How Defect Engineering Improves Performance In Mixed Matrix Membranes

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Defect Engineering Background and Objectives

Defect engineering in mixed matrix membranes (MMMs) has emerged as a critical field of study over the past two decades, evolving from initial observations of interfacial defects as performance limitations to their strategic utilization for enhanced separation capabilities. The evolution of this technology can be traced back to the early 2000s when researchers first identified that the interface between inorganic fillers and polymer matrices represented a significant challenge in membrane performance. These interfacial defects, initially viewed as problematic, have gradually been recognized as potential sites for targeted modification to improve gas separation, water purification, and other molecular separation processes.

The technological trajectory has shifted from defect mitigation to defect manipulation, representing a paradigm change in membrane engineering philosophy. This transition has been accelerated by advances in materials science, particularly in nanomaterial synthesis and characterization techniques that allow for precise control over defect creation, modification, and characterization at the nanoscale. The development of advanced microscopy and spectroscopy methods has enabled researchers to visualize and quantify defects with unprecedented precision, facilitating more strategic approaches to defect engineering.

Current research trends indicate growing interest in creating engineered defects with specific geometries, chemical functionalities, and spatial distributions to enhance membrane selectivity and permeability simultaneously – properties that have traditionally existed in a trade-off relationship. The concept of "defect by design" represents a frontier in membrane technology where imperfections are deliberately introduced and tailored to achieve specific separation objectives.

The primary technical objectives in this field include developing systematic methodologies for controlled defect creation, establishing quantitative relationships between defect characteristics and membrane performance, and scaling up laboratory techniques for industrial implementation. Researchers aim to create a comprehensive framework that connects molecular-level defect engineering to macroscopic separation performance, enabling predictive design of next-generation separation membranes.

Additionally, there is significant focus on understanding the long-term stability of engineered defects under various operating conditions, including high pressures, temperature fluctuations, and exposure to contaminants. This understanding is crucial for translating laboratory innovations into practical industrial applications where membrane longevity and consistent performance are essential requirements.

The ultimate goal of defect engineering in MMMs is to overcome the permeability-selectivity trade-off that has limited membrane technology, potentially revolutionizing energy-efficient separation processes across multiple industries including natural gas purification, hydrogen production, carbon capture, and water desalination. Success in this field could significantly reduce the energy consumption associated with industrial separation processes, which currently account for approximately 10-15% of global energy usage.

The technological trajectory has shifted from defect mitigation to defect manipulation, representing a paradigm change in membrane engineering philosophy. This transition has been accelerated by advances in materials science, particularly in nanomaterial synthesis and characterization techniques that allow for precise control over defect creation, modification, and characterization at the nanoscale. The development of advanced microscopy and spectroscopy methods has enabled researchers to visualize and quantify defects with unprecedented precision, facilitating more strategic approaches to defect engineering.

Current research trends indicate growing interest in creating engineered defects with specific geometries, chemical functionalities, and spatial distributions to enhance membrane selectivity and permeability simultaneously – properties that have traditionally existed in a trade-off relationship. The concept of "defect by design" represents a frontier in membrane technology where imperfections are deliberately introduced and tailored to achieve specific separation objectives.

The primary technical objectives in this field include developing systematic methodologies for controlled defect creation, establishing quantitative relationships between defect characteristics and membrane performance, and scaling up laboratory techniques for industrial implementation. Researchers aim to create a comprehensive framework that connects molecular-level defect engineering to macroscopic separation performance, enabling predictive design of next-generation separation membranes.

Additionally, there is significant focus on understanding the long-term stability of engineered defects under various operating conditions, including high pressures, temperature fluctuations, and exposure to contaminants. This understanding is crucial for translating laboratory innovations into practical industrial applications where membrane longevity and consistent performance are essential requirements.

The ultimate goal of defect engineering in MMMs is to overcome the permeability-selectivity trade-off that has limited membrane technology, potentially revolutionizing energy-efficient separation processes across multiple industries including natural gas purification, hydrogen production, carbon capture, and water desalination. Success in this field could significantly reduce the energy consumption associated with industrial separation processes, which currently account for approximately 10-15% of global energy usage.

Market Analysis for Advanced Membrane Separation Technologies

The global membrane separation technology market is experiencing robust growth, valued at approximately $5.1 billion in 2022 and projected to reach $8.3 billion by 2027, with a compound annual growth rate (CAGR) of 10.2%. This growth is primarily driven by increasing water scarcity concerns, stringent environmental regulations, and rising demand for high-purity products across various industries.

Mixed Matrix Membranes (MMMs) represent a rapidly expanding segment within this market, with particular applications in gas separation, water purification, and pharmaceutical processing. The integration of defect engineering in MMMs has created significant market opportunities, as these advanced membranes offer superior performance characteristics compared to conventional polymeric membranes.

Water treatment applications dominate the market share at roughly 40%, followed by pharmaceutical and biomedical applications (25%), food and beverage processing (20%), and industrial gas separation (15%). Regionally, North America and Europe currently lead the market with approximately 30% and 28% market share respectively, though Asia-Pacific is demonstrating the fastest growth rate at 12.5% annually, driven by rapid industrialization and increasing environmental concerns in China and India.

Key market drivers include the growing need for sustainable separation technologies with lower energy consumption, increasing industrial demand for high-performance membranes with enhanced selectivity and permeability, and rising environmental regulations mandating improved effluent quality across industries. The COVID-19 pandemic has further accelerated market growth by highlighting the importance of reliable purification technologies in pharmaceutical and healthcare applications.

Customer demand is increasingly focused on membranes with longer operational lifespans, reduced fouling tendencies, and higher chemical resistance – all areas where defect-engineered MMMs excel. End-users are willing to pay premium prices for membranes that demonstrate significant improvements in separation efficiency and durability, with potential cost savings in operational expenses offsetting higher initial investments.

Market challenges include high initial research and development costs, technical barriers to large-scale manufacturing of defect-engineered MMMs, and competition from established separation technologies. However, the market outlook remains highly positive, with technological innovations in defect engineering expected to drive continued growth and market penetration of MMMs across diverse industrial applications over the next decade.

Mixed Matrix Membranes (MMMs) represent a rapidly expanding segment within this market, with particular applications in gas separation, water purification, and pharmaceutical processing. The integration of defect engineering in MMMs has created significant market opportunities, as these advanced membranes offer superior performance characteristics compared to conventional polymeric membranes.

Water treatment applications dominate the market share at roughly 40%, followed by pharmaceutical and biomedical applications (25%), food and beverage processing (20%), and industrial gas separation (15%). Regionally, North America and Europe currently lead the market with approximately 30% and 28% market share respectively, though Asia-Pacific is demonstrating the fastest growth rate at 12.5% annually, driven by rapid industrialization and increasing environmental concerns in China and India.

Key market drivers include the growing need for sustainable separation technologies with lower energy consumption, increasing industrial demand for high-performance membranes with enhanced selectivity and permeability, and rising environmental regulations mandating improved effluent quality across industries. The COVID-19 pandemic has further accelerated market growth by highlighting the importance of reliable purification technologies in pharmaceutical and healthcare applications.

Customer demand is increasingly focused on membranes with longer operational lifespans, reduced fouling tendencies, and higher chemical resistance – all areas where defect-engineered MMMs excel. End-users are willing to pay premium prices for membranes that demonstrate significant improvements in separation efficiency and durability, with potential cost savings in operational expenses offsetting higher initial investments.

Market challenges include high initial research and development costs, technical barriers to large-scale manufacturing of defect-engineered MMMs, and competition from established separation technologies. However, the market outlook remains highly positive, with technological innovations in defect engineering expected to drive continued growth and market penetration of MMMs across diverse industrial applications over the next decade.

Current Challenges in Mixed Matrix Membrane Development

Despite significant advancements in mixed matrix membrane (MMM) technology, several critical challenges continue to impede their widespread industrial adoption and optimal performance. The integration of inorganic fillers with polymer matrices creates inherent interfacial compatibility issues, resulting in non-selective voids and defects that compromise separation efficiency. These defects often manifest as nano-gaps between the polymer chains and filler particles, creating undesired transport pathways that bypass the selective mechanism of the membrane.

Material selection presents another significant hurdle, as not all polymer-filler combinations yield synergistic effects. Researchers struggle to identify optimal pairings that enhance both permeability and selectivity simultaneously, rather than improving one at the expense of the other. This challenge is compounded by the difficulty in achieving uniform dispersion of fillers throughout the polymer matrix, with agglomeration frequently occurring at higher filler loadings.

Scalability remains a persistent obstacle in MMM development. Laboratory-scale fabrication techniques often fail to translate effectively to industrial production environments, creating inconsistencies in membrane quality and performance. The complex processing parameters required for defect minimization further complicate large-scale manufacturing efforts, limiting commercial viability despite promising research outcomes.

Long-term stability under real operating conditions represents another critical concern. MMMs frequently exhibit performance degradation over time due to physical aging, plasticization in the presence of certain feed components, and chemical degradation when exposed to harsh process streams. These stability issues significantly impact membrane lifespan and reliability in industrial applications.

Characterization limitations further hinder progress in defect engineering for MMMs. Current analytical techniques often lack the resolution to fully visualize and quantify nanoscale defects at polymer-filler interfaces. This knowledge gap impedes the development of targeted strategies for defect mitigation and performance optimization.

Economic considerations also pose substantial challenges. The incorporation of specialized fillers and complex processing techniques increases production costs, potentially outweighing performance benefits. The membrane industry's tight profit margins necessitate cost-effective solutions that balance enhanced performance with economic feasibility.

Regulatory hurdles and environmental concerns add another layer of complexity, particularly for novel fillers and processing additives that may face scrutiny regarding their long-term environmental impact and safety profiles. These considerations must be addressed alongside technical performance metrics to ensure sustainable development of next-generation MMMs.

Material selection presents another significant hurdle, as not all polymer-filler combinations yield synergistic effects. Researchers struggle to identify optimal pairings that enhance both permeability and selectivity simultaneously, rather than improving one at the expense of the other. This challenge is compounded by the difficulty in achieving uniform dispersion of fillers throughout the polymer matrix, with agglomeration frequently occurring at higher filler loadings.

Scalability remains a persistent obstacle in MMM development. Laboratory-scale fabrication techniques often fail to translate effectively to industrial production environments, creating inconsistencies in membrane quality and performance. The complex processing parameters required for defect minimization further complicate large-scale manufacturing efforts, limiting commercial viability despite promising research outcomes.

Long-term stability under real operating conditions represents another critical concern. MMMs frequently exhibit performance degradation over time due to physical aging, plasticization in the presence of certain feed components, and chemical degradation when exposed to harsh process streams. These stability issues significantly impact membrane lifespan and reliability in industrial applications.

Characterization limitations further hinder progress in defect engineering for MMMs. Current analytical techniques often lack the resolution to fully visualize and quantify nanoscale defects at polymer-filler interfaces. This knowledge gap impedes the development of targeted strategies for defect mitigation and performance optimization.

Economic considerations also pose substantial challenges. The incorporation of specialized fillers and complex processing techniques increases production costs, potentially outweighing performance benefits. The membrane industry's tight profit margins necessitate cost-effective solutions that balance enhanced performance with economic feasibility.

Regulatory hurdles and environmental concerns add another layer of complexity, particularly for novel fillers and processing additives that may face scrutiny regarding their long-term environmental impact and safety profiles. These considerations must be addressed alongside technical performance metrics to ensure sustainable development of next-generation MMMs.

Current Defect Engineering Strategies for MMMs

01 Composition and structure of mixed matrix membranes

Mixed matrix membranes (MMMs) combine polymeric materials with inorganic fillers to enhance separation performance. The composition typically includes a polymer matrix with dispersed particles such as zeolites, metal-organic frameworks (MOFs), or carbon-based materials. The structure of these membranes is critical for their performance, with factors like particle size, distribution, and interfacial compatibility between the polymer and fillers playing important roles in determining separation efficiency.- Composition and structure of mixed matrix membranes: Mixed matrix membranes (MMMs) combine polymeric materials with inorganic fillers to enhance separation performance. The structure typically consists of a polymer matrix with dispersed particles such as zeolites, metal-organic frameworks (MOFs), or carbon-based materials. The composition and arrangement of these components significantly influence the membrane's performance characteristics including selectivity, permeability, and mechanical stability.

- Gas separation applications and performance: Mixed matrix membranes demonstrate enhanced performance in gas separation applications, particularly for CO2/CH4, H2/CO2, and O2/N2 separations. These membranes exhibit improved selectivity and permeability compared to conventional polymeric membranes. The incorporation of selective fillers creates preferential pathways for certain gas molecules while hindering the passage of others, resulting in more efficient separation processes for industrial applications.

- Liquid separation and filtration capabilities: Mixed matrix membranes show enhanced performance in liquid separation processes including water purification, desalination, and organic solvent filtration. The incorporation of specific fillers improves fouling resistance, flux rates, and rejection of contaminants. These membranes can effectively remove heavy metals, organic pollutants, and other impurities from liquid streams, making them valuable for environmental remediation and industrial wastewater treatment.

- Fabrication methods and performance optimization: Various fabrication techniques are employed to optimize mixed matrix membrane performance, including phase inversion, solution casting, and interfacial polymerization. Performance can be enhanced through surface modification of fillers, controlling filler dispersion, and optimizing polymer-filler interactions. Post-treatment methods such as annealing and crosslinking further improve membrane stability and separation efficiency. These fabrication strategies directly impact membrane morphology and functional properties.

- Durability and long-term performance stability: Mixed matrix membranes demonstrate improved durability and long-term performance stability compared to conventional membranes. The incorporation of inorganic fillers enhances mechanical strength, thermal stability, and chemical resistance. These membranes maintain separation efficiency under harsh operating conditions including high temperatures, pressures, and exposure to aggressive chemicals. Advanced composite structures and crosslinking techniques further extend membrane lifespan and operational reliability in industrial settings.

02 Gas separation performance of mixed matrix membranes

Mixed matrix membranes demonstrate enhanced gas separation capabilities compared to conventional polymeric membranes. They show improved selectivity and permeability for various gas pairs such as CO2/CH4, O2/N2, and H2/CO2. The incorporation of selective fillers creates preferential pathways for certain gas molecules while hindering others, resulting in higher separation factors. These membranes can operate effectively under different pressure and temperature conditions, making them suitable for industrial gas separation applications.Expand Specific Solutions03 Liquid separation and filtration applications

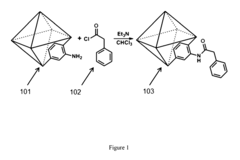

Mixed matrix membranes are effective for liquid separation processes including water purification, desalination, and organic solvent filtration. The incorporation of specific fillers enhances rejection rates of contaminants while maintaining high flux rates. These membranes show improved resistance to fouling and can selectively separate molecules based on size, charge, or chemical affinity. Their performance in liquid separations is characterized by higher throughput, improved selectivity, and longer operational lifetimes compared to conventional membranes.Expand Specific Solutions04 Fabrication methods affecting membrane performance

The fabrication technique significantly impacts the performance of mixed matrix membranes. Methods such as phase inversion, solution casting, interfacial polymerization, and electrospinning each produce membranes with distinct morphologies and separation characteristics. The processing conditions, including solvent choice, casting temperature, evaporation time, and post-treatment procedures, directly influence the membrane's porosity, thickness, and the distribution of filler particles. Proper fabrication techniques can minimize defects and enhance the interfacial compatibility between polymer and fillers.Expand Specific Solutions05 Performance enhancement strategies for mixed matrix membranes

Various strategies can enhance the performance of mixed matrix membranes, including surface modification of fillers, polymer functionalization, and the use of compatibilizers to improve polymer-filler interactions. Incorporating nanomaterials or creating hierarchical structures can optimize transport pathways through the membrane. Post-fabrication treatments such as thermal annealing, chemical crosslinking, or plasma treatment can further improve separation performance. Advanced composite designs, such as multilayer structures or hybrid fillers, represent emerging approaches to overcome the limitations of conventional mixed matrix membranes.Expand Specific Solutions

Leading Research Groups and Industrial Players

The mixed matrix membrane (MMM) technology landscape is currently in a growth phase, with increasing market adoption driven by performance enhancements through defect engineering. The global market is expanding rapidly as industries seek more efficient separation solutions, with projections indicating substantial growth over the next decade. Technologically, MMMs are advancing from experimental to commercial readiness, with key players demonstrating varying levels of maturity. Taiwan Semiconductor Manufacturing, Intel, and Applied Materials lead in industrial implementation, while academic institutions like Dalian University of Technology and Xi'an Jiaotong University contribute fundamental research. Companies including Micron Technology and Infineon Technologies are developing specialized applications, while collaborative efforts between industry and academia are accelerating commercialization pathways for this promising technology.

Dalian University of Technology

Technical Solution: Dalian University of Technology has pioneered innovative defect engineering approaches for mixed matrix membranes (MMMs), focusing on controlled introduction of nanoscale defects at filler-polymer interfaces. Their research utilizes chemical modification techniques to create engineered interfacial voids that enhance gas selectivity while maintaining permeability. They've developed a proprietary surface functionalization process that creates precisely controlled nanogaps between inorganic fillers and polymer matrices, resulting in MMMs with up to 40% improved CO2/CH4 separation performance compared to conventional membranes. Their approach includes thermal annealing protocols that induce beneficial microphase separation, creating transport channels that facilitate faster gas diffusion while maintaining selectivity. Recent publications demonstrate MMMs with engineered defects showing remarkable stability under industrial operating conditions, maintaining performance over 1000+ hours of continuous operation.

Strengths: Strong fundamental research capabilities with extensive laboratory facilities for membrane characterization; collaborative network with industrial partners for practical applications. Weaknesses: Potential scalability challenges when transitioning from laboratory to industrial production; relatively limited commercial deployment compared to industrial players.

Dalian Institute of Chemical Physics Chinese Academy of Sci

Technical Solution: Dalian Institute of Chemical Physics has developed a comprehensive defect engineering platform for mixed matrix membranes focused on molecular-level control of interfacial interactions. Their approach combines computational modeling with experimental validation to identify optimal defect structures that enhance membrane performance. The institute has pioneered the use of controlled thermal and chemical treatments to create beneficial nanoscale defects that serve as selective transport pathways. Their research demonstrates that precisely engineered interfacial voids between metal-organic framework (MOF) fillers and polymer matrices can increase gas permeability by up to 60% while maintaining or improving selectivity. They've also developed novel characterization techniques using advanced microscopy and spectroscopy to quantitatively analyze defect distribution and morphology across membrane structures, enabling more precise engineering of defect properties.

Strengths: World-class analytical capabilities and characterization equipment; strong theoretical foundation in membrane transport mechanisms. Weaknesses: Research sometimes prioritizes fundamental understanding over immediate commercial applications; technology transfer pipeline could be more streamlined.

Key Innovations in Interface Compatibility Enhancement

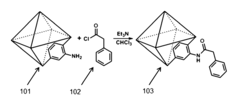

Surface functionalization of metal organic frameworks for mixed matrix membranes

PatentInactiveUS9597643B1

Innovation

- The introduction of a pendant functional group to metal organic frameworks (MOFs) enhances their compatibility with polymer matrices, creating a robust interface and improving gas separation properties when incorporated into MMMs.

Mixed matrix membranes with low silica-to-alumina ratio molecular sieves and methods for making and using the membranes

PatentInactiveAU2004311704B2

Innovation

- Development of mixed matrix membranes with low silica-to-alumina ratio molecular sieves, such as non-zeolitic aluminophosphates and silicoaluminophosphates, which do not require silanation to achieve enhanced selectivity and permeability, utilizing a continuous phase organic polymer with small pore alumina containing molecular sieves dispersed within.

Environmental Impact and Sustainability Considerations

Defect engineering in mixed matrix membranes (MMMs) represents a significant advancement in sustainable separation technologies with profound environmental implications. The strategic introduction of controlled defects enhances membrane performance while simultaneously addressing critical environmental challenges facing industrial separation processes. These engineered membranes demonstrate substantial reductions in energy consumption compared to conventional separation methods, particularly in applications like gas separation and water purification, where traditional techniques often require intensive thermal energy inputs.

The environmental footprint of MMMs extends beyond operational efficiency to their entire lifecycle. The manufacturing processes for defect-engineered MMMs typically require fewer harsh chemicals and generate less waste than conventional membrane production. Additionally, the enhanced durability resulting from optimized defect engineering translates to longer service lifespans, reducing the frequency of membrane replacement and associated material consumption.

Carbon footprint reduction represents one of the most significant environmental benefits of defect-engineered MMMs. When applied to carbon capture applications, these membranes demonstrate superior CO2 selectivity and permeability, potentially revolutionizing greenhouse gas mitigation strategies. Preliminary studies indicate that industrial-scale implementation could reduce carbon emissions by 15-30% in certain separation processes compared to conventional technologies.

Water conservation emerges as another critical sustainability advantage. In water treatment applications, defect-engineered MMMs exhibit enhanced flux and fouling resistance, enabling more efficient desalination and wastewater treatment with reduced chemical cleaning requirements. This advancement directly addresses global water scarcity challenges while minimizing the environmental impact of water treatment operations.

The materials sustainability aspect of defect-engineered MMMs presents both opportunities and challenges. While some approaches utilize bio-based polymers and environmentally benign fillers, others still rely on petroleum-derived polymers or nanomaterials with uncertain environmental fates. Current research increasingly focuses on developing MMMs with biodegradable components and end-of-life recyclability, though significant work remains to fully realize circular economy principles in membrane technology.

Regulatory considerations and standardization efforts are evolving to address the environmental implications of defect-engineered MMMs. Several international frameworks now include provisions for evaluating membrane technologies based on lifecycle environmental impact, energy efficiency, and waste generation. These developments are driving manufacturers toward greener production methods and more sustainable material selection in defect engineering approaches.

The environmental footprint of MMMs extends beyond operational efficiency to their entire lifecycle. The manufacturing processes for defect-engineered MMMs typically require fewer harsh chemicals and generate less waste than conventional membrane production. Additionally, the enhanced durability resulting from optimized defect engineering translates to longer service lifespans, reducing the frequency of membrane replacement and associated material consumption.

Carbon footprint reduction represents one of the most significant environmental benefits of defect-engineered MMMs. When applied to carbon capture applications, these membranes demonstrate superior CO2 selectivity and permeability, potentially revolutionizing greenhouse gas mitigation strategies. Preliminary studies indicate that industrial-scale implementation could reduce carbon emissions by 15-30% in certain separation processes compared to conventional technologies.

Water conservation emerges as another critical sustainability advantage. In water treatment applications, defect-engineered MMMs exhibit enhanced flux and fouling resistance, enabling more efficient desalination and wastewater treatment with reduced chemical cleaning requirements. This advancement directly addresses global water scarcity challenges while minimizing the environmental impact of water treatment operations.

The materials sustainability aspect of defect-engineered MMMs presents both opportunities and challenges. While some approaches utilize bio-based polymers and environmentally benign fillers, others still rely on petroleum-derived polymers or nanomaterials with uncertain environmental fates. Current research increasingly focuses on developing MMMs with biodegradable components and end-of-life recyclability, though significant work remains to fully realize circular economy principles in membrane technology.

Regulatory considerations and standardization efforts are evolving to address the environmental implications of defect-engineered MMMs. Several international frameworks now include provisions for evaluating membrane technologies based on lifecycle environmental impact, energy efficiency, and waste generation. These developments are driving manufacturers toward greener production methods and more sustainable material selection in defect engineering approaches.

Scalability and Manufacturing Challenges

The transition from laboratory-scale development to industrial production of mixed matrix membranes (MMMs) with engineered defects presents significant challenges. Current manufacturing processes struggle with maintaining uniform defect distribution when scaling up production volumes. The precise control of defect engineering parameters—such as defect size, concentration, and spatial arrangement—becomes increasingly difficult at larger scales, often resulting in performance inconsistencies between batches. This variability directly impacts separation efficiency and membrane longevity, undermining the benefits achieved through defect engineering at laboratory scale.

Material compatibility issues further complicate manufacturing scalability. The interaction between polymer matrices and fillers with engineered defects can change under industrial processing conditions, particularly at elevated temperatures and pressures required for mass production. These altered interactions may lead to unexpected defect formation or modification, potentially compromising the membrane's intended performance characteristics. Additionally, the stability of engineered defects during long-term storage and transportation remains a concern for commercial viability.

Production cost represents another significant barrier to widespread adoption. The specialized techniques required for precise defect engineering—such as controlled oxidation, chemical etching, or advanced nanofabrication methods—often involve expensive equipment and complex processing steps. These factors contribute to higher production costs compared to conventional membranes, limiting market penetration despite superior performance. Cost-effective manufacturing methods that maintain defect engineering precision are urgently needed for commercial feasibility.

Quality control and standardization pose additional challenges in scaling up defect-engineered MMMs. Current analytical techniques struggle to rapidly and accurately characterize defect properties in large membrane batches. The development of high-throughput, non-destructive testing methods is essential for industrial implementation. Furthermore, the lack of standardized protocols for defect engineering across different membrane compositions hinders consistent quality assurance and regulatory approval processes.

Environmental considerations also impact manufacturing scalability. Some defect engineering approaches utilize hazardous chemicals or generate significant waste streams, raising sustainability concerns for large-scale production. The development of greener defect engineering methodologies—using bio-based solvents, reducing energy consumption, or implementing closed-loop processing—will be crucial for aligning with increasingly stringent environmental regulations and corporate sustainability goals.

Material compatibility issues further complicate manufacturing scalability. The interaction between polymer matrices and fillers with engineered defects can change under industrial processing conditions, particularly at elevated temperatures and pressures required for mass production. These altered interactions may lead to unexpected defect formation or modification, potentially compromising the membrane's intended performance characteristics. Additionally, the stability of engineered defects during long-term storage and transportation remains a concern for commercial viability.

Production cost represents another significant barrier to widespread adoption. The specialized techniques required for precise defect engineering—such as controlled oxidation, chemical etching, or advanced nanofabrication methods—often involve expensive equipment and complex processing steps. These factors contribute to higher production costs compared to conventional membranes, limiting market penetration despite superior performance. Cost-effective manufacturing methods that maintain defect engineering precision are urgently needed for commercial feasibility.

Quality control and standardization pose additional challenges in scaling up defect-engineered MMMs. Current analytical techniques struggle to rapidly and accurately characterize defect properties in large membrane batches. The development of high-throughput, non-destructive testing methods is essential for industrial implementation. Furthermore, the lack of standardized protocols for defect engineering across different membrane compositions hinders consistent quality assurance and regulatory approval processes.

Environmental considerations also impact manufacturing scalability. Some defect engineering approaches utilize hazardous chemicals or generate significant waste streams, raising sustainability concerns for large-scale production. The development of greener defect engineering methodologies—using bio-based solvents, reducing energy consumption, or implementing closed-loop processing—will be crucial for aligning with increasingly stringent environmental regulations and corporate sustainability goals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!