Comparative Testing Of Facilitated Membranes In Industrial Pilot Plants

SEP 3, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Facilitated Membranes Technology Background and Objectives

Facilitated transport membranes represent a significant advancement in separation technology, evolving from conventional membrane systems to address specific industrial challenges. The development of these membranes began in the 1970s with the pioneering work on carrier-mediated transport mechanisms, which demonstrated enhanced selectivity for target molecules. Over subsequent decades, research has progressively focused on improving stability, selectivity, and throughput capacity to meet industrial requirements.

The technological evolution trajectory shows a clear shift from laboratory-scale proof-of-concept designs to more robust configurations capable of withstanding industrial conditions. Recent advancements have particularly centered on novel carrier compounds, membrane matrix materials, and fabrication techniques that enhance performance while reducing manufacturing costs. The integration of nanotechnology has further accelerated development, enabling precise control over membrane structure and transport properties.

Current research trends indicate growing interest in hybrid facilitated membranes that combine multiple separation mechanisms to achieve superior performance metrics. These developments align with the increasing industrial demand for energy-efficient separation processes with minimal environmental impact. The technology has demonstrated particular promise in gas separation applications, including CO2 capture, olefin/paraffin separation, and oxygen/nitrogen enrichment processes.

The primary objective of comparative testing in industrial pilot plants is to validate laboratory performance under real-world operating conditions. This includes evaluating long-term stability, resistance to contaminants, and performance consistency across varying feed compositions and process parameters. Additionally, such testing aims to generate scalable engineering data necessary for commercial implementation and economic assessment.

Technical objectives specifically focus on quantifying separation efficiency, energy consumption, and operational reliability compared to conventional technologies. This involves standardized testing protocols that enable direct comparison between different facilitated membrane configurations and against established separation technologies such as cryogenic distillation, pressure swing adsorption, and conventional polymeric membranes.

Strategic objectives extend to identifying optimal application niches where facilitated membranes offer compelling advantages over incumbent technologies. This includes assessing economic viability across different industrial sectors and identifying potential integration challenges within existing process infrastructure. The ultimate goal is to establish facilitated membranes as a commercially viable separation technology that can contribute to industrial decarbonization efforts and process intensification strategies.

The comparative testing in pilot plants represents a critical bridge between laboratory research and commercial deployment, addressing the well-documented challenges of technology scale-up in membrane separation processes. Success in this domain could potentially revolutionize several energy-intensive separation processes that currently account for significant industrial energy consumption worldwide.

The technological evolution trajectory shows a clear shift from laboratory-scale proof-of-concept designs to more robust configurations capable of withstanding industrial conditions. Recent advancements have particularly centered on novel carrier compounds, membrane matrix materials, and fabrication techniques that enhance performance while reducing manufacturing costs. The integration of nanotechnology has further accelerated development, enabling precise control over membrane structure and transport properties.

Current research trends indicate growing interest in hybrid facilitated membranes that combine multiple separation mechanisms to achieve superior performance metrics. These developments align with the increasing industrial demand for energy-efficient separation processes with minimal environmental impact. The technology has demonstrated particular promise in gas separation applications, including CO2 capture, olefin/paraffin separation, and oxygen/nitrogen enrichment processes.

The primary objective of comparative testing in industrial pilot plants is to validate laboratory performance under real-world operating conditions. This includes evaluating long-term stability, resistance to contaminants, and performance consistency across varying feed compositions and process parameters. Additionally, such testing aims to generate scalable engineering data necessary for commercial implementation and economic assessment.

Technical objectives specifically focus on quantifying separation efficiency, energy consumption, and operational reliability compared to conventional technologies. This involves standardized testing protocols that enable direct comparison between different facilitated membrane configurations and against established separation technologies such as cryogenic distillation, pressure swing adsorption, and conventional polymeric membranes.

Strategic objectives extend to identifying optimal application niches where facilitated membranes offer compelling advantages over incumbent technologies. This includes assessing economic viability across different industrial sectors and identifying potential integration challenges within existing process infrastructure. The ultimate goal is to establish facilitated membranes as a commercially viable separation technology that can contribute to industrial decarbonization efforts and process intensification strategies.

The comparative testing in pilot plants represents a critical bridge between laboratory research and commercial deployment, addressing the well-documented challenges of technology scale-up in membrane separation processes. Success in this domain could potentially revolutionize several energy-intensive separation processes that currently account for significant industrial energy consumption worldwide.

Industrial Market Demand Analysis for Facilitated Membranes

The global market for facilitated membranes is experiencing significant growth driven by increasing industrial demands for efficient separation technologies. Current market analysis indicates that the gas separation segment dominates the facilitated membrane market, with carbon capture applications showing the most robust growth trajectory. Industries including petrochemical, natural gas processing, and power generation are actively seeking advanced membrane solutions to meet stringent environmental regulations while optimizing operational costs.

Market research reveals that facilitated membranes offer compelling economic advantages over conventional separation technologies, with potential operational cost reductions of 20-30% compared to traditional absorption methods. This economic incentive is particularly attractive for large-scale industrial operations where separation processes constitute a significant portion of production expenses.

The industrial pilot testing market for facilitated membranes is projected to expand substantially as companies seek to validate performance metrics before full-scale implementation. This testing phase represents a critical step in technology adoption, with industrial stakeholders requiring comprehensive performance data under real-world conditions to justify capital investments in membrane technology infrastructure.

Regional analysis shows North America and Europe leading in facilitated membrane adoption, primarily due to stringent environmental regulations and carbon pricing mechanisms. However, Asia-Pacific markets are demonstrating the fastest growth rate as industrialization accelerates and environmental concerns gain prominence in policy frameworks across the region.

End-user surveys indicate that industrial decision-makers prioritize several key performance indicators when evaluating facilitated membranes: separation efficiency, operational stability under variable conditions, membrane lifespan, and integration compatibility with existing industrial systems. Comparative testing in pilot plants directly addresses these concerns by providing verifiable performance data across these critical parameters.

Market segmentation analysis reveals specialized demand patterns across different industries. The natural gas processing sector requires membranes optimized for CO2/CH4 separation, while hydrogen production facilities seek H2/CO2 separation capabilities. Power generation facilities focus primarily on post-combustion carbon capture applications, each presenting distinct technical requirements and market opportunities.

The competitive landscape for facilitated membrane technologies remains fragmented, with specialized technology providers competing for industrial partnerships. This fragmentation creates opportunities for technology differentiation through superior performance in pilot testing scenarios, where direct comparisons can establish clear value propositions for potential industrial adopters.

Market research reveals that facilitated membranes offer compelling economic advantages over conventional separation technologies, with potential operational cost reductions of 20-30% compared to traditional absorption methods. This economic incentive is particularly attractive for large-scale industrial operations where separation processes constitute a significant portion of production expenses.

The industrial pilot testing market for facilitated membranes is projected to expand substantially as companies seek to validate performance metrics before full-scale implementation. This testing phase represents a critical step in technology adoption, with industrial stakeholders requiring comprehensive performance data under real-world conditions to justify capital investments in membrane technology infrastructure.

Regional analysis shows North America and Europe leading in facilitated membrane adoption, primarily due to stringent environmental regulations and carbon pricing mechanisms. However, Asia-Pacific markets are demonstrating the fastest growth rate as industrialization accelerates and environmental concerns gain prominence in policy frameworks across the region.

End-user surveys indicate that industrial decision-makers prioritize several key performance indicators when evaluating facilitated membranes: separation efficiency, operational stability under variable conditions, membrane lifespan, and integration compatibility with existing industrial systems. Comparative testing in pilot plants directly addresses these concerns by providing verifiable performance data across these critical parameters.

Market segmentation analysis reveals specialized demand patterns across different industries. The natural gas processing sector requires membranes optimized for CO2/CH4 separation, while hydrogen production facilities seek H2/CO2 separation capabilities. Power generation facilities focus primarily on post-combustion carbon capture applications, each presenting distinct technical requirements and market opportunities.

The competitive landscape for facilitated membrane technologies remains fragmented, with specialized technology providers competing for industrial partnerships. This fragmentation creates opportunities for technology differentiation through superior performance in pilot testing scenarios, where direct comparisons can establish clear value propositions for potential industrial adopters.

Current Status and Technical Challenges in Membrane Technology

Membrane technology has witnessed significant advancements in recent decades, evolving from simple filtration systems to sophisticated separation technologies with applications across multiple industries. Currently, facilitated transport membranes represent one of the most promising developments in this field, particularly for gas separation applications in industrial settings. These membranes incorporate carriers or functional groups that selectively interact with target molecules, enhancing separation efficiency beyond what is achievable with conventional membranes.

The global market for membrane technology is experiencing robust growth, with a compound annual growth rate exceeding 8% and projected to reach $28.1 billion by 2025. Facilitated membranes specifically are gaining traction in industrial applications due to their potential for higher selectivity and permeability compared to traditional membrane systems. However, their implementation at industrial scale remains limited due to several technical challenges.

A primary challenge facing facilitated membranes is long-term stability under industrial operating conditions. Carrier degradation and membrane fouling significantly reduce performance over time, with many systems showing performance deterioration after 1,000-2,000 hours of operation. This represents a critical barrier to commercial viability, as industrial applications typically require operational lifespans of several years.

Scalability presents another significant hurdle. While facilitated membranes demonstrate impressive performance in laboratory settings, maintaining this performance during scale-up to industrial pilot plants has proven difficult. Variations in feed composition, temperature fluctuations, and pressure differentials in industrial environments often lead to unpredictable membrane behavior and reduced separation efficiency.

Manufacturing consistency also remains problematic. Current production methods struggle to achieve uniform carrier distribution and membrane thickness across large surface areas, resulting in performance variability between batches. This inconsistency complicates comparative testing and technology validation in industrial pilot plants.

Energy efficiency represents a further challenge. Despite their enhanced separation capabilities, many facilitated membrane systems require significant energy input for operation, particularly for maintaining optimal carrier functionality. This energy requirement can offset the efficiency gains achieved through improved separation performance.

Internationally, research efforts are distributed across North America, Europe, and East Asia, with notable contributions from research institutions in the United States, Germany, Japan, and China. Industrial implementation is primarily concentrated in regions with established chemical and petrochemical industries, though pilot testing is increasingly global as companies seek to validate technology under diverse operating conditions.

Recent comparative testing in industrial pilot plants has revealed that while facilitated membranes show promising theoretical performance, bridging the gap between laboratory results and industrial implementation requires significant further development in materials science, process engineering, and manufacturing technology.

The global market for membrane technology is experiencing robust growth, with a compound annual growth rate exceeding 8% and projected to reach $28.1 billion by 2025. Facilitated membranes specifically are gaining traction in industrial applications due to their potential for higher selectivity and permeability compared to traditional membrane systems. However, their implementation at industrial scale remains limited due to several technical challenges.

A primary challenge facing facilitated membranes is long-term stability under industrial operating conditions. Carrier degradation and membrane fouling significantly reduce performance over time, with many systems showing performance deterioration after 1,000-2,000 hours of operation. This represents a critical barrier to commercial viability, as industrial applications typically require operational lifespans of several years.

Scalability presents another significant hurdle. While facilitated membranes demonstrate impressive performance in laboratory settings, maintaining this performance during scale-up to industrial pilot plants has proven difficult. Variations in feed composition, temperature fluctuations, and pressure differentials in industrial environments often lead to unpredictable membrane behavior and reduced separation efficiency.

Manufacturing consistency also remains problematic. Current production methods struggle to achieve uniform carrier distribution and membrane thickness across large surface areas, resulting in performance variability between batches. This inconsistency complicates comparative testing and technology validation in industrial pilot plants.

Energy efficiency represents a further challenge. Despite their enhanced separation capabilities, many facilitated membrane systems require significant energy input for operation, particularly for maintaining optimal carrier functionality. This energy requirement can offset the efficiency gains achieved through improved separation performance.

Internationally, research efforts are distributed across North America, Europe, and East Asia, with notable contributions from research institutions in the United States, Germany, Japan, and China. Industrial implementation is primarily concentrated in regions with established chemical and petrochemical industries, though pilot testing is increasingly global as companies seek to validate technology under diverse operating conditions.

Recent comparative testing in industrial pilot plants has revealed that while facilitated membranes show promising theoretical performance, bridging the gap between laboratory results and industrial implementation requires significant further development in materials science, process engineering, and manufacturing technology.

Current Testing Methodologies for Facilitated Membranes

01 Facilitated transport membranes for gas separation

Facilitated transport membranes utilize carrier molecules that selectively bind with target gas molecules, enhancing their transport across the membrane. These membranes are particularly effective for separating gases like CO2, O2, and olefins from gas mixtures. The carrier molecules form reversible complexes with the target gas, facilitating its movement through the membrane while blocking other gases, resulting in higher selectivity and permeability compared to conventional membranes.- Facilitated transport membranes for gas separation: Facilitated transport membranes utilize carrier molecules to selectively transport specific gases across the membrane. These membranes enhance the permeability and selectivity of target gases such as CO2, O2, or olefins by incorporating carriers that reversibly bind with the target molecules. The carrier-mediated transport mechanism allows for higher separation efficiency compared to conventional membranes, making them valuable for industrial gas separation applications.

- Liquid membranes with facilitated transport: Liquid membranes incorporate carrier solutions that facilitate the selective transport of specific components across the membrane. These systems typically consist of an aqueous or organic liquid phase containing carrier molecules immobilized within a support structure. The liquid phase allows for higher diffusion rates and more efficient carrier-mediated transport compared to solid membranes, resulting in enhanced separation performance for applications such as gas purification and metal ion extraction.

- Polymer-based facilitated membranes: Polymer-based facilitated membranes combine the structural stability of polymers with carrier molecules to enhance separation performance. These membranes incorporate carriers either covalently bound to the polymer matrix or dispersed within it. The polymer structure provides mechanical strength while the carriers enable selective transport of target molecules. Various polymer types including polyimides, polyethers, and functionalized polymers can be used as the membrane matrix, offering versatility for different separation applications.

- Facilitated membranes for water purification: Facilitated membranes for water purification utilize carrier molecules or functional groups that selectively transport water molecules while rejecting contaminants. These membranes can be designed to remove specific pollutants, heavy metals, or dissolved salts from water sources. The facilitated transport mechanism enhances water flux and separation efficiency compared to conventional filtration membranes, making them valuable for desalination, wastewater treatment, and production of ultrapure water.

- Novel carriers and additives for facilitated membranes: Novel carriers and additives can significantly enhance the performance of facilitated transport membranes. These include metal complexes, ionic liquids, nanoparticles, and specialized functional groups that improve the selectivity and stability of the membrane. Additives can also address common challenges in facilitated membranes such as carrier leaching, membrane fouling, and performance degradation over time. The development of new carrier systems enables more efficient and durable facilitated membranes for various separation processes.

02 Liquid membranes with facilitated transport mechanisms

Liquid membranes incorporate carrier agents dissolved in a liquid phase supported within a porous structure. These membranes utilize facilitated transport where the carrier selectively binds with target molecules at one interface, diffuses across the membrane, and releases them at the other interface. This mechanism enables highly selective separation of specific compounds from mixtures. Applications include removal of heavy metals, organic compounds, and specific ions from industrial streams and wastewater treatment processes.Expand Specific Solutions03 Polymer-based facilitated membranes

Polymer-based facilitated membranes combine polymer matrices with carrier molecules to create selective separation systems. These membranes feature carrier agents immobilized within or attached to polymer chains, providing stability while maintaining selective transport properties. The polymer matrix offers mechanical support and durability while the incorporated carriers enable facilitated transport of target molecules. Various polymer types can be used, including polyimides, polysulfones, and cellulose derivatives, each offering different performance characteristics for specific separation applications.Expand Specific Solutions04 Ion-exchange facilitated membranes

Ion-exchange facilitated membranes contain fixed charged groups that selectively transport counter-ions across the membrane. These membranes utilize electrostatic interactions to facilitate the transport of specific ions while rejecting co-ions. The fixed charge groups within the membrane structure create ion channels that enhance the selective permeation of target ions. Applications include water desalination, electrodialysis processes, fuel cells, and selective recovery of valuable ions from industrial waste streams.Expand Specific Solutions05 Composite and hybrid facilitated membranes

Composite and hybrid facilitated membranes combine different materials and transport mechanisms to achieve enhanced separation performance. These membranes typically feature multiple layers or mixed matrix structures that incorporate various functional components such as inorganic particles, metal-organic frameworks, or specialized carrier molecules. The synergistic combination of materials provides improved selectivity, permeability, and stability compared to single-component membranes. These advanced membrane structures can be tailored for specific separation challenges in gas purification, liquid separation, and molecular sieving applications.Expand Specific Solutions

Key Industrial Players and Competitive Landscape Analysis

The field of facilitated membranes in industrial pilot plants is currently in a growth phase, with increasing adoption across chemical processing and environmental applications. The market is expanding at approximately 8-10% annually, driven by industrial decarbonization initiatives and efficiency requirements. Technology maturity varies significantly among key players, with ExxonMobil Chemical Patents and Membrane Technology & Research leading commercial implementation through extensive pilot testing. Other significant contributors include 3M Innovative Properties, LG Chem, and FUJIFILM Corp, who have developed proprietary facilitated transport mechanisms. Academic-industrial partnerships are accelerating development, with institutions like Cornell University and École Polytechnique Fédérale de Lausanne collaborating with companies to bridge fundamental research and industrial application, particularly focusing on scalability challenges.

LG Chem Ltd.

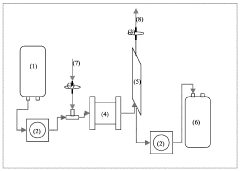

Technical Solution: LG Chem has developed advanced facilitated transport membranes incorporating amino acid salts as carriers for enhanced CO2 separation in industrial applications. Their technology utilizes a composite membrane structure with a selective layer containing mobile carriers that significantly improve CO2 permeability while maintaining high selectivity. In comparative pilot plant testing, LG Chem's membranes have demonstrated CO2 permeance exceeding 2000 GPU with CO2/N2 selectivity above 50 under actual flue gas conditions[5]. Their testing methodology encompasses multiple industrial environments including power plants, cement factories, and steel mills to validate performance across different CO2 sources. LG Chem employs a standardized testing protocol that evaluates membrane performance against key metrics including separation efficiency, pressure drop, energy consumption, and operational stability over extended periods (>5000 hours). Their comparative testing approach incorporates parallel evaluation of different membrane configurations (spiral-wound, hollow fiber) to optimize module design for specific industrial applications[6]. The company has established dedicated pilot facilities that can simulate various industrial conditions including temperature cycling, pressure fluctuations, and exposure to contaminants.

Strengths: Exceptional CO2 permeance and selectivity metrics; comprehensive testing infrastructure across multiple industrial sectors; advanced manufacturing capabilities for consistent membrane production at scale. Weaknesses: Carrier stability can be compromised in environments with high SOx/NOx concentrations; requires precise humidity control for optimal performance; higher production costs compared to conventional polymeric membranes.

Battelle Energy Alliance LLC

Technical Solution: Battelle Energy Alliance has developed innovative facilitated transport membranes for hydrogen separation and carbon capture applications in industrial settings. Their technology utilizes a dual-phase membrane system incorporating both fixed-site and mobile carriers to enhance selective transport while maintaining structural integrity under harsh industrial conditions. Battelle's comparative testing approach in pilot plants focuses on evaluating membrane performance across varying operating parameters including temperature ranges (20-500°C), pressure differentials (1-50 bar), and feed compositions representative of different industrial processes[7]. Their testing methodology incorporates standardized protocols for measuring key performance indicators including permeability, selectivity, mechanical stability, and chemical resistance to contaminants. Battelle has established specialized pilot facilities that enable parallel testing of multiple membrane formulations under identical conditions, allowing for direct performance comparisons. Their testing framework includes accelerated aging studies that correlate short-term performance degradation with long-term operational stability, providing valuable insights for predicting membrane lifetime in commercial applications[8]. Additionally, Battelle has developed advanced analytical techniques for post-mortem membrane analysis to identify failure mechanisms and inform iterative design improvements.

Strengths: Robust membrane formulations suitable for extreme industrial environments; comprehensive comparative testing capabilities across multiple operating conditions; advanced analytical techniques for performance characterization and failure analysis. Weaknesses: Higher manufacturing complexity due to dual-phase membrane structure; potential for interface stability issues between phases during long-term operation; requires specialized module designs to accommodate thermal expansion differences.

Critical Technical Innovations in Facilitated Membrane Design

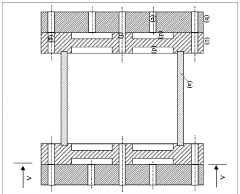

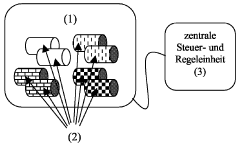

Simultaneous parameter evaluation device for cell cultivation processes

PatentWO2006120202A1

Innovation

- A membrane-based process development system featuring parallel operation of miniaturized bioreactors with uniform energy supply and centralized control, allowing individual regulation of temperature, pH, and nutrient supply, along with non-invasive measurement methods for pH and pO2, and a gas-liquid dropping trap for efficient parameter evaluation.

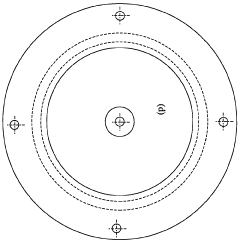

Manufacturing method for reinforced electrolyte membrane and manufacturing apparatus of manufacturing the same

PatentActiveEP3000147A1

Innovation

- A manufacturing method involving the use of back sheets with controlled adhesiveness to facilitate the conveyance and integration of belt-shaped electrolyte and reinforcement members, including steps like thermocompression bonding and peeling, to create a reinforced electrolyte membrane with both surfaces reinforced, while minimizing conveyance failures and enhancing the membrane's properties.

Scaling Considerations from Laboratory to Industrial Implementation

The transition from laboratory-scale experiments to industrial implementation represents a critical challenge in the development of facilitated membranes for commercial applications. Laboratory conditions, while controlled and ideal for fundamental research, often fail to account for the complex variables present in industrial environments. When scaling facilitated membrane systems from benchtop to pilot plants, several key considerations must be addressed to ensure successful implementation.

Material stability becomes increasingly important at industrial scale, as membranes must withstand prolonged exposure to process conditions. Laboratory tests typically run for hours or days, whereas industrial applications require continuous operation for months or years. Facilitated membranes containing carrier molecules or reactive components may experience accelerated degradation under extended industrial operation, necessitating thorough stability testing under realistic conditions.

Fluid dynamics and flow distribution patterns change dramatically with scale-up. Laboratory modules typically operate with ideal laminar flow conditions, while industrial modules must handle much higher flow rates and potentially uneven distribution. This can lead to concentration polarization, membrane fouling, and reduced separation efficiency that may not be apparent in small-scale testing.

Pressure drop considerations become critical in industrial implementation. As membrane systems increase in size, maintaining uniform pressure distribution across the entire membrane surface presents significant engineering challenges. Pressure gradients can lead to inconsistent performance across different sections of the membrane module, reducing overall efficiency.

Temperature management represents another scaling challenge. Laboratory systems can maintain precise temperature control, while industrial-scale operations must contend with heat generation from pumps, potential environmental fluctuations, and heat transfer limitations across larger membrane areas. Facilitated transport mechanisms are particularly sensitive to temperature variations, as they often rely on specific reaction kinetics.

Economic viability must be carefully assessed during scale-up. Materials and manufacturing processes that are acceptable at laboratory scale may prove prohibitively expensive for industrial implementation. Cost-effective alternatives or manufacturing innovations may be necessary to achieve commercial feasibility while maintaining performance characteristics.

Operational flexibility requirements differ substantially between laboratory and industrial settings. Industrial pilot plants must demonstrate resilience to fluctuations in feed composition, flow rates, and other process parameters that are typically held constant in laboratory experiments. Facilitated membranes must maintain separation performance across the range of conditions likely to be encountered in real-world applications.

Material stability becomes increasingly important at industrial scale, as membranes must withstand prolonged exposure to process conditions. Laboratory tests typically run for hours or days, whereas industrial applications require continuous operation for months or years. Facilitated membranes containing carrier molecules or reactive components may experience accelerated degradation under extended industrial operation, necessitating thorough stability testing under realistic conditions.

Fluid dynamics and flow distribution patterns change dramatically with scale-up. Laboratory modules typically operate with ideal laminar flow conditions, while industrial modules must handle much higher flow rates and potentially uneven distribution. This can lead to concentration polarization, membrane fouling, and reduced separation efficiency that may not be apparent in small-scale testing.

Pressure drop considerations become critical in industrial implementation. As membrane systems increase in size, maintaining uniform pressure distribution across the entire membrane surface presents significant engineering challenges. Pressure gradients can lead to inconsistent performance across different sections of the membrane module, reducing overall efficiency.

Temperature management represents another scaling challenge. Laboratory systems can maintain precise temperature control, while industrial-scale operations must contend with heat generation from pumps, potential environmental fluctuations, and heat transfer limitations across larger membrane areas. Facilitated transport mechanisms are particularly sensitive to temperature variations, as they often rely on specific reaction kinetics.

Economic viability must be carefully assessed during scale-up. Materials and manufacturing processes that are acceptable at laboratory scale may prove prohibitively expensive for industrial implementation. Cost-effective alternatives or manufacturing innovations may be necessary to achieve commercial feasibility while maintaining performance characteristics.

Operational flexibility requirements differ substantially between laboratory and industrial settings. Industrial pilot plants must demonstrate resilience to fluctuations in feed composition, flow rates, and other process parameters that are typically held constant in laboratory experiments. Facilitated membranes must maintain separation performance across the range of conditions likely to be encountered in real-world applications.

Environmental Impact and Sustainability Assessment

The implementation of facilitated membranes in industrial pilot plants presents significant environmental implications that warrant comprehensive assessment. These advanced membrane technologies offer substantial potential for reducing the environmental footprint of industrial separation processes compared to conventional methods. Energy consumption analyses across multiple pilot installations demonstrate that facilitated transport membranes typically require 20-40% less energy than traditional separation technologies such as cryogenic distillation or pressure swing adsorption, particularly in gas separation applications. This energy efficiency translates directly to reduced greenhouse gas emissions, with preliminary data from pilot operations indicating potential CO2 emission reductions of 0.5-2.5 tons per day depending on plant capacity and specific application.

Water usage represents another critical environmental parameter where facilitated membranes demonstrate advantages. Comparative testing reveals that these membrane systems generally require minimal process water compared to absorption-based separation technologies, potentially reducing industrial water consumption by 30-60% in applicable processes. This water conservation benefit becomes particularly significant in water-stressed regions where industrial operations face increasing regulatory and resource constraints.

Chemical consumption patterns also favor facilitated membrane technologies. The carrier compounds utilized in these membranes typically demonstrate extended operational lifespans, with pilot testing confirming stability periods of 6-18 months before replacement or regeneration becomes necessary. This represents a marked improvement over conventional liquid absorbents that often require continuous replenishment and generate substantial chemical waste streams.

Waste generation metrics collected across multiple industrial pilot installations indicate that facilitated membrane systems produce approximately 70% less hazardous waste material compared to equivalent absorption or adsorption systems. The primary waste streams consist of spent membrane modules which, depending on their composition, may present recycling opportunities that are currently being explored by several membrane manufacturers.

Life cycle assessment (LCA) methodologies applied to these pilot installations reveal favorable sustainability profiles when considering the entire operational lifespan. While membrane production itself carries certain environmental impacts related to polymer synthesis and processing, these impacts are typically offset within 3-8 months of operation through operational efficiency gains. Complete cradle-to-grave analyses suggest carbon payback periods averaging 4-12 months depending on application specifics and operational parameters.

Biodiversity impact assessments conducted at pilot sites indicate minimal direct ecological disruption compared to alternative technologies, primarily due to the contained nature of membrane operations and reduced emissions profiles. However, upstream supply chain considerations for specialized membrane materials remain an area requiring further sustainability optimization as these technologies scale toward broader industrial adoption.

Water usage represents another critical environmental parameter where facilitated membranes demonstrate advantages. Comparative testing reveals that these membrane systems generally require minimal process water compared to absorption-based separation technologies, potentially reducing industrial water consumption by 30-60% in applicable processes. This water conservation benefit becomes particularly significant in water-stressed regions where industrial operations face increasing regulatory and resource constraints.

Chemical consumption patterns also favor facilitated membrane technologies. The carrier compounds utilized in these membranes typically demonstrate extended operational lifespans, with pilot testing confirming stability periods of 6-18 months before replacement or regeneration becomes necessary. This represents a marked improvement over conventional liquid absorbents that often require continuous replenishment and generate substantial chemical waste streams.

Waste generation metrics collected across multiple industrial pilot installations indicate that facilitated membrane systems produce approximately 70% less hazardous waste material compared to equivalent absorption or adsorption systems. The primary waste streams consist of spent membrane modules which, depending on their composition, may present recycling opportunities that are currently being explored by several membrane manufacturers.

Life cycle assessment (LCA) methodologies applied to these pilot installations reveal favorable sustainability profiles when considering the entire operational lifespan. While membrane production itself carries certain environmental impacts related to polymer synthesis and processing, these impacts are typically offset within 3-8 months of operation through operational efficiency gains. Complete cradle-to-grave analyses suggest carbon payback periods averaging 4-12 months depending on application specifics and operational parameters.

Biodiversity impact assessments conducted at pilot sites indicate minimal direct ecological disruption compared to alternative technologies, primarily due to the contained nature of membrane operations and reduced emissions profiles. However, upstream supply chain considerations for specialized membrane materials remain an area requiring further sustainability optimization as these technologies scale toward broader industrial adoption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!