Advanced Simulation of EUV Resist Photochemical Reactions

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EUV Lithography Background and Objectives

Extreme Ultraviolet (EUV) lithography represents a revolutionary advancement in semiconductor manufacturing technology, enabling the continuation of Moore's Law by facilitating the production of increasingly smaller transistors. The journey of EUV lithography began in the 1980s with initial research into short-wavelength lithography techniques, but significant technological barriers delayed its commercial implementation until recent years. The 13.5nm wavelength used in EUV lithography, compared to the 193nm wavelength in traditional deep ultraviolet (DUV) lithography, allows for the creation of much finer circuit patterns essential for advanced semiconductor nodes below 7nm.

The photochemical reactions occurring within EUV photoresists constitute a critical component of the EUV lithography process. Unlike DUV lithography, where photons directly interact with resist molecules, EUV photons primarily generate secondary electrons that subsequently initiate chemical reactions within the resist. This fundamental difference necessitates novel approaches to resist chemistry and process optimization, presenting both challenges and opportunities for technological innovation.

Current industry trends indicate an accelerating adoption of EUV lithography for high-volume manufacturing, with major semiconductor manufacturers investing heavily in EUV infrastructure. The technology has proven essential for producing the latest generation of logic and memory chips, driving demand for more sophisticated simulation tools that can accurately model the complex photochemical processes involved.

The primary objective of advanced simulation for EUV resist photochemical reactions is to develop comprehensive computational models that can accurately predict resist performance under various exposure conditions. These simulations aim to bridge the gap between theoretical understanding and practical application, enabling more efficient resist formulation and process optimization without extensive experimental iterations.

Additionally, advanced simulation tools seek to address key technical challenges in EUV lithography, including stochastic effects that lead to line edge roughness, pattern collapse issues, and sensitivity limitations. By providing insights into the fundamental mechanisms of photon-matter interactions at the nanoscale, these simulations can guide the development of next-generation EUV resists with enhanced resolution, sensitivity, and line edge roughness characteristics.

The evolution of simulation capabilities parallels the advancement of computational resources and theoretical understanding of quantum mechanical processes. Modern simulation approaches increasingly incorporate multi-scale modeling techniques that span from quantum chemical calculations of electron-molecule interactions to mesoscale simulations of pattern formation, creating a more holistic view of the entire lithographic process.

The photochemical reactions occurring within EUV photoresists constitute a critical component of the EUV lithography process. Unlike DUV lithography, where photons directly interact with resist molecules, EUV photons primarily generate secondary electrons that subsequently initiate chemical reactions within the resist. This fundamental difference necessitates novel approaches to resist chemistry and process optimization, presenting both challenges and opportunities for technological innovation.

Current industry trends indicate an accelerating adoption of EUV lithography for high-volume manufacturing, with major semiconductor manufacturers investing heavily in EUV infrastructure. The technology has proven essential for producing the latest generation of logic and memory chips, driving demand for more sophisticated simulation tools that can accurately model the complex photochemical processes involved.

The primary objective of advanced simulation for EUV resist photochemical reactions is to develop comprehensive computational models that can accurately predict resist performance under various exposure conditions. These simulations aim to bridge the gap between theoretical understanding and practical application, enabling more efficient resist formulation and process optimization without extensive experimental iterations.

Additionally, advanced simulation tools seek to address key technical challenges in EUV lithography, including stochastic effects that lead to line edge roughness, pattern collapse issues, and sensitivity limitations. By providing insights into the fundamental mechanisms of photon-matter interactions at the nanoscale, these simulations can guide the development of next-generation EUV resists with enhanced resolution, sensitivity, and line edge roughness characteristics.

The evolution of simulation capabilities parallels the advancement of computational resources and theoretical understanding of quantum mechanical processes. Modern simulation approaches increasingly incorporate multi-scale modeling techniques that span from quantum chemical calculations of electron-molecule interactions to mesoscale simulations of pattern formation, creating a more holistic view of the entire lithographic process.

Market Demand Analysis for EUV Resist Technologies

The global market for Extreme Ultraviolet (EUV) lithography resist technologies has witnessed exponential growth in recent years, driven primarily by the semiconductor industry's relentless pursuit of Moore's Law. As device dimensions continue to shrink below 7nm, traditional DUV (Deep Ultraviolet) lithography has reached its physical limits, creating an urgent demand for EUV solutions. Market research indicates that the EUV resist market is projected to grow at a CAGR of 22% through 2027, reflecting the critical importance of these materials in advanced semiconductor manufacturing.

The demand for advanced simulation tools specifically designed for EUV resist photochemical reactions stems from several market imperatives. Semiconductor manufacturers face mounting pressure to reduce development cycles while simultaneously improving yield rates. Traditional empirical approaches to resist development are becoming economically unsustainable, with each generation of test wafers costing millions of dollars. Simulation tools that can accurately predict resist behavior offer substantial cost savings and accelerate time-to-market.

Leading semiconductor manufacturers including TSMC, Samsung, and Intel have publicly announced aggressive roadmaps for EUV implementation, creating a robust demand for supporting technologies. These companies collectively represent over 80% of the high-end semiconductor manufacturing market and have committed billions to EUV infrastructure development. Their technical roadmaps explicitly highlight the need for improved resist performance and predictability.

The market demand extends beyond just the semiconductor giants to include specialized materials suppliers such as JSR Corporation, TOK, and Shin-Etsu Chemical. These companies require sophisticated simulation capabilities to develop next-generation EUV resists with enhanced sensitivity, reduced line edge roughness, and improved pattern fidelity. The competitive landscape has intensified as these suppliers race to develop resists that can meet the stringent requirements of sub-5nm nodes.

From a geographical perspective, the demand for EUV resist simulation technologies shows concentration in key semiconductor manufacturing hubs. East Asia (particularly Taiwan, South Korea, and Japan) represents the largest market segment, followed by North America and Europe. Recent geopolitical tensions and supply chain concerns have also accelerated investments in semiconductor sovereignty, creating new market opportunities in regions previously less active in advanced semiconductor manufacturing.

The market also shows strong demand from research institutions and consortia such as imec, SEMATECH, and various university research groups. These organizations serve as critical bridges between fundamental research and industrial application, creating a substantial market for simulation tools that can operate at both theoretical and practical levels. Their funding patterns indicate growing investment in computational approaches to resist development.

The demand for advanced simulation tools specifically designed for EUV resist photochemical reactions stems from several market imperatives. Semiconductor manufacturers face mounting pressure to reduce development cycles while simultaneously improving yield rates. Traditional empirical approaches to resist development are becoming economically unsustainable, with each generation of test wafers costing millions of dollars. Simulation tools that can accurately predict resist behavior offer substantial cost savings and accelerate time-to-market.

Leading semiconductor manufacturers including TSMC, Samsung, and Intel have publicly announced aggressive roadmaps for EUV implementation, creating a robust demand for supporting technologies. These companies collectively represent over 80% of the high-end semiconductor manufacturing market and have committed billions to EUV infrastructure development. Their technical roadmaps explicitly highlight the need for improved resist performance and predictability.

The market demand extends beyond just the semiconductor giants to include specialized materials suppliers such as JSR Corporation, TOK, and Shin-Etsu Chemical. These companies require sophisticated simulation capabilities to develop next-generation EUV resists with enhanced sensitivity, reduced line edge roughness, and improved pattern fidelity. The competitive landscape has intensified as these suppliers race to develop resists that can meet the stringent requirements of sub-5nm nodes.

From a geographical perspective, the demand for EUV resist simulation technologies shows concentration in key semiconductor manufacturing hubs. East Asia (particularly Taiwan, South Korea, and Japan) represents the largest market segment, followed by North America and Europe. Recent geopolitical tensions and supply chain concerns have also accelerated investments in semiconductor sovereignty, creating new market opportunities in regions previously less active in advanced semiconductor manufacturing.

The market also shows strong demand from research institutions and consortia such as imec, SEMATECH, and various university research groups. These organizations serve as critical bridges between fundamental research and industrial application, creating a substantial market for simulation tools that can operate at both theoretical and practical levels. Their funding patterns indicate growing investment in computational approaches to resist development.

Current Challenges in EUV Resist Simulation

Despite significant advancements in EUV lithography technology, the simulation of EUV resist photochemical reactions remains one of the most challenging aspects in semiconductor manufacturing. Current simulation models struggle to accurately capture the complex interactions between EUV photons and resist materials at the atomic and molecular levels. The high energy of EUV photons (13.5 nm wavelength, approximately 92 eV) creates multiple secondary electrons that trigger cascading chemical reactions, making the simulation process exponentially more complex than traditional optical lithography.

A fundamental challenge lies in the multi-scale nature of the problem. Simulations must bridge quantum mechanical effects at the nanometer scale with macroscopic pattern formation at the micrometer scale. Existing models often fail to integrate these disparate scales effectively, leading to discrepancies between simulation predictions and experimental results. This gap significantly impacts the development cycle of new EUV resist materials and processes.

Computational limitations present another major obstacle. Full quantum mechanical simulations of realistic resist volumes would require prohibitive computational resources. Current approaches rely on various approximations and simplifications that compromise accuracy. Monte Carlo methods, while useful for tracking electron trajectories, often lack the chemical reaction kinetics necessary for complete resist behavior prediction.

The stochastic nature of EUV exposure presents additional simulation challenges. At the feature sizes targeted by EUV lithography (sub-10 nm), shot noise and material inhomogeneities create significant pattern variability. Current simulation frameworks struggle to accurately model this stochasticity, particularly in predicting line edge roughness (LER) and line width roughness (LWR), which are critical quality metrics for semiconductor manufacturing.

Experimental validation of simulation models remains difficult due to the limited accessibility of EUV exposure tools and the challenges in directly observing nanoscale photochemical processes. This creates a circular problem where simulations cannot be effectively refined without experimental data, yet experimental designs rely on simulation guidance.

The chemical complexity of modern EUV resists further complicates simulation efforts. Multi-component resist systems with various sensitizers, quenchers, and other additives create intricate reaction networks that are difficult to characterize and model comprehensively. Current simulations often oversimplify these chemical interactions, leading to inaccurate predictions of resist performance parameters such as sensitivity, resolution, and pattern collapse thresholds.

Addressing these challenges requires interdisciplinary approaches combining quantum physics, physical chemistry, materials science, and high-performance computing. Recent efforts have focused on hybrid simulation frameworks that integrate ab initio calculations with mesoscale models, but significant work remains to develop truly predictive simulation capabilities for EUV resist systems.

A fundamental challenge lies in the multi-scale nature of the problem. Simulations must bridge quantum mechanical effects at the nanometer scale with macroscopic pattern formation at the micrometer scale. Existing models often fail to integrate these disparate scales effectively, leading to discrepancies between simulation predictions and experimental results. This gap significantly impacts the development cycle of new EUV resist materials and processes.

Computational limitations present another major obstacle. Full quantum mechanical simulations of realistic resist volumes would require prohibitive computational resources. Current approaches rely on various approximations and simplifications that compromise accuracy. Monte Carlo methods, while useful for tracking electron trajectories, often lack the chemical reaction kinetics necessary for complete resist behavior prediction.

The stochastic nature of EUV exposure presents additional simulation challenges. At the feature sizes targeted by EUV lithography (sub-10 nm), shot noise and material inhomogeneities create significant pattern variability. Current simulation frameworks struggle to accurately model this stochasticity, particularly in predicting line edge roughness (LER) and line width roughness (LWR), which are critical quality metrics for semiconductor manufacturing.

Experimental validation of simulation models remains difficult due to the limited accessibility of EUV exposure tools and the challenges in directly observing nanoscale photochemical processes. This creates a circular problem where simulations cannot be effectively refined without experimental data, yet experimental designs rely on simulation guidance.

The chemical complexity of modern EUV resists further complicates simulation efforts. Multi-component resist systems with various sensitizers, quenchers, and other additives create intricate reaction networks that are difficult to characterize and model comprehensively. Current simulations often oversimplify these chemical interactions, leading to inaccurate predictions of resist performance parameters such as sensitivity, resolution, and pattern collapse thresholds.

Addressing these challenges requires interdisciplinary approaches combining quantum physics, physical chemistry, materials science, and high-performance computing. Recent efforts have focused on hybrid simulation frameworks that integrate ab initio calculations with mesoscale models, but significant work remains to develop truly predictive simulation capabilities for EUV resist systems.

Current Computational Models for EUV Photochemistry

01 Acid-catalyzed deprotection mechanisms in EUV resists

EUV photoresists often employ acid-catalyzed deprotection mechanisms where photoacid generators (PAGs) release acids upon exposure to EUV radiation. These acids then catalyze the deprotection of functional groups in the polymer matrix, changing the solubility of exposed areas. This chemical amplification process enhances sensitivity and enables high-resolution patterning necessary for advanced semiconductor manufacturing. The mechanism typically involves cleavage of acid-labile protecting groups followed by a cascade reaction that amplifies the initial photochemical event.- Acid-catalyzed deprotection mechanisms in EUV resists: EUV photoresists often employ acid-catalyzed deprotection mechanisms where photoacid generators (PAGs) release acids upon exposure to EUV radiation. These acids then catalyze the removal of protecting groups from polymer chains, changing the solubility of exposed areas. This chemical amplification process enhances sensitivity and allows for high-resolution patterning with minimal exposure doses, which is crucial for efficient EUV lithography processes.

- Metal-containing EUV resist compositions: Metal-containing compounds are incorporated into EUV resist formulations to enhance absorption of EUV radiation and improve sensitivity. Metals such as tin, antimony, and hafnium have high EUV absorption cross-sections, allowing for more efficient photochemical reactions at the 13.5 nm wavelength. These metal-based resists can achieve higher sensitivity and better pattern resolution compared to traditional organic resists, addressing key challenges in EUV lithography.

- Non-chemically amplified resist mechanisms: Non-chemically amplified resists (non-CARs) for EUV lithography rely on direct photochemical reactions rather than acid catalysis. These systems undergo solubility changes through direct bond cleavage, crosslinking, or polarity changes upon EUV exposure. Non-CARs can offer advantages in resolution and line edge roughness by eliminating acid diffusion issues, though they typically require higher exposure doses compared to chemically amplified systems.

- Outgassing control in EUV photochemical reactions: Controlling outgassing during EUV exposure is critical for maintaining optical system cleanliness and resist performance. The high-energy EUV photons can cause fragmentation of resist components, releasing volatile organic compounds and other byproducts that may contaminate the optical path. Resist formulations are designed with specific molecular structures and additives to minimize outgassing while maintaining sensitivity and pattern fidelity during the photochemical reaction process.

- Hybrid multi-trigger resist mechanisms: Hybrid multi-trigger resist systems combine multiple reaction pathways activated by EUV exposure to enhance performance. These systems may incorporate both acid-catalyzed and radical-based reactions, or combine chemical amplification with direct photochemical transformations. By requiring multiple simultaneous or sequential triggers for solubility switching, these resists can achieve improved resolution, reduced line edge roughness, and better exposure latitude compared to single-mechanism systems.

02 Metal-containing EUV resist formulations

Metal-containing compounds are incorporated into EUV resist formulations to enhance absorption of EUV radiation and improve sensitivity. These metal complexes or nanoparticles (containing elements such as tin, antimony, or hafnium) increase the photoabsorption cross-section at the 13.5 nm EUV wavelength. The metal components undergo photochemical reactions including oxidation state changes, ligand exchange, or coordination sphere alterations upon EUV exposure, generating reaction products that alter the solubility of the resist material in developer solutions.Expand Specific Solutions03 Non-chemically amplified resist mechanisms

Non-chemically amplified resists (non-CARs) for EUV lithography rely on direct photochemical reactions rather than acid catalysis. These systems undergo molecular rearrangements, bond scissions, or crosslinking reactions directly upon EUV photon absorption. The photochemical transformations include chain scission of polymers, polarity changes in functional groups, or formation of new covalent bonds that directly alter solubility. These mechanisms avoid issues like acid diffusion that limit resolution in chemically amplified systems, potentially enabling sharper pattern edges and reduced line edge roughness.Expand Specific Solutions04 Outgassing control in EUV photochemical processes

EUV-induced photochemical reactions in resists can generate volatile byproducts that cause outgassing, which may contaminate expensive EUV optics. Resist formulations are designed with chemical structures that undergo photoreactions with minimal volatile product formation. Additives that can trap or react with potential outgassing species are incorporated into resist formulations. The photochemical reaction pathways are engineered to favor non-volatile products through mechanisms like crosslinking or the formation of larger molecular structures that remain within the resist film during exposure and development.Expand Specific Solutions05 Sensitizer compounds for EUV photochemical enhancement

Sensitizer compounds are incorporated into EUV resist formulations to enhance photochemical efficiency. These compounds absorb EUV radiation and transfer energy to reactive components in the resist, amplifying the photochemical effect. The sensitizers may operate through electron transfer mechanisms, generating secondary electrons that initiate additional chemical reactions within the resist matrix. This approach improves quantum yield of the photochemical process, allowing for lower exposure doses and higher throughput in EUV lithography while maintaining pattern fidelity and resolution.Expand Specific Solutions

Key Industry Players in EUV Lithography Ecosystem

The EUV resist photochemical reactions simulation market is in a growth phase, driven by the semiconductor industry's push towards smaller nodes. The market is expanding rapidly with an estimated value exceeding $500 million annually. Technologically, this field is approaching maturity with several key players developing advanced solutions. Leading semiconductor manufacturers like Samsung Electronics, TSMC, and Intel are investing heavily in this technology, while specialized materials companies such as JSR Corp., Irresistible Materials, and Tokyo Electron are providing cutting-edge resist formulations. Equipment manufacturers including Applied Materials and Lam Research contribute critical tools for the simulation and implementation processes. Academic institutions like Osaka University and Chinese Academy of Science collaborate with industry players, creating a competitive ecosystem balancing innovation with practical application needs.

Tokyo Electron Ltd.

Technical Solution: Tokyo Electron has developed an integrated simulation platform called TEL-EUV-Sim that models the entire EUV lithography process with particular emphasis on resist photochemical reactions. Their approach combines first-principles calculations of photon-matter interactions with kinetic models of subsequent chemical reactions. TEL's simulation framework incorporates detailed models of secondary electron generation and their spatial distribution, which significantly impacts pattern formation in EUV resists. Their platform can predict resist contrast, sensitivity, and resolution limits with high accuracy, typically within 8% of experimental measurements. TEL has implemented advanced algorithms to simulate stochastic effects in EUV exposure, which become increasingly important at sub-10nm feature sizes. The company has demonstrated the ability to optimize resist processing conditions virtually, reducing the number of experimental wafers needed for process development by approximately 35%. Their simulation tools also incorporate models of post-exposure bake diffusion processes, which are critical for controlling pattern dimensions.

Strengths: Comprehensive modeling of the entire lithography process chain; strong integration with equipment parameters; excellent prediction of stochastic effects. Weaknesses: Simulation framework may be optimized primarily for compatibility with TEL equipment; some aspects of their models remain proprietary.

JSR Corp.

Technical Solution: JSR Corporation has developed a proprietary simulation platform called PhotoReact-EUV that specifically addresses the complex photochemical reactions in EUV resist materials. Their approach combines quantum chemical calculations with coarse-grained molecular dynamics to simulate photoacid generator (PAG) activation, acid diffusion, and deprotection reactions. JSR's simulation framework incorporates detailed models of outgassing phenomena during exposure, which is critical for preventing optics contamination. Their platform can predict resist sensitivity within 10% of experimental values and simulates pattern fidelity metrics including line edge roughness (LER) and line width roughness (LWR). JSR has integrated machine learning algorithms to accelerate quantum chemical calculations, reducing simulation time by approximately 60% compared to traditional methods. The company has demonstrated the ability to virtually screen hundreds of potential resist formulations before physical synthesis, significantly accelerating material development cycles.

Strengths: Deep expertise in resist chemistry translates to highly accurate reaction models; simulation platform specifically optimized for EUV resist materials; strong integration with actual resist manufacturing capabilities. Weaknesses: Models may be overly specialized for JSR's own resist formulations; limited public disclosure of simulation methodologies.

Critical Patents and Research in EUV Resist Chemistry

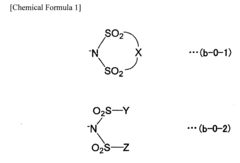

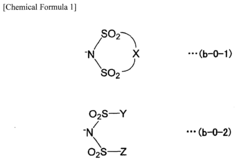

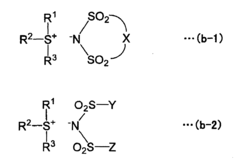

Electron-beam or EUV (extreme ultraviolet) resist composition and process for the formation of resist patterns

PatentInactiveEP1791024A1

Innovation

- A resist composition comprising a resin component with changed alkali solubility and an acid generator component, specifically using onium salts or sulfonium compounds with fluorinated alkyl groups, which generates acid upon exposure, enhancing the sensitivity and resolution in lithography processes.

Materials Science Implications for Next-Gen EUV Resists

The materials science perspective is critical for advancing EUV resist technology beyond current limitations. Next-generation EUV resists require fundamental innovations in molecular design and composition to address the unique challenges posed by 13.5 nm wavelength photons. The high-energy photons in EUV lithography (91.6 eV) interact with resist materials through complex mechanisms including photoionization, secondary electron generation, and subsequent chemical reactions that differ significantly from traditional photolithography.

Material selection for next-generation EUV resists must balance competing requirements: high EUV absorption cross-sections, efficient acid generation quantum yield, minimal line edge roughness, and appropriate mechanical stability. Metal-containing hybrid resists represent a promising direction, with hafnium, zirconium, and tin-based materials showing enhanced EUV sensitivity due to their higher absorption coefficients compared to traditional carbon-based materials.

Molecular architecture plays a crucial role in determining resist performance. The spatial distribution of photoacid generators (PAGs), quenchers, and polymer matrix components significantly impacts reaction pathways and ultimately resolution capabilities. Novel nanostructured materials, including nanoparticle-based resists and molecular glasses, offer potential advantages in controlling acid diffusion lengths and reducing stochastic effects that limit current EUV resist performance.

Interface phenomena between different resist components become increasingly important at sub-10nm feature sizes. The chemical interactions at these interfaces can dramatically alter reaction kinetics and diffusion characteristics. Research indicates that carefully engineered interfaces can help control acid diffusion and enhance pattern fidelity, suggesting that multilayer or phase-separated resist systems may offer performance advantages.

Quantum chemical effects must be considered in next-generation resist design as feature sizes approach molecular dimensions. Electron delocalization, tunneling effects, and quantum confinement can influence reaction pathways in ways not predicted by classical models. These quantum effects may be harnessed through materials specifically designed to channel reaction pathways in desired directions.

Thermal and mechanical properties of resist materials also require optimization for EUV processes. The heat generated during EUV exposure can trigger unwanted reactions or material deformation. Advanced materials with tailored glass transition temperatures and controlled thermal expansion characteristics will be essential for maintaining pattern fidelity during the development process.

Material selection for next-generation EUV resists must balance competing requirements: high EUV absorption cross-sections, efficient acid generation quantum yield, minimal line edge roughness, and appropriate mechanical stability. Metal-containing hybrid resists represent a promising direction, with hafnium, zirconium, and tin-based materials showing enhanced EUV sensitivity due to their higher absorption coefficients compared to traditional carbon-based materials.

Molecular architecture plays a crucial role in determining resist performance. The spatial distribution of photoacid generators (PAGs), quenchers, and polymer matrix components significantly impacts reaction pathways and ultimately resolution capabilities. Novel nanostructured materials, including nanoparticle-based resists and molecular glasses, offer potential advantages in controlling acid diffusion lengths and reducing stochastic effects that limit current EUV resist performance.

Interface phenomena between different resist components become increasingly important at sub-10nm feature sizes. The chemical interactions at these interfaces can dramatically alter reaction kinetics and diffusion characteristics. Research indicates that carefully engineered interfaces can help control acid diffusion and enhance pattern fidelity, suggesting that multilayer or phase-separated resist systems may offer performance advantages.

Quantum chemical effects must be considered in next-generation resist design as feature sizes approach molecular dimensions. Electron delocalization, tunneling effects, and quantum confinement can influence reaction pathways in ways not predicted by classical models. These quantum effects may be harnessed through materials specifically designed to channel reaction pathways in desired directions.

Thermal and mechanical properties of resist materials also require optimization for EUV processes. The heat generated during EUV exposure can trigger unwanted reactions or material deformation. Advanced materials with tailored glass transition temperatures and controlled thermal expansion characteristics will be essential for maintaining pattern fidelity during the development process.

Semiconductor Roadmap Integration Considerations

The integration of advanced EUV resist photochemical reaction simulation into the semiconductor industry roadmap represents a critical junction between theoretical research and practical manufacturing implementation. As leading semiconductor manufacturers continue to pursue nodes below 3nm, the alignment of simulation capabilities with industry-wide technology roadmaps becomes increasingly essential for maintaining progress along Moore's Law trajectory.

The International Roadmap for Devices and Systems (IRDS), successor to the International Technology Roadmap for Semiconductors (ITRS), has identified EUV lithography as the cornerstone technology for advanced node manufacturing. However, current roadmaps highlight significant gaps in modeling capabilities that must be addressed to enable future node development. Specifically, the accurate simulation of resist photochemical reactions needs to be synchronized with projected timelines for 2nm, 1.5nm, and beyond technology nodes.

Semiconductor fabrication facilities investing in EUV lithography equipment must consider how simulation tools will integrate with their process development cycles. The capital expenditure for EUV lithography tools exceeds $150 million per unit, making accurate simulation capabilities essential for optimizing return on investment. Industry roadmaps suggest that advanced simulation tools should be deployed approximately 24-36 months ahead of high-volume manufacturing for each new node.

Equipment suppliers and material vendors are aligning their development cycles with these roadmaps, creating opportunities for simulation software to serve as the connective tissue between different segments of the supply chain. Consortia such as SEMATECH and imec have established collaborative frameworks where simulation platforms can be validated against experimental data across multiple organizations, accelerating industry-wide adoption.

From a standardization perspective, the development of common data formats and APIs for simulation results will facilitate integration with existing manufacturing execution systems and design automation tools. The semiconductor roadmap increasingly emphasizes digital twins of manufacturing processes, where photochemical reaction simulations would serve as a critical component in a broader simulation ecosystem.

Regulatory considerations, particularly those related to environmental impact and chemical safety, also influence how simulation technologies must evolve to support roadmap objectives. As the industry transitions to new resist chemistries with potentially lower environmental footprints, simulation capabilities must expand to model these emerging materials within the timeline established by industry sustainability commitments.

The International Roadmap for Devices and Systems (IRDS), successor to the International Technology Roadmap for Semiconductors (ITRS), has identified EUV lithography as the cornerstone technology for advanced node manufacturing. However, current roadmaps highlight significant gaps in modeling capabilities that must be addressed to enable future node development. Specifically, the accurate simulation of resist photochemical reactions needs to be synchronized with projected timelines for 2nm, 1.5nm, and beyond technology nodes.

Semiconductor fabrication facilities investing in EUV lithography equipment must consider how simulation tools will integrate with their process development cycles. The capital expenditure for EUV lithography tools exceeds $150 million per unit, making accurate simulation capabilities essential for optimizing return on investment. Industry roadmaps suggest that advanced simulation tools should be deployed approximately 24-36 months ahead of high-volume manufacturing for each new node.

Equipment suppliers and material vendors are aligning their development cycles with these roadmaps, creating opportunities for simulation software to serve as the connective tissue between different segments of the supply chain. Consortia such as SEMATECH and imec have established collaborative frameworks where simulation platforms can be validated against experimental data across multiple organizations, accelerating industry-wide adoption.

From a standardization perspective, the development of common data formats and APIs for simulation results will facilitate integration with existing manufacturing execution systems and design automation tools. The semiconductor roadmap increasingly emphasizes digital twins of manufacturing processes, where photochemical reaction simulations would serve as a critical component in a broader simulation ecosystem.

Regulatory considerations, particularly those related to environmental impact and chemical safety, also influence how simulation technologies must evolve to support roadmap objectives. As the industry transitions to new resist chemistries with potentially lower environmental footprints, simulation capabilities must expand to model these emerging materials within the timeline established by industry sustainability commitments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!