Role Of Carbon Nanotube Channels In High-Flux Membrane Separation

SEP 3, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon Nanotube Membrane Technology Background and Objectives

Carbon nanotube (CNT) membrane technology represents a revolutionary advancement in separation science, emerging from the convergence of nanotechnology and membrane engineering. Since their discovery in 1991 by Iijima, carbon nanotubes have attracted significant scientific interest due to their exceptional properties, including remarkable mechanical strength, thermal stability, and unique transport characteristics. The evolution of CNT-based membranes began in the early 2000s when researchers first demonstrated the potential of aligned CNT arrays for fluid transport applications.

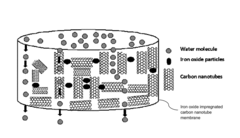

The fundamental premise of CNT membrane technology lies in the exploitation of the unique structural and chemical properties of carbon nanotubes. These cylindrical carbon structures, with diameters ranging from 0.7 to 100 nanometers, create channels that facilitate extraordinarily rapid transport of water molecules while maintaining high selectivity for solute rejection. This phenomenon, often referred to as "frictionless flow" or "hyper-fast water transport," defies conventional fluid dynamics predictions and offers transformative potential for separation processes.

The technological trajectory of CNT membranes has progressed through several distinct phases. Initial research focused on fundamental transport mechanisms and fabrication challenges. This was followed by efforts to incorporate CNTs into polymer matrices to create practical membrane structures. Recent developments have centered on scalable manufacturing techniques and surface functionalization strategies to enhance selectivity and address fouling issues.

The primary objectives of CNT membrane technology development are multifaceted. First, researchers aim to harness the exceptional flux capabilities of CNT channels to dramatically reduce energy consumption in separation processes compared to conventional membranes. Second, there is a focus on achieving precise molecular sieving through controlled CNT diameter and functionalization. Third, the field seeks to develop robust, scalable fabrication methods that maintain the integrity of CNT channels while enabling industrial-scale production.

Current research objectives also include understanding and optimizing the role of CNT channels in various separation contexts, including desalination, gas separation, pharmaceutical purification, and environmental remediation. Particular emphasis is placed on elucidating the fundamental transport mechanisms that enable CNTs to achieve water permeability orders of magnitude higher than conventional membranes while maintaining excellent selectivity.

The long-term technological vision encompasses the development of next-generation separation systems that leverage the unique properties of CNT channels to address global challenges in water scarcity, energy efficiency, and sustainable chemical processing. This includes the creation of adaptive, responsive membrane systems that can dynamically adjust their separation characteristics based on environmental conditions or process requirements.

The fundamental premise of CNT membrane technology lies in the exploitation of the unique structural and chemical properties of carbon nanotubes. These cylindrical carbon structures, with diameters ranging from 0.7 to 100 nanometers, create channels that facilitate extraordinarily rapid transport of water molecules while maintaining high selectivity for solute rejection. This phenomenon, often referred to as "frictionless flow" or "hyper-fast water transport," defies conventional fluid dynamics predictions and offers transformative potential for separation processes.

The technological trajectory of CNT membranes has progressed through several distinct phases. Initial research focused on fundamental transport mechanisms and fabrication challenges. This was followed by efforts to incorporate CNTs into polymer matrices to create practical membrane structures. Recent developments have centered on scalable manufacturing techniques and surface functionalization strategies to enhance selectivity and address fouling issues.

The primary objectives of CNT membrane technology development are multifaceted. First, researchers aim to harness the exceptional flux capabilities of CNT channels to dramatically reduce energy consumption in separation processes compared to conventional membranes. Second, there is a focus on achieving precise molecular sieving through controlled CNT diameter and functionalization. Third, the field seeks to develop robust, scalable fabrication methods that maintain the integrity of CNT channels while enabling industrial-scale production.

Current research objectives also include understanding and optimizing the role of CNT channels in various separation contexts, including desalination, gas separation, pharmaceutical purification, and environmental remediation. Particular emphasis is placed on elucidating the fundamental transport mechanisms that enable CNTs to achieve water permeability orders of magnitude higher than conventional membranes while maintaining excellent selectivity.

The long-term technological vision encompasses the development of next-generation separation systems that leverage the unique properties of CNT channels to address global challenges in water scarcity, energy efficiency, and sustainable chemical processing. This includes the creation of adaptive, responsive membrane systems that can dynamically adjust their separation characteristics based on environmental conditions or process requirements.

Market Analysis for High-Flux Separation Applications

The high-flux membrane separation market is experiencing significant growth driven by increasing industrial demand for efficient separation technologies. The global membrane separation market was valued at approximately $28.1 billion in 2021 and is projected to reach $48.2 billion by 2028, growing at a CAGR of 7.9%. Within this broader market, high-flux applications represent one of the fastest-growing segments due to their superior efficiency and reduced operational costs.

Water treatment and purification constitute the largest application segment, accounting for over 40% of the market share. This is primarily due to increasing water scarcity concerns and stringent regulations regarding water quality across industries. The pharmaceutical and biotechnology sectors follow closely, where high-flux membranes are essential for protein purification, virus filtration, and other critical separation processes.

Geographically, North America and Europe currently dominate the high-flux membrane market, collectively holding approximately 60% market share. However, the Asia-Pacific region is witnessing the highest growth rate, driven by rapid industrialization, urbanization, and increasing environmental regulations in countries like China and India.

Carbon nanotube (CNT) channels in high-flux membranes represent a disruptive innovation in this market landscape. Traditional polymer and ceramic membranes face limitations in achieving both high selectivity and high permeability simultaneously. CNT-based membranes address this trade-off, potentially creating a premium segment within the market with projected growth rates exceeding 15% annually.

End-user industries are increasingly demanding membranes with higher flux rates to reduce energy consumption and operational costs. For instance, in desalination applications, energy costs can be reduced by up to 30% with high-flux membranes compared to conventional technologies. This economic driver is creating strong market pull for CNT-based solutions.

The competitive landscape is characterized by both established membrane manufacturers investing in CNT research and startups focused exclusively on commercializing CNT membrane technology. Major chemical companies are forming strategic partnerships with research institutions to accelerate development and secure intellectual property in this space.

Market barriers include high production costs of CNT membranes, scalability challenges, and regulatory hurdles related to potential environmental and health impacts of nanomaterials. However, recent advancements in manufacturing techniques are gradually addressing cost and scalability concerns, potentially accelerating market adoption in the coming years.

Water treatment and purification constitute the largest application segment, accounting for over 40% of the market share. This is primarily due to increasing water scarcity concerns and stringent regulations regarding water quality across industries. The pharmaceutical and biotechnology sectors follow closely, where high-flux membranes are essential for protein purification, virus filtration, and other critical separation processes.

Geographically, North America and Europe currently dominate the high-flux membrane market, collectively holding approximately 60% market share. However, the Asia-Pacific region is witnessing the highest growth rate, driven by rapid industrialization, urbanization, and increasing environmental regulations in countries like China and India.

Carbon nanotube (CNT) channels in high-flux membranes represent a disruptive innovation in this market landscape. Traditional polymer and ceramic membranes face limitations in achieving both high selectivity and high permeability simultaneously. CNT-based membranes address this trade-off, potentially creating a premium segment within the market with projected growth rates exceeding 15% annually.

End-user industries are increasingly demanding membranes with higher flux rates to reduce energy consumption and operational costs. For instance, in desalination applications, energy costs can be reduced by up to 30% with high-flux membranes compared to conventional technologies. This economic driver is creating strong market pull for CNT-based solutions.

The competitive landscape is characterized by both established membrane manufacturers investing in CNT research and startups focused exclusively on commercializing CNT membrane technology. Major chemical companies are forming strategic partnerships with research institutions to accelerate development and secure intellectual property in this space.

Market barriers include high production costs of CNT membranes, scalability challenges, and regulatory hurdles related to potential environmental and health impacts of nanomaterials. However, recent advancements in manufacturing techniques are gradually addressing cost and scalability concerns, potentially accelerating market adoption in the coming years.

Current Status and Challenges in CNT Membrane Development

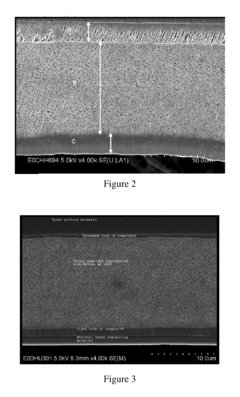

Carbon nanotube (CNT) membranes represent one of the most promising frontiers in separation technology, offering unprecedented flux rates while maintaining high selectivity. Currently, the field has progressed from theoretical predictions to laboratory-scale demonstrations, with several research groups successfully fabricating functional CNT membranes. These membranes typically consist of vertically aligned CNT arrays embedded in polymer or ceramic matrices, with the nanotubes serving as molecular channels.

Despite significant advancements, large-scale production of CNT membranes faces substantial challenges. The primary obstacle remains the controlled growth of high-density, vertically aligned CNTs with uniform diameter distribution. Current synthesis methods, including chemical vapor deposition (CVD), often produce CNTs with varying diameters and lengths, compromising membrane performance consistency. Additionally, the integration of CNTs into robust matrix materials without blocking tube ends or creating defects at the CNT-matrix interface presents significant fabrication difficulties.

The scalability of production represents another major hurdle. Laboratory demonstrations typically involve membranes with active areas of a few square centimeters, whereas industrial applications would require square meters of membrane area. The transition from lab to industrial scale has proven particularly challenging due to the precision required in CNT alignment and matrix formation over large areas.

Performance stability under real-world conditions remains inadequately addressed. CNT membranes often show degradation in selectivity or flux over time due to fouling, chemical degradation, or mechanical stress. The long-term durability of these membranes in harsh industrial environments (extreme pH, high temperature, presence of organic solvents) requires further investigation and improvement.

Cost considerations present another significant barrier to commercialization. Current fabrication methods for high-quality CNT membranes involve expensive processes and materials, making them economically unviable for most separation applications when compared to conventional membrane technologies. Reducing production costs while maintaining performance remains a critical challenge.

Geographically, research in CNT membrane technology is concentrated primarily in North America, East Asia, and Europe. The United States leads in fundamental research and patent filings, with significant contributions from research institutions like MIT, Lawrence Livermore National Laboratory, and Rice University. China has rapidly expanded its research output in this field, particularly focusing on scalable manufacturing approaches. European research centers, especially in Germany and the UK, have made notable advances in CNT functionalization for enhanced selectivity.

Regulatory hurdles and environmental concerns regarding potential CNT release during membrane operation or disposal must also be addressed before widespread adoption can occur. The potential toxicity of CNTs remains a subject of ongoing research, creating uncertainty in regulatory approval processes for CNT-based separation technologies.

Despite significant advancements, large-scale production of CNT membranes faces substantial challenges. The primary obstacle remains the controlled growth of high-density, vertically aligned CNTs with uniform diameter distribution. Current synthesis methods, including chemical vapor deposition (CVD), often produce CNTs with varying diameters and lengths, compromising membrane performance consistency. Additionally, the integration of CNTs into robust matrix materials without blocking tube ends or creating defects at the CNT-matrix interface presents significant fabrication difficulties.

The scalability of production represents another major hurdle. Laboratory demonstrations typically involve membranes with active areas of a few square centimeters, whereas industrial applications would require square meters of membrane area. The transition from lab to industrial scale has proven particularly challenging due to the precision required in CNT alignment and matrix formation over large areas.

Performance stability under real-world conditions remains inadequately addressed. CNT membranes often show degradation in selectivity or flux over time due to fouling, chemical degradation, or mechanical stress. The long-term durability of these membranes in harsh industrial environments (extreme pH, high temperature, presence of organic solvents) requires further investigation and improvement.

Cost considerations present another significant barrier to commercialization. Current fabrication methods for high-quality CNT membranes involve expensive processes and materials, making them economically unviable for most separation applications when compared to conventional membrane technologies. Reducing production costs while maintaining performance remains a critical challenge.

Geographically, research in CNT membrane technology is concentrated primarily in North America, East Asia, and Europe. The United States leads in fundamental research and patent filings, with significant contributions from research institutions like MIT, Lawrence Livermore National Laboratory, and Rice University. China has rapidly expanded its research output in this field, particularly focusing on scalable manufacturing approaches. European research centers, especially in Germany and the UK, have made notable advances in CNT functionalization for enhanced selectivity.

Regulatory hurdles and environmental concerns regarding potential CNT release during membrane operation or disposal must also be addressed before widespread adoption can occur. The potential toxicity of CNTs remains a subject of ongoing research, creating uncertainty in regulatory approval processes for CNT-based separation technologies.

State-of-the-Art CNT Channel Design Solutions

01 Carbon nanotube membranes for high-flux filtration

Carbon nanotube membranes can be engineered to create high-flux filtration systems. The unique structure of carbon nanotubes allows for exceptional water permeability while maintaining selectivity for certain molecules. These membranes exhibit significantly higher flow rates compared to conventional filtration materials due to the frictionless nature of the nanotube inner walls, making them ideal for water purification, desalination, and other separation processes.- Carbon nanotube membrane structures for high-flux filtration: Carbon nanotube membranes can be engineered with specific channel structures to enable high-flux filtration applications. These membranes utilize the unique properties of carbon nanotubes to create nanochannels that allow for rapid transport of water molecules while blocking larger contaminants. The uniform pore size and smooth interior of carbon nanotube channels contribute to their exceptional flux rates compared to conventional membrane materials, making them promising for water purification and desalination applications.

- Fabrication methods for aligned carbon nanotube channels: Various fabrication techniques have been developed to create aligned carbon nanotube channels for high-flux applications. These methods include chemical vapor deposition, template-assisted growth, and post-synthesis alignment processes. By controlling the growth conditions and substrate properties, researchers can produce vertically aligned carbon nanotube arrays with precise channel dimensions and spacing. These fabrication approaches enable the creation of membranes with optimized channel structures for enhanced flux performance.

- Surface functionalization of carbon nanotube channels: Surface functionalization of carbon nanotube channels can significantly enhance their high-flux properties. By modifying the surface chemistry of carbon nanotubes through chemical treatments or coating processes, researchers can control the hydrophilicity, selectivity, and anti-fouling properties of the channels. Functionalized carbon nanotube membranes demonstrate improved flux rates and selectivity for specific molecules, making them suitable for applications in separation technologies, molecular sieving, and controlled substance delivery.

- Carbon nanotube-polymer composite membranes for enhanced flux: Carbon nanotube-polymer composite membranes combine the high-flux properties of carbon nanotubes with the mechanical stability and processability of polymers. These composites incorporate aligned carbon nanotubes within a polymer matrix to create nanochannels for fluid transport. The synergistic interaction between the carbon nanotubes and polymer matrix results in membranes with superior flux rates compared to conventional polymer membranes, while maintaining structural integrity and flexibility for practical applications.

- Applications of high-flux carbon nanotube channels in energy and electronics: Beyond filtration, high-flux carbon nanotube channels have promising applications in energy storage, conversion, and electronic devices. The exceptional electron transport properties of carbon nanotubes enable their use in high-performance electrodes, sensors, and energy harvesting systems. Carbon nanotube channels can facilitate rapid ion transport in batteries and supercapacitors, enhancing charging rates and energy density. Additionally, these structures can be integrated into electronic devices for thermal management and as conductive pathways in next-generation semiconductor technologies.

02 Fabrication methods for aligned carbon nanotube channels

Various fabrication techniques have been developed to create aligned carbon nanotube channels for high-flux applications. These methods include chemical vapor deposition, template-assisted growth, and post-synthesis alignment procedures. The alignment of carbon nanotubes is critical for maximizing flux rates and ensuring consistent pore sizes. Advanced fabrication approaches focus on creating vertically aligned nanotube arrays embedded in polymer or ceramic matrices to form robust membrane structures.Expand Specific Solutions03 Functionalization of carbon nanotubes for selective transport

Chemical functionalization of carbon nanotubes can enhance their selectivity while maintaining high flux rates. By attaching specific functional groups to the nanotube openings or surfaces, these channels can be tailored to selectively transport certain molecules while blocking others. This approach enables the development of advanced separation technologies for applications in gas separation, pharmaceutical purification, and molecular sieving with unprecedented efficiency.Expand Specific Solutions04 Carbon nanotube-polymer composite membranes

Incorporating carbon nanotubes into polymer matrices creates composite membranes with enhanced flux properties. These composites combine the mechanical stability of polymers with the high-flux channels provided by carbon nanotubes. The interface between the nanotubes and polymer matrix is engineered to prevent leakage while maximizing flow through the nanotube channels. These membranes show promise for industrial-scale applications due to their scalability and improved durability compared to pure nanotube arrays.Expand Specific Solutions05 Carbon nanotube channels for energy generation and storage applications

Beyond filtration, carbon nanotube channels with high-flux properties are being utilized in energy applications. These include flow batteries, capacitive deionization systems, and osmotic power generation. The exceptional ion transport capabilities of carbon nanotube channels enable faster charging/discharging rates in energy storage devices and more efficient energy conversion in flow-based systems. The controlled diameter and surface properties of nanotubes allow for optimized ion transport kinetics.Expand Specific Solutions

Leading Organizations in CNT Membrane Research and Commercialization

Carbon nanotube (CNT) channels in high-flux membrane separation represent an emerging technology at the early growth stage of industry development. The market is expanding rapidly with projections reaching $500-700 million by 2025, driven by increasing demand for efficient water purification and molecular separation solutions. Technologically, the field is transitioning from laboratory research to commercial applications, with varying degrees of maturity among key players. Leading research institutions like Dalian University of Technology, Colorado School of Mines, and Rensselaer Polytechnic Institute are advancing fundamental understanding of CNT transport mechanisms, while companies including NEC Corp., Intel, and Fujitsu are developing scalable manufacturing processes. The National University of Singapore and Chinese Academy of Sciences are pioneering novel CNT membrane architectures, while Applied NanoStructured Solutions and Lawrence Livermore National Security are focusing on practical implementation challenges for industrial-scale separation processes.

Zhejiang University

Technical Solution: Zhejiang University has developed sophisticated carbon nanotube (CNT) membrane technologies focusing on hierarchical structures for enhanced separation performance. Their approach combines vertically aligned CNT arrays with secondary nanoporous structures to create multi-scale transport pathways. The university's research team has pioneered techniques for precise diameter control of CNTs through catalyst engineering and growth parameter optimization, achieving narrow pore size distributions critical for molecular separation applications. Their membranes demonstrate water permeability up to 10,000 L/m²·h·bar while maintaining high rejection rates for contaminants. Zhejiang's innovations include novel surface modification strategies using plasma treatment and chemical grafting to introduce specific functional groups at CNT entrances, enabling selective molecular recognition and transport. Recent developments focus on addressing fouling issues through the incorporation of antimicrobial nanoparticles and photocatalytic materials within the CNT membrane structure, significantly extending operational lifetimes in challenging separation environments such as industrial wastewater treatment and bioprocessing applications.

Strengths: Hierarchical membrane structure providing both high flux and selectivity; Advanced surface modification techniques for targeted separations; Innovative anti-fouling strategies. Weaknesses: Complex manufacturing process limiting large-scale production; Higher energy requirements for certain modification processes; Potential for performance degradation under harsh chemical environments.

Chinese Academy of Sciences Institute of Physics

Technical Solution: The Chinese Academy of Sciences Institute of Physics has developed cutting-edge carbon nanotube (CNT) membrane technology focusing on fundamental transport mechanisms and structural optimization. Their approach leverages precise control over CNT diameter, length, and surface chemistry to create membranes with exceptional separation performance. The institute has pioneered novel synthesis methods for ultra-narrow CNTs with sub-nanometer diameters, enabling molecular sieving capabilities while maintaining high flux rates. Their research demonstrates that water transport through these confined channels can achieve flow rates exceeding theoretical predictions based on continuum fluid dynamics, with enhancement factors of 1000-3000 times compared to conventional membranes. The institute has developed innovative techniques for creating high-density, vertically aligned CNT arrays with controlled spacing and orientation, maximizing effective membrane area while minimizing tortuosity. Recent advances include the development of composite membranes incorporating CNTs with two-dimensional materials like graphene oxide, creating synergistic transport pathways that combine the high flux of CNT channels with the molecular selectivity of nanosheets.

Strengths: Exceptional control over CNT structural parameters; Fundamental understanding of nanoscale transport phenomena; Advanced composite membrane architectures. Weaknesses: Significant challenges in scaling laboratory techniques to industrial production; High precision requirements increasing manufacturing complexity; Limited demonstration in real-world separation environments.

Critical Patents and Research on CNT Channel Optimization

Carbon nanotube composite membrane

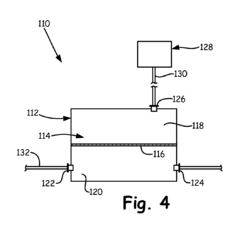

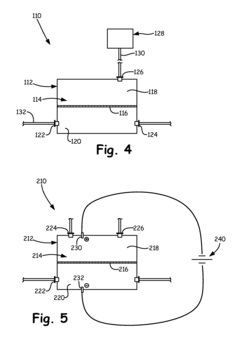

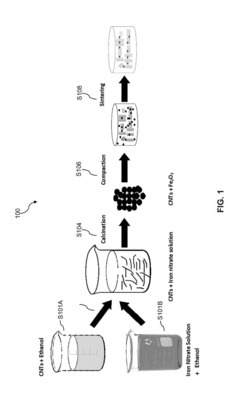

PatentActiveEP2826546A1

Innovation

- A composite membrane structure incorporating a non-woven array of intermingled carbon nanotubes with a polymer matrix, which maintains strength while minimizing interference with permeability, allowing for reduced polymer usage and enhanced separation performance.

Carbon nanotube membranes

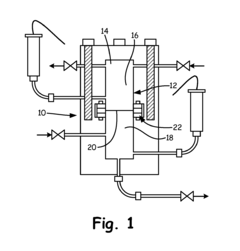

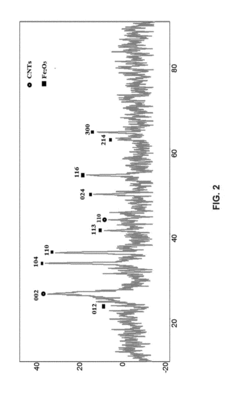

PatentInactiveUS20170312696A1

Innovation

- A polymer-free, binder-free, and template-free process for fabricating iron oxide impregnated carbon nanotube membranes by dispersing iron oxide nanoparticles onto carbon nanotubes, pressing them into discs, and sintering to create a membrane with high porosity and hydrophilicity, enhancing water flux and antifouling properties.

Environmental Impact and Sustainability Considerations

Carbon nanotube (CNT) membranes represent a significant advancement in separation technology with potentially transformative environmental benefits. The environmental footprint of conventional membrane separation processes is substantial, characterized by high energy consumption and chemical usage. CNT-based high-flux membranes offer remarkable potential for reducing these impacts through their exceptional permeability characteristics, which enable equivalent separation performance at significantly lower operating pressures.

Energy efficiency stands as perhaps the most compelling environmental advantage of CNT membrane technology. Studies indicate that CNT-enhanced membranes can achieve up to 40-60% reduction in energy consumption compared to conventional polymeric membranes in applications such as desalination and industrial wastewater treatment. This efficiency derives from the frictionless water transport through hydrophobic carbon nanotube channels, dramatically reducing the pumping energy required to achieve desired flux rates.

The manufacturing sustainability of CNT membranes presents a complex environmental consideration. Current production methods for carbon nanotubes remain energy-intensive and often utilize hazardous chemicals. However, recent advancements in green synthesis approaches, including catalyst-free growth methods and bio-inspired fabrication techniques, show promise for reducing the environmental burden of CNT production. Life cycle assessments suggest that despite higher initial embodied energy, the operational efficiency of CNT membranes can offset manufacturing impacts within 1-3 years of continuous operation.

Waste reduction represents another significant environmental benefit of CNT membrane technology. The extended lifespan of CNT-enhanced membranes—potentially 2-3 times longer than conventional membranes due to superior mechanical strength and fouling resistance—translates to reduced membrane replacement frequency and associated waste generation. Additionally, the precision separation capabilities of CNT membranes enable more efficient resource recovery from waste streams, supporting circular economy principles.

Water conservation implications of CNT membrane technology extend beyond energy efficiency. The higher flux rates and selectivity of CNT membranes enable treatment of previously challenging water sources, potentially expanding available water resources in water-stressed regions. Furthermore, the ability to operate effectively at lower pressures makes decentralized treatment systems more viable, reducing water transportation requirements and associated environmental impacts.

Chemical usage reduction presents another environmental advantage, as CNT membranes typically demonstrate enhanced resistance to biofouling and chemical degradation. This characteristic potentially reduces the frequency and intensity of chemical cleaning procedures, decreasing the environmental burden associated with cleaning agent production, transportation, and disposal. Some research indicates up to 30% reduction in cleaning chemical requirements for certain applications.

Energy efficiency stands as perhaps the most compelling environmental advantage of CNT membrane technology. Studies indicate that CNT-enhanced membranes can achieve up to 40-60% reduction in energy consumption compared to conventional polymeric membranes in applications such as desalination and industrial wastewater treatment. This efficiency derives from the frictionless water transport through hydrophobic carbon nanotube channels, dramatically reducing the pumping energy required to achieve desired flux rates.

The manufacturing sustainability of CNT membranes presents a complex environmental consideration. Current production methods for carbon nanotubes remain energy-intensive and often utilize hazardous chemicals. However, recent advancements in green synthesis approaches, including catalyst-free growth methods and bio-inspired fabrication techniques, show promise for reducing the environmental burden of CNT production. Life cycle assessments suggest that despite higher initial embodied energy, the operational efficiency of CNT membranes can offset manufacturing impacts within 1-3 years of continuous operation.

Waste reduction represents another significant environmental benefit of CNT membrane technology. The extended lifespan of CNT-enhanced membranes—potentially 2-3 times longer than conventional membranes due to superior mechanical strength and fouling resistance—translates to reduced membrane replacement frequency and associated waste generation. Additionally, the precision separation capabilities of CNT membranes enable more efficient resource recovery from waste streams, supporting circular economy principles.

Water conservation implications of CNT membrane technology extend beyond energy efficiency. The higher flux rates and selectivity of CNT membranes enable treatment of previously challenging water sources, potentially expanding available water resources in water-stressed regions. Furthermore, the ability to operate effectively at lower pressures makes decentralized treatment systems more viable, reducing water transportation requirements and associated environmental impacts.

Chemical usage reduction presents another environmental advantage, as CNT membranes typically demonstrate enhanced resistance to biofouling and chemical degradation. This characteristic potentially reduces the frequency and intensity of chemical cleaning procedures, decreasing the environmental burden associated with cleaning agent production, transportation, and disposal. Some research indicates up to 30% reduction in cleaning chemical requirements for certain applications.

Scalability and Manufacturing Challenges

The scaling of carbon nanotube (CNT) membrane technology from laboratory prototypes to industrial-scale production represents one of the most significant challenges in commercializing this promising separation technology. Current manufacturing methods for CNT membranes are predominantly limited to small-scale production, with typical membrane areas ranging from square millimeters to a few square centimeters. This limitation severely restricts their practical application in industrial settings where membrane areas of several square meters are standard.

A primary manufacturing challenge lies in the controlled growth of vertically aligned carbon nanotubes with consistent diameter, spacing, and orientation across large areas. Chemical vapor deposition (CVD) techniques, while effective for small-scale production, face significant uniformity issues when scaled up. Temperature gradients, gas flow dynamics, and catalyst deactivation across larger substrates lead to heterogeneous CNT forests, compromising membrane performance consistency.

Matrix material integration presents another critical challenge. The infiltration of polymer or ceramic matrices between CNTs must be uniform to prevent the formation of non-selective pathways. As membrane dimensions increase, ensuring complete and consistent matrix infiltration becomes exponentially more difficult, often resulting in defect formation and reduced selectivity in larger membranes.

Post-processing steps such as CNT tip opening and surface functionalization also face scalability issues. Current methods like plasma etching or chemical oxidation are difficult to apply uniformly across large membrane areas, leading to variability in pore openings and surface chemistry. This inconsistency directly impacts separation performance metrics including flux and selectivity.

Cost considerations further complicate manufacturing scale-up. The high-purity catalysts, specialized equipment, and precise control requirements for CNT growth contribute to prohibitive production costs. Current estimates suggest that large-scale CNT membranes would be 10-50 times more expensive than conventional polymeric membranes, creating a significant barrier to market entry despite their superior performance characteristics.

Quality control and reproducibility represent additional challenges. The lack of standardized testing protocols and in-line monitoring techniques for CNT membrane production makes consistent quality assurance difficult at larger scales. Variations between production batches remain high, with performance metrics sometimes differing by orders of magnitude between supposedly identical membranes.

Addressing these manufacturing challenges requires interdisciplinary approaches combining advances in materials science, chemical engineering, and process technology. Recent developments in roll-to-roll processing, continuous CVD systems, and automated quality control offer promising pathways toward industrial-scale production, though significant research investment is still needed to bridge the gap between laboratory success and commercial viability.

A primary manufacturing challenge lies in the controlled growth of vertically aligned carbon nanotubes with consistent diameter, spacing, and orientation across large areas. Chemical vapor deposition (CVD) techniques, while effective for small-scale production, face significant uniformity issues when scaled up. Temperature gradients, gas flow dynamics, and catalyst deactivation across larger substrates lead to heterogeneous CNT forests, compromising membrane performance consistency.

Matrix material integration presents another critical challenge. The infiltration of polymer or ceramic matrices between CNTs must be uniform to prevent the formation of non-selective pathways. As membrane dimensions increase, ensuring complete and consistent matrix infiltration becomes exponentially more difficult, often resulting in defect formation and reduced selectivity in larger membranes.

Post-processing steps such as CNT tip opening and surface functionalization also face scalability issues. Current methods like plasma etching or chemical oxidation are difficult to apply uniformly across large membrane areas, leading to variability in pore openings and surface chemistry. This inconsistency directly impacts separation performance metrics including flux and selectivity.

Cost considerations further complicate manufacturing scale-up. The high-purity catalysts, specialized equipment, and precise control requirements for CNT growth contribute to prohibitive production costs. Current estimates suggest that large-scale CNT membranes would be 10-50 times more expensive than conventional polymeric membranes, creating a significant barrier to market entry despite their superior performance characteristics.

Quality control and reproducibility represent additional challenges. The lack of standardized testing protocols and in-line monitoring techniques for CNT membrane production makes consistent quality assurance difficult at larger scales. Variations between production batches remain high, with performance metrics sometimes differing by orders of magnitude between supposedly identical membranes.

Addressing these manufacturing challenges requires interdisciplinary approaches combining advances in materials science, chemical engineering, and process technology. Recent developments in roll-to-roll processing, continuous CVD systems, and automated quality control offer promising pathways toward industrial-scale production, though significant research investment is still needed to bridge the gap between laboratory success and commercial viability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!