Integration Of Membrane Carbon Capture With Direct Air Capture Systems

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Membrane-DAC Integration Background and Objectives

The integration of membrane technology with Direct Air Capture (DAC) systems represents a significant frontier in carbon capture innovation. This convergence builds upon decades of separate development in membrane separation science and carbon capture technologies. Membrane-based separation processes have evolved since the 1970s, initially focused on gas separation for industrial applications, while DAC emerged in the early 2000s as a direct response to rising atmospheric CO2 levels. The intersection of these technologies offers promising pathways for enhancing carbon capture efficiency while reducing energy requirements.

The primary objective of membrane-DAC integration is to overcome the fundamental challenges that have limited DAC deployment: high energy consumption, substantial capital costs, and operational inefficiencies. Membrane technology, with its inherent advantages in selective permeation and modular design, presents an opportunity to address these limitations by providing more energy-efficient separation mechanisms for capturing CO2 from ambient air, where carbon dioxide exists at extremely dilute concentrations (approximately 420 ppm).

Technical evolution in this field has accelerated significantly since 2015, driven by advances in material science that have produced membranes with enhanced CO2 selectivity and permeability. Polymeric membranes, mixed matrix membranes (MMMs), and facilitated transport membranes have emerged as particularly promising candidates for DAC applications. The development trajectory suggests a convergence toward hybrid systems that leverage the strengths of both membrane separation and traditional sorbent-based DAC approaches.

Current research aims to achieve several critical technical milestones: membranes with CO2/N2 selectivity exceeding 100, permeability rates above 1000 Barrer, and stability under variable atmospheric conditions including fluctuating humidity levels. Additionally, integration objectives include reducing the energy requirement below 1 GJ per ton of CO2 captured—a significant improvement over current DAC systems that typically require 4-7 GJ per ton.

The global context for membrane-DAC integration has been shaped by increasing climate policy stringency and carbon pricing mechanisms. The 2015 Paris Agreement and subsequent national commitments to carbon neutrality have created a favorable environment for carbon capture innovation. Furthermore, recent policy developments, such as the U.S. Inflation Reduction Act and the EU's Carbon Border Adjustment Mechanism, have established financial incentives that improve the economic viability of advanced carbon capture technologies.

Looking forward, membrane-DAC integration aims to deliver scalable, modular systems capable of gigaton-scale carbon removal with substantially reduced energy penalties compared to first-generation DAC technologies. This represents a critical pathway toward achieving negative emissions targets considered essential by the IPCC for limiting global warming to 1.5°C above pre-industrial levels.

The primary objective of membrane-DAC integration is to overcome the fundamental challenges that have limited DAC deployment: high energy consumption, substantial capital costs, and operational inefficiencies. Membrane technology, with its inherent advantages in selective permeation and modular design, presents an opportunity to address these limitations by providing more energy-efficient separation mechanisms for capturing CO2 from ambient air, where carbon dioxide exists at extremely dilute concentrations (approximately 420 ppm).

Technical evolution in this field has accelerated significantly since 2015, driven by advances in material science that have produced membranes with enhanced CO2 selectivity and permeability. Polymeric membranes, mixed matrix membranes (MMMs), and facilitated transport membranes have emerged as particularly promising candidates for DAC applications. The development trajectory suggests a convergence toward hybrid systems that leverage the strengths of both membrane separation and traditional sorbent-based DAC approaches.

Current research aims to achieve several critical technical milestones: membranes with CO2/N2 selectivity exceeding 100, permeability rates above 1000 Barrer, and stability under variable atmospheric conditions including fluctuating humidity levels. Additionally, integration objectives include reducing the energy requirement below 1 GJ per ton of CO2 captured—a significant improvement over current DAC systems that typically require 4-7 GJ per ton.

The global context for membrane-DAC integration has been shaped by increasing climate policy stringency and carbon pricing mechanisms. The 2015 Paris Agreement and subsequent national commitments to carbon neutrality have created a favorable environment for carbon capture innovation. Furthermore, recent policy developments, such as the U.S. Inflation Reduction Act and the EU's Carbon Border Adjustment Mechanism, have established financial incentives that improve the economic viability of advanced carbon capture technologies.

Looking forward, membrane-DAC integration aims to deliver scalable, modular systems capable of gigaton-scale carbon removal with substantially reduced energy penalties compared to first-generation DAC technologies. This represents a critical pathway toward achieving negative emissions targets considered essential by the IPCC for limiting global warming to 1.5°C above pre-industrial levels.

Market Analysis for Integrated Carbon Capture Solutions

The global carbon capture market is experiencing significant growth, driven by increasing environmental regulations and corporate sustainability commitments. The integrated membrane carbon capture and direct air capture (DAC) systems market is projected to reach $7.6 billion by 2030, with a compound annual growth rate of 19.8% from 2023 to 2030. This growth trajectory is supported by substantial government investments, with the United States allocating $3.5 billion for DAC hubs through the Infrastructure Investment and Jobs Act.

The market segmentation reveals distinct customer categories with varying needs. Industrial facilities seeking to reduce emissions from point sources represent approximately 65% of the current market, while companies pursuing carbon neutrality goals through atmospheric carbon removal constitute about 25%. Government entities and research institutions make up the remaining 10%, primarily focused on technology development and demonstration projects.

Regional market analysis indicates North America leads with 42% market share, followed by Europe at 31%, Asia-Pacific at 18%, and other regions comprising 9%. The United States and Canada dominate the North American market due to favorable policy environments and substantial private investments. In Europe, countries like Germany, the Netherlands, and the UK are at the forefront, driven by stringent emission reduction targets and carbon pricing mechanisms.

Key market drivers include tightening regulatory frameworks, with over 40 countries implementing carbon pricing mechanisms. The average carbon price in the European Union Emissions Trading System reached €80 per ton in 2022, creating strong economic incentives for carbon capture solutions. Additionally, corporate net-zero commitments have surged, with over 1,500 major companies pledging carbon neutrality by 2050.

Market barriers include high capital expenditure requirements, with integrated membrane-DAC systems currently costing between $250-600 per ton of CO₂ captured. Technological maturity remains a challenge, particularly for direct air capture components which are still in early commercial deployment phases. Infrastructure limitations for CO₂ transport and storage also constrain market growth in regions lacking appropriate geological formations or pipeline networks.

Future market trends indicate movement toward modular, scalable systems that can be deployed across diverse settings. Integration with renewable energy sources is becoming standard practice to minimize operational costs and carbon footprints. Emerging business models include carbon capture as a service (CCaaS), allowing customers to purchase carbon removal without capital investment in physical infrastructure.

The market segmentation reveals distinct customer categories with varying needs. Industrial facilities seeking to reduce emissions from point sources represent approximately 65% of the current market, while companies pursuing carbon neutrality goals through atmospheric carbon removal constitute about 25%. Government entities and research institutions make up the remaining 10%, primarily focused on technology development and demonstration projects.

Regional market analysis indicates North America leads with 42% market share, followed by Europe at 31%, Asia-Pacific at 18%, and other regions comprising 9%. The United States and Canada dominate the North American market due to favorable policy environments and substantial private investments. In Europe, countries like Germany, the Netherlands, and the UK are at the forefront, driven by stringent emission reduction targets and carbon pricing mechanisms.

Key market drivers include tightening regulatory frameworks, with over 40 countries implementing carbon pricing mechanisms. The average carbon price in the European Union Emissions Trading System reached €80 per ton in 2022, creating strong economic incentives for carbon capture solutions. Additionally, corporate net-zero commitments have surged, with over 1,500 major companies pledging carbon neutrality by 2050.

Market barriers include high capital expenditure requirements, with integrated membrane-DAC systems currently costing between $250-600 per ton of CO₂ captured. Technological maturity remains a challenge, particularly for direct air capture components which are still in early commercial deployment phases. Infrastructure limitations for CO₂ transport and storage also constrain market growth in regions lacking appropriate geological formations or pipeline networks.

Future market trends indicate movement toward modular, scalable systems that can be deployed across diverse settings. Integration with renewable energy sources is becoming standard practice to minimize operational costs and carbon footprints. Emerging business models include carbon capture as a service (CCaaS), allowing customers to purchase carbon removal without capital investment in physical infrastructure.

Technical Challenges in Membrane-DAC Integration

The integration of membrane technology with Direct Air Capture (DAC) systems presents several significant technical challenges that must be addressed for successful implementation. The primary obstacle lies in the extremely low concentration of CO2 in ambient air (approximately 420 ppm), which necessitates highly selective membrane materials capable of efficiently capturing CO2 while rejecting other atmospheric components.

Membrane fouling represents another critical challenge, as airborne particulates, moisture, and contaminants can rapidly degrade membrane performance. Unlike controlled industrial environments, DAC systems operate in variable outdoor conditions, exposing membranes to dust, pollen, and pollutants that can block pores and active sites, significantly reducing separation efficiency and operational lifespan.

Temperature and humidity fluctuations pose substantial difficulties for membrane-based DAC systems. Most membrane materials exhibit performance characteristics that are highly sensitive to environmental conditions. Daily and seasonal variations can cause membrane swelling, contraction, and altered selectivity properties, leading to inconsistent capture rates and reduced overall system efficiency.

Energy requirements present a formidable barrier to widespread adoption. Current membrane-based separation processes for dilute CO2 streams demand significant energy inputs to create the necessary pressure differentials or to regenerate sorbents. This energy intensity directly impacts the economic viability and carbon balance of the entire DAC operation, particularly when scaling to climate-relevant capacities.

Material durability under continuous operation represents a substantial engineering challenge. Membranes must maintain structural integrity and separation performance over thousands of cycles in varying conditions. Current materials often demonstrate performance degradation after extended operation, necessitating frequent replacement and increasing operational costs.

Scale-up challenges further complicate implementation, as laboratory-proven membrane technologies often face difficulties when transitioning to industrial scales. The massive membrane surface area required for meaningful CO2 capture from ambient air presents manufacturing, quality control, and system integration hurdles that have not been fully resolved.

Integration with downstream processes also presents technical obstacles. Captured CO2 must be effectively desorbed and concentrated for utilization or sequestration, requiring careful engineering of the membrane-DAC system interface to maintain energy efficiency across the entire carbon capture value chain.

Membrane fouling represents another critical challenge, as airborne particulates, moisture, and contaminants can rapidly degrade membrane performance. Unlike controlled industrial environments, DAC systems operate in variable outdoor conditions, exposing membranes to dust, pollen, and pollutants that can block pores and active sites, significantly reducing separation efficiency and operational lifespan.

Temperature and humidity fluctuations pose substantial difficulties for membrane-based DAC systems. Most membrane materials exhibit performance characteristics that are highly sensitive to environmental conditions. Daily and seasonal variations can cause membrane swelling, contraction, and altered selectivity properties, leading to inconsistent capture rates and reduced overall system efficiency.

Energy requirements present a formidable barrier to widespread adoption. Current membrane-based separation processes for dilute CO2 streams demand significant energy inputs to create the necessary pressure differentials or to regenerate sorbents. This energy intensity directly impacts the economic viability and carbon balance of the entire DAC operation, particularly when scaling to climate-relevant capacities.

Material durability under continuous operation represents a substantial engineering challenge. Membranes must maintain structural integrity and separation performance over thousands of cycles in varying conditions. Current materials often demonstrate performance degradation after extended operation, necessitating frequent replacement and increasing operational costs.

Scale-up challenges further complicate implementation, as laboratory-proven membrane technologies often face difficulties when transitioning to industrial scales. The massive membrane surface area required for meaningful CO2 capture from ambient air presents manufacturing, quality control, and system integration hurdles that have not been fully resolved.

Integration with downstream processes also presents technical obstacles. Captured CO2 must be effectively desorbed and concentrated for utilization or sequestration, requiring careful engineering of the membrane-DAC system interface to maintain energy efficiency across the entire carbon capture value chain.

Current Membrane-DAC Integration Approaches

01 Membrane technology for carbon capture efficiency

Advanced membrane technologies are being developed to enhance carbon capture efficiency in both direct air capture (DAC) systems and point source applications. These membranes feature selective permeability properties that allow CO2 to pass through while blocking other gases, significantly improving capture rates. Recent innovations include composite membranes with functionalized surfaces, thin-film membranes with high CO2 selectivity, and temperature-responsive membrane materials that can adjust their permeability based on operating conditions.- Membrane technology for carbon capture: Advanced membrane technologies are being developed for efficient carbon capture from both direct air and point sources. These membranes feature selective permeability that allows CO2 to pass through while blocking other gases. The integration of specialized polymers and composite materials enhances separation efficiency and durability. These membrane systems can operate at lower energy requirements compared to traditional carbon capture methods, making them particularly suitable for integration with direct air capture systems.

- Hybrid direct air capture systems: Hybrid systems combining membrane technology with other carbon capture methods show improved efficiency in direct air capture applications. These integrated approaches utilize membranes as pre-concentration or final purification steps alongside absorption, adsorption, or cryogenic processes. The synergistic effect of combining multiple technologies addresses the challenges of capturing CO2 from ambient air where concentrations are low. Such hybrid systems can achieve higher capture rates while maintaining reasonable energy consumption profiles.

- Energy optimization in integrated capture systems: Energy efficiency improvements are critical for viable carbon capture systems. Innovations include waste heat recovery, renewable energy integration, and process optimization to reduce the parasitic energy load of carbon capture operations. Advanced heat exchange systems and pressure swing mechanisms minimize energy requirements. Some systems incorporate renewable energy sources directly into the capture process, creating more sustainable and economically viable carbon removal solutions.

- Novel membrane materials for enhanced selectivity: Development of specialized membrane materials with enhanced CO2 selectivity and permeability is advancing carbon capture efficiency. These materials include facilitated transport membranes, mixed matrix membranes, and thermally rearranged polymers. Some incorporate carrier molecules that specifically bind with CO2, increasing separation performance. Nanostructured materials and metal-organic frameworks are being integrated into membrane structures to create highly selective pathways for CO2 molecules while blocking other atmospheric gases.

- System integration and process control: Advanced control systems and integration strategies are being developed to optimize the performance of combined membrane and direct air capture systems. These include real-time monitoring, adaptive control algorithms, and modular designs that can be scaled according to capture requirements. Sophisticated process integration approaches minimize energy consumption while maximizing capture efficiency. Some systems incorporate artificial intelligence to continuously optimize operating parameters based on environmental conditions and system performance metrics.

02 Integration of membrane systems with direct air capture

The integration of membrane systems with direct air capture technologies creates hybrid systems that overcome limitations of standalone approaches. These integrated systems use membranes as pre-concentration devices before the air contacts traditional sorbents, reducing energy requirements and increasing overall efficiency. The membrane component can operate continuously while the DAC component undergoes regeneration cycles, maintaining constant carbon capture rates. This integration also allows for modular design and scalability across different deployment scenarios.Expand Specific Solutions03 Energy optimization in combined membrane-DAC systems

Energy consumption is a critical factor in carbon capture systems. Combined membrane-DAC systems incorporate various energy optimization techniques including waste heat recovery, renewable energy integration, and process heat recycling. Advanced control systems dynamically adjust operating parameters based on environmental conditions and energy availability. Some designs incorporate thermal management systems that utilize temperature gradients to drive separation processes, while others employ pressure swing mechanisms that minimize external energy inputs.Expand Specific Solutions04 Novel sorbent-membrane hybrid materials

Researchers have developed hybrid materials that combine properties of both membranes and sorbents to enhance carbon capture efficiency. These materials feature microporous structures with functionalized surfaces that can both selectively transport and bind CO2 molecules. Some designs incorporate liquid membranes with suspended capture agents, while others use solid-state materials with engineered pore structures. These hybrid materials demonstrate improved selectivity, capacity, and regeneration characteristics compared to conventional approaches, leading to higher overall system efficiency.Expand Specific Solutions05 System integration and process optimization

Effective integration of membrane carbon capture with direct air capture requires sophisticated system design and process optimization. This includes optimized flow configurations, pressure management systems, and feedback control mechanisms that adapt to changing conditions. Advanced modeling techniques help predict system performance across various operating scenarios, while machine learning algorithms continuously optimize process parameters. Some systems incorporate multi-stage capture processes with different membrane types optimized for specific concentration ranges, maximizing overall efficiency across the entire capture process.Expand Specific Solutions

Leading Organizations in Membrane and DAC Technologies

The integration of membrane carbon capture with direct air capture (DAC) systems represents an emerging technological frontier in carbon management, currently in its early growth phase. The global carbon capture market is projected to reach $7-10 billion by 2030, with membrane technologies gaining traction due to their energy efficiency advantages. Technical maturity varies significantly across key players: established companies like IBM and Climeworks demonstrate commercial-scale implementations, while academic institutions (Southeast University, Tianjin University, EPFL) focus on fundamental research advancements. Chinese research entities (Xi'an Thermal Power Research Institute, Huaneng Clean Energy Research Institute) are rapidly developing membrane technologies for industrial applications, while startups like Capture6 and Captura are pioneering innovative hybrid approaches combining membrane systems with direct air capture methodologies, accelerating the technology's commercial viability.

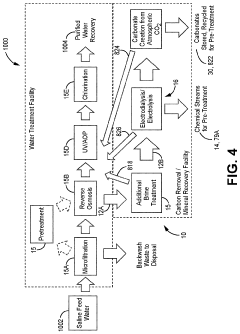

École Polytechnique Fédérale de Lausanne

Technical Solution: EPFL has developed an advanced integrated membrane-DAC system utilizing metal-organic framework (MOF) enhanced membranes. Their approach incorporates specially engineered MOF particles within thin-film composite membranes to create materials with exceptional CO2 selectivity and permeability. The system operates through a pressure-vacuum swing process where ambient air is forced through the membrane modules under slight pressure (1.2-1.5 bar), while a vacuum is maintained on the permeate side to maximize CO2 flux. This configuration achieves separation factors exceeding 50 for CO2/N2 with permeance values of 1000-1500 GPU. EPFL's technology integrates these high-performance membranes with a secondary capture loop utilizing a mild alkaline solution for final CO2 concentration and purification. The system demonstrates energy requirements of approximately 1.8-2.2 MWh per ton of CO2 captured, with laboratory demonstrations achieving capture rates of 1-2 kg CO2/m² of membrane area per day. Their approach emphasizes fundamental materials science innovation to overcome traditional membrane performance limitations, with particular focus on stability under varying humidity conditions and resistance to contaminant fouling.

Strengths: Exceptionally high CO2 selectivity compared to conventional membrane materials; lower pressure requirements reduce energy consumption; advanced materials science approach provides pathway to continuous performance improvements. Weaknesses: MOF-enhanced membranes have higher manufacturing costs than conventional polymeric membranes; technology remains primarily at laboratory/pilot scale; long-term stability under real-world conditions still being validated.

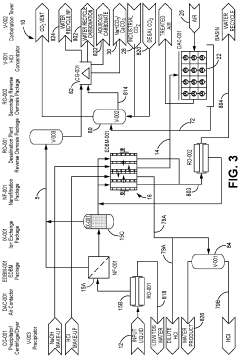

Captura Corp.

Technical Solution: Captura has developed an innovative electrochemical membrane-based system that integrates direct air capture with seawater carbon extraction. Their proprietary technology employs ion-exchange membranes in an electrochemical cell configuration that leverages the natural carbon chemistry of seawater. The system extracts dissolved CO2 from ocean water (which naturally equilibrates with atmospheric CO2) while simultaneously addressing ocean acidification. Captura's process operates at ambient temperature and pressure, utilizing specialized selective membranes that allow for CO2 separation with minimal energy input. The technology achieves approximately 70-80% capture efficiency with energy consumption of around 1.5-2 MWh per ton of CO2 captured. Their integrated approach combines the membrane separation with electrochemical pH swing processes, creating a continuous carbon capture cycle that can be powered by renewable energy sources. The system's modular design enables deployment at various scales, from small distributed units to large coastal installations.

Strengths: Lower energy requirements than many competing DAC technologies; dual benefit of carbon capture and ocean de-acidification; can be deployed in coastal areas with access to abundant seawater and renewable energy. Weaknesses: Limited to coastal deployment locations; membrane performance degradation in biologically active seawater environments; technology still at early commercial scale with limited long-term operational data.

Key Patents and Research in Hybrid Carbon Capture Systems

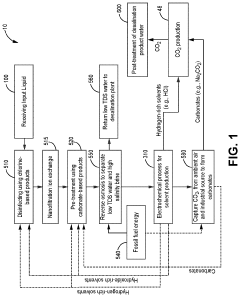

Systems and methods for integrated direct air carbon dioxide capture and desalination mineral recovery

PatentPendingUS20240123400A1

Innovation

- Integrating carbon capture and desalination processes to synergistically use byproducts, such as using brine waste from desalination for carbon capture, reducing energy consumption and waste, and employing electrochemical processes to produce hydroxide-rich streams for direct CO2 capture from air.

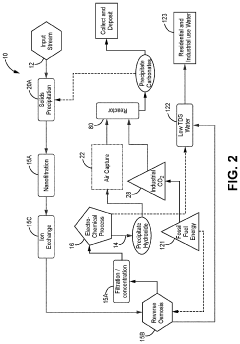

Direct air capture system removing carbon dioxide

PatentActiveUS11484831B1

Innovation

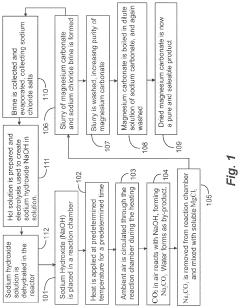

- A DAC system using sodium hydroxide in a reaction chamber to capture CO2, producing sodium carbonate and water, followed by a closed-loop process with magnesium chloride to form magnesium carbonate, which is then purified and reused, with byproducts chlorine and hydrogen gases being repurposed through electrolysis.

Economic Viability and Scalability Assessment

The economic viability of integrating membrane carbon capture with Direct Air Capture (DAC) systems hinges on several critical factors. Current cost estimates for standalone DAC systems range from $250-600 per ton of CO2 captured, significantly higher than point-source carbon capture technologies. Membrane integration offers potential cost reductions through improved energy efficiency, with preliminary studies suggesting possible operational cost decreases of 15-30% compared to traditional DAC approaches.

Capital expenditure remains a significant barrier, with membrane systems requiring substantial initial investment. However, the modular nature of membrane technology provides scalability advantages, allowing for incremental capacity expansion that aligns with funding availability and market demand. This contrasts with conventional DAC systems that often require large-scale installations to achieve economic efficiency.

Energy consumption represents approximately 60-75% of operational costs for integrated systems. Membrane technologies demonstrate promising energy efficiency metrics, with advanced polymer membranes requiring 1.5-2.5 GJ per ton of CO2 captured, compared to 4-7 GJ for traditional amine-based DAC systems. This efficiency translates directly to improved economic performance, particularly in regions with high energy costs.

Scalability assessment reveals both opportunities and challenges. Membrane manufacturing can leverage existing industrial processes, potentially enabling rapid production scaling. Current global membrane manufacturing capacity could support deployment capturing approximately 5-10 million tons of CO2 annually, representing less than 0.1% of global emissions. Significant manufacturing expansion would be required for climate-relevant implementation.

Market analysis indicates that carbon pricing mechanisms significantly impact economic viability. The integrated systems become commercially viable at carbon prices of approximately $150-200 per ton, lower than the $200-350 threshold for conventional DAC systems. This positions membrane-integrated DAC as potentially competitive in markets with robust carbon pricing or regulatory frameworks.

Long-term economic projections suggest that learning rates of 15-20% could reduce costs to below $100 per ton by 2035-2040, contingent upon sustained research investment and deployment at scale. This trajectory would position integrated membrane-DAC systems as economically competitive with other negative emissions technologies and potentially viable for large-scale commercial deployment without substantial subsidies.

Capital expenditure remains a significant barrier, with membrane systems requiring substantial initial investment. However, the modular nature of membrane technology provides scalability advantages, allowing for incremental capacity expansion that aligns with funding availability and market demand. This contrasts with conventional DAC systems that often require large-scale installations to achieve economic efficiency.

Energy consumption represents approximately 60-75% of operational costs for integrated systems. Membrane technologies demonstrate promising energy efficiency metrics, with advanced polymer membranes requiring 1.5-2.5 GJ per ton of CO2 captured, compared to 4-7 GJ for traditional amine-based DAC systems. This efficiency translates directly to improved economic performance, particularly in regions with high energy costs.

Scalability assessment reveals both opportunities and challenges. Membrane manufacturing can leverage existing industrial processes, potentially enabling rapid production scaling. Current global membrane manufacturing capacity could support deployment capturing approximately 5-10 million tons of CO2 annually, representing less than 0.1% of global emissions. Significant manufacturing expansion would be required for climate-relevant implementation.

Market analysis indicates that carbon pricing mechanisms significantly impact economic viability. The integrated systems become commercially viable at carbon prices of approximately $150-200 per ton, lower than the $200-350 threshold for conventional DAC systems. This positions membrane-integrated DAC as potentially competitive in markets with robust carbon pricing or regulatory frameworks.

Long-term economic projections suggest that learning rates of 15-20% could reduce costs to below $100 per ton by 2035-2040, contingent upon sustained research investment and deployment at scale. This trajectory would position integrated membrane-DAC systems as economically competitive with other negative emissions technologies and potentially viable for large-scale commercial deployment without substantial subsidies.

Environmental Impact and Policy Frameworks

The integration of membrane carbon capture with direct air capture (DAC) systems presents significant environmental implications that must be carefully evaluated within existing and emerging policy frameworks. These combined technologies offer promising pathways for carbon dioxide removal, potentially delivering substantial climate mitigation benefits compared to standalone systems. When properly implemented, integrated membrane-DAC systems can achieve higher carbon capture efficiency while reducing the overall environmental footprint associated with traditional carbon capture methods.

From an environmental perspective, membrane-based systems typically require less energy and fewer chemical inputs than conventional amine-based capture technologies. This translates to reduced water consumption, decreased chemical waste generation, and lower indirect emissions from energy production. However, the manufacturing of advanced membrane materials often involves energy-intensive processes and specialized polymers or materials that may present end-of-life disposal challenges.

Land use considerations represent another critical environmental dimension. Integrated membrane-DAC systems generally require less physical space than standalone DAC facilities, potentially reducing habitat disruption and land conversion impacts. This spatial efficiency becomes particularly valuable in regions where land availability is constrained or ecologically sensitive areas must be preserved.

Current policy frameworks addressing these integrated technologies remain fragmented across jurisdictions. The European Union's Carbon Border Adjustment Mechanism and enhanced Emissions Trading System provide economic incentives for deployment, while the United States' 45Q tax credits specifically target carbon capture technologies with increasing financial support. Several Asian nations, particularly China and Japan, have established regulatory sandboxes to accelerate membrane carbon capture innovation within their broader carbon neutrality strategies.

International climate agreements increasingly recognize negative emissions technologies as essential components of climate action portfolios. The Paris Agreement's enhanced transparency framework and nationally determined contributions create mechanisms through which countries can incorporate membrane-DAC systems into their climate commitments. However, standardized methodologies for measuring, reporting, and verifying carbon removal from these integrated systems remain underdeveloped.

Regulatory gaps persist regarding long-term carbon storage verification, liability frameworks for potential leakage, and comprehensive lifecycle assessment requirements. Policy innovation is needed to establish technology-specific performance standards, create market-based incentives that recognize efficiency improvements from integration, and develop certification protocols that can support emerging carbon removal markets and corporate net-zero commitments.

From an environmental perspective, membrane-based systems typically require less energy and fewer chemical inputs than conventional amine-based capture technologies. This translates to reduced water consumption, decreased chemical waste generation, and lower indirect emissions from energy production. However, the manufacturing of advanced membrane materials often involves energy-intensive processes and specialized polymers or materials that may present end-of-life disposal challenges.

Land use considerations represent another critical environmental dimension. Integrated membrane-DAC systems generally require less physical space than standalone DAC facilities, potentially reducing habitat disruption and land conversion impacts. This spatial efficiency becomes particularly valuable in regions where land availability is constrained or ecologically sensitive areas must be preserved.

Current policy frameworks addressing these integrated technologies remain fragmented across jurisdictions. The European Union's Carbon Border Adjustment Mechanism and enhanced Emissions Trading System provide economic incentives for deployment, while the United States' 45Q tax credits specifically target carbon capture technologies with increasing financial support. Several Asian nations, particularly China and Japan, have established regulatory sandboxes to accelerate membrane carbon capture innovation within their broader carbon neutrality strategies.

International climate agreements increasingly recognize negative emissions technologies as essential components of climate action portfolios. The Paris Agreement's enhanced transparency framework and nationally determined contributions create mechanisms through which countries can incorporate membrane-DAC systems into their climate commitments. However, standardized methodologies for measuring, reporting, and verifying carbon removal from these integrated systems remain underdeveloped.

Regulatory gaps persist regarding long-term carbon storage verification, liability frameworks for potential leakage, and comprehensive lifecycle assessment requirements. Policy innovation is needed to establish technology-specific performance standards, create market-based incentives that recognize efficiency improvements from integration, and develop certification protocols that can support emerging carbon removal markets and corporate net-zero commitments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!