Advancements in Self-cleaning Surfaces for Food Safety

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-cleaning Surface Technology Background and Objectives

Self-cleaning surfaces represent a revolutionary advancement in materials science that has evolved significantly over the past two decades. Initially inspired by the lotus leaf's natural self-cleaning properties, this technology has progressed from basic hydrophobic coatings to sophisticated multi-functional surfaces capable of repelling various contaminants. The evolution trajectory shows a clear shift from passive self-cleaning mechanisms toward active systems that can respond to environmental triggers and eliminate microbial threats without human intervention.

In the context of food safety, self-cleaning surfaces address critical challenges in preventing cross-contamination and reducing foodborne illness outbreaks. Historical data indicates that approximately 600 million people worldwide suffer from foodborne illnesses annually, with contaminated food preparation surfaces being a significant vector. This underscores the urgent need for innovative solutions that can maintain hygienic conditions in food processing environments.

The technological objectives for advanced self-cleaning surfaces in food safety applications are multifaceted. Primary goals include developing surfaces that can maintain antimicrobial properties over extended periods, function effectively under varying temperature and humidity conditions typical in food processing environments, and withstand frequent exposure to diverse food substances and cleaning agents without degradation of performance.

Recent technological breakthroughs have focused on incorporating nanomaterials and photocatalytic compounds that can actively decompose organic contaminants and inactivate pathogens. Titanium dioxide (TiO₂) has emerged as a leading material due to its photocatalytic properties when exposed to UV light, though newer research aims to extend this functionality to visible light spectrum for greater practical application.

The integration of self-cleaning technologies with food-grade materials presents unique challenges that distinguish this application from other self-cleaning surface uses. Materials must simultaneously demonstrate excellent self-cleaning properties while meeting strict food safety regulations, including non-toxicity and chemical stability under food processing conditions.

Looking forward, the technological roadmap for self-cleaning surfaces in food safety applications aims to achieve several key milestones: development of cost-effective manufacturing processes for widespread industrial adoption, creation of surfaces with prolonged antimicrobial efficacy (targeting 6+ months without performance degradation), and integration with smart monitoring systems that can verify surface hygiene status in real-time.

The convergence of nanotechnology, materials science, and microbiology is expected to drive the next generation of innovations in this field, potentially revolutionizing food safety protocols across the global food supply chain.

In the context of food safety, self-cleaning surfaces address critical challenges in preventing cross-contamination and reducing foodborne illness outbreaks. Historical data indicates that approximately 600 million people worldwide suffer from foodborne illnesses annually, with contaminated food preparation surfaces being a significant vector. This underscores the urgent need for innovative solutions that can maintain hygienic conditions in food processing environments.

The technological objectives for advanced self-cleaning surfaces in food safety applications are multifaceted. Primary goals include developing surfaces that can maintain antimicrobial properties over extended periods, function effectively under varying temperature and humidity conditions typical in food processing environments, and withstand frequent exposure to diverse food substances and cleaning agents without degradation of performance.

Recent technological breakthroughs have focused on incorporating nanomaterials and photocatalytic compounds that can actively decompose organic contaminants and inactivate pathogens. Titanium dioxide (TiO₂) has emerged as a leading material due to its photocatalytic properties when exposed to UV light, though newer research aims to extend this functionality to visible light spectrum for greater practical application.

The integration of self-cleaning technologies with food-grade materials presents unique challenges that distinguish this application from other self-cleaning surface uses. Materials must simultaneously demonstrate excellent self-cleaning properties while meeting strict food safety regulations, including non-toxicity and chemical stability under food processing conditions.

Looking forward, the technological roadmap for self-cleaning surfaces in food safety applications aims to achieve several key milestones: development of cost-effective manufacturing processes for widespread industrial adoption, creation of surfaces with prolonged antimicrobial efficacy (targeting 6+ months without performance degradation), and integration with smart monitoring systems that can verify surface hygiene status in real-time.

The convergence of nanotechnology, materials science, and microbiology is expected to drive the next generation of innovations in this field, potentially revolutionizing food safety protocols across the global food supply chain.

Food Safety Market Demand Analysis

The global food safety market is experiencing significant growth, driven by increasing consumer awareness and regulatory pressures. According to recent market research, the global food safety testing market was valued at approximately $17.1 billion in 2021 and is projected to reach $24.4 billion by 2026, growing at a CAGR of 7.3%. This growth trajectory underscores the critical importance of innovations in food safety technologies, particularly self-cleaning surfaces.

Consumer demand for safer food products has intensified following high-profile foodborne illness outbreaks across various regions. The CDC estimates that 48 million people get sick, 128,000 are hospitalized, and 3,000 die from foodborne diseases in the United States alone each year. These statistics have heightened consumer vigilance regarding food safety measures throughout the supply chain.

The food processing industry faces mounting pressure to implement more effective contamination prevention systems. Traditional cleaning methods are labor-intensive, time-consuming, and often insufficient in eliminating pathogens completely. This inefficiency creates substantial market demand for self-cleaning surfaces that can continuously prevent microbial contamination without manual intervention.

Regulatory bodies worldwide have strengthened food safety standards, with the FDA's Food Safety Modernization Act (FSMA) in the US and similar regulations in the EU emphasizing preventive controls rather than reactive measures. These regulatory frameworks are compelling food manufacturers to invest in advanced technologies like self-cleaning surfaces to ensure compliance and avoid costly recalls.

The COVID-19 pandemic has further accelerated market demand for antimicrobial and self-cleaning surfaces across the food industry. Consumer research indicates that 76% of shoppers have become more concerned about food safety since the pandemic began, creating new market opportunities for innovative surface technologies.

Economic factors also drive market demand, as foodborne illness outbreaks result in significant financial losses. The USDA Economic Research Service estimates the annual cost of major foodborne illnesses at $15.6 billion. Self-cleaning surfaces offer potential cost savings by reducing cleaning labor, minimizing production downtime, and decreasing the risk of contamination-related recalls.

Regional analysis reveals particularly strong growth potential in Asia-Pacific markets, where rapid industrialization of food processing, coupled with increasing middle-class consumption, is creating demand for advanced food safety technologies. North America and Europe remain significant markets, driven by stringent regulatory frameworks and consumer expectations for food safety assurance.

Consumer demand for safer food products has intensified following high-profile foodborne illness outbreaks across various regions. The CDC estimates that 48 million people get sick, 128,000 are hospitalized, and 3,000 die from foodborne diseases in the United States alone each year. These statistics have heightened consumer vigilance regarding food safety measures throughout the supply chain.

The food processing industry faces mounting pressure to implement more effective contamination prevention systems. Traditional cleaning methods are labor-intensive, time-consuming, and often insufficient in eliminating pathogens completely. This inefficiency creates substantial market demand for self-cleaning surfaces that can continuously prevent microbial contamination without manual intervention.

Regulatory bodies worldwide have strengthened food safety standards, with the FDA's Food Safety Modernization Act (FSMA) in the US and similar regulations in the EU emphasizing preventive controls rather than reactive measures. These regulatory frameworks are compelling food manufacturers to invest in advanced technologies like self-cleaning surfaces to ensure compliance and avoid costly recalls.

The COVID-19 pandemic has further accelerated market demand for antimicrobial and self-cleaning surfaces across the food industry. Consumer research indicates that 76% of shoppers have become more concerned about food safety since the pandemic began, creating new market opportunities for innovative surface technologies.

Economic factors also drive market demand, as foodborne illness outbreaks result in significant financial losses. The USDA Economic Research Service estimates the annual cost of major foodborne illnesses at $15.6 billion. Self-cleaning surfaces offer potential cost savings by reducing cleaning labor, minimizing production downtime, and decreasing the risk of contamination-related recalls.

Regional analysis reveals particularly strong growth potential in Asia-Pacific markets, where rapid industrialization of food processing, coupled with increasing middle-class consumption, is creating demand for advanced food safety technologies. North America and Europe remain significant markets, driven by stringent regulatory frameworks and consumer expectations for food safety assurance.

Current State and Challenges in Self-cleaning Surface Technology

Self-cleaning surface technology has witnessed significant advancements globally, with research institutions and companies across North America, Europe, and Asia making substantial contributions. Current self-cleaning technologies primarily fall into three categories: hydrophobic/superhydrophobic surfaces, photocatalytic surfaces, and enzyme-based active surfaces. Each approach offers distinct advantages for food safety applications but faces unique implementation challenges.

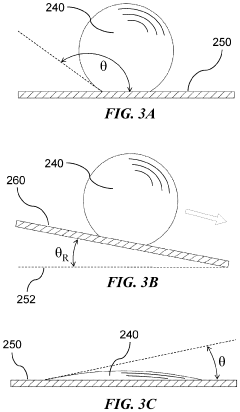

Superhydrophobic surfaces, inspired by the lotus leaf effect, demonstrate excellent water and contaminant repellency. These surfaces typically achieve water contact angles exceeding 150° through micro/nano-structured topographies combined with low surface energy materials. While effective against water-based contamination, they often struggle with oil-based food residues and protein adhesion, limiting their practical application in food processing environments.

Photocatalytic self-cleaning surfaces, predominantly utilizing titanium dioxide (TiO₂), decompose organic contaminants through UV light activation. Recent innovations have expanded this technology to visible light spectrum through doping and composite materials. However, these surfaces face efficiency challenges in low-light conditions and require sufficient light exposure time, making them less suitable for continuous food processing operations or enclosed equipment.

Enzyme-based active surfaces represent the newest frontier, incorporating immobilized enzymes that specifically target food contaminants. While promising for targeted decomposition of proteins, fats, and carbohydrates, these surfaces struggle with enzyme stability over time and may introduce regulatory complications regarding food contact materials.

A significant technical challenge across all approaches is durability under harsh food processing conditions. Self-cleaning surfaces must withstand frequent cleaning cycles with aggressive chemicals, mechanical abrasion, temperature fluctuations, and high-pressure washing. Current technologies typically demonstrate performance degradation after 50-200 cleaning cycles, falling short of industry requirements.

Scalability presents another major hurdle. Laboratory-scale successes often fail to translate to industrial-scale manufacturing due to process complexity, material costs, and quality control issues. The average cost of self-cleaning surfaces remains 3-5 times higher than conventional materials, creating adoption barriers despite potential long-term savings.

Regulatory compliance further complicates advancement, with food contact materials facing stringent safety requirements. Many nanomaterials and novel surface treatments lack comprehensive safety data, slowing approval processes. Additionally, standardized testing protocols for self-cleaning efficacy in food environments remain underdeveloped, creating uncertainty in performance claims and complicating comparative assessments.

Superhydrophobic surfaces, inspired by the lotus leaf effect, demonstrate excellent water and contaminant repellency. These surfaces typically achieve water contact angles exceeding 150° through micro/nano-structured topographies combined with low surface energy materials. While effective against water-based contamination, they often struggle with oil-based food residues and protein adhesion, limiting their practical application in food processing environments.

Photocatalytic self-cleaning surfaces, predominantly utilizing titanium dioxide (TiO₂), decompose organic contaminants through UV light activation. Recent innovations have expanded this technology to visible light spectrum through doping and composite materials. However, these surfaces face efficiency challenges in low-light conditions and require sufficient light exposure time, making them less suitable for continuous food processing operations or enclosed equipment.

Enzyme-based active surfaces represent the newest frontier, incorporating immobilized enzymes that specifically target food contaminants. While promising for targeted decomposition of proteins, fats, and carbohydrates, these surfaces struggle with enzyme stability over time and may introduce regulatory complications regarding food contact materials.

A significant technical challenge across all approaches is durability under harsh food processing conditions. Self-cleaning surfaces must withstand frequent cleaning cycles with aggressive chemicals, mechanical abrasion, temperature fluctuations, and high-pressure washing. Current technologies typically demonstrate performance degradation after 50-200 cleaning cycles, falling short of industry requirements.

Scalability presents another major hurdle. Laboratory-scale successes often fail to translate to industrial-scale manufacturing due to process complexity, material costs, and quality control issues. The average cost of self-cleaning surfaces remains 3-5 times higher than conventional materials, creating adoption barriers despite potential long-term savings.

Regulatory compliance further complicates advancement, with food contact materials facing stringent safety requirements. Many nanomaterials and novel surface treatments lack comprehensive safety data, slowing approval processes. Additionally, standardized testing protocols for self-cleaning efficacy in food environments remain underdeveloped, creating uncertainty in performance claims and complicating comparative assessments.

Current Self-cleaning Solutions for Food Contact Surfaces

01 Photocatalytic self-cleaning surfaces

Photocatalytic materials, particularly titanium dioxide (TiO2) coatings, can be applied to surfaces to create self-cleaning properties. When exposed to UV light, these materials trigger photocatalytic reactions that break down organic contaminants on the surface. This technology enhances cleaning efficiency by continuously degrading dirt, pollutants, and bacteria without manual intervention, making it particularly useful for exterior building surfaces, windows, and solar panels where regular cleaning is challenging.- Hydrophobic and self-cleaning coatings: Hydrophobic coatings can be applied to surfaces to create self-cleaning properties. These coatings repel water and prevent dirt and contaminants from adhering to the surface. When water droplets roll off the surface, they carry away dirt particles, enhancing cleaning efficiency. These coatings often mimic the lotus leaf effect found in nature, where water beads up and rolls off, taking contaminants with it.

- Photocatalytic self-cleaning surfaces: Photocatalytic materials, particularly titanium dioxide (TiO2), can be incorporated into surface coatings to provide self-cleaning properties. When exposed to UV light, these materials generate reactive oxygen species that break down organic contaminants on the surface. This process effectively decomposes dirt, bacteria, and other pollutants, improving cleaning efficiency without requiring manual intervention or harsh chemicals.

- Automated cleaning systems for self-cleaning surfaces: Automated systems can be integrated with self-cleaning surfaces to enhance cleaning efficiency. These systems may include programmable cleaning cycles, sensors to detect dirt accumulation, and mechanical components that distribute cleaning agents or activate self-cleaning mechanisms. By automating the cleaning process, these systems ensure consistent cleaning performance and reduce the need for manual intervention.

- Thermal self-cleaning technologies: Thermal self-cleaning technologies utilize heat to remove contaminants from surfaces. These systems can include heating elements embedded within the surface material or external heating mechanisms that raise the surface temperature to levels that decompose or vaporize organic materials. This approach is particularly effective for removing stubborn contaminants and can be combined with other self-cleaning methods to enhance overall cleaning efficiency.

- Nanotechnology-enhanced self-cleaning surfaces: Nanotechnology can be applied to create advanced self-cleaning surfaces with enhanced cleaning efficiency. Nanostructured surfaces can be designed with specific patterns and textures that minimize contact area for contaminants, making them easier to remove. Additionally, nanoparticles can be incorporated into coatings to provide antimicrobial properties, repel water and oil, and catalyze the breakdown of organic materials, resulting in more effective self-cleaning performance.

02 Hydrophobic and superhydrophobic coatings

Hydrophobic and superhydrophobic coatings create water-repellent surfaces that enhance self-cleaning efficiency. These coatings minimize water adhesion, causing droplets to bead up and roll off surfaces, carrying away dirt particles in the process. This lotus leaf-inspired effect significantly reduces cleaning frequency and improves efficiency by preventing contaminant adhesion. The technology is applicable to various surfaces including glass, textiles, and automotive exteriors, providing both water-repellent and dirt-resistant properties.Expand Specific Solutions03 Automated cleaning systems

Automated cleaning systems incorporate sensors, robotics, and programmable controls to enhance cleaning efficiency of surfaces without human intervention. These systems can detect dirt accumulation and automatically initiate cleaning cycles using optimized water and cleaning agent distribution. Advanced versions include robotic cleaners with specialized brushes, sprayers, and vacuum systems that can navigate complex surface geometries. The automation reduces labor costs while improving consistency and thoroughness of cleaning operations.Expand Specific Solutions04 Nanostructured surface modifications

Nanostructured surface modifications create self-cleaning properties by altering surface topography at the nanoscale. These modifications can create surfaces with reduced contact area for contaminants, making adhesion difficult. Some nanostructured surfaces combine physical features with chemical properties to repel water, oil, and other contaminants. The nanoscale patterns can be engineered to enhance cleaning efficiency by minimizing the energy required to remove particles from the surface, resulting in easier maintenance and improved longevity of clean conditions.Expand Specific Solutions05 Thermal self-cleaning mechanisms

Thermal self-cleaning mechanisms utilize controlled heating elements to remove contaminants from surfaces. These systems can be programmed to reach specific temperatures that effectively break down organic materials, evaporate liquids, or loosen adherent particles without damaging the underlying surface. Some implementations include pyrolytic self-cleaning that carbonizes residues for easy removal. This approach is particularly effective for surfaces exposed to oily residues, food particles, or biological contaminants, and can significantly reduce the need for chemical cleaners.Expand Specific Solutions

Key Industry Players in Self-cleaning Surface Development

The self-cleaning surfaces for food safety market is currently in a growth phase, with increasing adoption across food processing and household appliance sectors. The market is projected to expand significantly due to heightened consumer awareness about food safety and hygiene. Leading research institutions like MIT and Naval Research Laboratory are pioneering fundamental technologies, while commercial players demonstrate varying levels of technical maturity. BSH Hausgeräte and SEB SA lead in household appliance applications, with Ecolab and S.C. Johnson advancing in industrial cleaning solutions. Chinese manufacturers including Midea, Gree, and Joyoung are rapidly scaling up R&D investments to close the technology gap with Western counterparts. The competitive landscape shows a blend of established players and innovative startups like Redi Technology, with collaboration between academic institutions and industry becoming increasingly common to accelerate commercialization.

Naval Research Laboratory

Technical Solution: The Naval Research Laboratory (NRL) has made significant contributions to self-cleaning surface technology applicable to food safety through their advanced materials research program. Their pioneering work focuses on omniphobic surfaces that repel both water and oil-based contaminants through hierarchical micro/nano-structured surfaces combined with low surface energy coatings. NRL researchers have developed fluorine-free alternatives to traditional perfluorinated compounds, addressing environmental and health concerns while maintaining exceptional repellency. Their proprietary SLIPS (Slippery Liquid-Infused Porous Surfaces) technology creates ultra-slippery surfaces that prevent bacterial adhesion and biofilm formation even under challenging conditions. The laboratory has demonstrated these surfaces can reduce bacterial attachment by over 99.9% compared to conventional materials. Recent innovations include self-healing coatings that can repair minor damage through embedded microcapsules containing repair agents, extending the functional lifetime of self-cleaning properties in demanding environments.

Strengths: Exceptional durability under extreme conditions; environmentally sustainable formulations; highly effective against both hydrophilic and hydrophobic contaminants. Weaknesses: Technology transfer to commercial food applications still in development; higher production costs; some formulations require specialized application techniques.

Massachusetts Institute of Technology

Technical Solution: MIT has developed advanced self-cleaning surfaces using LiquiGlide technology, a revolutionary liquid-impregnated surface coating that creates ultra-slippery surfaces. This technology creates a permanently wet surface by locking lubricating liquid in place with a textured solid, preventing bacterial adhesion and biofilm formation. MIT researchers have further enhanced this technology with the development of SLIPS (Slippery Liquid-Infused Porous Surfaces) that repel virtually all liquids and biological materials, including food residues and bacterial contamination. The surfaces maintain their repellency under high-pressure conditions and extreme temperatures, making them ideal for food processing environments. Recent advancements include incorporating antimicrobial nanoparticles into these surfaces to actively kill bacteria while maintaining the self-cleaning properties.

Strengths: Superior repellency against a wide range of substances; extremely durable under harsh conditions; reduces cleaning chemical usage by up to 90%; applicable to various substrate materials. Weaknesses: Higher initial implementation costs; requires specific maintenance protocols; potential regulatory hurdles for food contact applications.

Core Patents and Innovations in Self-cleaning Materials

Self-cleaning surfaces comprising elevations formed by hydrophobic particles and having improved mechanical strength

PatentActiveUS7846529B2

Innovation

- A self-cleaning surface is created using a mixture of hydrophobic particles, including semimetal or metal oxides, silicas, and wax particles, fixed to a substrate, which enhances mechanical stability and maintains the self-cleaning properties by providing support and resilience against abrasion.

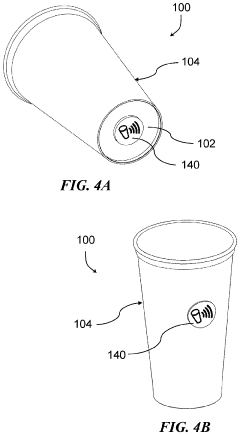

Reusable container with self-cleaning surface and identification device

PatentInactiveUS20230182979A1

Innovation

- A reusable container with self-cleaning surfaces and an identification device that enables efficient cleaning and sanitizing using minimal resources, allowing automated tracking and incentivization, such as through discounts and priority service, by incorporating technologies like superhydrophobic, superoleophobic, or photocatalytic surfaces and RFID/NFC tags.

Regulatory Framework for Food Contact Materials

The regulatory landscape governing food contact materials plays a crucial role in the development and commercialization of self-cleaning surfaces for food safety applications. In the United States, the Food and Drug Administration (FDA) regulates materials that come into contact with food through the Food, Drug, and Cosmetic Act, with specific provisions under 21 CFR 174-178. These regulations establish requirements for substances used in food-contact surfaces, including antimicrobial agents and nanotechnology-based coatings that are increasingly common in self-cleaning applications.

The European Union employs a more comprehensive approach through Regulation (EC) No 1935/2004, which establishes the general principles of safety and inertness for all food contact materials. Additionally, the EU has implemented specific measures for certain materials, such as plastics (Regulation EU No 10/2011), which are relevant for polymer-based self-cleaning coatings. The regulation includes a positive list of authorized substances and specific migration limits to ensure consumer safety.

In Asia, regulatory frameworks vary significantly. Japan's Food Sanitation Act and China's GB standards (particularly GB 4806 series) govern food contact materials with increasing attention to novel technologies like self-cleaning surfaces. These regulations typically require extensive migration testing and safety assessments before market approval.

A key regulatory challenge for self-cleaning surfaces involves the novel materials and technologies employed, such as photocatalytic titanium dioxide, superhydrophobic coatings, and antimicrobial nanoparticles. Many regulatory frameworks were not designed with these advanced materials in mind, creating potential gaps in oversight. The classification of these surfaces—whether as food contact materials, biocidal products, or novel foods—can significantly impact the approval pathway and testing requirements.

Migration testing represents another critical regulatory consideration. Manufacturers must demonstrate that components of self-cleaning surfaces do not migrate into food at levels exceeding regulatory limits. This is particularly challenging for nanoparticle-based coatings, where traditional migration testing protocols may not adequately capture potential risks.

Recent regulatory trends indicate movement toward harmonization of standards internationally through organizations like the Codex Alimentarius Commission. Additionally, there is growing regulatory interest in sustainability aspects of food contact materials, with some jurisdictions implementing restrictions on persistent chemicals that may affect certain self-cleaning technologies.

Companies developing self-cleaning surfaces for food applications must navigate this complex regulatory landscape early in the development process to avoid costly reformulations or market access barriers. Proactive engagement with regulatory authorities through consultation procedures can help address uncertainties regarding novel materials and technologies.

The European Union employs a more comprehensive approach through Regulation (EC) No 1935/2004, which establishes the general principles of safety and inertness for all food contact materials. Additionally, the EU has implemented specific measures for certain materials, such as plastics (Regulation EU No 10/2011), which are relevant for polymer-based self-cleaning coatings. The regulation includes a positive list of authorized substances and specific migration limits to ensure consumer safety.

In Asia, regulatory frameworks vary significantly. Japan's Food Sanitation Act and China's GB standards (particularly GB 4806 series) govern food contact materials with increasing attention to novel technologies like self-cleaning surfaces. These regulations typically require extensive migration testing and safety assessments before market approval.

A key regulatory challenge for self-cleaning surfaces involves the novel materials and technologies employed, such as photocatalytic titanium dioxide, superhydrophobic coatings, and antimicrobial nanoparticles. Many regulatory frameworks were not designed with these advanced materials in mind, creating potential gaps in oversight. The classification of these surfaces—whether as food contact materials, biocidal products, or novel foods—can significantly impact the approval pathway and testing requirements.

Migration testing represents another critical regulatory consideration. Manufacturers must demonstrate that components of self-cleaning surfaces do not migrate into food at levels exceeding regulatory limits. This is particularly challenging for nanoparticle-based coatings, where traditional migration testing protocols may not adequately capture potential risks.

Recent regulatory trends indicate movement toward harmonization of standards internationally through organizations like the Codex Alimentarius Commission. Additionally, there is growing regulatory interest in sustainability aspects of food contact materials, with some jurisdictions implementing restrictions on persistent chemicals that may affect certain self-cleaning technologies.

Companies developing self-cleaning surfaces for food applications must navigate this complex regulatory landscape early in the development process to avoid costly reformulations or market access barriers. Proactive engagement with regulatory authorities through consultation procedures can help address uncertainties regarding novel materials and technologies.

Environmental Impact and Sustainability Considerations

The development of self-cleaning surfaces for food safety applications carries significant environmental implications that must be carefully considered. Traditional cleaning methods in food processing facilities typically involve large quantities of water, harsh chemicals, and substantial energy consumption. Self-cleaning surfaces offer promising alternatives that can dramatically reduce these environmental burdens while maintaining or improving food safety standards.

Water conservation represents one of the most immediate environmental benefits of self-cleaning surfaces. Food processing facilities traditionally consume enormous volumes of water for cleaning operations. Advanced hydrophobic and oleophobic coatings can reduce water usage by up to 80% in some applications, as these surfaces require minimal water for effective cleaning. This conservation aspect becomes increasingly critical as water scarcity affects more regions globally.

Chemical reduction constitutes another substantial environmental advantage. Conventional cleaning protocols rely heavily on detergents, sanitizers, and other chemical agents that eventually enter wastewater streams. Self-cleaning surfaces, particularly those utilizing photocatalytic properties, can break down organic contaminants using only light activation, significantly reducing chemical dependencies and the associated environmental contamination.

Energy efficiency improvements also merit consideration. The reduced need for hot water cleaning, steam sanitization, and energy-intensive drying processes translates to lower carbon footprints across food processing operations. Studies indicate potential energy savings of 30-50% when implementing comprehensive self-cleaning surface technologies throughout processing facilities.

Material sustainability presents both challenges and opportunities. While some advanced self-cleaning coatings incorporate nanomaterials that raise concerns about environmental persistence and bioaccumulation, others utilize biodegradable or naturally derived compounds. Research increasingly focuses on bio-inspired self-cleaning surfaces that mimic natural phenomena like lotus leaf hydrophobicity, offering potentially more sustainable alternatives to synthetic approaches.

Lifecycle assessment of self-cleaning surfaces reveals complex sustainability considerations. Manufacturing processes for certain advanced materials may initially require greater energy inputs than conventional surfaces. However, their extended functional lifespan and reduced maintenance requirements often yield net positive environmental outcomes over time. Comprehensive cradle-to-grave analyses suggest that well-designed self-cleaning surfaces can reduce overall environmental impact by 40-60% compared to conventional materials requiring regular intensive cleaning.

Waste reduction represents another significant environmental benefit. By extending the functional lifespan of food contact surfaces and reducing biofilm formation, self-cleaning technologies can decrease the frequency of equipment replacement and associated waste generation. Additionally, the reduced need for single-use cleaning materials further minimizes waste streams from food processing operations.

Water conservation represents one of the most immediate environmental benefits of self-cleaning surfaces. Food processing facilities traditionally consume enormous volumes of water for cleaning operations. Advanced hydrophobic and oleophobic coatings can reduce water usage by up to 80% in some applications, as these surfaces require minimal water for effective cleaning. This conservation aspect becomes increasingly critical as water scarcity affects more regions globally.

Chemical reduction constitutes another substantial environmental advantage. Conventional cleaning protocols rely heavily on detergents, sanitizers, and other chemical agents that eventually enter wastewater streams. Self-cleaning surfaces, particularly those utilizing photocatalytic properties, can break down organic contaminants using only light activation, significantly reducing chemical dependencies and the associated environmental contamination.

Energy efficiency improvements also merit consideration. The reduced need for hot water cleaning, steam sanitization, and energy-intensive drying processes translates to lower carbon footprints across food processing operations. Studies indicate potential energy savings of 30-50% when implementing comprehensive self-cleaning surface technologies throughout processing facilities.

Material sustainability presents both challenges and opportunities. While some advanced self-cleaning coatings incorporate nanomaterials that raise concerns about environmental persistence and bioaccumulation, others utilize biodegradable or naturally derived compounds. Research increasingly focuses on bio-inspired self-cleaning surfaces that mimic natural phenomena like lotus leaf hydrophobicity, offering potentially more sustainable alternatives to synthetic approaches.

Lifecycle assessment of self-cleaning surfaces reveals complex sustainability considerations. Manufacturing processes for certain advanced materials may initially require greater energy inputs than conventional surfaces. However, their extended functional lifespan and reduced maintenance requirements often yield net positive environmental outcomes over time. Comprehensive cradle-to-grave analyses suggest that well-designed self-cleaning surfaces can reduce overall environmental impact by 40-60% compared to conventional materials requiring regular intensive cleaning.

Waste reduction represents another significant environmental benefit. By extending the functional lifespan of food contact surfaces and reducing biofilm formation, self-cleaning technologies can decrease the frequency of equipment replacement and associated waste generation. Additionally, the reduced need for single-use cleaning materials further minimizes waste streams from food processing operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!