Role Of Metal-Organic Framework Fillers In Mixed Matrix Membranes

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MOF Fillers Background and Research Objectives

Metal-Organic Frameworks (MOFs) represent a revolutionary class of porous crystalline materials composed of metal ions or clusters coordinated with organic ligands. Since their emergence in the late 1990s, MOFs have garnered significant attention due to their exceptional properties including ultrahigh porosity, tunable pore size, and vast internal surface areas often exceeding 6,000 m²/g. These characteristics position MOFs as ideal candidates for numerous applications, particularly in separation technologies.

The integration of MOFs as fillers in mixed matrix membranes (MMMs) has emerged as a promising approach to overcome the inherent limitations of conventional polymeric membranes. Traditional polymeric membranes face a critical trade-off between permeability and selectivity, commonly known as the Robeson upper bound. This technological constraint has driven researchers to explore hybrid membrane systems that can transcend this performance ceiling.

The evolution of MOF-based MMMs has progressed through several distinct phases. Initial research focused on proof-of-concept studies demonstrating the feasibility of incorporating MOFs into polymer matrices. This was followed by systematic investigations into MOF-polymer compatibility and interfacial engineering to address challenges related to agglomeration and poor adhesion between components.

Recent technological advancements have shifted toward the rational design of MOF structures specifically tailored for membrane applications. This includes the development of MOFs with hierarchical porosity, functionalized surfaces, and stimuli-responsive properties that can dynamically adjust separation performance based on external conditions.

The primary objective of current research in this field is to establish fundamental structure-property relationships that govern the performance of MOF-based MMMs. This includes understanding how MOF characteristics such as pore geometry, functional groups, and metal centers influence membrane separation mechanisms including molecular sieving, solution-diffusion, and facilitated transport.

Additionally, researchers aim to develop scalable and economically viable fabrication methods that can translate laboratory successes into industrial applications. This involves addressing challenges related to MOF synthesis costs, membrane formation techniques, and long-term operational stability under realistic process conditions.

Another critical research goal is to expand the application scope of MOF-based MMMs beyond traditional gas separations to emerging areas such as water purification, organic solvent nanofiltration, and pharmaceutical separations. This diversification requires tailoring MOF properties to accommodate different molecular species and operating environments.

The technological trajectory suggests that future developments will focus on multifunctional MMMs that combine separation capabilities with additional functionalities such as catalytic activity, sensing capabilities, or self-healing properties, thereby creating next-generation materials for advanced separation processes.

The integration of MOFs as fillers in mixed matrix membranes (MMMs) has emerged as a promising approach to overcome the inherent limitations of conventional polymeric membranes. Traditional polymeric membranes face a critical trade-off between permeability and selectivity, commonly known as the Robeson upper bound. This technological constraint has driven researchers to explore hybrid membrane systems that can transcend this performance ceiling.

The evolution of MOF-based MMMs has progressed through several distinct phases. Initial research focused on proof-of-concept studies demonstrating the feasibility of incorporating MOFs into polymer matrices. This was followed by systematic investigations into MOF-polymer compatibility and interfacial engineering to address challenges related to agglomeration and poor adhesion between components.

Recent technological advancements have shifted toward the rational design of MOF structures specifically tailored for membrane applications. This includes the development of MOFs with hierarchical porosity, functionalized surfaces, and stimuli-responsive properties that can dynamically adjust separation performance based on external conditions.

The primary objective of current research in this field is to establish fundamental structure-property relationships that govern the performance of MOF-based MMMs. This includes understanding how MOF characteristics such as pore geometry, functional groups, and metal centers influence membrane separation mechanisms including molecular sieving, solution-diffusion, and facilitated transport.

Additionally, researchers aim to develop scalable and economically viable fabrication methods that can translate laboratory successes into industrial applications. This involves addressing challenges related to MOF synthesis costs, membrane formation techniques, and long-term operational stability under realistic process conditions.

Another critical research goal is to expand the application scope of MOF-based MMMs beyond traditional gas separations to emerging areas such as water purification, organic solvent nanofiltration, and pharmaceutical separations. This diversification requires tailoring MOF properties to accommodate different molecular species and operating environments.

The technological trajectory suggests that future developments will focus on multifunctional MMMs that combine separation capabilities with additional functionalities such as catalytic activity, sensing capabilities, or self-healing properties, thereby creating next-generation materials for advanced separation processes.

Market Analysis for MOF-Enhanced Membrane Applications

The global market for membrane separation technologies is experiencing robust growth, with the mixed matrix membranes (MMMs) segment emerging as a particularly dynamic area. The incorporation of Metal-Organic Frameworks (MOFs) as fillers in these membranes has created significant commercial opportunities across multiple industries. Current market valuations place the global membrane separation market at approximately 5.1 billion USD in 2023, with projections indicating growth to reach 7.8 billion USD by 2028, representing a compound annual growth rate (CAGR) of 8.9%.

Within this broader market, MOF-enhanced membranes are gaining substantial traction in several key application sectors. The gas separation segment currently dominates, accounting for roughly 38% of the MOF-MMM market share, driven primarily by applications in carbon capture, natural gas purification, and hydrogen separation. The water treatment sector follows closely at 31%, where MOF-MMMs are increasingly deployed for desalination, wastewater treatment, and removal of emerging contaminants.

Pharmaceutical and bioprocessing applications represent the fastest-growing segment with a CAGR of 12.3%, as these industries increasingly adopt MOF-MMMs for protein separation, drug purification, and biofuel production. The food and beverage industry has also begun implementing these advanced membrane technologies for processes such as juice clarification and dairy product filtration.

Geographically, North America and Europe currently lead the market adoption of MOF-enhanced membranes, collectively accounting for approximately 58% of global market share. However, the Asia-Pacific region is experiencing the most rapid growth rate at 14.2% annually, driven by expanding industrial activities in China, Japan, South Korea, and India, coupled with increasing environmental regulations.

Market analysis reveals several key drivers propelling the MOF-MMM market forward. Stringent environmental regulations regarding emissions and water quality standards are creating regulatory push factors. Simultaneously, the superior performance characteristics of MOF-MMMs—including enhanced selectivity, permeability, and fouling resistance—are generating strong technology pull factors. The growing emphasis on sustainable industrial processes and circular economy principles is further accelerating market adoption.

Despite positive growth indicators, certain market barriers persist. The relatively high production costs of MOF materials compared to conventional fillers remains a significant challenge, with current price premiums ranging from 30-200% depending on the specific MOF type. Additionally, scalability issues in manufacturing consistent, defect-free MOF-MMMs at industrial scales continue to limit broader market penetration, particularly in cost-sensitive applications.

Within this broader market, MOF-enhanced membranes are gaining substantial traction in several key application sectors. The gas separation segment currently dominates, accounting for roughly 38% of the MOF-MMM market share, driven primarily by applications in carbon capture, natural gas purification, and hydrogen separation. The water treatment sector follows closely at 31%, where MOF-MMMs are increasingly deployed for desalination, wastewater treatment, and removal of emerging contaminants.

Pharmaceutical and bioprocessing applications represent the fastest-growing segment with a CAGR of 12.3%, as these industries increasingly adopt MOF-MMMs for protein separation, drug purification, and biofuel production. The food and beverage industry has also begun implementing these advanced membrane technologies for processes such as juice clarification and dairy product filtration.

Geographically, North America and Europe currently lead the market adoption of MOF-enhanced membranes, collectively accounting for approximately 58% of global market share. However, the Asia-Pacific region is experiencing the most rapid growth rate at 14.2% annually, driven by expanding industrial activities in China, Japan, South Korea, and India, coupled with increasing environmental regulations.

Market analysis reveals several key drivers propelling the MOF-MMM market forward. Stringent environmental regulations regarding emissions and water quality standards are creating regulatory push factors. Simultaneously, the superior performance characteristics of MOF-MMMs—including enhanced selectivity, permeability, and fouling resistance—are generating strong technology pull factors. The growing emphasis on sustainable industrial processes and circular economy principles is further accelerating market adoption.

Despite positive growth indicators, certain market barriers persist. The relatively high production costs of MOF materials compared to conventional fillers remains a significant challenge, with current price premiums ranging from 30-200% depending on the specific MOF type. Additionally, scalability issues in manufacturing consistent, defect-free MOF-MMMs at industrial scales continue to limit broader market penetration, particularly in cost-sensitive applications.

Current Challenges in MOF-MMM Technology Development

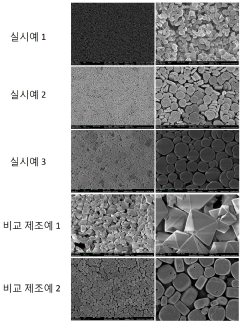

Despite significant advancements in MOF-MMM technology, several critical challenges continue to impede widespread industrial adoption and optimal performance. One of the most persistent issues is the interfacial compatibility between MOF particles and polymer matrices. Poor adhesion at these interfaces creates non-selective voids that compromise membrane selectivity and mechanical stability. This challenge is particularly pronounced with hydrophilic MOFs in hydrophobic polymer matrices, resulting in agglomeration and uneven dispersion.

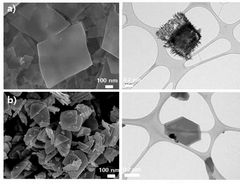

The size control and uniform dispersion of MOF fillers represent another significant hurdle. Current synthesis methods often produce MOF particles with broad size distributions, leading to inconsistent membrane performance. When particle size exceeds 200-300 nm, significant sedimentation occurs during membrane casting, creating heterogeneous structures with unpredictable separation properties. Additionally, higher MOF loadings (>20 wt%) frequently result in agglomeration, negating the benefits of increased filler content.

Long-term stability under real operating conditions remains inadequately addressed in most research studies. Many MOFs exhibit sensitivity to moisture, chemical contaminants, and mechanical stress, potentially degrading over time. This instability is particularly problematic for industrial applications requiring continuous operation over extended periods. The trade-off between permeability and selectivity—known as the Robeson upper bound—continues to constrain membrane performance optimization.

Scalable and reproducible manufacturing processes present formidable challenges for commercial implementation. Laboratory-scale fabrication methods often fail to translate effectively to industrial production scales. The high cost of MOF synthesis, particularly for more complex and specialized frameworks, further limits economic viability for large-scale applications. Additionally, quality control measures for ensuring consistent membrane properties across production batches remain underdeveloped.

Environmental and safety concerns associated with solvents used in MOF synthesis and membrane casting require attention. Many conventional processes employ toxic or environmentally harmful solvents that pose regulatory challenges for industrial adoption. Furthermore, the life cycle assessment and end-of-life management of MOF-MMMs have received minimal research focus, leaving questions about their overall environmental sustainability unanswered.

Standardization of testing protocols and performance metrics represents another critical gap. The diversity of testing conditions across research studies complicates meaningful comparison of different MOF-MMM systems, hindering technology assessment and optimization efforts. This lack of standardization also impedes regulatory approval processes necessary for commercial deployment in sensitive applications like medical devices or food packaging.

The size control and uniform dispersion of MOF fillers represent another significant hurdle. Current synthesis methods often produce MOF particles with broad size distributions, leading to inconsistent membrane performance. When particle size exceeds 200-300 nm, significant sedimentation occurs during membrane casting, creating heterogeneous structures with unpredictable separation properties. Additionally, higher MOF loadings (>20 wt%) frequently result in agglomeration, negating the benefits of increased filler content.

Long-term stability under real operating conditions remains inadequately addressed in most research studies. Many MOFs exhibit sensitivity to moisture, chemical contaminants, and mechanical stress, potentially degrading over time. This instability is particularly problematic for industrial applications requiring continuous operation over extended periods. The trade-off between permeability and selectivity—known as the Robeson upper bound—continues to constrain membrane performance optimization.

Scalable and reproducible manufacturing processes present formidable challenges for commercial implementation. Laboratory-scale fabrication methods often fail to translate effectively to industrial production scales. The high cost of MOF synthesis, particularly for more complex and specialized frameworks, further limits economic viability for large-scale applications. Additionally, quality control measures for ensuring consistent membrane properties across production batches remain underdeveloped.

Environmental and safety concerns associated with solvents used in MOF synthesis and membrane casting require attention. Many conventional processes employ toxic or environmentally harmful solvents that pose regulatory challenges for industrial adoption. Furthermore, the life cycle assessment and end-of-life management of MOF-MMMs have received minimal research focus, leaving questions about their overall environmental sustainability unanswered.

Standardization of testing protocols and performance metrics represents another critical gap. The diversity of testing conditions across research studies complicates meaningful comparison of different MOF-MMM systems, hindering technology assessment and optimization efforts. This lack of standardization also impedes regulatory approval processes necessary for commercial deployment in sensitive applications like medical devices or food packaging.

Contemporary MOF-MMM Fabrication Approaches

01 MOF-based mixed matrix membranes for gas separation

Metal-organic frameworks (MOFs) can be incorporated as fillers in mixed matrix membranes to enhance gas separation performance. These membranes combine the processability of polymers with the superior separation properties of MOFs, resulting in improved selectivity and permeability for various gas pairs such as CO2/CH4 and CO2/N2. The porous structure of MOFs allows for molecular sieving while maintaining good mechanical stability in the polymer matrix.- MOF-based mixed matrix membranes for gas separation: Metal-organic frameworks (MOFs) can be incorporated as fillers in mixed matrix membranes to enhance gas separation performance. These membranes combine the processability of polymers with the superior separation properties of MOFs. The porous structure of MOFs allows for selective gas transport, making them effective for applications such as CO2 capture, natural gas purification, and hydrogen separation. The integration of MOFs into polymer matrices creates synergistic effects that improve permeability and selectivity beyond what either component could achieve alone.

- MOF fillers for water purification membranes: Mixed matrix membranes containing metal-organic framework fillers can be designed for water purification applications. These membranes leverage the unique pore structures and functionalities of MOFs to remove contaminants from water through mechanisms such as adsorption, size exclusion, and catalytic degradation. The incorporation of MOFs enhances membrane performance in terms of water flux, contaminant rejection, and fouling resistance. Applications include desalination, removal of heavy metals, organic pollutants, and micropollutants from wastewater and drinking water sources.

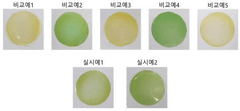

- Synthesis and fabrication methods for MOF-based mixed matrix membranes: Various techniques can be employed to synthesize and fabricate mixed matrix membranes containing metal-organic framework fillers. These methods include solution casting, phase inversion, interfacial polymerization, and in-situ growth of MOFs within polymer matrices. The fabrication process significantly influences the dispersion of MOF particles, interfacial compatibility between MOF and polymer, and overall membrane morphology. Proper selection of solvents, polymer-MOF ratios, and post-treatment conditions is crucial for optimizing membrane performance and preventing defects such as interfacial voids and agglomeration.

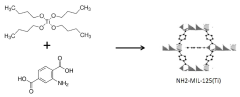

- Surface modification of MOF fillers for enhanced compatibility: Surface modification techniques can be applied to metal-organic framework fillers to improve their compatibility with polymer matrices in mixed matrix membranes. These modifications include functionalization with organic ligands, polymer grafting, and silane coupling agents. Enhanced compatibility reduces interfacial defects and improves filler dispersion, leading to better mechanical properties and separation performance. Modified MOFs can form stronger interactions with the polymer matrix through hydrogen bonding, covalent bonding, or other intermolecular forces, resulting in membranes with improved stability and longevity.

- Novel MOF structures for specialized separation applications: Innovative metal-organic framework structures are being developed as fillers for mixed matrix membranes in specialized separation applications. These include hierarchical MOFs with multiple pore sizes, stimuli-responsive MOFs that change properties under external triggers, and MOFs with tailored functional groups for specific molecular interactions. Such advanced MOF designs enable membranes with unprecedented separation capabilities for challenging mixtures, including isomer separation, chiral molecule separation, and capture of trace contaminants. The ability to precisely engineer MOF pore size, shape, and chemistry allows for highly selective membrane-based separation processes.

02 MOF modification techniques for improved membrane compatibility

Various modification techniques can be applied to MOFs to improve their compatibility with polymer matrices in mixed matrix membranes. These include surface functionalization, post-synthetic modification, and the use of coupling agents to enhance the MOF-polymer interface. Modified MOFs show reduced agglomeration, better dispersion, and stronger adhesion to the polymer matrix, resulting in membranes with fewer non-selective voids and enhanced separation performance.Expand Specific Solutions03 Fabrication methods for MOF-based mixed matrix membranes

Different fabrication methods can be employed to prepare MOF-based mixed matrix membranes with optimized morphology and performance. These include solution casting, phase inversion, interfacial polymerization, and in-situ growth of MOFs within polymer matrices. The choice of fabrication method significantly affects the distribution of MOF particles, membrane thickness, and overall separation efficiency. Advanced techniques like 3D printing and electrospinning can also be used to create novel membrane architectures.Expand Specific Solutions04 MOF selection criteria for specific separation applications

The selection of appropriate MOF fillers for mixed matrix membranes depends on the target separation application. Factors such as pore size, chemical stability, framework flexibility, and functional groups play crucial roles in determining separation performance. ZIF-8, UiO-66, and MIL-53 are commonly used MOFs due to their tunable properties and stability. For CO2 capture, MOFs with basic functionalities are preferred, while water-stable MOFs are essential for pervaporation and water treatment applications.Expand Specific Solutions05 Hybrid and composite MOF-based membrane systems

Hybrid and composite systems incorporating MOFs with other materials can create synergistic effects in mixed matrix membranes. These include MOF/graphene oxide composites, MOF/nanoparticle hybrids, and multi-component fillers combining MOFs with zeolites or silica. Such hybrid systems can address limitations of single-component fillers, offering enhanced permeability, selectivity, mechanical strength, and fouling resistance. The combination of different materials allows for tailoring membrane properties for specific separation challenges.Expand Specific Solutions

Leading Institutions and Companies in MOF-MMM Research

The metal-organic framework (MOF) fillers in mixed matrix membranes (MMMs) market is currently in a growth phase, with increasing research and commercial interest. The global market size for MOF-based membranes is expanding rapidly, projected to reach significant value by 2030 due to growing applications in gas separation, water purification, and chemical processing. Technologically, this field shows varying maturity levels across different applications. Academic institutions like Zhejiang University of Technology, King Abdullah University of Science & Technology, and University of Delaware are driving fundamental research, while companies such as UOP LLC, SABIC, and China Petroleum & Chemical Corp are advancing commercial applications. The integration between academic innovation and industrial implementation is creating a competitive landscape where specialized knowledge in MOF synthesis and membrane fabrication represents a significant competitive advantage.

UOP LLC

Technical Solution: UOP LLC (霍尼韦尔旗下)开发了一系列基于MOF填料的混合基质膜技术,专注于气体分离应用。其核心技术方案包括将ZIF-8、HKUST-1和UiO-66等MOF材料与聚酰亚胺(PI)、聚砜(PSf)等高性能聚合物基质结合,形成具有优异气体选择性的复合膜。UOP的技术特点是通过精确控制MOF颗粒尺寸(通常在50-200nm范围)和表面化学修饰,显著改善MOF-聚合物界面相容性,减少界面缺陷。其专利技术包括使用偶联剂处理MOF表面,创建聚合物与MOF之间的共价键连接,有效解决了传统混合基质膜中的界面空隙问题。UOP还开发了连续卷对卷生产工艺,实现了MOF基混合基质膜的规模化制备,膜厚度可控制在1-5μm范围,保证了产品的一致性和可靠性。

优势:拥有成熟的工业化生产能力和丰富的商业应用经验;MOF-聚合物界面改性技术领先;气体分离性能稳定,选择性高。劣势:生产成本相对较高;部分高性能MOF材料合成复杂,难以大规模应用;在高温高压环境下膜性能衰减问题尚未完全解决。

SABIC Global Technologies BV

Technical Solution: SABIC Global Technologies开发了专有的MOF-聚合物复合膜系统,主要应用于石油化工领域的气体分离和纯化。其技术方案围绕两个核心方向:一是开发了一系列具有高热稳定性的ZIF类MOF材料(如ZIF-67、ZIF-90)与工程塑料(如聚醚砜、聚醚酰亚胺)的复合体系,通过精确控制MOF晶体生长方向和尺寸分布(平均粒径控制在100-300nm),显著提高了CO2/CH4、H2/CO2等气体对的分离因子;二是创新性地采用原位聚合技术,在MOF表面引发聚合反应,形成具有核壳结构的MOF@聚合物复合颗粒,再将其均匀分散于聚合物基质中,有效解决了传统混合基质膜中MOF团聚和界面缺陷问题。SABIC的混合基质膜在150°C高温条件下仍能保持稳定的分离性能,CO2渗透率比传统聚合物膜提高了约200%,同时保持了较高的选择性。

优势:MOF材料合成和改性技术先进;原位聚合技术有效解决界面兼容性问题;产品在高温环境下性能稳定。劣势:技术路线复杂,生产工艺要求高;部分高性能MOF成本高昂;在高湿度环境下MOF结构稳定性仍有待提高;膜的机械强度与纯聚合物膜相比有所降低。

Critical Patents and Literature on MOF-MMM Interfaces

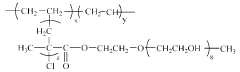

Mixed matrix membrane comprising metal organic frameworks for separating gases and method for preparing the same

PatentActiveKR1020230037088A

Innovation

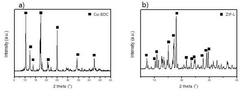

- A mixed medium separation membrane using two types of plate-shaped metal-organic frameworks, specifically copper-based and zeolite-based frameworks, improves dispersion characteristics and enables the production of uniform films, enhancing both permeability and selectivity.

Mixed matrix membrane comprising metal organic frameworks for separating carbon dioxide

PatentInactiveKR1020190081086A

Innovation

- A mixed separation membrane is developed using a nanometer-sized metal-organic framework and a branched copolymer, prepared by specific synthesis steps involving an organic linker with an amine group, a glycidyl-based compound, and a metal precursor, combined with a halogenated polymer compound to enhance dispersibility and selectivity.

Sustainability Impact of MOF-Based Separation Technologies

The integration of Metal-Organic Framework (MOF) fillers in mixed matrix membranes represents a significant advancement in sustainable separation technologies with far-reaching environmental implications. These hybrid membrane systems offer substantial reductions in energy consumption compared to conventional separation methods such as distillation and cryogenic separation, which typically account for 10-15% of global energy usage in industrial processes.

MOF-based separation technologies contribute directly to several United Nations Sustainable Development Goals, particularly those related to clean water and sanitation (SDG 6), affordable and clean energy (SDG 7), and responsible consumption and production (SDG 12). By enabling more efficient carbon capture processes, these technologies also support climate action initiatives (SDG 13), addressing one of the most pressing environmental challenges of our time.

The environmental footprint of MOF-MMMs is notably smaller than traditional separation methods. Life cycle assessments indicate that despite the energy required for MOF synthesis, the operational efficiency gains over membrane lifetime result in net positive environmental impacts. For instance, MOF-incorporated membranes used in natural gas purification can reduce carbon dioxide emissions by up to 30% compared to amine scrubbing technologies, while simultaneously decreasing water usage and chemical waste.

In water treatment applications, MOF-enhanced membranes demonstrate exceptional performance in removing emerging contaminants such as pharmaceuticals, microplastics, and heavy metals. This capability addresses growing concerns about water quality and scarcity, particularly in regions facing severe water stress. The selective adsorption properties of MOFs enable targeted removal of specific pollutants without extensive pre-treatment requirements.

Economic sustainability analyses reveal that while initial implementation costs for MOF-based separation technologies may be higher, the long-term operational savings and extended membrane lifespans create favorable total cost of ownership profiles. Industries adopting these technologies typically observe return on investment within 3-5 years, depending on application scale and specific separation requirements.

The circular economy potential of MOF-MMMs is particularly promising. Research indicates that certain MOF structures can be regenerated and reused multiple times without significant performance degradation. Additionally, end-of-life recovery strategies for extracting valuable metals from spent MOFs are being developed, further enhancing their sustainability credentials and reducing dependence on primary resource extraction.

As regulatory frameworks increasingly emphasize environmental performance and carbon pricing mechanisms gain traction globally, the sustainability advantages of MOF-based separation technologies position them favorably for widespread industrial adoption in the coming decade.

MOF-based separation technologies contribute directly to several United Nations Sustainable Development Goals, particularly those related to clean water and sanitation (SDG 6), affordable and clean energy (SDG 7), and responsible consumption and production (SDG 12). By enabling more efficient carbon capture processes, these technologies also support climate action initiatives (SDG 13), addressing one of the most pressing environmental challenges of our time.

The environmental footprint of MOF-MMMs is notably smaller than traditional separation methods. Life cycle assessments indicate that despite the energy required for MOF synthesis, the operational efficiency gains over membrane lifetime result in net positive environmental impacts. For instance, MOF-incorporated membranes used in natural gas purification can reduce carbon dioxide emissions by up to 30% compared to amine scrubbing technologies, while simultaneously decreasing water usage and chemical waste.

In water treatment applications, MOF-enhanced membranes demonstrate exceptional performance in removing emerging contaminants such as pharmaceuticals, microplastics, and heavy metals. This capability addresses growing concerns about water quality and scarcity, particularly in regions facing severe water stress. The selective adsorption properties of MOFs enable targeted removal of specific pollutants without extensive pre-treatment requirements.

Economic sustainability analyses reveal that while initial implementation costs for MOF-based separation technologies may be higher, the long-term operational savings and extended membrane lifespans create favorable total cost of ownership profiles. Industries adopting these technologies typically observe return on investment within 3-5 years, depending on application scale and specific separation requirements.

The circular economy potential of MOF-MMMs is particularly promising. Research indicates that certain MOF structures can be regenerated and reused multiple times without significant performance degradation. Additionally, end-of-life recovery strategies for extracting valuable metals from spent MOFs are being developed, further enhancing their sustainability credentials and reducing dependence on primary resource extraction.

As regulatory frameworks increasingly emphasize environmental performance and carbon pricing mechanisms gain traction globally, the sustainability advantages of MOF-based separation technologies position them favorably for widespread industrial adoption in the coming decade.

Scalability and Industrial Implementation Considerations

The scalability of Metal-Organic Framework (MOF) fillers in Mixed Matrix Membranes (MMMs) represents a critical challenge for industrial implementation. Current laboratory-scale synthesis methods for MOFs often yield only gram quantities, which are insufficient for commercial membrane production that requires kilogram to ton scales. This scale-up gap necessitates significant process engineering to maintain consistent MOF properties while increasing production volume.

Manufacturing consistency presents another major hurdle in industrial implementation. The reproducibility of MOF particle size, morphology, and dispersion quality directly impacts membrane performance. Industrial settings require standardized protocols that can deliver consistent MOF quality across multiple production batches. Additionally, the integration of MOFs into polymer matrices at industrial scale demands specialized equipment and processing techniques that differ substantially from laboratory methods.

Cost considerations significantly influence the commercial viability of MOF-based MMMs. Raw material expenses for MOF synthesis, particularly specialized organic linkers and metal precursors, can be prohibitively high for large-scale production. Process economics must account for energy-intensive activation procedures and potential solvent recovery systems. Manufacturers must balance enhanced membrane performance against increased production costs to ensure market competitiveness.

Environmental and safety regulations present additional implementation challenges. Many MOF synthesis routes utilize solvents with environmental concerns, requiring closed-loop recovery systems or alternative green synthesis methods for industrial compliance. Worker safety protocols must address potential hazards associated with fine MOF powders and chemical precursors used in large-scale production environments.

Membrane module fabrication represents the final critical step in industrial implementation. The translation from flat-sheet laboratory membranes to commercial hollow fiber or spiral-wound configurations introduces new engineering challenges. MOF distribution must remain uniform throughout these complex geometries, and membrane mechanical stability must withstand industrial operating conditions. Specialized fabrication equipment and quality control systems are essential for successful module production.

Long-term stability under actual operating conditions ultimately determines commercial adoption. Industrial membranes must maintain separation performance over months or years, requiring comprehensive aging studies that account for chemical, thermal, and mechanical stresses. Accelerated testing protocols must be developed to predict membrane lifetimes accurately, as industrial users require reliable performance guarantees before adopting new membrane technologies.

Manufacturing consistency presents another major hurdle in industrial implementation. The reproducibility of MOF particle size, morphology, and dispersion quality directly impacts membrane performance. Industrial settings require standardized protocols that can deliver consistent MOF quality across multiple production batches. Additionally, the integration of MOFs into polymer matrices at industrial scale demands specialized equipment and processing techniques that differ substantially from laboratory methods.

Cost considerations significantly influence the commercial viability of MOF-based MMMs. Raw material expenses for MOF synthesis, particularly specialized organic linkers and metal precursors, can be prohibitively high for large-scale production. Process economics must account for energy-intensive activation procedures and potential solvent recovery systems. Manufacturers must balance enhanced membrane performance against increased production costs to ensure market competitiveness.

Environmental and safety regulations present additional implementation challenges. Many MOF synthesis routes utilize solvents with environmental concerns, requiring closed-loop recovery systems or alternative green synthesis methods for industrial compliance. Worker safety protocols must address potential hazards associated with fine MOF powders and chemical precursors used in large-scale production environments.

Membrane module fabrication represents the final critical step in industrial implementation. The translation from flat-sheet laboratory membranes to commercial hollow fiber or spiral-wound configurations introduces new engineering challenges. MOF distribution must remain uniform throughout these complex geometries, and membrane mechanical stability must withstand industrial operating conditions. Specialized fabrication equipment and quality control systems are essential for successful module production.

Long-term stability under actual operating conditions ultimately determines commercial adoption. Industrial membranes must maintain separation performance over months or years, requiring comprehensive aging studies that account for chemical, thermal, and mechanical stresses. Accelerated testing protocols must be developed to predict membrane lifetimes accurately, as industrial users require reliable performance guarantees before adopting new membrane technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!