Comparative Testing Of Polymer Blends In CO2 Separation

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polymer Blend CO2 Separation Technology Background and Objectives

Carbon dioxide separation technology has evolved significantly over the past several decades, driven by increasing environmental concerns and industrial demands. Polymer membranes emerged in the 1980s as a promising alternative to traditional CO2 separation methods such as amine scrubbing and cryogenic distillation. The fundamental principle behind polymer-based CO2 separation relies on the selective permeability of different gas molecules through polymer matrices, with factors such as diffusivity and solubility playing crucial roles in separation efficiency.

The evolution of polymer blend technology for CO2 separation has progressed through distinct phases. Initial research focused on single-polymer membranes, which demonstrated limited selectivity-permeability trade-offs. The field then advanced to polymer blending in the 1990s, which offered improved performance by combining the beneficial properties of different polymers. Recent developments have centered on mixed matrix membranes incorporating both polymeric materials and inorganic fillers to overcome inherent limitations of pure polymer systems.

Current technological trends indicate a growing interest in tailored polymer blends specifically designed for CO2 separation applications. These include thermally rearranged polymers, polymers of intrinsic microporosity (PIMs), and various block copolymer systems that demonstrate enhanced CO2 selectivity and permeability. The integration of computational modeling with experimental approaches has accelerated the development process, allowing for more precise prediction of blend performance.

The primary objective of comparative testing of polymer blends for CO2 separation is to identify optimal material combinations that surpass the Robeson upper bound—a theoretical limit describing the trade-off between permeability and selectivity. Researchers aim to develop blends that offer high CO2 permeability while maintaining excellent selectivity over other gases commonly found in industrial streams, such as N2, CH4, and H2.

Additional technical goals include enhancing mechanical stability under high-pressure conditions, improving resistance to plasticization effects caused by CO2 sorption, and extending membrane operational lifetimes in industrial environments. Cost-effectiveness and scalability of production represent critical considerations for commercial viability, as polymer blend membranes must compete economically with established separation technologies.

The environmental impact of polymer blend manufacturing and disposal has also emerged as an important consideration, with increasing focus on developing sustainable materials and processes. This includes exploration of bio-based polymers and environmentally benign processing methods that align with global sustainability objectives while maintaining high separation performance.

The evolution of polymer blend technology for CO2 separation has progressed through distinct phases. Initial research focused on single-polymer membranes, which demonstrated limited selectivity-permeability trade-offs. The field then advanced to polymer blending in the 1990s, which offered improved performance by combining the beneficial properties of different polymers. Recent developments have centered on mixed matrix membranes incorporating both polymeric materials and inorganic fillers to overcome inherent limitations of pure polymer systems.

Current technological trends indicate a growing interest in tailored polymer blends specifically designed for CO2 separation applications. These include thermally rearranged polymers, polymers of intrinsic microporosity (PIMs), and various block copolymer systems that demonstrate enhanced CO2 selectivity and permeability. The integration of computational modeling with experimental approaches has accelerated the development process, allowing for more precise prediction of blend performance.

The primary objective of comparative testing of polymer blends for CO2 separation is to identify optimal material combinations that surpass the Robeson upper bound—a theoretical limit describing the trade-off between permeability and selectivity. Researchers aim to develop blends that offer high CO2 permeability while maintaining excellent selectivity over other gases commonly found in industrial streams, such as N2, CH4, and H2.

Additional technical goals include enhancing mechanical stability under high-pressure conditions, improving resistance to plasticization effects caused by CO2 sorption, and extending membrane operational lifetimes in industrial environments. Cost-effectiveness and scalability of production represent critical considerations for commercial viability, as polymer blend membranes must compete economically with established separation technologies.

The environmental impact of polymer blend manufacturing and disposal has also emerged as an important consideration, with increasing focus on developing sustainable materials and processes. This includes exploration of bio-based polymers and environmentally benign processing methods that align with global sustainability objectives while maintaining high separation performance.

Market Analysis for CO2 Separation Membrane Technologies

The global market for CO2 separation technologies has experienced significant growth in recent years, driven by increasing environmental regulations and the urgent need to reduce greenhouse gas emissions. The membrane-based CO2 separation segment, particularly utilizing polymer blends, represents one of the fastest-growing sectors within this market, with an estimated annual growth rate of 8-10% over the past five years.

Industrial applications constitute the largest market segment for CO2 separation membranes, with natural gas processing, hydrogen production, and flue gas treatment being the primary end-users. The power generation sector, especially coal and natural gas-fired plants, represents a substantial potential market as carbon capture regulations become more stringent worldwide.

Regionally, North America and Europe currently dominate the market for advanced CO2 separation membranes, accounting for approximately two-thirds of global installations. However, the Asia-Pacific region, particularly China and India, is witnessing the fastest growth due to rapid industrialization coupled with increasing environmental awareness and regulatory pressure.

Market dynamics are heavily influenced by performance metrics, with separation efficiency, durability, and operational costs being the key decision factors for end-users. Polymer blend membranes that demonstrate superior CO2/N2 and CO2/CH4 selectivity while maintaining high permeability are commanding premium pricing in the market, typically 20-30% higher than conventional single-polymer membranes.

Cost considerations remain a significant market barrier, as the initial capital investment for membrane-based systems can be substantial. However, the total cost of ownership analysis increasingly favors membrane technologies over traditional amine scrubbing when factoring in operational expenses, energy consumption, and maintenance requirements over a 10-15 year lifecycle.

Customer requirements are evolving toward more robust membranes capable of withstanding harsh industrial conditions, including high temperatures, presence of contaminants, and pressure fluctuations. This trend is creating market opportunities for advanced polymer blends that offer enhanced stability and resistance to plasticization under real-world operating conditions.

The competitive landscape features both established industrial gas companies and specialized membrane manufacturers, with increasing collaboration between material science companies and equipment manufacturers to develop integrated solutions. Recent market consolidation through mergers and acquisitions indicates the strategic importance of this technology segment, with several major transactions valued at over $100 million occurring in the past three years.

Industrial applications constitute the largest market segment for CO2 separation membranes, with natural gas processing, hydrogen production, and flue gas treatment being the primary end-users. The power generation sector, especially coal and natural gas-fired plants, represents a substantial potential market as carbon capture regulations become more stringent worldwide.

Regionally, North America and Europe currently dominate the market for advanced CO2 separation membranes, accounting for approximately two-thirds of global installations. However, the Asia-Pacific region, particularly China and India, is witnessing the fastest growth due to rapid industrialization coupled with increasing environmental awareness and regulatory pressure.

Market dynamics are heavily influenced by performance metrics, with separation efficiency, durability, and operational costs being the key decision factors for end-users. Polymer blend membranes that demonstrate superior CO2/N2 and CO2/CH4 selectivity while maintaining high permeability are commanding premium pricing in the market, typically 20-30% higher than conventional single-polymer membranes.

Cost considerations remain a significant market barrier, as the initial capital investment for membrane-based systems can be substantial. However, the total cost of ownership analysis increasingly favors membrane technologies over traditional amine scrubbing when factoring in operational expenses, energy consumption, and maintenance requirements over a 10-15 year lifecycle.

Customer requirements are evolving toward more robust membranes capable of withstanding harsh industrial conditions, including high temperatures, presence of contaminants, and pressure fluctuations. This trend is creating market opportunities for advanced polymer blends that offer enhanced stability and resistance to plasticization under real-world operating conditions.

The competitive landscape features both established industrial gas companies and specialized membrane manufacturers, with increasing collaboration between material science companies and equipment manufacturers to develop integrated solutions. Recent market consolidation through mergers and acquisitions indicates the strategic importance of this technology segment, with several major transactions valued at over $100 million occurring in the past three years.

Current Challenges in Polymer Blend CO2 Separation

Despite significant advancements in polymer blend technology for CO2 separation, several critical challenges continue to impede widespread industrial implementation. The primary obstacle remains achieving the optimal balance between permeability and selectivity, commonly known as the Robeson upper bound. While numerous polymer blends demonstrate promising CO2 separation capabilities in laboratory settings, their performance often deteriorates under real-world industrial conditions characterized by high pressures, variable temperatures, and complex gas mixtures.

Material stability presents another significant challenge, particularly in harsh industrial environments. Polymer blends frequently experience plasticization when exposed to high CO2 partial pressures, leading to swelling, reduced selectivity, and compromised mechanical integrity. This phenomenon becomes especially problematic in long-term operations where consistent separation performance is crucial for economic viability.

Scalability issues further complicate industrial adoption. Laboratory-scale synthesis methods that produce high-performance polymer blends often prove difficult to scale up without sacrificing material quality or increasing production costs prohibitively. The complex morphology control required for optimal blend performance becomes increasingly challenging at industrial production scales.

Membrane fabrication techniques represent another technical hurdle. Creating defect-free, thin-film composite membranes with consistent thickness and properties remains difficult, particularly when incorporating novel polymer blends. Interface compatibility between different polymers in the blend often leads to phase separation or weak boundary layers that compromise mechanical strength and separation performance.

Aging and fouling resistance constitute persistent concerns in practical applications. Many promising polymer blends exhibit performance degradation over time due to physical aging, chemical degradation, or fouling by contaminants in feed streams. This necessitates frequent membrane replacement, significantly increasing operational costs and reducing economic feasibility.

The lack of standardized testing protocols further complicates comparative analysis across different research groups. Variations in testing conditions, equipment, and methodologies make direct performance comparisons challenging, hindering the identification of truly superior materials and slowing industry adoption.

Economic considerations also present substantial barriers. The cost-performance ratio of advanced polymer blends must compete with established separation technologies like pressure swing adsorption or amine scrubbing. Many novel materials with excellent separation properties utilize expensive monomers or complex synthesis routes that make commercial viability questionable without significant process optimization.

Finally, the environmental impact of polymer blend production and disposal requires greater attention. As sustainability becomes increasingly important in industrial processes, the life cycle assessment of polymer blend membranes, including raw material sourcing, energy consumption during production, and end-of-life management, must be comprehensively evaluated.

Material stability presents another significant challenge, particularly in harsh industrial environments. Polymer blends frequently experience plasticization when exposed to high CO2 partial pressures, leading to swelling, reduced selectivity, and compromised mechanical integrity. This phenomenon becomes especially problematic in long-term operations where consistent separation performance is crucial for economic viability.

Scalability issues further complicate industrial adoption. Laboratory-scale synthesis methods that produce high-performance polymer blends often prove difficult to scale up without sacrificing material quality or increasing production costs prohibitively. The complex morphology control required for optimal blend performance becomes increasingly challenging at industrial production scales.

Membrane fabrication techniques represent another technical hurdle. Creating defect-free, thin-film composite membranes with consistent thickness and properties remains difficult, particularly when incorporating novel polymer blends. Interface compatibility between different polymers in the blend often leads to phase separation or weak boundary layers that compromise mechanical strength and separation performance.

Aging and fouling resistance constitute persistent concerns in practical applications. Many promising polymer blends exhibit performance degradation over time due to physical aging, chemical degradation, or fouling by contaminants in feed streams. This necessitates frequent membrane replacement, significantly increasing operational costs and reducing economic feasibility.

The lack of standardized testing protocols further complicates comparative analysis across different research groups. Variations in testing conditions, equipment, and methodologies make direct performance comparisons challenging, hindering the identification of truly superior materials and slowing industry adoption.

Economic considerations also present substantial barriers. The cost-performance ratio of advanced polymer blends must compete with established separation technologies like pressure swing adsorption or amine scrubbing. Many novel materials with excellent separation properties utilize expensive monomers or complex synthesis routes that make commercial viability questionable without significant process optimization.

Finally, the environmental impact of polymer blend production and disposal requires greater attention. As sustainability becomes increasingly important in industrial processes, the life cycle assessment of polymer blend membranes, including raw material sourcing, energy consumption during production, and end-of-life management, must be comprehensively evaluated.

Current Polymer Blend Formulations and Testing Methodologies

01 Polymer blend composition for enhanced separation efficiency

Specific polymer blend compositions can be formulated to enhance separation efficiency in various applications. These blends typically combine polymers with complementary properties to create materials with optimized separation characteristics. The selection of polymers with different chemical structures, molecular weights, and functional groups allows for the creation of blends with tailored porosity, permeability, and selectivity. These specialized compositions can significantly improve the efficiency of separation processes compared to single-polymer systems.- Polymer blend composition for enhanced separation efficiency: Specific polymer blend compositions can significantly enhance separation efficiency in various applications. These blends typically combine polymers with complementary properties to create materials with optimized separation characteristics. The selection of polymers with different molecular weights, chemical structures, and functional groups allows for the creation of membranes or filters with controlled porosity, selectivity, and permeability. These specialized polymer blends can be used in gas separation, liquid filtration, and other separation processes.

- Processing methods for polymer blend separation: Various processing methods can be employed to optimize the separation efficiency of polymer blends. These methods include specific extrusion techniques, controlled phase separation, and post-processing treatments. By carefully controlling processing parameters such as temperature, pressure, and cooling rates, the morphology and interface properties of polymer blends can be tailored for specific separation applications. These processing methods can significantly improve the performance of polymer blend-based separation systems.

- Membrane technology using polymer blends: Polymer blend membranes represent an important application for separation technology. By combining different polymers in specific ratios and configurations, membranes with enhanced selectivity, permeability, and mechanical stability can be developed. These membranes can be designed with controlled pore sizes and surface properties to target specific separation challenges. The synergistic effects between different polymers in the blend can result in separation performance that exceeds what could be achieved with single-polymer membranes.

- Nanocomposite polymer blends for separation applications: Incorporating nanoparticles or nanostructures into polymer blends can significantly enhance separation efficiency. These nanocomposite polymer blends combine the benefits of polymer materials with the unique properties of nanomaterials, resulting in improved separation performance. The nanoparticles can modify the free volume, create preferential pathways, or add specific functionality to the polymer matrix. This approach has been successfully applied in gas separation, water purification, and other challenging separation processes.

- Environmentally responsive polymer blends for controlled separation: Polymer blends that respond to environmental stimuli offer advanced control over separation processes. These smart materials can change their separation properties in response to changes in temperature, pH, light, or other external triggers. By incorporating responsive polymers into blends, separation systems can be developed that adapt to changing conditions or that can be actively controlled during operation. This approach enables more efficient and selective separation processes that can be tuned for specific applications or operating conditions.

02 Membrane fabrication techniques for polymer blend separators

Various fabrication techniques can be employed to create polymer blend membranes with enhanced separation efficiency. These techniques include phase inversion, electrospinning, solution casting, and melt processing. The processing conditions, such as solvent selection, temperature, and coagulation parameters, significantly influence the membrane morphology and separation performance. By controlling these parameters, membranes with optimized pore size distribution, surface properties, and mechanical stability can be produced, resulting in improved separation efficiency for specific applications.Expand Specific Solutions03 Surface modification of polymer blend separators

Surface modification techniques can be applied to polymer blend separators to enhance their separation efficiency. These modifications include chemical grafting, plasma treatment, coating with functional materials, and incorporation of nanoparticles. Such treatments can alter the surface hydrophilicity, charge, roughness, and chemical functionality of the separator, leading to improved selectivity and reduced fouling. Surface-modified polymer blend separators demonstrate enhanced performance in various separation applications, including gas separation, water purification, and chemical processing.Expand Specific Solutions04 Polymer blend compatibility and phase separation control

Controlling the compatibility and phase separation behavior of polymer blends is crucial for achieving high separation efficiency. Techniques such as adding compatibilizers, controlling processing conditions, and incorporating specific additives can be used to manipulate the phase morphology of the blend. The degree of phase separation, domain size, and interfacial properties significantly impact the transport properties and separation performance of the resulting materials. Optimized phase morphology leads to enhanced permeability, selectivity, and overall separation efficiency in various applications.Expand Specific Solutions05 Application-specific polymer blend systems

Specialized polymer blend systems can be designed for specific separation applications to maximize efficiency. These include blends for gas separation membranes, liquid filtration, chromatographic separations, and electrolyte separators for energy storage devices. By tailoring the polymer blend composition, morphology, and properties to the specific requirements of the separation task, significantly improved performance can be achieved. These application-specific systems often incorporate functional additives or reinforcing materials to further enhance their separation efficiency under particular operating conditions.Expand Specific Solutions

Leading Companies and Research Institutions in CO2 Separation

The CO2 separation polymer blend market is in a growth phase, characterized by increasing demand for sustainable gas separation technologies. The market size is expanding due to stringent environmental regulations and industrial decarbonization efforts. Technologically, the field shows moderate maturity with ongoing innovation. Key players include UOP LLC and Saudi Arabian Oil Co., who lead with established membrane technologies, while Dow Global Technologies and Nitto Denko focus on advanced polymer formulations. Academic institutions like Harvard, National University of Singapore, and King Abdullah University contribute significant research advancements. Companies such as Calera Corp. and Tricida are developing specialized applications, while China National Petroleum and Chevron U.S.A. represent end-users driving commercial implementation. The competitive landscape reflects a balance between established industrial players and emerging technology developers.

UOP LLC

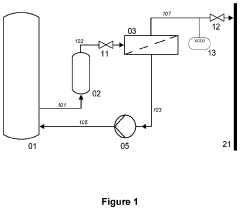

Technical Solution: UOP has developed a sophisticated comparative testing platform for polymer blend membranes targeting CO2 separation from various industrial gas streams. Their approach integrates membrane material development with process engineering to create holistic separation solutions. UOP's testing methodology employs both laboratory-scale permeation cells and pilot-scale membrane modules to evaluate performance across different scales. Their proprietary "AccuSep" testing protocol evaluates membrane performance under dynamic conditions, including pressure and composition fluctuations that mimic real industrial operations. UOP has focused particularly on polymer blends incorporating facilitated transport mechanisms, where specific chemical groups in the polymer matrix interact reversibly with CO2 molecules to enhance selectivity. Their comparative testing includes accelerated aging studies that simulate years of operation in compressed timeframes, providing insights into long-term membrane durability and performance stability.

Strengths: Comprehensive testing approach that bridges laboratory performance to actual industrial implementation. Their polymer blends demonstrate excellent balance between permeability and selectivity for specific applications. Weaknesses: Some facilitated transport mechanisms show sensitivity to trace contaminants, and manufacturing complexity increases costs for certain specialized formulations.

Saudi Arabian Oil Co.

Technical Solution: Saudi Aramco has developed an innovative testing framework for polymer blend membranes targeting CO2 separation from natural gas streams and carbon capture applications. Their approach focuses on polymer blends incorporating thermally rearranged polymers (TRPs) and thermally stable polymers like polybenzimidazole (PBI) to create high-performance separation materials. Aramco's testing methodology employs custom-designed high-pressure mixed gas permeation systems that can operate at pressures up to 120 bar and temperatures up to 150°C, simulating actual field conditions in natural gas processing. Their comparative testing protocols evaluate not only separation performance but also long-term stability under exposure to contaminants commonly found in natural gas streams, including higher hydrocarbons, H2S, and moisture. Aramco has particularly focused on developing polymer blends that maintain performance under aggressive operating conditions while offering economically viable manufacturing pathways.

Strengths: Extensive testing under realistic field conditions provides highly reliable performance data. Their polymer blends demonstrate excellent thermal and chemical stability in harsh environments. Weaknesses: Some formulations show limited mechanical durability under pressure cycling, and manufacturing scale-up remains challenging for certain specialized polymer components.

Key Patents and Scientific Breakthroughs in CO2 Separation Membranes

Polymer separation membrane for purifying methane

PatentPendingUS20230416174A1

Innovation

- The use of polymer separation membranes that operate above their glass transition temperature, with inverted selectivity ratios (α1/α2 < 1) for CO2/CH4 separation, allowing for efficient separation of CO2 from CH4 with higher selectivity than hydrogen, reducing the number of separation steps and energy consumption.

Environmental Impact and Sustainability Assessment

The environmental impact of polymer membrane technologies for CO2 separation represents a critical consideration in their industrial adoption. Current polymer blend membranes offer significant environmental advantages over traditional carbon capture methods, primarily through reduced energy consumption. Conventional amine scrubbing processes typically require 2.5-3.5 GJ/ton of CO2 captured, while advanced polymer membrane systems can achieve separation with energy requirements as low as 0.5-1.2 GJ/ton, representing a potential 60-80% reduction in energy-related emissions.

Life cycle assessment (LCA) studies of polymer blend membranes reveal favorable environmental profiles compared to alternative separation technologies. The production phase of these membranes generates approximately 30-45% less greenhouse gas emissions than comparable ceramic or metal-based separation systems. Additionally, polymer membranes demonstrate reduced water consumption during manufacturing, with some blends requiring only 40-60% of the water needed for alternative materials.

The sustainability of polymer blend membranes is further enhanced by their operational longevity and recyclability potential. Recent advancements in polymer chemistry have extended membrane lifespans from 2-3 years to 5-7 years in industrial applications, significantly reducing replacement frequency and associated material consumption. End-of-life considerations reveal that certain polymer blends, particularly those incorporating bio-based polymers, can be recycled or repurposed, with up to 70% material recovery possible through advanced recycling techniques.

Chemical safety profiles of polymer blends used in CO2 separation present both advantages and challenges. While most polymers demonstrate low toxicity and minimal environmental persistence, certain additives and cross-linking agents may pose environmental concerns. Recent comparative testing indicates that fluorinated polymers, despite their excellent separation properties, present higher environmental risks than hydrocarbon-based alternatives due to their persistence and potential for bioaccumulation.

The carbon footprint reduction potential of implementing polymer blend membrane technology at scale is substantial. Industrial modeling suggests that widespread adoption in power generation and industrial processes could reduce global CO2 emissions by 0.4-0.7 gigatons annually by 2030. This represents approximately 1-2% of current global emissions, highlighting the significant role these materials could play in climate change mitigation strategies.

Water usage efficiency represents another key environmental advantage of polymer membrane systems. Comparative testing reveals that membrane-based CO2 separation requires 50-80% less process water than conventional absorption technologies, a critical consideration in water-stressed regions where industrial carbon capture implementation is expanding.

Life cycle assessment (LCA) studies of polymer blend membranes reveal favorable environmental profiles compared to alternative separation technologies. The production phase of these membranes generates approximately 30-45% less greenhouse gas emissions than comparable ceramic or metal-based separation systems. Additionally, polymer membranes demonstrate reduced water consumption during manufacturing, with some blends requiring only 40-60% of the water needed for alternative materials.

The sustainability of polymer blend membranes is further enhanced by their operational longevity and recyclability potential. Recent advancements in polymer chemistry have extended membrane lifespans from 2-3 years to 5-7 years in industrial applications, significantly reducing replacement frequency and associated material consumption. End-of-life considerations reveal that certain polymer blends, particularly those incorporating bio-based polymers, can be recycled or repurposed, with up to 70% material recovery possible through advanced recycling techniques.

Chemical safety profiles of polymer blends used in CO2 separation present both advantages and challenges. While most polymers demonstrate low toxicity and minimal environmental persistence, certain additives and cross-linking agents may pose environmental concerns. Recent comparative testing indicates that fluorinated polymers, despite their excellent separation properties, present higher environmental risks than hydrocarbon-based alternatives due to their persistence and potential for bioaccumulation.

The carbon footprint reduction potential of implementing polymer blend membrane technology at scale is substantial. Industrial modeling suggests that widespread adoption in power generation and industrial processes could reduce global CO2 emissions by 0.4-0.7 gigatons annually by 2030. This represents approximately 1-2% of current global emissions, highlighting the significant role these materials could play in climate change mitigation strategies.

Water usage efficiency represents another key environmental advantage of polymer membrane systems. Comparative testing reveals that membrane-based CO2 separation requires 50-80% less process water than conventional absorption technologies, a critical consideration in water-stressed regions where industrial carbon capture implementation is expanding.

Scalability and Industrial Implementation Challenges

The scaling of polymer blend technologies for CO2 separation from laboratory to industrial scale presents significant challenges that must be addressed for commercial viability. Current pilot-scale implementations reveal that maintaining consistent membrane performance across larger surface areas remains problematic. Polymer blends that demonstrate excellent separation properties in laboratory conditions often experience performance degradation when manufactured at industrial scales, primarily due to inconsistencies in blend morphology and interfacial properties.

Manufacturing scalability represents a critical hurdle, as the precise control of polymer blend composition, thickness uniformity, and defect minimization becomes increasingly difficult with larger membrane areas. Industrial production requires robust and reproducible fabrication methods that can maintain the nanoscale morphological features responsible for enhanced gas separation properties. Current industrial membrane manufacturing techniques, such as phase inversion and solution casting, require substantial modification to accommodate the specific requirements of high-performance polymer blends.

Process integration challenges further complicate industrial implementation. Existing gas separation infrastructure is typically designed for conventional membrane materials, necessitating modifications to accommodate the different operating parameters of polymer blend membranes. These modifications include adjustments to feed gas pretreatment systems, operating pressures, and membrane module designs to optimize the performance of polymer blend membranes under real-world conditions.

Long-term stability under industrial operating conditions presents another significant challenge. Polymer blend membranes must maintain separation performance when exposed to contaminants, varying feed compositions, pressure fluctuations, and temperature variations typical in industrial settings. Current research indicates that some promising polymer blends exhibit plasticization effects when exposed to high CO2 partial pressures for extended periods, resulting in diminished selectivity over time.

Economic considerations also impact scalability, as the cost-performance ratio must justify the transition from established technologies. Many high-performance polymer blends incorporate expensive specialty polymers or require complex processing steps, increasing production costs. A comprehensive techno-economic analysis reveals that for industrial adoption, either the separation performance must significantly exceed current technologies or manufacturing costs must be substantially reduced.

Regulatory and safety considerations further complicate industrial implementation, particularly for novel polymer materials without established safety profiles. Comprehensive testing for environmental impact, chemical stability, and compliance with industry standards is necessary before widespread adoption can occur.

Manufacturing scalability represents a critical hurdle, as the precise control of polymer blend composition, thickness uniformity, and defect minimization becomes increasingly difficult with larger membrane areas. Industrial production requires robust and reproducible fabrication methods that can maintain the nanoscale morphological features responsible for enhanced gas separation properties. Current industrial membrane manufacturing techniques, such as phase inversion and solution casting, require substantial modification to accommodate the specific requirements of high-performance polymer blends.

Process integration challenges further complicate industrial implementation. Existing gas separation infrastructure is typically designed for conventional membrane materials, necessitating modifications to accommodate the different operating parameters of polymer blend membranes. These modifications include adjustments to feed gas pretreatment systems, operating pressures, and membrane module designs to optimize the performance of polymer blend membranes under real-world conditions.

Long-term stability under industrial operating conditions presents another significant challenge. Polymer blend membranes must maintain separation performance when exposed to contaminants, varying feed compositions, pressure fluctuations, and temperature variations typical in industrial settings. Current research indicates that some promising polymer blends exhibit plasticization effects when exposed to high CO2 partial pressures for extended periods, resulting in diminished selectivity over time.

Economic considerations also impact scalability, as the cost-performance ratio must justify the transition from established technologies. Many high-performance polymer blends incorporate expensive specialty polymers or require complex processing steps, increasing production costs. A comprehensive techno-economic analysis reveals that for industrial adoption, either the separation performance must significantly exceed current technologies or manufacturing costs must be substantially reduced.

Regulatory and safety considerations further complicate industrial implementation, particularly for novel polymer materials without established safety profiles. Comprehensive testing for environmental impact, chemical stability, and compliance with industry standards is necessary before widespread adoption can occur.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!