Comparative Scalability Of Flat-Sheet Versus Hollow Fiber Membrane Designs

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Membrane Technology Evolution and Objectives

Membrane technology has evolved significantly since its inception in the mid-20th century. Initially developed for microfiltration and ultrafiltration applications, membrane technology has expanded to include nanofiltration, reverse osmosis, and forward osmosis processes. The evolution trajectory shows a clear shift from simple separation mechanisms to sophisticated selective transport systems capable of molecular-level discrimination.

The 1960s marked the commercialization of asymmetric cellulose acetate membranes by Loeb and Sourirajan, revolutionizing water desalination. The 1970s and 1980s witnessed the development of thin-film composite membranes, significantly improving flux rates and selectivity. By the 1990s, hollow fiber configurations emerged as an alternative to flat-sheet designs, offering higher packing density and surface-area-to-volume ratios.

Recent advancements have focused on enhancing membrane performance through novel materials such as graphene, carbon nanotubes, and mixed matrix membranes. These innovations aim to address persistent challenges including fouling resistance, chlorine tolerance, and energy efficiency. The integration of nanotechnology has enabled precise control over pore size distribution and surface properties, leading to membranes with unprecedented separation capabilities.

The comparative scalability between flat-sheet and hollow fiber membrane designs represents a critical juncture in membrane technology evolution. Flat-sheet membranes, characterized by their planar geometry, offer manufacturing simplicity and ease of cleaning but face limitations in packing density. Conversely, hollow fiber configurations provide superior surface area efficiency but present challenges in manufacturing consistency and module assembly.

The primary objectives of current membrane technology research include developing scalable manufacturing processes that maintain performance consistency across different membrane configurations. For flat-sheet membranes, objectives focus on improving module designs to enhance packing density while maintaining operational simplicity. For hollow fiber membranes, research aims to streamline production processes to reduce manufacturing variability and defect rates.

Additional objectives include developing membrane materials and structures that simultaneously optimize permeability, selectivity, mechanical strength, and chemical resistance. The industry also seeks to establish standardized testing protocols that accurately predict full-scale performance from laboratory-scale experiments, particularly important when comparing different membrane geometries like flat-sheet and hollow fiber designs.

The ultimate goal remains creating membrane systems that deliver consistent performance at industrial scale while minimizing energy consumption, reducing environmental impact, and lowering operational costs. This requires a holistic approach that considers not only membrane material and configuration but also module design, system integration, and operational parameters.

The 1960s marked the commercialization of asymmetric cellulose acetate membranes by Loeb and Sourirajan, revolutionizing water desalination. The 1970s and 1980s witnessed the development of thin-film composite membranes, significantly improving flux rates and selectivity. By the 1990s, hollow fiber configurations emerged as an alternative to flat-sheet designs, offering higher packing density and surface-area-to-volume ratios.

Recent advancements have focused on enhancing membrane performance through novel materials such as graphene, carbon nanotubes, and mixed matrix membranes. These innovations aim to address persistent challenges including fouling resistance, chlorine tolerance, and energy efficiency. The integration of nanotechnology has enabled precise control over pore size distribution and surface properties, leading to membranes with unprecedented separation capabilities.

The comparative scalability between flat-sheet and hollow fiber membrane designs represents a critical juncture in membrane technology evolution. Flat-sheet membranes, characterized by their planar geometry, offer manufacturing simplicity and ease of cleaning but face limitations in packing density. Conversely, hollow fiber configurations provide superior surface area efficiency but present challenges in manufacturing consistency and module assembly.

The primary objectives of current membrane technology research include developing scalable manufacturing processes that maintain performance consistency across different membrane configurations. For flat-sheet membranes, objectives focus on improving module designs to enhance packing density while maintaining operational simplicity. For hollow fiber membranes, research aims to streamline production processes to reduce manufacturing variability and defect rates.

Additional objectives include developing membrane materials and structures that simultaneously optimize permeability, selectivity, mechanical strength, and chemical resistance. The industry also seeks to establish standardized testing protocols that accurately predict full-scale performance from laboratory-scale experiments, particularly important when comparing different membrane geometries like flat-sheet and hollow fiber designs.

The ultimate goal remains creating membrane systems that deliver consistent performance at industrial scale while minimizing energy consumption, reducing environmental impact, and lowering operational costs. This requires a holistic approach that considers not only membrane material and configuration but also module design, system integration, and operational parameters.

Market Analysis for Membrane Filtration Systems

The membrane filtration systems market has experienced significant growth over the past decade, driven by increasing water scarcity concerns, stringent environmental regulations, and growing industrial applications. The global market was valued at approximately $13.5 billion in 2022 and is projected to reach $22.1 billion by 2028, representing a compound annual growth rate (CAGR) of 8.6% during the forecast period.

When analyzing the market specifically for flat-sheet versus hollow fiber membrane designs, distinct trends emerge. Hollow fiber membranes currently dominate the market with roughly 65% market share due to their higher packing density and established presence in municipal water treatment applications. Flat-sheet membranes account for approximately 30% of the market, with the remaining 5% comprising other configurations such as tubular and spiral-wound designs.

The water treatment sector represents the largest application segment, accounting for 41% of the total membrane filtration market. Within this segment, municipal drinking water and wastewater treatment facilities are the primary end-users. Industrial applications follow closely at 37%, with particularly strong growth in food and beverage, pharmaceuticals, and biotechnology sectors where product purity requirements are increasingly stringent.

Geographically, North America and Europe currently lead the market with a combined share of 58%, attributed to advanced infrastructure and early adoption of membrane technologies. However, the Asia-Pacific region is witnessing the fastest growth at 10.2% CAGR, driven by rapid industrialization, urbanization, and increasing water quality concerns in countries like China and India.

Customer demand is increasingly shifting toward scalable, modular systems that can be expanded incrementally as needs grow. This trend particularly benefits hollow fiber configurations, which offer more straightforward modularity. However, flat-sheet membranes are gaining traction in specialized applications requiring higher fouling resistance and easier cleaning protocols.

Cost sensitivity varies significantly by application segment. Municipal projects typically prioritize total lifecycle costs, while industrial applications often focus on performance specifications and operational reliability. The average cost per square meter of membrane area has decreased by approximately 18% over the past five years, making both technologies more accessible to smaller-scale applications.

Market forecasts indicate that while hollow fiber membranes will maintain their dominant position in large-scale municipal applications, flat-sheet designs will see accelerated growth in industrial segments, particularly in food processing and pharmaceutical applications where cleaning efficiency and product recovery are paramount considerations.

When analyzing the market specifically for flat-sheet versus hollow fiber membrane designs, distinct trends emerge. Hollow fiber membranes currently dominate the market with roughly 65% market share due to their higher packing density and established presence in municipal water treatment applications. Flat-sheet membranes account for approximately 30% of the market, with the remaining 5% comprising other configurations such as tubular and spiral-wound designs.

The water treatment sector represents the largest application segment, accounting for 41% of the total membrane filtration market. Within this segment, municipal drinking water and wastewater treatment facilities are the primary end-users. Industrial applications follow closely at 37%, with particularly strong growth in food and beverage, pharmaceuticals, and biotechnology sectors where product purity requirements are increasingly stringent.

Geographically, North America and Europe currently lead the market with a combined share of 58%, attributed to advanced infrastructure and early adoption of membrane technologies. However, the Asia-Pacific region is witnessing the fastest growth at 10.2% CAGR, driven by rapid industrialization, urbanization, and increasing water quality concerns in countries like China and India.

Customer demand is increasingly shifting toward scalable, modular systems that can be expanded incrementally as needs grow. This trend particularly benefits hollow fiber configurations, which offer more straightforward modularity. However, flat-sheet membranes are gaining traction in specialized applications requiring higher fouling resistance and easier cleaning protocols.

Cost sensitivity varies significantly by application segment. Municipal projects typically prioritize total lifecycle costs, while industrial applications often focus on performance specifications and operational reliability. The average cost per square meter of membrane area has decreased by approximately 18% over the past five years, making both technologies more accessible to smaller-scale applications.

Market forecasts indicate that while hollow fiber membranes will maintain their dominant position in large-scale municipal applications, flat-sheet designs will see accelerated growth in industrial segments, particularly in food processing and pharmaceutical applications where cleaning efficiency and product recovery are paramount considerations.

Current Challenges in Membrane Design Scalability

Despite significant advancements in membrane technology, scaling up membrane designs from laboratory to industrial applications presents substantial challenges. The scalability comparison between flat-sheet and hollow fiber configurations reveals distinct obstacles that engineers must overcome. Flat-sheet membranes, while conceptually simpler, face significant challenges in maintaining uniform flow distribution when scaled to industrial dimensions. This non-uniformity can lead to concentration polarization, membrane fouling, and reduced separation efficiency in larger systems.

Hollow fiber membranes, conversely, offer higher packing density but encounter manufacturing complexities during scale-up. The production of consistent fiber dimensions and properties becomes increasingly difficult at industrial scales, leading to performance variability. Additionally, the complex flow patterns within hollow fiber modules can create dead zones and channeling effects that are minimal in laboratory prototypes but become problematic in full-scale operations.

Both designs struggle with mechanical integrity issues during scale-up. Flat-sheet membranes require robust support structures to prevent deformation under pressure in large-scale applications, adding complexity and cost. Hollow fiber arrangements face challenges with fiber breakage and module integrity when scaled up, particularly under high-pressure operations or with aggressive feed streams.

The economic aspects of scalability present another significant hurdle. While hollow fiber membranes typically offer better space efficiency, their manufacturing processes often involve more complex equipment and quality control measures. Flat-sheet membranes may be simpler to produce but require more physical space and supporting infrastructure when scaled to industrial capacities.

Energy efficiency during scale-up represents a critical challenge for both designs. As system size increases, pressure drop and pumping requirements can escalate non-linearly, particularly in hollow fiber configurations with their intricate flow paths. Flat-sheet designs may require additional energy for effective fluid distribution across larger membrane surfaces.

Material consistency becomes increasingly problematic at industrial scales. Minor variations in membrane composition or structure that might be negligible in laboratory settings can lead to significant performance discrepancies in large-scale operations. This challenge is particularly acute for hollow fiber membranes, where maintaining consistent fiber diameter, wall thickness, and pore structure throughout kilometers of fiber is technically demanding.

Cleaning and maintenance protocols that work effectively for small-scale systems often prove inadequate or impractical for industrial installations. Flat-sheet configurations may offer better accessibility but cleaning large surface areas uniformly presents logistical challenges. Hollow fiber systems, while more compact, face difficulties with internal fouling that becomes increasingly problematic as scale increases.

Hollow fiber membranes, conversely, offer higher packing density but encounter manufacturing complexities during scale-up. The production of consistent fiber dimensions and properties becomes increasingly difficult at industrial scales, leading to performance variability. Additionally, the complex flow patterns within hollow fiber modules can create dead zones and channeling effects that are minimal in laboratory prototypes but become problematic in full-scale operations.

Both designs struggle with mechanical integrity issues during scale-up. Flat-sheet membranes require robust support structures to prevent deformation under pressure in large-scale applications, adding complexity and cost. Hollow fiber arrangements face challenges with fiber breakage and module integrity when scaled up, particularly under high-pressure operations or with aggressive feed streams.

The economic aspects of scalability present another significant hurdle. While hollow fiber membranes typically offer better space efficiency, their manufacturing processes often involve more complex equipment and quality control measures. Flat-sheet membranes may be simpler to produce but require more physical space and supporting infrastructure when scaled to industrial capacities.

Energy efficiency during scale-up represents a critical challenge for both designs. As system size increases, pressure drop and pumping requirements can escalate non-linearly, particularly in hollow fiber configurations with their intricate flow paths. Flat-sheet designs may require additional energy for effective fluid distribution across larger membrane surfaces.

Material consistency becomes increasingly problematic at industrial scales. Minor variations in membrane composition or structure that might be negligible in laboratory settings can lead to significant performance discrepancies in large-scale operations. This challenge is particularly acute for hollow fiber membranes, where maintaining consistent fiber diameter, wall thickness, and pore structure throughout kilometers of fiber is technically demanding.

Cleaning and maintenance protocols that work effectively for small-scale systems often prove inadequate or impractical for industrial installations. Flat-sheet configurations may offer better accessibility but cleaning large surface areas uniformly presents logistical challenges. Hollow fiber systems, while more compact, face difficulties with internal fouling that becomes increasingly problematic as scale increases.

Technical Comparison of Flat-Sheet and Hollow Fiber Designs

01 Flat-sheet membrane design and scalability

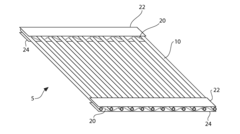

Flat-sheet membrane designs offer advantages for scalability in various applications. These membranes can be stacked in plate-and-frame configurations or spiral-wound modules to increase surface area while maintaining structural integrity. The flat geometry allows for uniform flow distribution and effective cleaning procedures, which are crucial for large-scale operations. Advanced manufacturing techniques enable the production of flat-sheet membranes with consistent properties at industrial scales, making them suitable for applications requiring high throughput and reliability.- Flat-sheet membrane design and scalability: Flat-sheet membrane designs offer advantages for scalability in various applications. These membranes provide uniform surface area distribution and can be easily stacked in modules to increase capacity. The design allows for efficient packing density while maintaining good flow distribution. Flat-sheet configurations can be scaled up by adding more membrane sheets in parallel arrangements, making them suitable for industrial applications where space efficiency and consistent performance across scale are required.

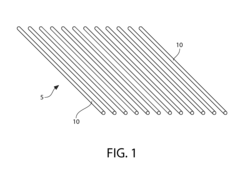

- Hollow fiber membrane design and scalability: Hollow fiber membrane designs provide high surface area to volume ratio, making them highly scalable for various applications. These membranes consist of small tubular fibers bundled together, allowing for compact module design and efficient mass transfer. The scalability of hollow fiber systems can be achieved by increasing the number of fibers or modules. Their cylindrical geometry provides mechanical stability during operation, making them suitable for large-scale industrial applications requiring high throughput.

- Hybrid membrane systems combining flat-sheet and hollow fiber designs: Hybrid membrane systems that combine both flat-sheet and hollow fiber designs leverage the advantages of each configuration to optimize performance and scalability. These systems can be tailored to specific application requirements by utilizing flat-sheet membranes for certain process stages and hollow fiber membranes for others. The hybrid approach allows for more flexible scaling strategies and can overcome limitations inherent to either design alone, resulting in improved overall system efficiency and reduced footprint when scaling up.

- Manufacturing techniques for scalable membrane production: Advanced manufacturing techniques are crucial for producing membranes at scale while maintaining consistent quality and performance. These techniques include automated extrusion processes for hollow fibers, precision casting methods for flat-sheet membranes, and quality control systems that ensure uniformity across large production volumes. Innovations in manufacturing technology enable cost-effective scaling of membrane production while minimizing defects and performance variations, which is essential for commercial viability of membrane-based separation processes.

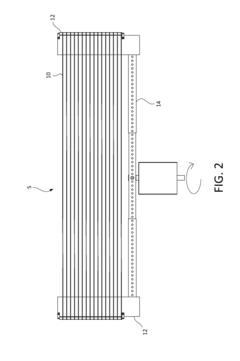

- Module design and system integration for industrial scale applications: Module design and system integration are critical factors in scaling membrane technologies from laboratory to industrial applications. Effective module designs optimize flow distribution, minimize pressure drop, and facilitate maintenance and membrane replacement. System integration considerations include feed pretreatment, process control strategies, and energy efficiency measures that become increasingly important at larger scales. Properly designed modules and integrated systems can maintain performance parameters across different scales while addressing practical operational challenges in industrial environments.

02 Hollow fiber membrane design and scalability

Hollow fiber membranes offer exceptional scalability due to their high packing density and surface area-to-volume ratio. These cylindrical structures can be bundled together in modules, allowing for compact system designs that process large volumes of fluid. The self-supporting nature of hollow fibers reduces the need for extensive support structures, facilitating easier scale-up. Manufacturing processes for hollow fiber membranes have been optimized for mass production, enabling consistent quality across large batches for industrial applications.Expand Specific Solutions03 Membrane module design for industrial scale applications

Membrane module designs are critical for successful industrial scale implementation of both flat-sheet and hollow fiber membranes. These modules incorporate features such as optimized flow channels, uniform fluid distribution systems, and robust housing materials to ensure consistent performance at scale. Advanced module designs address issues like concentration polarization and fouling that become more pronounced in large-scale operations. Modular approaches allow for flexible capacity expansion and easier maintenance, which are essential considerations for industrial membrane systems.Expand Specific Solutions04 Manufacturing techniques for scalable membrane production

Specialized manufacturing techniques have been developed to enable the scalable production of both flat-sheet and hollow fiber membranes. These include continuous casting processes for flat-sheet membranes and spinning technologies for hollow fibers that maintain consistent pore size, thickness, and mechanical properties across large production runs. Advanced quality control systems using real-time monitoring ensure uniformity in membrane characteristics. Innovations in polymer formulation and processing conditions have improved the reproducibility of membrane properties, which is essential for commercial-scale manufacturing.Expand Specific Solutions05 Scale-up considerations for membrane system integration

Scaling up membrane systems requires careful consideration of integration factors beyond the membrane itself. These include optimized fluid dynamics to prevent dead zones and ensure uniform flow distribution across large membrane areas. Energy efficiency becomes increasingly important at scale, necessitating designs that minimize pressure drops and pumping requirements. System controls and automation are essential for managing the complexity of large-scale operations. Additionally, considerations for cleaning-in-place systems, membrane replacement strategies, and overall footprint optimization are critical for successful industrial implementation.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The membrane filtration market is currently in a growth phase, with increasing demand for water treatment solutions driving innovation in both flat-sheet and hollow fiber membrane designs. The competitive landscape features established players like Toray Industries, Fresenius Medical Care, and Mitsubishi Rayon dominating with comprehensive product portfolios, while specialized innovators such as Fibracast are disrupting with hybrid technologies. Flat-sheet membranes offer simplicity and lower fouling tendencies, while hollow fiber designs provide higher packing density and throughput. Technical maturity varies between designs, with hollow fiber technology being more established but flat-sheet designs gaining momentum due to advancements in material science and manufacturing techniques by companies like Ovivo and Kolon Industries. The market is expected to reach $3.5 billion by 2025, with growth driven by increasing water scarcity and stricter environmental regulations.

Toray Industries, Inc.

Technical Solution: Toray has developed advanced flat-sheet membrane technology utilizing polyvinylidene fluoride (PVDF) and polyamide composite materials. Their flat-sheet designs feature uniform pore distribution and high mechanical strength, achieving flux rates of 30-50 LMH at operating pressures below 0.1 MPa. For water treatment applications, Toray's MEMBRAY™ flat-sheet membranes incorporate a proprietary surface modification technique that enhances fouling resistance while maintaining high permeability. Their manufacturing process allows for precise control of membrane thickness (typically 0.1-0.2 mm), resulting in consistent performance across large membrane areas. Toray has also developed specialized spacer designs that optimize flow dynamics across flat-sheet surfaces, reducing concentration polarization effects by approximately 25% compared to conventional designs.

Strengths: Excellent chemical resistance, high mechanical durability, and superior fouling resistance. Flat-sheet designs offer easier visual inspection and cleaning protocols. Weaknesses: Higher manufacturing costs per unit area compared to hollow fiber, larger footprint requirements, and more complex module assembly processes.

Fresenius Medical Care Deutschland GmbH

Technical Solution: Fresenius has developed specialized hollow fiber membranes for hemodialysis and related medical applications. Their Fresenius Polysulfone® hollow fiber membranes feature precisely controlled inner diameters (200-220 μm) and wall thicknesses (35-45 μm), optimized for blood filtration with minimal hemolysis. The company's manufacturing process creates asymmetric pore structures with tight pore size distribution (typically 0.003-0.01 μm), enabling selective filtration of uremic toxins while retaining essential proteins. Their dialyzers achieve clearance rates of 180-280 mL/min for urea and 150-220 mL/min for creatinine at blood flow rates of 300 mL/min. Fresenius has also developed specialized fiber potting techniques that ensure leak-free operation under pulsatile flow conditions. Their hollow fiber modules demonstrate exceptional biocompatibility with complement activation reduction of 40-60% compared to earlier generation membranes.

Strengths: Exceptional biocompatibility, precise control of molecular weight cutoff, and high reliability in critical medical applications. Hollow fiber design provides optimal blood-membrane interface with minimal pressure drops. Weaknesses: Higher production costs due to stringent quality requirements, limited application outside medical field, and more complex sterilization procedures compared to flat-sheet alternatives.

Key Patents in Membrane Scalability Solutions

Fluoropolymer Hollow Fiber Membrane with Fluoro-copolymer and Fluoro -terpolymer bonded end portion(s)

PatentInactiveUS20150041389A1

Innovation

- A polymeric film potting system that uses a thin, chemically resistant film to bind PTFE hollow fibers together without softening them, allowing for high packing densities and efficient assembly with controlled fiber spacing, and is compatible with a wide range of fiber diameters and porosities, enabling the creation of robust and efficient membrane contactors.

Cost-Benefit Analysis of Membrane Configuration Options

When evaluating membrane configuration options for water treatment and industrial separation processes, a comprehensive cost-benefit analysis reveals significant differences between flat-sheet and hollow fiber designs. Initial capital expenditure for flat-sheet membrane systems typically exceeds that of hollow fiber configurations by 15-30%, primarily due to the more complex frame structures and spacer materials required. However, this higher upfront investment must be balanced against operational considerations over the system lifecycle.

Operational expenditure patterns diverge substantially between these configurations. Flat-sheet membranes generally demonstrate 10-20% lower energy consumption during operation, attributable to their lower pressure drop characteristics. This energy efficiency advantage becomes particularly significant in large-scale installations where power costs represent a major operational expense. Maintenance requirements also differ markedly, with flat-sheet designs offering easier visual inspection and cleaning protocols that can reduce maintenance labor hours by approximately 25% compared to hollow fiber systems.

Membrane replacement economics present another critical cost factor. While hollow fiber modules typically cost 15-25% less per unit area than flat-sheet membranes, their replacement frequency is often higher in applications with challenging feed characteristics. The average service life of flat-sheet membranes extends 1.5-2 years beyond hollow fiber counterparts in high-fouling environments, offsetting their higher unit cost through reduced replacement frequency.

Space utilization efficiency strongly favors hollow fiber configurations, which can pack 3-5 times more membrane surface area per unit volume. This spatial advantage translates to smaller footprint requirements and reduced civil infrastructure costs, particularly valuable in space-constrained installations or when retrofitting existing facilities. The associated reduction in building footprint can yield 20-30% savings in construction and real estate costs.

Scalability economics demonstrate that hollow fiber systems generally maintain more consistent cost-per-unit-capacity as system size increases. Analysis of installations ranging from 1,000 to 100,000 m³/day shows that hollow fiber configurations exhibit a scaling factor of approximately 0.7-0.8, compared to 0.8-0.9 for flat-sheet systems, indicating better economies of scale for hollow fiber technology in very large installations.

Risk assessment must also factor into cost-benefit calculations. Flat-sheet configurations typically demonstrate 15-20% lower catastrophic failure rates, as damage to individual membrane elements does not compromise the entire module. This reliability advantage translates to reduced downtime costs and lower operational risk, particularly in critical applications where system failure carries significant consequences.

Operational expenditure patterns diverge substantially between these configurations. Flat-sheet membranes generally demonstrate 10-20% lower energy consumption during operation, attributable to their lower pressure drop characteristics. This energy efficiency advantage becomes particularly significant in large-scale installations where power costs represent a major operational expense. Maintenance requirements also differ markedly, with flat-sheet designs offering easier visual inspection and cleaning protocols that can reduce maintenance labor hours by approximately 25% compared to hollow fiber systems.

Membrane replacement economics present another critical cost factor. While hollow fiber modules typically cost 15-25% less per unit area than flat-sheet membranes, their replacement frequency is often higher in applications with challenging feed characteristics. The average service life of flat-sheet membranes extends 1.5-2 years beyond hollow fiber counterparts in high-fouling environments, offsetting their higher unit cost through reduced replacement frequency.

Space utilization efficiency strongly favors hollow fiber configurations, which can pack 3-5 times more membrane surface area per unit volume. This spatial advantage translates to smaller footprint requirements and reduced civil infrastructure costs, particularly valuable in space-constrained installations or when retrofitting existing facilities. The associated reduction in building footprint can yield 20-30% savings in construction and real estate costs.

Scalability economics demonstrate that hollow fiber systems generally maintain more consistent cost-per-unit-capacity as system size increases. Analysis of installations ranging from 1,000 to 100,000 m³/day shows that hollow fiber configurations exhibit a scaling factor of approximately 0.7-0.8, compared to 0.8-0.9 for flat-sheet systems, indicating better economies of scale for hollow fiber technology in very large installations.

Risk assessment must also factor into cost-benefit calculations. Flat-sheet configurations typically demonstrate 15-20% lower catastrophic failure rates, as damage to individual membrane elements does not compromise the entire module. This reliability advantage translates to reduced downtime costs and lower operational risk, particularly in critical applications where system failure carries significant consequences.

Environmental Impact and Sustainability Considerations

The environmental impact of membrane filtration systems is increasingly becoming a critical factor in technology selection, particularly when comparing flat-sheet and hollow fiber membrane designs. Life cycle assessment (LCA) studies indicate that hollow fiber membranes generally demonstrate a smaller environmental footprint during manufacturing processes due to their higher packing density, which requires less raw material per functional unit of filtration area.

Energy consumption represents a significant sustainability consideration in membrane operations. Hollow fiber systems typically operate at lower transmembrane pressures compared to flat-sheet configurations, potentially reducing energy requirements by 15-30% in large-scale applications. However, this advantage diminishes in smaller installations where system design factors may outweigh the inherent efficiency differences between membrane types.

Waste generation during operation presents another important environmental metric. Flat-sheet membranes often require more frequent chemical cleaning cycles, increasing chemical consumption and generating larger volumes of waste streams containing cleaning agents. Conversely, hollow fiber systems may experience more frequent fiber breakage in certain applications, necessitating module replacement and contributing to solid waste generation.

Water footprint analysis reveals that manufacturing hollow fiber membranes typically consumes 30-45% less water than producing equivalent filtration area in flat-sheet format. This difference becomes particularly significant when scaling to industrial applications where thousands of square meters of membrane area are required.

End-of-life considerations favor flat-sheet designs in some contexts, as their simpler construction can facilitate material separation for recycling. Hollow fiber modules, with their more complex potting and housing arrangements, may present greater challenges for material recovery, though advances in design are gradually addressing this limitation.

Carbon footprint calculations across the full life cycle indicate that the operational phase dominates environmental impact for both designs, with manufacturing impacts becoming secondary. The lower energy requirements of hollow fiber systems typically translate to reduced greenhouse gas emissions over the system lifetime, though this advantage must be weighed against potential shorter service life in certain applications.

Emerging sustainability metrics are beginning to incorporate resource circularity potential, where membrane designs that facilitate material recovery and reuse gain preference. Recent innovations in bio-based polymers for membrane manufacturing show promise for reducing the environmental impact of both designs, though commercial implementation remains limited.

Energy consumption represents a significant sustainability consideration in membrane operations. Hollow fiber systems typically operate at lower transmembrane pressures compared to flat-sheet configurations, potentially reducing energy requirements by 15-30% in large-scale applications. However, this advantage diminishes in smaller installations where system design factors may outweigh the inherent efficiency differences between membrane types.

Waste generation during operation presents another important environmental metric. Flat-sheet membranes often require more frequent chemical cleaning cycles, increasing chemical consumption and generating larger volumes of waste streams containing cleaning agents. Conversely, hollow fiber systems may experience more frequent fiber breakage in certain applications, necessitating module replacement and contributing to solid waste generation.

Water footprint analysis reveals that manufacturing hollow fiber membranes typically consumes 30-45% less water than producing equivalent filtration area in flat-sheet format. This difference becomes particularly significant when scaling to industrial applications where thousands of square meters of membrane area are required.

End-of-life considerations favor flat-sheet designs in some contexts, as their simpler construction can facilitate material separation for recycling. Hollow fiber modules, with their more complex potting and housing arrangements, may present greater challenges for material recovery, though advances in design are gradually addressing this limitation.

Carbon footprint calculations across the full life cycle indicate that the operational phase dominates environmental impact for both designs, with manufacturing impacts becoming secondary. The lower energy requirements of hollow fiber systems typically translate to reduced greenhouse gas emissions over the system lifetime, though this advantage must be weighed against potential shorter service life in certain applications.

Emerging sustainability metrics are beginning to incorporate resource circularity potential, where membrane designs that facilitate material recovery and reuse gain preference. Recent innovations in bio-based polymers for membrane manufacturing show promise for reducing the environmental impact of both designs, though commercial implementation remains limited.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!