How Defect Distribution Impacts Composite Membrane Performance

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Composite Membrane Defect Analysis Background and Objectives

Composite membranes have emerged as critical components in various industrial applications, including water purification, gas separation, and energy storage systems. The evolution of membrane technology has witnessed significant advancements over the past decades, transitioning from simple single-layer structures to sophisticated multi-layered composite designs that offer enhanced performance characteristics. Understanding how defects within these membranes impact their overall performance has become increasingly important as industries demand higher efficiency, durability, and selectivity from membrane-based separation processes.

The development trajectory of composite membrane technology reveals a continuous pursuit of optimizing the balance between permeability and selectivity—two properties that typically exhibit an inverse relationship. Historical challenges in membrane science have centered around overcoming this trade-off while maintaining mechanical stability and chemical resistance. Recent technological breakthroughs have enabled the creation of asymmetric composite membranes with distinct functional layers, each contributing specific properties to the overall membrane performance.

Defects in composite membranes represent a fundamental challenge that has been recognized but inadequately characterized throughout the evolution of membrane technology. These defects—ranging from nanoscale pinholes to macroscopic cracks—can dramatically alter membrane performance in ways that are often difficult to predict using conventional modeling approaches. The distribution pattern of these defects, rather than merely their presence, has emerged as a critical factor that determines the extent of performance degradation.

The primary objective of this technical research is to establish a comprehensive framework for understanding how the spatial distribution, size variation, and concentration gradients of defects influence composite membrane performance metrics. This includes investigating the correlation between defect distribution patterns and key performance indicators such as flux rates, rejection capabilities, and long-term stability under various operating conditions.

Additionally, this research aims to develop predictive models that can accurately simulate the impact of different defect distribution scenarios on membrane performance, enabling more informed design decisions during membrane fabrication. By identifying critical defect distribution thresholds beyond which performance deteriorates significantly, this research seeks to establish new quality control parameters for membrane manufacturing processes.

The ultimate goal is to translate these insights into practical guidelines for membrane design and fabrication that minimize the negative impact of inevitable defects. This includes exploring novel fabrication techniques that can control defect formation and distribution, as well as developing post-fabrication treatments that can mitigate the effects of existing defects without compromising the membrane's fundamental properties.

The development trajectory of composite membrane technology reveals a continuous pursuit of optimizing the balance between permeability and selectivity—two properties that typically exhibit an inverse relationship. Historical challenges in membrane science have centered around overcoming this trade-off while maintaining mechanical stability and chemical resistance. Recent technological breakthroughs have enabled the creation of asymmetric composite membranes with distinct functional layers, each contributing specific properties to the overall membrane performance.

Defects in composite membranes represent a fundamental challenge that has been recognized but inadequately characterized throughout the evolution of membrane technology. These defects—ranging from nanoscale pinholes to macroscopic cracks—can dramatically alter membrane performance in ways that are often difficult to predict using conventional modeling approaches. The distribution pattern of these defects, rather than merely their presence, has emerged as a critical factor that determines the extent of performance degradation.

The primary objective of this technical research is to establish a comprehensive framework for understanding how the spatial distribution, size variation, and concentration gradients of defects influence composite membrane performance metrics. This includes investigating the correlation between defect distribution patterns and key performance indicators such as flux rates, rejection capabilities, and long-term stability under various operating conditions.

Additionally, this research aims to develop predictive models that can accurately simulate the impact of different defect distribution scenarios on membrane performance, enabling more informed design decisions during membrane fabrication. By identifying critical defect distribution thresholds beyond which performance deteriorates significantly, this research seeks to establish new quality control parameters for membrane manufacturing processes.

The ultimate goal is to translate these insights into practical guidelines for membrane design and fabrication that minimize the negative impact of inevitable defects. This includes exploring novel fabrication techniques that can control defect formation and distribution, as well as developing post-fabrication treatments that can mitigate the effects of existing defects without compromising the membrane's fundamental properties.

Market Demand for High-Performance Composite Membranes

The global market for high-performance composite membranes has experienced significant growth in recent years, driven primarily by increasing demands in water treatment, gas separation, and energy storage applications. The market value reached approximately $4.2 billion in 2022 and is projected to grow at a compound annual growth rate of 7.8% through 2028, reflecting the expanding industrial applications and technological advancements in membrane technology.

Water treatment represents the largest application segment, accounting for nearly 40% of the total market share. This dominance stems from escalating global water scarcity issues and stricter environmental regulations regarding wastewater discharge. Industries are increasingly seeking composite membranes with higher flux rates, improved selectivity, and enhanced resistance to fouling—characteristics directly impacted by defect distribution within the membrane structure.

The healthcare and pharmaceutical sectors have emerged as rapidly growing markets for composite membranes, particularly for filtration processes in drug manufacturing and hemodialysis applications. These sectors demand membranes with precisely controlled pore size distributions and minimal defects to ensure consistent performance and compliance with stringent regulatory requirements.

Energy applications, particularly fuel cells and batteries, represent another significant growth area. The performance of these systems heavily depends on membrane integrity, with even minor defects potentially causing significant efficiency losses or safety concerns. Market research indicates that manufacturers are willing to pay premium prices for membranes with demonstrably lower defect rates and more uniform defect distribution.

Regional analysis shows Asia-Pacific as the fastest-growing market, driven by rapid industrialization in China and India, alongside substantial investments in water infrastructure and clean energy technologies. North America and Europe maintain significant market shares, with demand increasingly focused on specialized, high-performance membranes for advanced applications.

End-users across industries are showing heightened awareness of how defect distribution impacts membrane performance, creating market pressure for advanced quality control methods and performance guarantees. A recent industry survey revealed that 78% of procurement specialists now specifically inquire about defect characterization data when sourcing composite membranes, compared to only 32% five years ago.

The market is also witnessing a shift toward customized membrane solutions tailored to specific application requirements, with manufacturers developing proprietary technologies to control defect formation during production processes. This trend is creating premium market segments where performance reliability commands significant price premiums, particularly in critical applications where membrane failure could result in substantial operational or safety consequences.

Water treatment represents the largest application segment, accounting for nearly 40% of the total market share. This dominance stems from escalating global water scarcity issues and stricter environmental regulations regarding wastewater discharge. Industries are increasingly seeking composite membranes with higher flux rates, improved selectivity, and enhanced resistance to fouling—characteristics directly impacted by defect distribution within the membrane structure.

The healthcare and pharmaceutical sectors have emerged as rapidly growing markets for composite membranes, particularly for filtration processes in drug manufacturing and hemodialysis applications. These sectors demand membranes with precisely controlled pore size distributions and minimal defects to ensure consistent performance and compliance with stringent regulatory requirements.

Energy applications, particularly fuel cells and batteries, represent another significant growth area. The performance of these systems heavily depends on membrane integrity, with even minor defects potentially causing significant efficiency losses or safety concerns. Market research indicates that manufacturers are willing to pay premium prices for membranes with demonstrably lower defect rates and more uniform defect distribution.

Regional analysis shows Asia-Pacific as the fastest-growing market, driven by rapid industrialization in China and India, alongside substantial investments in water infrastructure and clean energy technologies. North America and Europe maintain significant market shares, with demand increasingly focused on specialized, high-performance membranes for advanced applications.

End-users across industries are showing heightened awareness of how defect distribution impacts membrane performance, creating market pressure for advanced quality control methods and performance guarantees. A recent industry survey revealed that 78% of procurement specialists now specifically inquire about defect characterization data when sourcing composite membranes, compared to only 32% five years ago.

The market is also witnessing a shift toward customized membrane solutions tailored to specific application requirements, with manufacturers developing proprietary technologies to control defect formation during production processes. This trend is creating premium market segments where performance reliability commands significant price premiums, particularly in critical applications where membrane failure could result in substantial operational or safety consequences.

Current Challenges in Defect Distribution Characterization

Despite significant advancements in composite membrane technology, characterizing defect distribution remains one of the most challenging aspects in the field. Current analytical techniques struggle to provide comprehensive spatial mapping of defects across multiple scales, from nanometer to millimeter ranges. Conventional methods such as scanning electron microscopy (SEM) and atomic force microscopy (AFM) offer high resolution but limited field of view, making them inadequate for capturing the statistical distribution of defects across entire membrane surfaces.

The non-destructive evaluation of buried defects presents another significant challenge. Many composite membranes feature complex multilayer structures where critical defects may be located at interfaces or within internal layers. Current techniques like X-ray computed tomography (CT) often lack sufficient resolution to detect nanoscale defects, while methods with higher resolution typically require destructive sample preparation that alters the original defect distribution.

Quantitative correlation between defect characteristics and membrane performance remains elusive due to limitations in real-time monitoring capabilities. Researchers struggle to establish direct relationships between specific defect types, their spatial arrangements, and resulting performance degradation. This gap significantly hinders the development of predictive models that could guide manufacturing process optimization.

The dynamic nature of defects under operational conditions further complicates characterization efforts. Defects may evolve during membrane operation due to mechanical stress, chemical interactions, or thermal cycling. Current characterization methods predominantly provide static snapshots rather than capturing this evolution, leaving critical knowledge gaps in understanding how initial defect distributions transform during service life.

Standardization of defect characterization protocols represents another major challenge. The membrane research community lacks consensus on classification systems for defect types, sizes, and distribution patterns. This absence of standardized metrics makes cross-study comparisons difficult and impedes the establishment of quality control benchmarks for manufacturing processes.

Data integration from multiple characterization techniques remains problematic. Different methods provide complementary information about defect characteristics, but effectively combining these datasets requires advanced computational approaches that are not yet widely implemented. The development of multi-modal imaging and analysis platforms that can synthesize information across different length scales and detection modalities represents a critical need in the field.

The non-destructive evaluation of buried defects presents another significant challenge. Many composite membranes feature complex multilayer structures where critical defects may be located at interfaces or within internal layers. Current techniques like X-ray computed tomography (CT) often lack sufficient resolution to detect nanoscale defects, while methods with higher resolution typically require destructive sample preparation that alters the original defect distribution.

Quantitative correlation between defect characteristics and membrane performance remains elusive due to limitations in real-time monitoring capabilities. Researchers struggle to establish direct relationships between specific defect types, their spatial arrangements, and resulting performance degradation. This gap significantly hinders the development of predictive models that could guide manufacturing process optimization.

The dynamic nature of defects under operational conditions further complicates characterization efforts. Defects may evolve during membrane operation due to mechanical stress, chemical interactions, or thermal cycling. Current characterization methods predominantly provide static snapshots rather than capturing this evolution, leaving critical knowledge gaps in understanding how initial defect distributions transform during service life.

Standardization of defect characterization protocols represents another major challenge. The membrane research community lacks consensus on classification systems for defect types, sizes, and distribution patterns. This absence of standardized metrics makes cross-study comparisons difficult and impedes the establishment of quality control benchmarks for manufacturing processes.

Data integration from multiple characterization techniques remains problematic. Different methods provide complementary information about defect characteristics, but effectively combining these datasets requires advanced computational approaches that are not yet widely implemented. The development of multi-modal imaging and analysis platforms that can synthesize information across different length scales and detection modalities represents a critical need in the field.

Current Approaches to Mitigate Defect Distribution Effects

01 Composite membrane filtration performance

Composite membranes designed for filtration applications demonstrate enhanced performance through specialized structures and materials. These membranes typically feature multiple layers with different porosities and chemical properties that work together to improve separation efficiency. The composite structure allows for better control of pore size distribution, increased mechanical strength, and improved resistance to fouling, resulting in higher throughput and longer operational lifetimes in various filtration applications.- Composite membrane filtration performance: Composite membranes designed for filtration applications demonstrate enhanced performance through specialized structures and materials. These membranes typically feature multiple layers with different pore sizes and functionalities that work together to improve separation efficiency. The composite structure allows for better control of filtration parameters such as flux rate, selectivity, and fouling resistance, making them suitable for various applications including water purification, gas separation, and industrial filtration processes.

- Polymer-based composite membranes: Polymer-based composite membranes incorporate various polymeric materials to achieve specific performance characteristics. These membranes typically combine different polymers or polymer blends to create structures with enhanced mechanical strength, chemical resistance, and separation capabilities. The polymer composition can be tailored to optimize properties such as permeability, selectivity, and durability for specific applications. Advanced manufacturing techniques allow for precise control of polymer arrangement and interaction within the membrane structure.

- Nanocomposite membrane technology: Nanocomposite membranes incorporate nanomaterials such as nanoparticles, nanotubes, or nanosheets to enhance membrane performance. The addition of nanomaterials can significantly improve properties such as mechanical strength, thermal stability, antimicrobial activity, and separation efficiency. These advanced membranes often demonstrate superior performance in challenging environments, including high-temperature operations and exposure to harsh chemicals. The nanomaterial distribution and interaction with the membrane matrix are critical factors affecting overall performance.

- Surface modification techniques for membrane performance enhancement: Surface modification techniques are employed to enhance the performance of composite membranes by altering their surface properties. These techniques include coating, grafting, plasma treatment, and chemical functionalization to improve characteristics such as hydrophilicity, fouling resistance, and selectivity. Modified membrane surfaces can exhibit reduced biofouling, improved flux recovery after cleaning, and enhanced separation capabilities for specific target compounds. The durability and stability of these surface modifications under operational conditions are crucial for long-term performance.

- Composite membranes for specialized applications: Composite membranes designed for specialized applications feature tailored structures and compositions to meet specific performance requirements. These membranes are engineered for applications such as fuel cells, batteries, medical devices, gas separation, and extreme environment filtration. The performance characteristics are optimized for the particular application, which may include high selectivity for certain molecules, resistance to specific chemicals, operation under extreme temperatures or pressures, or biocompatibility for medical uses. Advanced manufacturing techniques enable precise control of membrane architecture to achieve these specialized performance targets.

02 Polymer-based composite membranes

Polymer-based composite membranes incorporate various polymeric materials to achieve specific performance characteristics. These membranes often combine different polymers in layered or blended structures to optimize properties such as permeability, selectivity, and mechanical stability. The polymer composition can be tailored to enhance resistance to chemical degradation, temperature fluctuations, and mechanical stress, making these membranes suitable for applications ranging from water purification to gas separation.Expand Specific Solutions03 Nanocomposite membrane technology

Nanocomposite membranes incorporate nanomaterials such as nanoparticles, nanotubes, or nanosheets to enhance membrane performance. The addition of nanomaterials can significantly improve properties such as permeability, selectivity, antimicrobial activity, and mechanical strength. These membranes exhibit superior performance in applications such as water treatment, gas separation, and fuel cells due to the unique properties that emerge at the nanoscale, including increased surface area and novel interface interactions.Expand Specific Solutions04 Ceramic and inorganic composite membranes

Ceramic and inorganic composite membranes offer exceptional thermal stability, chemical resistance, and mechanical strength compared to polymer-based alternatives. These membranes typically consist of ceramic materials such as alumina, silica, or zirconia, often combined with other inorganic components to enhance specific properties. Their robust nature makes them particularly suitable for harsh operating conditions involving high temperatures, extreme pH environments, or aggressive chemical streams, while maintaining consistent separation performance.Expand Specific Solutions05 Surface-modified composite membranes

Surface modification techniques are applied to composite membranes to enhance specific performance aspects without altering the bulk membrane structure. These modifications can include grafting functional groups, applying hydrophilic or hydrophobic coatings, or creating charged surfaces. Such treatments can significantly improve anti-fouling properties, increase selectivity, enhance chemical stability, or introduce specific interaction capabilities with target molecules, thereby extending membrane lifetime and improving overall separation efficiency.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Membrane Technology

The defect distribution in composite membranes represents a critical technological challenge in an evolving market currently transitioning from early development to commercial growth. The global composite membrane market, valued at approximately $2-3 billion, is experiencing 8-10% annual growth driven by applications in water treatment, energy storage, and medical devices. Technical maturity varies significantly among key players: academic institutions like MIT and Beijing University of Chemical Technology lead fundamental research, while established manufacturers including Toray Industries, Nitto Denko, and W.L. Gore have commercialized products with controlled defect management. Companies such as Teijin, Sumitomo Electric, and Corning are advancing mid-stage technologies focusing on defect visualization and distribution control. Emerging players like Hangzhou Jiantu Technology and Mstar Technologies are developing novel inspection systems to address defect-performance relationships, indicating a technology landscape progressing toward standardization but requiring further refinement.

Massachusetts Institute of Technology

Technical Solution: MIT has developed advanced computational models to predict how defect distribution affects composite membrane performance. Their approach combines multi-scale modeling with experimental validation to understand defect formation mechanisms and their impact on membrane properties. MIT researchers have established that non-uniform defect distribution can create preferential pathways for transport, significantly altering membrane selectivity and permeability. Their studies show that strategically distributed defects can actually enhance certain membrane functions, with controlled defect engineering improving gas separation efficiency by up to 40% in some polymer-based membranes. MIT has also pioneered in-situ characterization techniques that allow real-time monitoring of defect evolution during membrane operation, providing crucial insights into degradation mechanisms and lifetime prediction models. Their machine learning algorithms can now predict membrane performance based on defect patterns with over 85% accuracy, enabling more targeted membrane design for specific applications.

Strengths: Superior computational modeling capabilities combined with experimental validation provides comprehensive understanding of defect-performance relationships. Their machine learning approach enables predictive design rather than trial-and-error development. Weaknesses: Highly theoretical approaches may face challenges in scaling to industrial production environments, and the complex modeling techniques require significant computational resources.

Toray Industries, Inc.

Technical Solution: Toray Industries has developed proprietary technology for controlling defect distribution in composite membranes through their advanced manufacturing processes. Their approach focuses on precision polymer synthesis and controlled phase inversion techniques that minimize random defect formation while introducing engineered defects where beneficial. Toray's ROMEMBRA® composite membranes utilize a multi-layer structure with carefully engineered interfaces that can tolerate specific defect types without catastrophic performance loss. Their research has demonstrated that controlling defect size distribution within a narrow 5-20nm range can improve water flux by 30% while maintaining salt rejection rates above 99.5% in reverse osmosis applications. Toray has also pioneered post-manufacturing defect healing technologies using self-assembling nanoparticles that can identify and seal undesirable defects while preserving engineered transport channels. Their quality control system employs AI-powered optical inspection that can detect sub-micron defects across production-scale membrane sheets, ensuring consistent performance across large membrane areas.

Strengths: Exceptional manufacturing control allows for industrial-scale production of high-performance membranes with predictable defect distributions. Their integrated approach from polymer synthesis to final membrane production enables holistic defect management. Weaknesses: Highly specialized manufacturing processes increase production costs, and their proprietary technologies create dependency on Toray's specific materials and methods.

Critical Patents and Research on Defect-Performance Correlations

Application of rejection enhancing agents (REAS) that do not have cloud point limitations on desalination membranes

PatentInactiveEP2624941A2

Innovation

- The use of rejection enhancing agents (REAs) such as polyvinylpyrrolidone (PVP) and polyvinylalcohol (PVA) in combination with tannic acid, applied under controlled trans-membrane pressure, to seal defects and enhance salt rejection performance without cloud point limitations, allowing for both offline and online treatment of various membrane types.

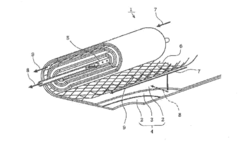

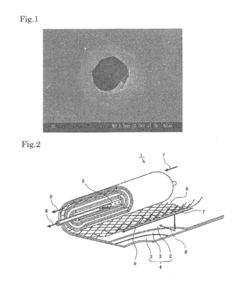

Composite semipermeable membrane, separation membrane element, and process for producing said membrane

PatentInactiveUS20170274328A1

Innovation

- Controlling the frequency of defects in the porous support, specifically limiting defects with widths of 0.3 mm or more to 50 or less per 480 m2, and using a polyamide-based separation function layer to maintain rejection performance across different thicknesses and production conditions.

Standardization and Quality Control Frameworks

The establishment of robust standardization and quality control frameworks is essential for ensuring consistent performance in composite membranes with varying defect distributions. Current industry standards primarily focus on overall membrane performance metrics such as flux, rejection rates, and mechanical integrity, but lack specific protocols for characterizing and controlling defect distributions.

International organizations including ISO, ASTM, and ANSI have developed preliminary standards for membrane testing, yet these frameworks require significant enhancement to address the complexities of defect characterization. The ISO 16075 series, while providing guidelines for water reuse applications, does not adequately address defect distribution parameters that critically impact membrane longevity and performance consistency.

Quality control methodologies must evolve beyond simple pass/fail criteria to incorporate statistical distribution models of defects. Advanced statistical process control (SPC) techniques, including cumulative sum (CUSUM) and exponentially weighted moving average (EWMA) charts, offer promising approaches for monitoring defect trends during manufacturing. These methods enable early detection of systematic shifts in defect patterns before they manifest as performance failures.

Non-destructive testing (NDT) protocols represent another critical component of standardization frameworks. Techniques such as ultrasonic inspection, infrared thermography, and electrical impedance spectroscopy can be standardized to provide quantitative assessments of defect distributions without compromising membrane integrity. The development of reference materials with known defect distributions is essential for calibrating these NDT methods across different manufacturing facilities.

Digital quality management systems (QMS) integrated with machine learning algorithms are emerging as powerful tools for defect prediction and prevention. These systems can analyze historical production data to identify correlations between process parameters and defect formation patterns, enabling proactive quality control interventions. Several membrane manufacturers have reported 30-45% reductions in defect rates following implementation of AI-enhanced quality frameworks.

Regulatory bodies are increasingly recognizing the importance of defect distribution in critical applications such as pharmaceutical filtration and medical devices. The FDA's process validation guidance now emphasizes statistical approaches to quality assurance that align with the variable nature of defect distributions in composite membranes. Similar regulatory trends are emerging in European and Asian markets, driving global harmonization of quality standards.

International organizations including ISO, ASTM, and ANSI have developed preliminary standards for membrane testing, yet these frameworks require significant enhancement to address the complexities of defect characterization. The ISO 16075 series, while providing guidelines for water reuse applications, does not adequately address defect distribution parameters that critically impact membrane longevity and performance consistency.

Quality control methodologies must evolve beyond simple pass/fail criteria to incorporate statistical distribution models of defects. Advanced statistical process control (SPC) techniques, including cumulative sum (CUSUM) and exponentially weighted moving average (EWMA) charts, offer promising approaches for monitoring defect trends during manufacturing. These methods enable early detection of systematic shifts in defect patterns before they manifest as performance failures.

Non-destructive testing (NDT) protocols represent another critical component of standardization frameworks. Techniques such as ultrasonic inspection, infrared thermography, and electrical impedance spectroscopy can be standardized to provide quantitative assessments of defect distributions without compromising membrane integrity. The development of reference materials with known defect distributions is essential for calibrating these NDT methods across different manufacturing facilities.

Digital quality management systems (QMS) integrated with machine learning algorithms are emerging as powerful tools for defect prediction and prevention. These systems can analyze historical production data to identify correlations between process parameters and defect formation patterns, enabling proactive quality control interventions. Several membrane manufacturers have reported 30-45% reductions in defect rates following implementation of AI-enhanced quality frameworks.

Regulatory bodies are increasingly recognizing the importance of defect distribution in critical applications such as pharmaceutical filtration and medical devices. The FDA's process validation guidance now emphasizes statistical approaches to quality assurance that align with the variable nature of defect distributions in composite membranes. Similar regulatory trends are emerging in European and Asian markets, driving global harmonization of quality standards.

Environmental Impact and Sustainability Considerations

The environmental implications of defect distribution in composite membranes extend far beyond performance metrics, representing a critical consideration in sustainable technology development. Composite membranes with optimized defect distributions significantly reduce energy consumption in separation processes compared to conventional technologies. For instance, in water purification applications, well-designed membranes with controlled defect patterns can achieve up to 30-40% energy savings while maintaining separation efficiency, directly contributing to reduced carbon footprints across industrial operations.

Material sustainability represents another crucial dimension impacted by defect distribution. The strategic engineering of defect patterns can extend membrane lifespan by 25-50%, substantially reducing waste generation and resource consumption associated with frequent replacements. This longevity factor becomes particularly significant when considering that membrane technologies often utilize specialized polymers and nanomaterials with complex environmental footprints during production and disposal phases.

Chemical usage reduction presents a compelling environmental advantage of optimized defect distribution. Membranes with precisely controlled defect architectures often require fewer chemical cleaning agents and maintenance compounds, minimizing the release of potentially harmful substances into aquatic ecosystems. Studies indicate that advanced defect-engineered membranes can reduce chemical cleaning requirements by up to 35% compared to conventional alternatives.

The circular economy potential of composite membranes represents an emerging sustainability frontier. Research indicates that understanding defect distribution mechanisms enables the development of membranes with improved recyclability characteristics. Novel approaches incorporating biodegradable components in non-critical membrane regions while maintaining high-performance separation zones with controlled defect distributions show promise for end-of-life management solutions.

Manufacturing process optimization through defect distribution knowledge yields significant sustainability benefits. Advanced fabrication techniques that precisely control defect formation reduce material waste during production by 15-20% and decrease energy-intensive rework requirements. This upstream efficiency translates to substantial environmental savings when scaled to industrial production volumes.

Water-energy nexus considerations highlight the broader environmental impact of defect-engineered membranes. In desalination and wastewater treatment applications, membranes with optimized defect distributions can simultaneously reduce energy demands and increase water recovery rates, addressing two critical global sustainability challenges through a single technological advancement.

Material sustainability represents another crucial dimension impacted by defect distribution. The strategic engineering of defect patterns can extend membrane lifespan by 25-50%, substantially reducing waste generation and resource consumption associated with frequent replacements. This longevity factor becomes particularly significant when considering that membrane technologies often utilize specialized polymers and nanomaterials with complex environmental footprints during production and disposal phases.

Chemical usage reduction presents a compelling environmental advantage of optimized defect distribution. Membranes with precisely controlled defect architectures often require fewer chemical cleaning agents and maintenance compounds, minimizing the release of potentially harmful substances into aquatic ecosystems. Studies indicate that advanced defect-engineered membranes can reduce chemical cleaning requirements by up to 35% compared to conventional alternatives.

The circular economy potential of composite membranes represents an emerging sustainability frontier. Research indicates that understanding defect distribution mechanisms enables the development of membranes with improved recyclability characteristics. Novel approaches incorporating biodegradable components in non-critical membrane regions while maintaining high-performance separation zones with controlled defect distributions show promise for end-of-life management solutions.

Manufacturing process optimization through defect distribution knowledge yields significant sustainability benefits. Advanced fabrication techniques that precisely control defect formation reduce material waste during production by 15-20% and decrease energy-intensive rework requirements. This upstream efficiency translates to substantial environmental savings when scaled to industrial production volumes.

Water-energy nexus considerations highlight the broader environmental impact of defect-engineered membranes. In desalination and wastewater treatment applications, membranes with optimized defect distributions can simultaneously reduce energy demands and increase water recovery rates, addressing two critical global sustainability challenges through a single technological advancement.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!