly aligned with broader climate change mitigation strategies, with specific targets for performance metrics that would make membrane-based capture competitive with established technologies like amine scrubbing. As global carbon reduction targets become more stringent, the advancement of efficient and cost-effective FTM technology represents a critical pathway toward sustainable industrial operations in a carbon-constrained world.

The fundamental principle behind FTMs involves the incorporation of carrier molecules that selectively and reversibly react with CO2, facilitating its transport across the membrane while restricting the passage of other gases. This mechanism allows FTMs to overcome the traditional permeability-selectivity trade-off that limits conventional polymeric membranes, potentially achieving both high permeance and high selectivity simultaneously.

The evolution of FTM technology has been marked by several key developments. Early research focused primarily on liquid membranes containing mobile carriers, which demonstrated excellent selectivity but suffered from stability issues. The field then progressed toward fixed-carrier membranes, where the carrier molecules are immobilized within a polymer matrix, offering improved mechanical stability and operational longevity.

Recent technological advances have focused on novel carrier molecules, innovative polymer matrices, and composite structures that combine the advantages of different materials. The integration of nanomaterials and the development of mixed matrix membranes represent cutting-edge approaches that have significantly enhanced the performance of FTMs in laboratory settings.

The primary objective of current FTM development is to create membrane systems that can efficiently capture CO2 from post-combustion flue gases under realistic operating conditions. This includes addressing challenges such as the presence of contaminants (SOx, NOx, water vapor), the relatively low CO2 partial pressure in flue gas, and the need for long-term stability under continuous operation.

Additional technical goals include reducing the energy penalty associated with carbon capture, minimizing membrane fouling and plasticization, and developing scalable manufacturing processes that can transition laboratory successes to industrial applications. Researchers are also focusing on enhancing the CO2/N2 selectivity while maintaining high CO2 permeance, as this combination is crucial for economic viability.

The development trajectory of FTMs is increasingly aligned with broader climate change mitigation strategies, with specific targets for performance metrics that would make membrane-based capture competitive with established technologies like amine scrubbing. As global carbon reduction targets become more stringent, the advancement of efficient and cost-effective FTM technology represents a critical pathway toward sustainable industrial operations in a carbon-constrained world.

Market Analysis for Post-Combustion Carbon Capture Technologies

The global market for post-combustion carbon capture technologies is experiencing significant growth, driven by increasing environmental regulations and corporate sustainability commitments. Current market valuations indicate that the carbon capture and storage (CCS) sector reached approximately $7.5 billion in 2022, with projections suggesting growth to $15.3 billion by 2030, representing a compound annual growth rate of 9.2%. Within this broader market, membrane-based technologies are gaining traction due to their energy efficiency and operational advantages.

Post-combustion capture represents the largest segment of carbon capture applications, accounting for over 60% of the total market share. This dominance stems from the relative ease of retrofitting existing power plants and industrial facilities with post-combustion capture systems, rather than requiring complete facility redesigns. The market for facilitated transport membranes specifically is emerging as a high-growth subsector, with increasing investment from both private and public sources.

Regional analysis reveals that North America currently leads the market with approximately 35% share, followed by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to demonstrate the fastest growth rate in the coming decade, particularly driven by China's ambitious carbon neutrality goals and increasing industrial carbon management requirements.

Key market drivers include stringent emission regulations, carbon pricing mechanisms, and tax incentives for carbon capture implementation. The European Union's Emissions Trading System (ETS) and similar carbon pricing mechanisms in other regions have created economic incentives for industries to adopt carbon capture technologies. Additionally, government subsidies and research grants are accelerating technology development and commercial deployment.

Customer segments for post-combustion capture technologies include power generation (representing 45% of the market), cement production (15%), steel manufacturing (12%), chemical processing (10%), and other industrial applications (18%). The power generation sector remains the primary target market due to its significant carbon footprint and the technical compatibility of post-combustion systems with existing infrastructure.

Market barriers include high capital expenditure requirements, energy penalties associated with capture processes, and uncertain regulatory frameworks in some regions. The average cost of carbon capture using current membrane technologies ranges from $40-80 per ton of CO2, which remains higher than many carbon pricing schemes, creating adoption challenges.

Competitive analysis indicates that traditional solvent-based technologies (primarily amine scrubbing) currently dominate with approximately 75% market share, while membrane technologies account for roughly 15% and solid sorbents for 10%. However, facilitated transport membranes are projected to gain market share due to their potential for lower energy consumption and operational costs.

Post-combustion capture represents the largest segment of carbon capture applications, accounting for over 60% of the total market share. This dominance stems from the relative ease of retrofitting existing power plants and industrial facilities with post-combustion capture systems, rather than requiring complete facility redesigns. The market for facilitated transport membranes specifically is emerging as a high-growth subsector, with increasing investment from both private and public sources.

Regional analysis reveals that North America currently leads the market with approximately 35% share, followed by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to demonstrate the fastest growth rate in the coming decade, particularly driven by China's ambitious carbon neutrality goals and increasing industrial carbon management requirements.

Key market drivers include stringent emission regulations, carbon pricing mechanisms, and tax incentives for carbon capture implementation. The European Union's Emissions Trading System (ETS) and similar carbon pricing mechanisms in other regions have created economic incentives for industries to adopt carbon capture technologies. Additionally, government subsidies and research grants are accelerating technology development and commercial deployment.

Customer segments for post-combustion capture technologies include power generation (representing 45% of the market), cement production (15%), steel manufacturing (12%), chemical processing (10%), and other industrial applications (18%). The power generation sector remains the primary target market due to its significant carbon footprint and the technical compatibility of post-combustion systems with existing infrastructure.

Market barriers include high capital expenditure requirements, energy penalties associated with capture processes, and uncertain regulatory frameworks in some regions. The average cost of carbon capture using current membrane technologies ranges from $40-80 per ton of CO2, which remains higher than many carbon pricing schemes, creating adoption challenges.

Competitive analysis indicates that traditional solvent-based technologies (primarily amine scrubbing) currently dominate with approximately 75% market share, while membrane technologies account for roughly 15% and solid sorbents for 10%. However, facilitated transport membranes are projected to gain market share due to their potential for lower energy consumption and operational costs.

Current Status and Technical Barriers in FTM Development

Facilitated Transport Membranes (FTMs) have emerged as a promising technology for post-combustion CO2 capture, offering potential advantages over conventional absorption processes. Currently, FTM development has reached a stage where laboratory-scale demonstrations have shown encouraging results, with CO2 permeance values exceeding 1000 GPU and CO2/N2 selectivity above 100 under ideal conditions. Several research institutions and companies worldwide have successfully fabricated thin-film composite membranes incorporating various carriers such as amino acid salts, amines, and ionic liquids.

Despite these advancements, FTMs face significant technical barriers that hinder their commercial deployment. The most critical challenge remains the trade-off between selectivity and permeability. While high carrier concentrations enhance selectivity, they often reduce overall gas permeability due to increased viscosity and diffusion limitations. This fundamental limitation has prevented many promising laboratory formulations from achieving the performance metrics required for industrial implementation.

Carrier stability represents another major obstacle in FTM development. Many effective CO2 carriers suffer from degradation through various mechanisms including oxidation, leaching, and volatilization under actual flue gas conditions. Studies have shown that exposure to trace contaminants such as SOx and NOx can reduce carrier effectiveness by up to 50% within just 100 hours of operation, significantly compromising long-term membrane performance.

Membrane fabrication challenges also persist, particularly in achieving consistent thin selective layers below 100 nm while maintaining defect-free surfaces over large areas. Current manufacturing techniques struggle to produce membranes with the necessary combination of thinness, mechanical strength, and uniformity required for industrial-scale modules. The scale-up from laboratory samples (typically <100 cm²) to commercial modules (>10 m²) introduces additional complexities in quality control and performance consistency.

Water management within FTMs presents another significant barrier. While some moisture is beneficial for carrier mobility, excessive water accumulation can lead to carrier dilution and reduced selectivity. Conversely, insufficient hydration can limit carrier effectiveness and transport mechanisms. This delicate balance is particularly challenging to maintain under the variable humidity conditions typical in real flue gas streams.

From a geographical perspective, FTM research is concentrated primarily in North America, Europe, and East Asia, with the United States, Germany, China, and Japan leading in patent filings and research publications. This distribution reflects both the technical capabilities and the regulatory environments driving carbon capture technology development globally. Notably, there is limited research activity in regions with emerging economies despite their growing carbon emissions, indicating a potential gap in technology transfer and adaptation.

Despite these advancements, FTMs face significant technical barriers that hinder their commercial deployment. The most critical challenge remains the trade-off between selectivity and permeability. While high carrier concentrations enhance selectivity, they often reduce overall gas permeability due to increased viscosity and diffusion limitations. This fundamental limitation has prevented many promising laboratory formulations from achieving the performance metrics required for industrial implementation.

Carrier stability represents another major obstacle in FTM development. Many effective CO2 carriers suffer from degradation through various mechanisms including oxidation, leaching, and volatilization under actual flue gas conditions. Studies have shown that exposure to trace contaminants such as SOx and NOx can reduce carrier effectiveness by up to 50% within just 100 hours of operation, significantly compromising long-term membrane performance.

Membrane fabrication challenges also persist, particularly in achieving consistent thin selective layers below 100 nm while maintaining defect-free surfaces over large areas. Current manufacturing techniques struggle to produce membranes with the necessary combination of thinness, mechanical strength, and uniformity required for industrial-scale modules. The scale-up from laboratory samples (typically <100 cm²) to commercial modules (>10 m²) introduces additional complexities in quality control and performance consistency.

Water management within FTMs presents another significant barrier. While some moisture is beneficial for carrier mobility, excessive water accumulation can lead to carrier dilution and reduced selectivity. Conversely, insufficient hydration can limit carrier effectiveness and transport mechanisms. This delicate balance is particularly challenging to maintain under the variable humidity conditions typical in real flue gas streams.

From a geographical perspective, FTM research is concentrated primarily in North America, Europe, and East Asia, with the United States, Germany, China, and Japan leading in patent filings and research publications. This distribution reflects both the technical capabilities and the regulatory environments driving carbon capture technology development globally. Notably, there is limited research activity in regions with emerging economies despite their growing carbon emissions, indicating a potential gap in technology transfer and adaptation.

State-of-the-Art FTM Solutions for CO2 Separation

01 Facilitated transport membranes for gas separation

Facilitated transport membranes utilize carrier molecules to selectively transport specific gas molecules across the membrane, enhancing separation efficiency. These membranes are particularly effective for separating gases like CO2, O2, and other industrial gases. The carrier molecules form reversible complexes with target gas molecules, facilitating their transport through the membrane while blocking other gases. This technology offers higher selectivity compared to conventional membranes and can be optimized for various gas separation applications.- Facilitated transport membranes for gas separation: Facilitated transport membranes utilize carrier molecules to selectively transport specific gas molecules across the membrane, enhancing separation efficiency. These membranes contain mobile or fixed carriers that reversibly react with target gas species, facilitating their transport while blocking other gases. This technology is particularly effective for separating gases with similar molecular sizes but different chemical properties, such as CO2/N2 or O2/N2 separations, offering higher selectivity than conventional membranes.

- Carbon dioxide capture using facilitated transport membranes: Specialized facilitated transport membranes have been developed for carbon dioxide capture applications. These membranes incorporate carriers such as amines or carbonate salts that selectively bind with CO2 molecules, enabling efficient separation from flue gases or natural gas streams. The membranes can achieve high CO2 permeability and selectivity, making them promising for industrial carbon capture and sequestration processes, as well as natural gas sweetening operations.

- Liquid membranes for facilitated transport: Liquid membranes represent a specific type of facilitated transport membrane where the carrier is dissolved in a liquid phase supported within a porous structure. These membranes can contain aqueous or organic solutions with carriers that selectively bind to target molecules. The liquid nature allows for higher diffusion rates and carrier mobility compared to solid membranes, potentially offering enhanced separation performance for various applications including gas separation, metal ion extraction, and pharmaceutical purification.

- Facilitated transport membranes for energy applications: Facilitated transport membranes have been applied in various energy-related technologies, including fuel cells, electrolyzers, and energy storage systems. These membranes can selectively transport ions or molecules critical for energy conversion processes, such as protons, oxygen ions, or specific redox species. By enhancing transport rates and selectivity, these membranes can improve energy efficiency, power density, and operational stability of energy conversion and storage devices.

- Biomimetic and biological facilitated transport membranes: Biomimetic facilitated transport membranes draw inspiration from biological systems, incorporating natural or synthetic components that mimic biological transport mechanisms. These membranes may utilize proteins, enzymes, or synthetic analogs as carriers to achieve highly selective and efficient transport. Applications include water purification, biosensors, drug delivery systems, and artificial organs. The biomimetic approach offers potential advantages in selectivity, efficiency, and biocompatibility compared to conventional synthetic membranes.

02 Liquid membranes with mobile carriers

Liquid membranes incorporate mobile carrier molecules dissolved in a liquid phase supported within a porous structure. These carriers can move freely within the membrane, allowing for enhanced mass transfer and transport rates. The liquid phase typically consists of solvents or ionic liquids that maintain carrier mobility while providing stability. This membrane type is particularly useful for separating gases and liquids in industrial processes, offering advantages in terms of flux and selectivity compared to solid membranes with fixed carriers.Expand Specific Solutions03 Fixed-site carrier membranes

Fixed-site carrier membranes feature transport agents that are chemically bound to the membrane matrix rather than being mobile within it. This design prevents carrier leaching and enhances membrane stability over time. The fixed carriers maintain their functionality while being immobilized, allowing for selective transport of target molecules through specific binding interactions. These membranes are particularly valuable in applications requiring long-term stability and consistent separation performance under challenging operating conditions.Expand Specific Solutions04 Facilitated transport membranes for water purification

Facilitated transport membranes designed for water purification applications utilize specific carriers to selectively remove contaminants from water streams. These membranes can target heavy metals, organic pollutants, or specific ions through carrier-mediated transport mechanisms. The membrane composition typically includes hydrophilic polymers with incorporated functional groups that facilitate the transport of water molecules while rejecting contaminants. This technology offers advantages in desalination, wastewater treatment, and the removal of specific pollutants from drinking water sources.Expand Specific Solutions05 Biomimetic facilitated transport membranes

Biomimetic facilitated transport membranes draw inspiration from biological transport systems, incorporating protein channels, enzymes, or synthetic analogs of biological carriers. These membranes mimic the highly selective and efficient transport mechanisms found in cell membranes. By incorporating biological components or their synthetic equivalents, these membranes achieve exceptional selectivity for specific molecules. Applications include biosensors, controlled drug delivery systems, and specialized separation processes requiring molecular-level discrimination between similar compounds.Expand Specific Solutions

Leading Organizations in FTM Research and Commercialization

The post-combustion carbon capture membrane technology market is currently in a growth phase, with increasing demand driven by global decarbonization efforts. The facilitated transport membrane sector represents a specialized segment with significant potential for efficiency improvements over conventional technologies. Key players include established research institutions like KIST Corp. (South Korea) and Dalian Institute of Chemical Physics, alongside commercial entities such as Membrane Technology & Research, Inc., Airrane Co., and UOP LLC. The competitive landscape features collaboration between academic institutions (Southeast University, University of Cincinnati) and industrial partners (PETRONAS, China Petroleum & Chemical Corp.), focusing on membrane performance enhancement, cost reduction, and scalability. The technology remains in mid-maturity stage, with ongoing R&D efforts to address selectivity, permeability, and long-term stability challenges before widespread commercial deployment.

UOP LLC

Technical Solution: UOP LLC (a Honeywell company) has developed advanced facilitated transport membranes for post-combustion CO2 capture utilizing their extensive experience in gas separation technologies. Their proprietary membrane system incorporates fixed-site carriers within a polymer matrix that selectively binds with CO2 molecules, facilitating their transport across the membrane. UOP's technology employs a composite membrane structure with an ultrathin selective layer (approximately 0.2-0.5 μm) supported on a porous substrate, optimized for industrial-scale applications. The membrane chemistry includes specially designed amino-functional groups that create reversible interactions with CO2, enabling separation factors exceeding 80 for CO2/N2 while maintaining high permeance (>1000 GPU). UOP has integrated these membranes into their modular separation systems that can be retrofitted to existing power plants with minimal modifications. Their technology has been demonstrated at pilot scale, processing actual flue gas streams with CO2 capture rates above 85% while consuming significantly less energy than conventional amine scrubbing processes. UOP's facilitated transport membranes are designed to maintain performance stability even in the presence of common flue gas contaminants.

Strengths: Extensive industrial deployment experience, robust membrane manufacturing capabilities, and integrated system approach that addresses practical implementation challenges. Weaknesses: Higher initial capital investment compared to some competing technologies, potential for performance degradation in the presence of certain flue gas impurities, and requires precise control of operating conditions to maintain optimal separation efficiency.

Airrane Co., Ltd.

Technical Solution: Airrane Co., Ltd. has developed proprietary facilitated transport membranes for post-combustion CO2 capture based on their patented fixed-carrier technology. Their approach incorporates specially designed amino-functional groups covalently bonded to polymer backbones, creating permanent CO2-selective pathways within the membrane structure. Airrane's membranes utilize a composite structure with an ultrathin selective layer (typically 0.3-0.8 μm) on a highly porous support, optimized for maximum flux while maintaining mechanical integrity. Their technology employs a unique cross-linking method that enhances both the stability and separation performance of the membranes, achieving CO2 permeance values of 1200-1800 GPU with CO2/N2 selectivity of 80-120 under actual flue gas conditions. Airrane has successfully scaled their manufacturing process to produce large-area membrane modules in both flat-sheet and hollow-fiber configurations. Their membranes have demonstrated remarkable resistance to plasticization and competitive sorption effects that typically plague conventional polymeric membranes in mixed-gas environments. Field tests at power plants have shown that Airrane's facilitated transport membranes can maintain stable performance for over 3000 hours of continuous operation with minimal performance degradation, even in the presence of trace contaminants like SOx and NOx.

Strengths: Highly scalable manufacturing process, excellent long-term stability in real operating conditions, and superior resistance to contaminant-induced performance degradation. Weaknesses: Optimal performance requires careful control of feed gas humidity, higher production costs compared to conventional membranes, and potential for reduced efficiency at very high or low operating temperatures.

Critical Patents and Scientific Advances in FTM Technology

Facilitated transport membranes

PatentInactiveEP1466660B1

Innovation

- A facilitated transport membrane is developed using a solid polymer electrolyte composed of a transition metal salt and a polymer with double carbon bonds, which forms a π-complex with the metal ion, allowing selective and reversible interaction with alkene hydrocarbons, maintaining activity even under long-term dry conditions without the need for solvents.

Self-forming membrane for high flux and selective electrochemistry-based co2 capture

PatentActiveUS20190022576A1

Innovation

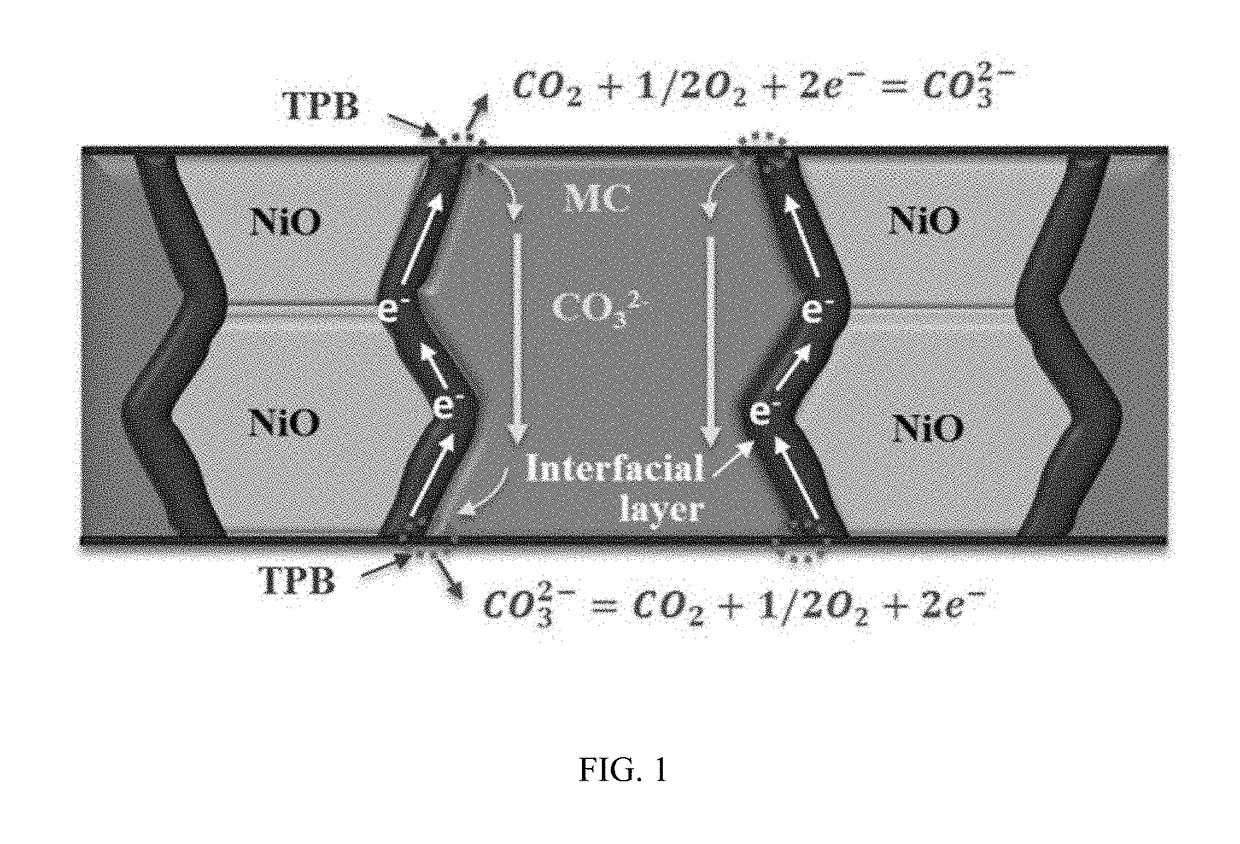

- A mixed electron and carbon-ion conductor membrane with a solid porous matrix, molten carbonate phase, and a self-formed lithiated metal oxide interphase, using nickel oxide as the electron conducting phase, which is cost-effective and stable at high temperatures.

Environmental Impact and Sustainability Assessment

The implementation of facilitated transport membranes for post-combustion carbon capture represents a significant advancement in environmental protection technologies. These membranes offer substantial environmental benefits compared to conventional carbon capture methods, particularly amine-based absorption systems which are energy-intensive and require hazardous chemicals. Facilitated transport membranes can reduce the overall energy penalty of carbon capture by up to 30%, translating to lower fossil fuel consumption and reduced greenhouse gas emissions from power generation facilities.

From a life cycle assessment perspective, facilitated transport membranes demonstrate favorable environmental profiles. The production phase involves lower environmental impacts than traditional capture technologies, with reduced requirements for raw materials and less intensive manufacturing processes. The operational phase shows particular promise, with minimal chemical waste generation and significantly lower water consumption compared to solvent-based systems which typically require substantial cooling water.

The sustainability advantages extend to resource efficiency considerations. These membranes generally have longer operational lifespans than conventional absorption materials, reducing replacement frequency and associated material consumption. Additionally, many facilitated transport membrane designs incorporate environmentally benign materials, moving away from the toxic and corrosive chemicals common in traditional capture systems.

When evaluating carbon footprint metrics, facilitated transport membrane systems demonstrate net positive carbon balances even when accounting for membrane production emissions. Studies indicate that for every ton of CO2 captured, the embodied carbon in membrane production represents less than 5% of the total, ensuring strong climate mitigation benefits throughout the technology lifecycle.

Water usage represents another critical environmental dimension where these membranes excel. Unlike conventional wet scrubbing technologies that consume 1-2 tons of water per ton of CO2 captured, membrane-based systems operate with minimal water requirements, an increasingly important consideration in water-stressed regions where power generation facilities often operate.

The end-of-life management of facilitated transport membranes presents both challenges and opportunities. Current research focuses on developing recyclable membrane materials and environmentally responsible disposal methods. Some promising approaches include the recovery of valuable carrier compounds and the development of biodegradable support structures that minimize landfill impacts.

Overall, facilitated transport membranes align strongly with sustainable development principles by offering a pathway to decarbonization that minimizes collateral environmental impacts. Their continued development and deployment could significantly contribute to meeting climate goals while maintaining ecological integrity across multiple environmental indicators.

From a life cycle assessment perspective, facilitated transport membranes demonstrate favorable environmental profiles. The production phase involves lower environmental impacts than traditional capture technologies, with reduced requirements for raw materials and less intensive manufacturing processes. The operational phase shows particular promise, with minimal chemical waste generation and significantly lower water consumption compared to solvent-based systems which typically require substantial cooling water.

The sustainability advantages extend to resource efficiency considerations. These membranes generally have longer operational lifespans than conventional absorption materials, reducing replacement frequency and associated material consumption. Additionally, many facilitated transport membrane designs incorporate environmentally benign materials, moving away from the toxic and corrosive chemicals common in traditional capture systems.

When evaluating carbon footprint metrics, facilitated transport membrane systems demonstrate net positive carbon balances even when accounting for membrane production emissions. Studies indicate that for every ton of CO2 captured, the embodied carbon in membrane production represents less than 5% of the total, ensuring strong climate mitigation benefits throughout the technology lifecycle.

Water usage represents another critical environmental dimension where these membranes excel. Unlike conventional wet scrubbing technologies that consume 1-2 tons of water per ton of CO2 captured, membrane-based systems operate with minimal water requirements, an increasingly important consideration in water-stressed regions where power generation facilities often operate.

The end-of-life management of facilitated transport membranes presents both challenges and opportunities. Current research focuses on developing recyclable membrane materials and environmentally responsible disposal methods. Some promising approaches include the recovery of valuable carrier compounds and the development of biodegradable support structures that minimize landfill impacts.

Overall, facilitated transport membranes align strongly with sustainable development principles by offering a pathway to decarbonization that minimizes collateral environmental impacts. Their continued development and deployment could significantly contribute to meeting climate goals while maintaining ecological integrity across multiple environmental indicators.

Economic Viability and Scale-up Considerations

The economic viability of facilitated transport membranes (FTMs) for post-combustion carbon capture represents a critical factor in their potential industrial adoption. Current cost analyses indicate that FTM technology could achieve capture costs between $30-50 per ton of CO2, which compares favorably with conventional amine scrubbing technologies that typically range from $40-80 per ton. However, these projections remain largely theoretical as most FTM systems have not been demonstrated beyond laboratory or small pilot scales.

Capital expenditure considerations for FTM implementation include membrane module fabrication, supporting infrastructure, and integration with existing power plants. The membrane material costs vary significantly depending on the carrier compounds used, with metal-organic frameworks and ionic liquids representing higher initial investments but potentially offering superior long-term performance. Operating expenses are dominated by energy requirements for maintaining optimal temperature and pressure differentials, replacement of degraded membrane components, and system maintenance.

Scale-up of FTM technology faces several engineering challenges that directly impact economic feasibility. The membrane surface area required for industrial-scale carbon capture is substantial, necessitating efficient module designs that maximize surface-to-volume ratios while minimizing pressure drops. Current estimates suggest that a 500 MW coal-fired power plant would require approximately 100,000-200,000 m² of membrane area, presenting significant manufacturing and installation challenges.

Membrane stability under real flue gas conditions remains a primary concern for long-term economic viability. Contaminants such as SOx, NOx, and particulate matter can rapidly degrade carrier compounds, reducing separation efficiency and necessitating more frequent membrane replacement. Economic models indicate that achieving membrane lifespans of at least 3-5 years is necessary for competitive operational costs, yet many current FTM formulations demonstrate significant performance degradation after only months of operation.

Manufacturing scalability presents another economic hurdle. Current laboratory-scale production methods for high-performance FTMs often involve complex synthesis procedures that are difficult to translate to industrial-scale manufacturing. Roll-to-roll processing shows promise for thin-film composite membranes, but carrier immobilization techniques that maintain high facilitation factors at scale remain challenging to implement cost-effectively.

Integration with existing power infrastructure represents a significant capital consideration. Retrofit applications typically incur 20-30% higher costs than new-build installations due to space constraints and the need for custom engineering solutions. However, the modular nature of membrane systems potentially allows for phased implementation, distributing capital costs over longer timeframes compared to alternative capture technologies.

Capital expenditure considerations for FTM implementation include membrane module fabrication, supporting infrastructure, and integration with existing power plants. The membrane material costs vary significantly depending on the carrier compounds used, with metal-organic frameworks and ionic liquids representing higher initial investments but potentially offering superior long-term performance. Operating expenses are dominated by energy requirements for maintaining optimal temperature and pressure differentials, replacement of degraded membrane components, and system maintenance.

Scale-up of FTM technology faces several engineering challenges that directly impact economic feasibility. The membrane surface area required for industrial-scale carbon capture is substantial, necessitating efficient module designs that maximize surface-to-volume ratios while minimizing pressure drops. Current estimates suggest that a 500 MW coal-fired power plant would require approximately 100,000-200,000 m² of membrane area, presenting significant manufacturing and installation challenges.

Membrane stability under real flue gas conditions remains a primary concern for long-term economic viability. Contaminants such as SOx, NOx, and particulate matter can rapidly degrade carrier compounds, reducing separation efficiency and necessitating more frequent membrane replacement. Economic models indicate that achieving membrane lifespans of at least 3-5 years is necessary for competitive operational costs, yet many current FTM formulations demonstrate significant performance degradation after only months of operation.

Manufacturing scalability presents another economic hurdle. Current laboratory-scale production methods for high-performance FTMs often involve complex synthesis procedures that are difficult to translate to industrial-scale manufacturing. Roll-to-roll processing shows promise for thin-film composite membranes, but carrier immobilization techniques that maintain high facilitation factors at scale remain challenging to implement cost-effectively.

Integration with existing power infrastructure represents a significant capital consideration. Retrofit applications typically incur 20-30% higher costs than new-build installations due to space constraints and the need for custom engineering solutions. However, the modular nature of membrane systems potentially allows for phased implementation, distributing capital costs over longer timeframes compared to alternative capture technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!