Role Of Pervaporation Membranes In CO2 Dehydration Processes

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CO2 Dehydration Technology Background and Objectives

Carbon dioxide dehydration has emerged as a critical process in various industrial applications, particularly in natural gas processing, carbon capture and storage (CCS), and enhanced oil recovery (EOR). The evolution of CO2 dehydration technologies can be traced back to the mid-20th century when industrial gas processing became increasingly important. Initially, conventional methods such as absorption using glycols, adsorption with molecular sieves, and cryogenic separation dominated the field.

The technological trajectory has shifted significantly over the past three decades with the introduction of membrane-based separation processes. Pervaporation, a membrane-based technology that combines permeation and evaporation, has gained substantial attention due to its energy efficiency and operational flexibility. This technology represents a paradigm shift from traditional thermal separation methods toward more sustainable approaches.

Current industry trends indicate a growing demand for efficient CO2 dehydration solutions, driven by stringent environmental regulations and the expanding carbon capture industry. The global commitment to reduce greenhouse gas emissions, as outlined in the Paris Agreement and subsequent climate accords, has accelerated research and development in this domain. Consequently, pervaporation membrane technology has evolved from laboratory-scale experiments to commercial applications.

The primary technical objective in pervaporation membrane development for CO2 dehydration is to achieve high water selectivity while maintaining adequate permeation flux under industrial operating conditions. This involves designing membranes with optimized hydrophilicity, mechanical stability, and chemical resistance to withstand the harsh environments typical in CO2 processing streams.

Another crucial goal is to minimize energy consumption compared to conventional dehydration methods. Pervaporation membranes aim to operate at moderate temperatures and pressures, thereby reducing the overall carbon footprint of the dehydration process. This aligns with the broader industry objective of developing environmentally sustainable separation technologies.

Long-term technical objectives include developing membranes with extended operational lifespans, reduced fouling tendencies, and enhanced resistance to plasticization under high-pressure CO2 environments. Additionally, there is a push toward creating modular and scalable membrane systems that can be easily integrated into existing industrial infrastructure.

The intersection of material science, chemical engineering, and environmental technology has fostered interdisciplinary approaches to membrane development. Recent advances in polymer chemistry, nanotechnology, and computational modeling have accelerated innovation in this field, opening new possibilities for next-generation pervaporation membranes specifically tailored for CO2 dehydration applications.

The technological trajectory has shifted significantly over the past three decades with the introduction of membrane-based separation processes. Pervaporation, a membrane-based technology that combines permeation and evaporation, has gained substantial attention due to its energy efficiency and operational flexibility. This technology represents a paradigm shift from traditional thermal separation methods toward more sustainable approaches.

Current industry trends indicate a growing demand for efficient CO2 dehydration solutions, driven by stringent environmental regulations and the expanding carbon capture industry. The global commitment to reduce greenhouse gas emissions, as outlined in the Paris Agreement and subsequent climate accords, has accelerated research and development in this domain. Consequently, pervaporation membrane technology has evolved from laboratory-scale experiments to commercial applications.

The primary technical objective in pervaporation membrane development for CO2 dehydration is to achieve high water selectivity while maintaining adequate permeation flux under industrial operating conditions. This involves designing membranes with optimized hydrophilicity, mechanical stability, and chemical resistance to withstand the harsh environments typical in CO2 processing streams.

Another crucial goal is to minimize energy consumption compared to conventional dehydration methods. Pervaporation membranes aim to operate at moderate temperatures and pressures, thereby reducing the overall carbon footprint of the dehydration process. This aligns with the broader industry objective of developing environmentally sustainable separation technologies.

Long-term technical objectives include developing membranes with extended operational lifespans, reduced fouling tendencies, and enhanced resistance to plasticization under high-pressure CO2 environments. Additionally, there is a push toward creating modular and scalable membrane systems that can be easily integrated into existing industrial infrastructure.

The intersection of material science, chemical engineering, and environmental technology has fostered interdisciplinary approaches to membrane development. Recent advances in polymer chemistry, nanotechnology, and computational modeling have accelerated innovation in this field, opening new possibilities for next-generation pervaporation membranes specifically tailored for CO2 dehydration applications.

Market Demand Analysis for CO2 Dehydration Solutions

The global market for CO2 dehydration solutions has been experiencing significant growth, driven by the increasing focus on carbon capture, utilization, and storage (CCUS) technologies. As industries worldwide strive to reduce carbon emissions, the demand for efficient CO2 processing technologies, including dehydration solutions, has surged dramatically. Current market estimates value the CO2 capture and processing equipment market at approximately 7 billion USD, with projections indicating growth to reach 12 billion USD by 2028.

The oil and gas sector remains the primary consumer of CO2 dehydration technologies, particularly for enhanced oil recovery (EOR) operations where dry CO2 is injected into oil reservoirs to improve extraction efficiency. This application alone accounts for nearly 40% of the current market demand. The presence of water in CO2 streams can lead to corrosion issues and hydrate formation, making dehydration a critical process step.

Industrial gas production represents another significant market segment, where high-purity CO2 is required for various applications including food and beverage production, pharmaceutical manufacturing, and chemical synthesis. These industries demand CO2 with moisture content below 10 ppm to ensure product quality and process efficiency.

The emerging hydrogen economy is creating new market opportunities for CO2 dehydration technologies. Blue hydrogen production, which involves natural gas reforming coupled with carbon capture, requires effective CO2 dehydration systems to ensure the captured carbon can be safely transported and stored or utilized.

Market analysis reveals a growing preference for energy-efficient and environmentally friendly dehydration technologies. Traditional methods such as temperature swing adsorption (TSA) and pressure swing adsorption (PSA) are increasingly being challenged by membrane-based technologies, including pervaporation membranes, which offer lower energy consumption and operational costs.

Regional market distribution shows North America leading with approximately 35% market share, followed by Europe at 28% and Asia-Pacific at 25%. The fastest growth is expected in the Asia-Pacific region, particularly in China and India, where rapid industrialization and increasing environmental regulations are driving demand for carbon capture technologies.

Customer requirements are evolving toward more compact, modular, and automated dehydration systems that can be easily integrated into existing infrastructure. There is also increasing demand for solutions that can handle varying CO2 flow rates and impurity profiles, reflecting the diverse sources of captured CO2 across different industries.

The oil and gas sector remains the primary consumer of CO2 dehydration technologies, particularly for enhanced oil recovery (EOR) operations where dry CO2 is injected into oil reservoirs to improve extraction efficiency. This application alone accounts for nearly 40% of the current market demand. The presence of water in CO2 streams can lead to corrosion issues and hydrate formation, making dehydration a critical process step.

Industrial gas production represents another significant market segment, where high-purity CO2 is required for various applications including food and beverage production, pharmaceutical manufacturing, and chemical synthesis. These industries demand CO2 with moisture content below 10 ppm to ensure product quality and process efficiency.

The emerging hydrogen economy is creating new market opportunities for CO2 dehydration technologies. Blue hydrogen production, which involves natural gas reforming coupled with carbon capture, requires effective CO2 dehydration systems to ensure the captured carbon can be safely transported and stored or utilized.

Market analysis reveals a growing preference for energy-efficient and environmentally friendly dehydration technologies. Traditional methods such as temperature swing adsorption (TSA) and pressure swing adsorption (PSA) are increasingly being challenged by membrane-based technologies, including pervaporation membranes, which offer lower energy consumption and operational costs.

Regional market distribution shows North America leading with approximately 35% market share, followed by Europe at 28% and Asia-Pacific at 25%. The fastest growth is expected in the Asia-Pacific region, particularly in China and India, where rapid industrialization and increasing environmental regulations are driving demand for carbon capture technologies.

Customer requirements are evolving toward more compact, modular, and automated dehydration systems that can be easily integrated into existing infrastructure. There is also increasing demand for solutions that can handle varying CO2 flow rates and impurity profiles, reflecting the diverse sources of captured CO2 across different industries.

Pervaporation Membrane Technology Status and Challenges

Pervaporation membrane technology has emerged as a promising solution for CO2 dehydration processes, offering significant advantages over conventional separation methods. Currently, the global landscape of pervaporation membrane development shows uneven distribution, with major research centers concentrated in North America, Europe, and East Asia. The United States, Germany, Japan, and China lead in both academic research output and industrial applications, accounting for approximately 70% of patents in this field.

The current state of pervaporation membranes for CO2 dehydration faces several technical challenges. Membrane selectivity remains a critical issue, as most existing membranes struggle to maintain optimal water/CO2 separation factors under industrial operating conditions. Commercial pervaporation membranes typically achieve separation factors between 100-500, which falls short of the theoretical potential exceeding 1000 under ideal conditions.

Stability presents another significant hurdle. Long-term exposure to acidic CO2 environments causes gradual performance degradation in many polymer-based membranes. Studies indicate that most current membranes lose 15-30% of their initial performance within 1000 hours of operation in industrial CO2 dehydration settings. This necessitates frequent replacement, increasing operational costs and limiting widespread adoption.

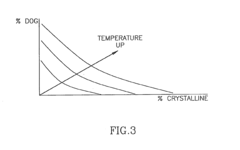

Material limitations constitute a fundamental constraint. While hydrophilic polymers like polyvinyl alcohol (PVA) and chitosan demonstrate excellent water selectivity, they often suffer from excessive swelling and mechanical weakness under continuous operation. Conversely, more robust materials like polydimethylsiloxane (PDMS) lack sufficient selectivity for efficient water/CO2 separation.

Scalability challenges persist in transitioning from laboratory success to industrial implementation. The manufacturing of defect-free, large-scale membrane modules with consistent performance remains technically demanding. Current production methods struggle with quality control when scaling beyond 50-100 m² membrane area modules.

Energy efficiency represents another limitation. While pervaporation theoretically offers energy savings compared to distillation, the vacuum requirements and heating needs for permeate vaporization still consume significant energy. Current systems typically require 0.8-1.5 kWh per cubic meter of treated gas, presenting opportunities for further optimization.

The integration of pervaporation systems with existing CO2 capture and utilization infrastructure poses additional engineering challenges. Compatibility issues with upstream and downstream processes often necessitate custom engineering solutions, increasing implementation costs and complexity.

Despite these challenges, recent advances in materials science, particularly in mixed matrix membranes and facilitated transport mechanisms, show promising directions for overcoming current limitations. The development of composite membranes incorporating both hydrophilic and mechanically robust components represents a particularly active research frontier with potential for breakthrough performance.

The current state of pervaporation membranes for CO2 dehydration faces several technical challenges. Membrane selectivity remains a critical issue, as most existing membranes struggle to maintain optimal water/CO2 separation factors under industrial operating conditions. Commercial pervaporation membranes typically achieve separation factors between 100-500, which falls short of the theoretical potential exceeding 1000 under ideal conditions.

Stability presents another significant hurdle. Long-term exposure to acidic CO2 environments causes gradual performance degradation in many polymer-based membranes. Studies indicate that most current membranes lose 15-30% of their initial performance within 1000 hours of operation in industrial CO2 dehydration settings. This necessitates frequent replacement, increasing operational costs and limiting widespread adoption.

Material limitations constitute a fundamental constraint. While hydrophilic polymers like polyvinyl alcohol (PVA) and chitosan demonstrate excellent water selectivity, they often suffer from excessive swelling and mechanical weakness under continuous operation. Conversely, more robust materials like polydimethylsiloxane (PDMS) lack sufficient selectivity for efficient water/CO2 separation.

Scalability challenges persist in transitioning from laboratory success to industrial implementation. The manufacturing of defect-free, large-scale membrane modules with consistent performance remains technically demanding. Current production methods struggle with quality control when scaling beyond 50-100 m² membrane area modules.

Energy efficiency represents another limitation. While pervaporation theoretically offers energy savings compared to distillation, the vacuum requirements and heating needs for permeate vaporization still consume significant energy. Current systems typically require 0.8-1.5 kWh per cubic meter of treated gas, presenting opportunities for further optimization.

The integration of pervaporation systems with existing CO2 capture and utilization infrastructure poses additional engineering challenges. Compatibility issues with upstream and downstream processes often necessitate custom engineering solutions, increasing implementation costs and complexity.

Despite these challenges, recent advances in materials science, particularly in mixed matrix membranes and facilitated transport mechanisms, show promising directions for overcoming current limitations. The development of composite membranes incorporating both hydrophilic and mechanically robust components represents a particularly active research frontier with potential for breakthrough performance.

Current Pervaporation Membrane Solutions for CO2 Dehydration

01 Polymer-based pervaporation membranes for dehydration

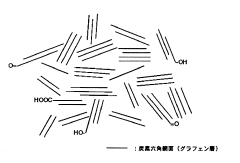

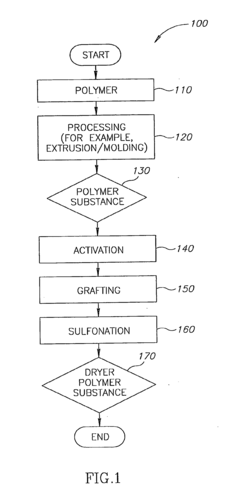

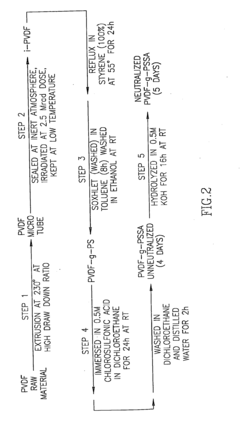

Polymer-based membranes are widely used in pervaporation dehydration processes due to their excellent separation properties. These membranes can be fabricated from various polymers such as polyvinyl alcohol (PVA), chitosan, and polyimides, which offer high selectivity for water molecules. The membranes can be modified through crosslinking or blending to enhance their stability and separation performance in harsh operating conditions. These polymer-based membranes are particularly effective for the dehydration of organic solvents and azeotropic mixtures.- Polymer-based pervaporation membranes: Polymer-based membranes are widely used in pervaporation dehydration processes due to their selective permeability and mechanical stability. These membranes can be fabricated from various polymers such as polyvinyl alcohol (PVA), chitosan, and polyimides, which exhibit high hydrophilicity and water selectivity. The performance of these membranes can be enhanced through crosslinking, blending, or incorporating fillers to improve their separation efficiency and durability in dehydration applications.

- Composite and mixed matrix pervaporation membranes: Composite and mixed matrix membranes combine the advantages of different materials to achieve superior pervaporation performance. These membranes typically consist of a thin selective layer supported on a porous substrate, or incorporate inorganic fillers within a polymer matrix. The incorporation of materials such as zeolites, metal-organic frameworks, or silica nanoparticles can significantly enhance water selectivity, flux, and membrane stability for dehydration applications, while reducing the swelling tendency of the membrane.

- Ceramic and inorganic pervaporation membranes: Ceramic and inorganic membranes offer exceptional thermal and chemical stability for pervaporation dehydration processes under harsh conditions. These membranes, typically made from materials such as alumina, silica, or zeolites, can withstand high temperatures and aggressive chemical environments. Their rigid structure prevents swelling issues common in polymer membranes, making them particularly suitable for dehydration of organic solvents and industrial process streams where durability and consistent performance are required.

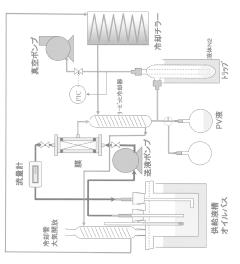

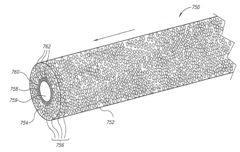

- Pervaporation membrane module designs and systems: The design of pervaporation membrane modules and systems plays a crucial role in optimizing dehydration efficiency. Various configurations such as plate-and-frame, spiral-wound, tubular, and hollow fiber modules have been developed to maximize membrane surface area while minimizing concentration polarization and pressure drop. Advanced system designs incorporate features like vacuum pumps, condensers, and heat exchangers to maintain optimal operating conditions and energy efficiency during the dehydration process.

- Surface modification and functionalization of pervaporation membranes: Surface modification and functionalization techniques are employed to enhance the performance of pervaporation membranes for dehydration applications. These methods include grafting hydrophilic functional groups, plasma treatment, layer-by-layer assembly, and chemical vapor deposition. Such modifications can significantly improve water selectivity, reduce fouling, and enhance the overall separation efficiency of the membrane. Additionally, these techniques can be used to tailor the membrane surface properties for specific dehydration applications.

02 Mixed matrix membranes for enhanced pervaporation performance

Mixed matrix membranes combine polymeric materials with inorganic fillers to create composite structures with improved pervaporation dehydration performance. By incorporating materials such as zeolites, metal-organic frameworks (MOFs), or silica nanoparticles into the polymer matrix, these membranes exhibit enhanced permeability, selectivity, and mechanical strength. The inorganic fillers can create preferential pathways for water molecules while blocking organic compounds, resulting in higher separation efficiency. These membranes also demonstrate better resistance to swelling and plasticization during the dehydration process.Expand Specific Solutions03 Ceramic and inorganic pervaporation membranes

Ceramic and inorganic membranes offer exceptional thermal and chemical stability for pervaporation dehydration applications. These membranes, typically made from materials such as alumina, silica, or zeolites, can withstand harsh operating conditions including high temperatures and corrosive environments. Their rigid structure prevents swelling and maintains consistent separation performance over extended periods. Ceramic membranes are particularly suitable for the dehydration of aggressive organic solvents where polymeric membranes might degrade. The pore size and surface properties of these membranes can be tailored to achieve optimal water selectivity.Expand Specific Solutions04 Membrane module designs and system configurations

Various membrane module designs and system configurations have been developed to optimize pervaporation dehydration processes. These include flat sheet, spiral wound, hollow fiber, and tubular modules, each offering specific advantages in terms of packing density, pressure drop, and mass transfer efficiency. Multi-stage pervaporation systems can be employed to achieve higher degrees of dehydration, while hybrid processes combining pervaporation with other separation techniques (such as distillation) can improve overall process efficiency. Advanced module designs also incorporate features to minimize concentration polarization and temperature gradient effects that can reduce separation performance.Expand Specific Solutions05 Surface modification techniques for pervaporation membranes

Surface modification techniques are employed to enhance the performance of pervaporation membranes for dehydration applications. These techniques include grafting hydrophilic functional groups, plasma treatment, layer-by-layer assembly, and surface coating. By altering the surface properties of the membrane, these modifications can improve water selectivity, reduce fouling, and enhance flux. Surface-modified membranes often demonstrate better long-term stability and separation efficiency compared to unmodified membranes. These techniques can be applied to both polymeric and inorganic membrane materials to optimize their dehydration performance for specific applications.Expand Specific Solutions

Key Industry Players in Pervaporation Membrane Development

The pervaporation membrane market for CO2 dehydration is in a growth phase, with increasing demand driven by carbon capture and storage initiatives. The global market is expanding as industries seek efficient gas separation solutions. Technologically, academic institutions like Zhejiang University, Rensselaer Polytechnic Institute, and University of South Carolina are advancing fundamental research, while companies demonstrate varying maturity levels. Membrane Technology & Research and Air Products & Chemicals lead with commercial solutions, while Renaissance Energy Research and NGK Insulators focus on specialized membrane development. Saudi Aramco and Sinopec are integrating these technologies into large-scale operations. Chinese manufacturers like Ningbo Xinyuan Membrane Industry are emerging as significant players, indicating the technology's global diffusion and industrial adoption.

Air Products & Chemicals, Inc.

Technical Solution: Air Products has developed an innovative pervaporation membrane technology for CO2 dehydration that integrates seamlessly with their existing gas processing solutions. Their system utilizes composite membranes featuring a thin-film selective layer supported on a porous substrate, specifically engineered to withstand the acidic conditions created by CO2-water mixtures. The company's pervaporation membranes operate at moderate pressures (5-20 bar) and temperatures (40-70°C), optimizing the driving force for water transport while minimizing energy consumption. Air Products' technology incorporates a multi-stage membrane configuration that achieves water content reduction to below 10 ppm in the final CO2 stream, meeting stringent specifications for carbon capture and storage applications. Their membrane modules feature proprietary flow distribution designs that minimize concentration polarization and maximize effective membrane area utilization.

Strengths: Extensive integration experience with existing gas processing infrastructure, robust membrane materials resistant to CO2-induced degradation, and comprehensive technical support services. Weaknesses: Higher capital costs compared to conventional dehydration technologies and limited performance data in extremely high-pressure applications (>100 bar).

Ningbo Xinyuan Membrane Industry Co. Ltd.

Technical Solution: Ningbo Xinyuan has pioneered cost-effective pervaporation membrane solutions specifically targeting CO2 dehydration applications. Their technology employs hydrophilic ceramic-polymer composite membranes that combine the thermal stability of ceramic materials with the selective permeation properties of specialized polymers. The company's pervaporation systems operate effectively at temperatures between 50-90°C and can process CO2 streams with initial water content ranging from 1-5% by weight. Ningbo Xinyuan's membrane modules utilize a plate-and-frame configuration that facilitates easy maintenance and membrane replacement. Their manufacturing process incorporates proprietary surface modification techniques that enhance water flux while maintaining high selectivity. The company has successfully deployed their pervaporation technology in several industrial-scale CO2 purification facilities across Asia, demonstrating water removal efficiencies of up to 98% with minimal pressure drop across the membrane system.

Strengths: Competitive pricing compared to Western manufacturers, excellent chemical resistance to CO2-induced degradation, and flexible module designs adaptable to various installation constraints. Weaknesses: Limited global service network outside Asia and relatively newer entrant to the market with less established long-term performance data.

Critical Patents and Technical Literature in Pervaporation Technology

Method of manufacturing pervaporation membrane and pervaporation method

PatentInactiveJP2013193053A

Innovation

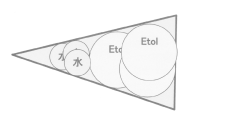

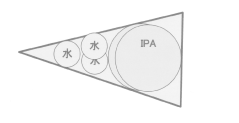

- Forming a carbon membrane with 0.4 to 1.0 nm average pore diameter and supporting isopropyl alcohol (IPA) in the pores by pervaporation treatment, replacing ethanol with IPA to enhance water permeability and maintain high dehydration efficiency.

Drying substances, preparation and use thereof

PatentActiveUS20140230652A1

Innovation

- A robust, high-performance polymer substance with a porous support member filled with a cross-linked co-polymer containing cationic, anionic, or zwitterionic monomers, which is adapted for pervaporation, offering improved water evaporation rates and mechanical stability.

Environmental Impact and Sustainability Considerations

The implementation of pervaporation membranes in CO2 dehydration processes offers significant environmental advantages compared to conventional dehydration technologies. These membranes operate at lower temperatures and pressures than traditional methods such as pressure swing adsorption or cryogenic separation, resulting in substantially reduced energy consumption. Studies indicate that pervaporation-based systems can achieve energy savings of 20-40% compared to thermal separation processes, directly translating to lower greenhouse gas emissions from power generation.

Carbon footprint analyses of membrane-based dehydration systems demonstrate their environmental superiority. The production of pervaporation membranes does require energy-intensive polymers or ceramic materials, but life cycle assessments reveal that these initial environmental costs are typically offset within 1-3 years of operation through operational efficiency gains. Furthermore, the selective nature of these membranes minimizes waste generation and reduces the need for additional purification steps.

Water conservation represents another critical environmental benefit of pervaporation technology. Unlike absorption processes that may require significant quantities of water or chemical solvents, pervaporation membranes facilitate water removal without additional consumables. This aspect is particularly valuable in water-stressed regions where industrial water usage faces increasing scrutiny and regulation.

The durability and longevity of modern pervaporation membranes also contribute to their sustainability profile. High-performance membranes can maintain operational efficiency for 3-5 years before replacement, reducing material consumption and waste generation compared to systems requiring frequent regeneration or replacement of absorbents. Additionally, many membrane materials can be recycled or repurposed at end-of-life, further reducing environmental impact.

From a regulatory perspective, pervaporation membrane systems align well with increasingly stringent environmental standards worldwide. Their minimal chemical usage, reduced emissions, and lower energy requirements help facilities meet compliance requirements while potentially qualifying for sustainability incentives or carbon credits in certain jurisdictions. As carbon pricing mechanisms expand globally, the economic case for membrane-based dehydration becomes even more compelling.

Looking forward, ongoing research into bio-based and environmentally benign membrane materials promises to further enhance the sustainability credentials of pervaporation technology. Innovations in membrane fabrication using renewable resources and biodegradable polymers could significantly reduce the environmental footprint of membrane production while maintaining or improving separation performance.

Carbon footprint analyses of membrane-based dehydration systems demonstrate their environmental superiority. The production of pervaporation membranes does require energy-intensive polymers or ceramic materials, but life cycle assessments reveal that these initial environmental costs are typically offset within 1-3 years of operation through operational efficiency gains. Furthermore, the selective nature of these membranes minimizes waste generation and reduces the need for additional purification steps.

Water conservation represents another critical environmental benefit of pervaporation technology. Unlike absorption processes that may require significant quantities of water or chemical solvents, pervaporation membranes facilitate water removal without additional consumables. This aspect is particularly valuable in water-stressed regions where industrial water usage faces increasing scrutiny and regulation.

The durability and longevity of modern pervaporation membranes also contribute to their sustainability profile. High-performance membranes can maintain operational efficiency for 3-5 years before replacement, reducing material consumption and waste generation compared to systems requiring frequent regeneration or replacement of absorbents. Additionally, many membrane materials can be recycled or repurposed at end-of-life, further reducing environmental impact.

From a regulatory perspective, pervaporation membrane systems align well with increasingly stringent environmental standards worldwide. Their minimal chemical usage, reduced emissions, and lower energy requirements help facilities meet compliance requirements while potentially qualifying for sustainability incentives or carbon credits in certain jurisdictions. As carbon pricing mechanisms expand globally, the economic case for membrane-based dehydration becomes even more compelling.

Looking forward, ongoing research into bio-based and environmentally benign membrane materials promises to further enhance the sustainability credentials of pervaporation technology. Innovations in membrane fabrication using renewable resources and biodegradable polymers could significantly reduce the environmental footprint of membrane production while maintaining or improving separation performance.

Economic Feasibility and Scale-up Potential

The economic feasibility of pervaporation membrane technology for CO2 dehydration processes hinges on several critical factors. Initial capital investment for membrane systems typically ranges from $500,000 to $2 million depending on scale, which is generally lower than traditional dehydration technologies such as pressure swing adsorption or cryogenic separation. Operating costs are primarily driven by membrane replacement cycles (typically 2-3 years) and energy consumption for maintaining optimal process conditions.

Energy efficiency represents a significant economic advantage, with pervaporation membranes consuming approximately 30-50% less energy than conventional thermal separation methods. This translates to operational savings of $0.5-1.5 per ton of CO2 processed, which becomes substantial at industrial scales. Maintenance costs are relatively modest, averaging 3-7% of capital expenditure annually, compared to 8-12% for alternative technologies.

Scale-up potential for pervaporation membrane technology demonstrates promising characteristics. The modular nature of membrane systems allows for incremental capacity expansion without proportional cost increases - a phenomenon known as "economies of scale." Studies indicate that doubling processing capacity typically increases capital costs by only 60-70%, creating favorable economics at larger scales.

Industrial implementation has shown that pervaporation membrane systems become economically competitive at processing capacities above 50 tons of CO2 per day. At scales exceeding 200 tons daily, the technology often outperforms conventional methods in terms of levelized cost of dehydration. Return on investment periods generally range from 2.5 to 4 years, depending on energy costs and operational parameters.

Market analysis reveals growing adoption in sectors where high-purity CO2 commands premium pricing, such as food and beverage industries, enhanced oil recovery, and specialized manufacturing. The technology's economic viability improves significantly when integrated with existing carbon capture systems, as it can leverage process synergies and shared infrastructure.

Challenges to widespread economic adoption include relatively high membrane replacement costs and performance degradation over time. However, recent advances in membrane materials science suggest potential for extending operational lifespans by 30-50%, which would substantially improve long-term economics. Sensitivity analysis indicates that membrane durability improvements represent the single most impactful factor for enhancing economic feasibility at commercial scales.

Energy efficiency represents a significant economic advantage, with pervaporation membranes consuming approximately 30-50% less energy than conventional thermal separation methods. This translates to operational savings of $0.5-1.5 per ton of CO2 processed, which becomes substantial at industrial scales. Maintenance costs are relatively modest, averaging 3-7% of capital expenditure annually, compared to 8-12% for alternative technologies.

Scale-up potential for pervaporation membrane technology demonstrates promising characteristics. The modular nature of membrane systems allows for incremental capacity expansion without proportional cost increases - a phenomenon known as "economies of scale." Studies indicate that doubling processing capacity typically increases capital costs by only 60-70%, creating favorable economics at larger scales.

Industrial implementation has shown that pervaporation membrane systems become economically competitive at processing capacities above 50 tons of CO2 per day. At scales exceeding 200 tons daily, the technology often outperforms conventional methods in terms of levelized cost of dehydration. Return on investment periods generally range from 2.5 to 4 years, depending on energy costs and operational parameters.

Market analysis reveals growing adoption in sectors where high-purity CO2 commands premium pricing, such as food and beverage industries, enhanced oil recovery, and specialized manufacturing. The technology's economic viability improves significantly when integrated with existing carbon capture systems, as it can leverage process synergies and shared infrastructure.

Challenges to widespread economic adoption include relatively high membrane replacement costs and performance degradation over time. However, recent advances in membrane materials science suggest potential for extending operational lifespans by 30-50%, which would substantially improve long-term economics. Sensitivity analysis indicates that membrane durability improvements represent the single most impactful factor for enhancing economic feasibility at commercial scales.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!