Self-cleaning Surfaces: Enhancements in Anti-fogging Technologies

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-cleaning and Anti-fogging Technology Background and Objectives

Self-cleaning and anti-fogging technologies have evolved significantly over the past few decades, transitioning from laboratory curiosities to commercially viable solutions across multiple industries. The fundamental principles behind these technologies stem from biomimetic approaches, particularly inspired by the lotus leaf effect discovered in the 1970s, which demonstrated how micro and nano-structured surfaces could repel water and self-clean through the rolling action of water droplets.

The evolution of these technologies has been marked by several key milestones, including the development of photocatalytic titanium dioxide coatings in the 1990s, which could break down organic contaminants under UV light exposure. By the early 2000s, researchers had begun combining hydrophobic and hydrophilic properties to create more versatile self-cleaning surfaces, while the 2010s saw significant advancements in durability and application methods.

Current technological trends indicate a convergence of self-cleaning and anti-fogging functionalities, as both rely on controlling surface wettability and water-surface interactions. The integration of nanotechnology has been particularly transformative, enabling precise manipulation of surface structures at scales that directly influence water droplet behavior and light transmission properties.

The primary objective of current research in this field is to develop robust, environmentally friendly, and cost-effective solutions that can maintain optical clarity under varying environmental conditions while requiring minimal maintenance. Specific technical goals include creating coatings that demonstrate long-term durability under harsh conditions, function effectively across a wide temperature range, and can be applied to diverse substrate materials.

Another critical objective is reducing the environmental impact of these technologies by eliminating harmful chemicals often used in traditional anti-fogging agents and cleaning products. This aligns with growing regulatory pressure and consumer demand for sustainable solutions across industries.

The advancement of these technologies aims to address persistent challenges in sectors such as automotive (windshields and mirrors), eyewear, medical devices (endoscopes and surgical equipment), architectural glass, solar panels, and optical sensors. Each application domain presents unique requirements regarding transparency, durability, and performance under specific environmental conditions.

Research is increasingly focused on developing multifunctional surfaces that combine self-cleaning and anti-fogging properties with additional functionalities such as anti-reflection, anti-bacterial properties, and scratch resistance, creating comprehensive solutions that address multiple challenges simultaneously.

The evolution of these technologies has been marked by several key milestones, including the development of photocatalytic titanium dioxide coatings in the 1990s, which could break down organic contaminants under UV light exposure. By the early 2000s, researchers had begun combining hydrophobic and hydrophilic properties to create more versatile self-cleaning surfaces, while the 2010s saw significant advancements in durability and application methods.

Current technological trends indicate a convergence of self-cleaning and anti-fogging functionalities, as both rely on controlling surface wettability and water-surface interactions. The integration of nanotechnology has been particularly transformative, enabling precise manipulation of surface structures at scales that directly influence water droplet behavior and light transmission properties.

The primary objective of current research in this field is to develop robust, environmentally friendly, and cost-effective solutions that can maintain optical clarity under varying environmental conditions while requiring minimal maintenance. Specific technical goals include creating coatings that demonstrate long-term durability under harsh conditions, function effectively across a wide temperature range, and can be applied to diverse substrate materials.

Another critical objective is reducing the environmental impact of these technologies by eliminating harmful chemicals often used in traditional anti-fogging agents and cleaning products. This aligns with growing regulatory pressure and consumer demand for sustainable solutions across industries.

The advancement of these technologies aims to address persistent challenges in sectors such as automotive (windshields and mirrors), eyewear, medical devices (endoscopes and surgical equipment), architectural glass, solar panels, and optical sensors. Each application domain presents unique requirements regarding transparency, durability, and performance under specific environmental conditions.

Research is increasingly focused on developing multifunctional surfaces that combine self-cleaning and anti-fogging properties with additional functionalities such as anti-reflection, anti-bacterial properties, and scratch resistance, creating comprehensive solutions that address multiple challenges simultaneously.

Market Analysis for Self-cleaning Surface Applications

The self-cleaning surfaces market has experienced significant growth over the past decade, driven by increasing demand across multiple sectors including automotive, construction, electronics, and healthcare. The global market for self-cleaning surfaces was valued at approximately $3.5 billion in 2022 and is projected to reach $6.7 billion by 2028, representing a compound annual growth rate (CAGR) of 11.4% during the forecast period.

Anti-fogging technologies, as a subset of self-cleaning surfaces, have witnessed particularly strong demand growth due to their applications in optical devices, protective equipment, and automotive windshields. This segment alone accounted for roughly 18% of the total self-cleaning surfaces market in 2022, with expectations to expand to 22% by 2028.

The automotive sector remains the largest end-user of self-cleaning and anti-fogging technologies, constituting approximately 32% of market share. This dominance is attributed to the integration of these technologies in windshields, mirrors, and sensors for advanced driver assistance systems (ADAS). The construction industry follows closely at 27% market share, with applications in windows, solar panels, and exterior building surfaces.

Regional analysis reveals that North America and Europe currently lead the market with combined market share of 58%, primarily due to higher adoption rates in premium automotive segments and commercial buildings. However, the Asia-Pacific region is expected to demonstrate the highest growth rate at 13.8% CAGR through 2028, driven by rapid industrialization, increasing disposable income, and growing automotive production.

Consumer willingness to pay premium prices for self-cleaning and anti-fogging features has been steadily increasing, with surveys indicating that 64% of consumers would pay an additional 5-10% for products with these capabilities. This trend is particularly pronounced in regions with high pollution levels or extreme weather conditions.

Market challenges include the relatively high initial cost of implementation, durability concerns in harsh environments, and competition from alternative technologies. However, technological advancements in nanomaterials and hydrophobic coatings are gradually addressing these limitations, expanding the potential market reach.

The COVID-19 pandemic has accelerated market growth, particularly in healthcare and public transportation sectors, due to heightened awareness of surface cleanliness and hygiene. This has created new market opportunities for anti-fogging technologies in face shields, protective eyewear, and medical equipment, with this segment growing at 15.2% annually since 2020.

Anti-fogging technologies, as a subset of self-cleaning surfaces, have witnessed particularly strong demand growth due to their applications in optical devices, protective equipment, and automotive windshields. This segment alone accounted for roughly 18% of the total self-cleaning surfaces market in 2022, with expectations to expand to 22% by 2028.

The automotive sector remains the largest end-user of self-cleaning and anti-fogging technologies, constituting approximately 32% of market share. This dominance is attributed to the integration of these technologies in windshields, mirrors, and sensors for advanced driver assistance systems (ADAS). The construction industry follows closely at 27% market share, with applications in windows, solar panels, and exterior building surfaces.

Regional analysis reveals that North America and Europe currently lead the market with combined market share of 58%, primarily due to higher adoption rates in premium automotive segments and commercial buildings. However, the Asia-Pacific region is expected to demonstrate the highest growth rate at 13.8% CAGR through 2028, driven by rapid industrialization, increasing disposable income, and growing automotive production.

Consumer willingness to pay premium prices for self-cleaning and anti-fogging features has been steadily increasing, with surveys indicating that 64% of consumers would pay an additional 5-10% for products with these capabilities. This trend is particularly pronounced in regions with high pollution levels or extreme weather conditions.

Market challenges include the relatively high initial cost of implementation, durability concerns in harsh environments, and competition from alternative technologies. However, technological advancements in nanomaterials and hydrophobic coatings are gradually addressing these limitations, expanding the potential market reach.

The COVID-19 pandemic has accelerated market growth, particularly in healthcare and public transportation sectors, due to heightened awareness of surface cleanliness and hygiene. This has created new market opportunities for anti-fogging technologies in face shields, protective eyewear, and medical equipment, with this segment growing at 15.2% annually since 2020.

Current Challenges in Anti-fogging Surface Technologies

Despite significant advancements in anti-fogging technologies, several persistent challenges continue to impede widespread adoption and optimal performance of self-cleaning surfaces. The fundamental challenge remains achieving long-term durability of anti-fogging properties under diverse environmental conditions. Current coatings often degrade when exposed to UV radiation, temperature fluctuations, and mechanical abrasion, limiting their practical lifespan in real-world applications.

Water condensation mechanisms present another significant hurdle. While hydrophilic surfaces effectively spread water into transparent films, they can become saturated in high humidity environments. Conversely, superhydrophobic surfaces that repel water droplets may suffer from reduced optical clarity and are vulnerable to contamination that diminishes their performance over time.

Material compatibility issues further complicate implementation across diverse substrates. Anti-fogging technologies that perform well on glass may exhibit reduced effectiveness on plastics, metals, or composite materials. This substrate-dependent performance variability necessitates customized formulations, increasing development complexity and manufacturing costs.

Scalability and cost-effectiveness represent major barriers to commercial viability. Laboratory-scale successes often encounter significant challenges during industrial scale-up, particularly in maintaining consistent coating thickness, adhesion, and functional properties. Current manufacturing processes for high-performance anti-fogging surfaces frequently involve complex multi-step procedures requiring specialized equipment and controlled environments.

Environmental and health concerns pose additional constraints. Many effective anti-fogging formulations contain fluorinated compounds or other potentially harmful chemicals that face increasing regulatory scrutiny. The industry must balance performance requirements with growing demands for environmentally sustainable and non-toxic solutions.

Optical performance trade-offs remain problematic in many applications. Enhancing anti-fogging properties often comes at the expense of light transmission, color neutrality, or refractive properties. This is particularly challenging for precision optical applications in medical devices, automotive safety systems, and advanced imaging technologies.

Cross-functional performance requirements create further complexity. Modern applications frequently demand surfaces that simultaneously exhibit anti-fogging, anti-reflective, antimicrobial, and scratch-resistant properties. Achieving this multi-functionality without compromising individual performance characteristics represents a significant technical challenge that current solutions struggle to address effectively.

Water condensation mechanisms present another significant hurdle. While hydrophilic surfaces effectively spread water into transparent films, they can become saturated in high humidity environments. Conversely, superhydrophobic surfaces that repel water droplets may suffer from reduced optical clarity and are vulnerable to contamination that diminishes their performance over time.

Material compatibility issues further complicate implementation across diverse substrates. Anti-fogging technologies that perform well on glass may exhibit reduced effectiveness on plastics, metals, or composite materials. This substrate-dependent performance variability necessitates customized formulations, increasing development complexity and manufacturing costs.

Scalability and cost-effectiveness represent major barriers to commercial viability. Laboratory-scale successes often encounter significant challenges during industrial scale-up, particularly in maintaining consistent coating thickness, adhesion, and functional properties. Current manufacturing processes for high-performance anti-fogging surfaces frequently involve complex multi-step procedures requiring specialized equipment and controlled environments.

Environmental and health concerns pose additional constraints. Many effective anti-fogging formulations contain fluorinated compounds or other potentially harmful chemicals that face increasing regulatory scrutiny. The industry must balance performance requirements with growing demands for environmentally sustainable and non-toxic solutions.

Optical performance trade-offs remain problematic in many applications. Enhancing anti-fogging properties often comes at the expense of light transmission, color neutrality, or refractive properties. This is particularly challenging for precision optical applications in medical devices, automotive safety systems, and advanced imaging technologies.

Cross-functional performance requirements create further complexity. Modern applications frequently demand surfaces that simultaneously exhibit anti-fogging, anti-reflective, antimicrobial, and scratch-resistant properties. Achieving this multi-functionality without compromising individual performance characteristics represents a significant technical challenge that current solutions struggle to address effectively.

Current Anti-fogging and Self-cleaning Technical Solutions

01 Titanium dioxide-based photocatalytic coatings

Titanium dioxide (TiO2) is widely used in self-cleaning and anti-fogging surface coatings due to its photocatalytic properties. When exposed to UV light, TiO2 generates reactive oxygen species that break down organic contaminants on the surface. Additionally, the photocatalytic reaction creates a highly hydrophilic surface that prevents water droplets from forming, thus providing anti-fogging properties. These coatings can be applied to various substrates including glass, plastics, and metals.- Titanium dioxide-based photocatalytic coatings: Titanium dioxide (TiO2) is widely used in self-cleaning and anti-fogging surface treatments due to its photocatalytic properties. When exposed to UV light, TiO2 coatings generate reactive oxygen species that break down organic contaminants on the surface. Additionally, these coatings create a hydrophilic surface that allows water to spread evenly rather than forming droplets, preventing fogging. The photocatalytic activity can be enhanced by controlling the crystalline structure, particle size, and incorporation of dopants.

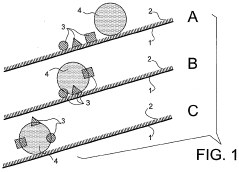

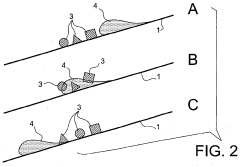

- Hydrophobic nanostructured surfaces: Hydrophobic nanostructured surfaces repel water droplets, creating a self-cleaning effect known as the lotus effect. These surfaces typically incorporate nanoscale roughness combined with low surface energy materials such as fluoropolymers or silicones. When water droplets contact these surfaces, they form nearly spherical beads that roll off easily, carrying away contaminants. This approach is particularly effective for outdoor applications where natural rainfall can maintain cleanliness without manual intervention.

- Silica-based anti-fogging coatings: Silica-based coatings provide excellent anti-fogging properties through their highly hydrophilic nature. These coatings typically contain porous silica nanoparticles that absorb moisture and prevent condensation. The high surface area of these materials allows them to rapidly spread water into a thin, transparent film rather than discrete droplets that cause fogging. Various modifications of silica coatings, including the incorporation of functional groups or polymer matrices, can enhance durability and performance in different environmental conditions.

- Polymer-based multifunctional coatings: Polymer-based coatings offer versatile solutions for self-cleaning and anti-fogging applications. These formulations typically combine hydrophilic polymers with functional additives to achieve multiple properties simultaneously. Cross-linked polymer networks can provide durability while maintaining transparency. Some formulations incorporate phase-change materials or stimuli-responsive polymers that adapt their properties based on environmental conditions. These coatings can be applied through conventional methods such as spraying, dipping, or spin-coating.

- Metal oxide nanocomposite coatings: Metal oxide nanocomposites combine different metal oxides or metal oxides with other materials to achieve enhanced self-cleaning and anti-fogging properties. These coatings often incorporate zinc oxide, tungsten oxide, or tin oxide alongside titanium dioxide to broaden the spectrum of light absorption or improve photocatalytic efficiency. The synergistic effects between different components can provide superior performance compared to single-component systems. These nanocomposites can be engineered to maintain their functionality under various lighting conditions and environments.

02 Hydrophobic nanostructured surfaces

Hydrophobic nanostructured surfaces utilize nanoscale roughness combined with low surface energy materials to create superhydrophobic properties. These surfaces cause water droplets to form high contact angles and roll off easily, carrying away dirt particles in the process (lotus effect). The air trapped in the nanostructures prevents water condensation, providing anti-fogging properties. These surfaces can be created using various methods including nanoparticle deposition, etching processes, or application of fluorinated compounds.Expand Specific Solutions03 Polymer-based anti-fogging coatings

Specialized polymers and polymer blends can be formulated to create surfaces with excellent anti-fogging and self-cleaning properties. These formulations typically include hydrophilic polymers that absorb moisture and prevent droplet formation, combined with additives that repel dirt and contaminants. Some polymer systems incorporate phase separation techniques to create micro or nano-structured surfaces that enhance both properties. These coatings are particularly useful for applications requiring optical clarity such as eyewear, vehicle windows, and optical instruments.Expand Specific Solutions04 Silica-based sol-gel coatings

Sol-gel technology using silica precursors creates durable self-cleaning and anti-fogging coatings. These coatings form a porous network structure that can be tailored to be either hydrophilic (for anti-fogging) or hydrophobic (for self-cleaning). The sol-gel process allows for incorporation of functional additives such as photocatalysts or hydrophobic agents. The resulting coatings exhibit excellent adhesion to various substrates, good optical transparency, and mechanical durability, making them suitable for applications in building materials, automotive glass, and optical devices.Expand Specific Solutions05 Multi-functional composite coatings

Advanced composite coatings combine multiple functional materials to achieve both self-cleaning and anti-fogging properties along with additional benefits. These coatings typically incorporate a combination of nanoparticles (such as TiO2, SiO2, or ZnO), polymeric binders, and functional additives. The synergistic effects between components provide enhanced performance including antimicrobial properties, scratch resistance, UV protection, and durability. These multi-functional coatings can be applied using various methods including spray coating, dip coating, or roll-to-roll processes for industrial applications.Expand Specific Solutions

Key Industry Players in Advanced Surface Treatment

The self-cleaning and anti-fogging surfaces market is currently in a growth phase, with an estimated global market size of $10-15 billion and projected annual growth of 5-7%. The technology has reached moderate maturity but continues to evolve rapidly. Leading players include established chemical companies like Evonik Operations, PPG Industries, and 3M Innovative Properties, who leverage their materials expertise to develop commercial solutions. Academic institutions such as ETH Zurich, Nanyang Technological University, and Technical University of Denmark drive fundamental research innovations. Japanese firms Nippon Sheet Glass and Mitsui Chemicals have established strong positions in automotive and optical applications, while Airbus Operations focuses on aerospace implementations. The competitive landscape shows a healthy balance between corporate R&D and academic research, with increasing collaboration between sectors to accelerate commercialization of advanced anti-fogging technologies.

Evonik Operations GmbH

Technical Solution: Evonik has developed TEGO® Phobe, an advanced silicone-based anti-fogging technology that creates a permanent hydrophilic surface through covalent bonding with the substrate. Their proprietary formulation incorporates specialized siloxane polymers with hydrophilic functional groups that maintain water-spreading capabilities even after repeated cleaning cycles. Evonik's technology creates a nanoscale surface modification that increases surface energy, ensuring water forms a transparent film rather than discrete droplets. The company has enhanced their core technology with additives that provide additional functionalities, including antimicrobial properties that prevent biofilm formation which can degrade anti-fogging performance over time. Their manufacturing process allows for application through conventional coating methods including spray, dip, and roll coating, making it adaptable to various industrial production environments. Evonik has optimized their formulations for specific applications including automotive glass, optical lenses, and bathroom mirrors, with each variant engineered to meet the particular environmental challenges of its intended use. Their latest generation incorporates self-crosslinking chemistry that improves abrasion resistance while maintaining optical clarity.

Strengths: Chemical durability with resistance to common cleaning agents and solvents; versatile application methods compatible with existing manufacturing processes; established supply chain and quality control systems ensuring consistent performance. Weaknesses: Requires careful surface preparation for optimal adhesion and performance; some formulations have limited UV stability requiring additional protective measures for outdoor applications; potential for reduced effectiveness in extremely low humidity environments.

PPG Industries Ohio, Inc.

Technical Solution: PPG has pioneered self-cleaning anti-fog technologies through their advanced hydrophilic coating systems specifically designed for automotive, aerospace, and architectural glass applications. Their technology utilizes a combination of silica nanoparticles and hydrophilic polymers that create a super-wettable surface, causing water to spread evenly rather than forming visibility-reducing droplets. PPG's proprietary formulations incorporate photocatalytic titanium dioxide that breaks down organic contaminants when exposed to UV light, maintaining the surface's anti-fogging properties over time. The company has developed multi-functional coatings that simultaneously provide anti-fog, anti-reflective, and scratch-resistant properties, addressing multiple performance requirements in a single application. Their latest innovations include thermally-activated self-healing properties that can repair minor surface damage, extending the functional lifetime of the coating. PPG's manufacturing process allows for precise thickness control, ensuring optimal optical performance while maintaining the mechanical durability required for real-world applications.

Strengths: Exceptional durability in harsh environmental conditions; multi-functional performance combining anti-fog with other desirable properties; established manufacturing infrastructure allowing for large-scale production and consistent quality. Weaknesses: Higher implementation costs compared to conventional solutions; some formulations require specific curing conditions that may limit application methods; potential for reduced effectiveness in extremely cold environments where water can freeze before spreading.

Core Patents and Innovations in Hydrophobic Coatings

Self-cleaning and/or antifouling and/or Anti-condensation surface

PatentWO2003022463A1

Innovation

- A surface with small, slender protuberances that are grafted onto the surface, providing excellent self-cleaning, anti-soiling, and anti-condensation properties without affecting the inherent properties of the material, such as transparency or mechanical strength, by reducing contact surface area and using hydrophobic or hydrophilic ends to repel pollutants and liquids.

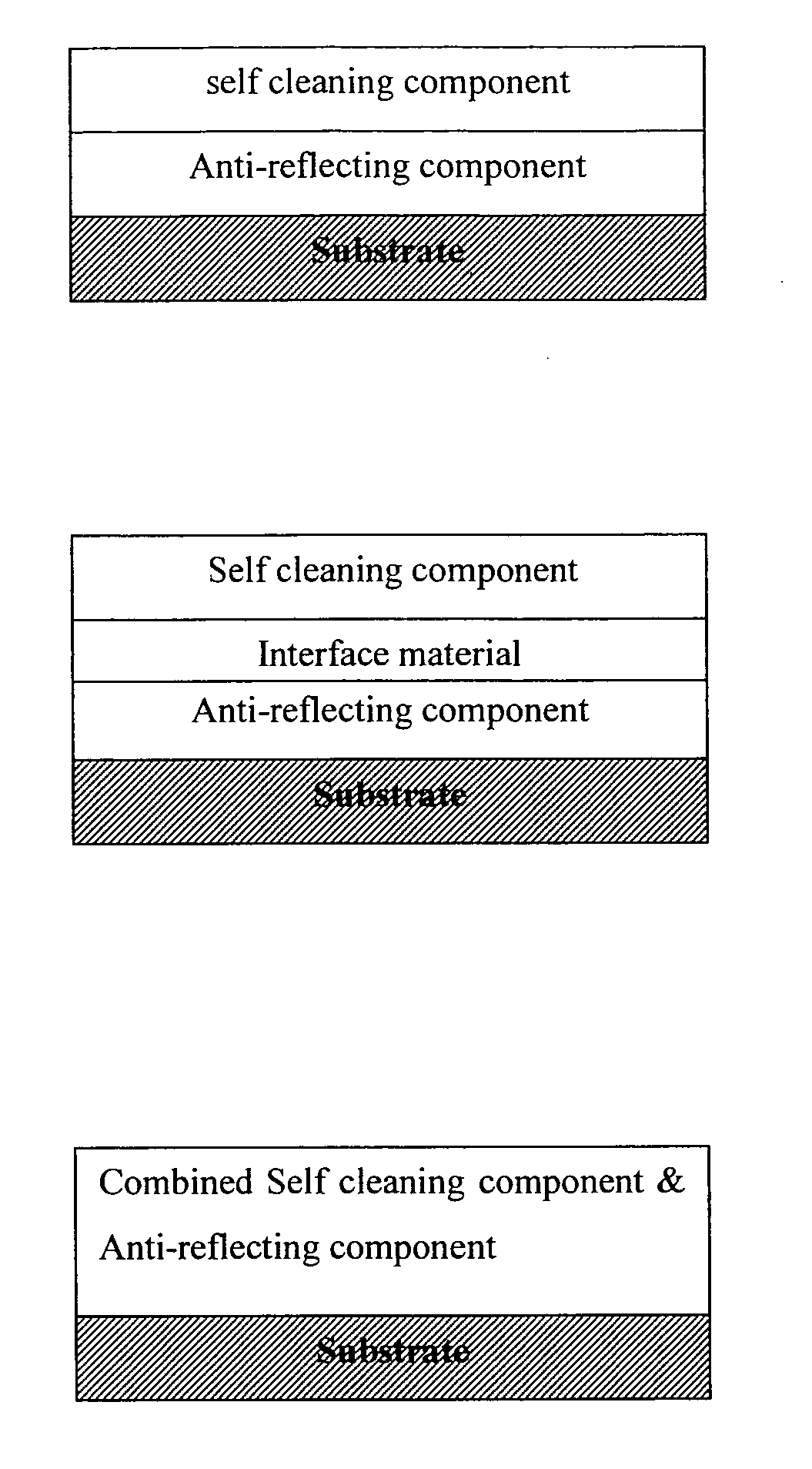

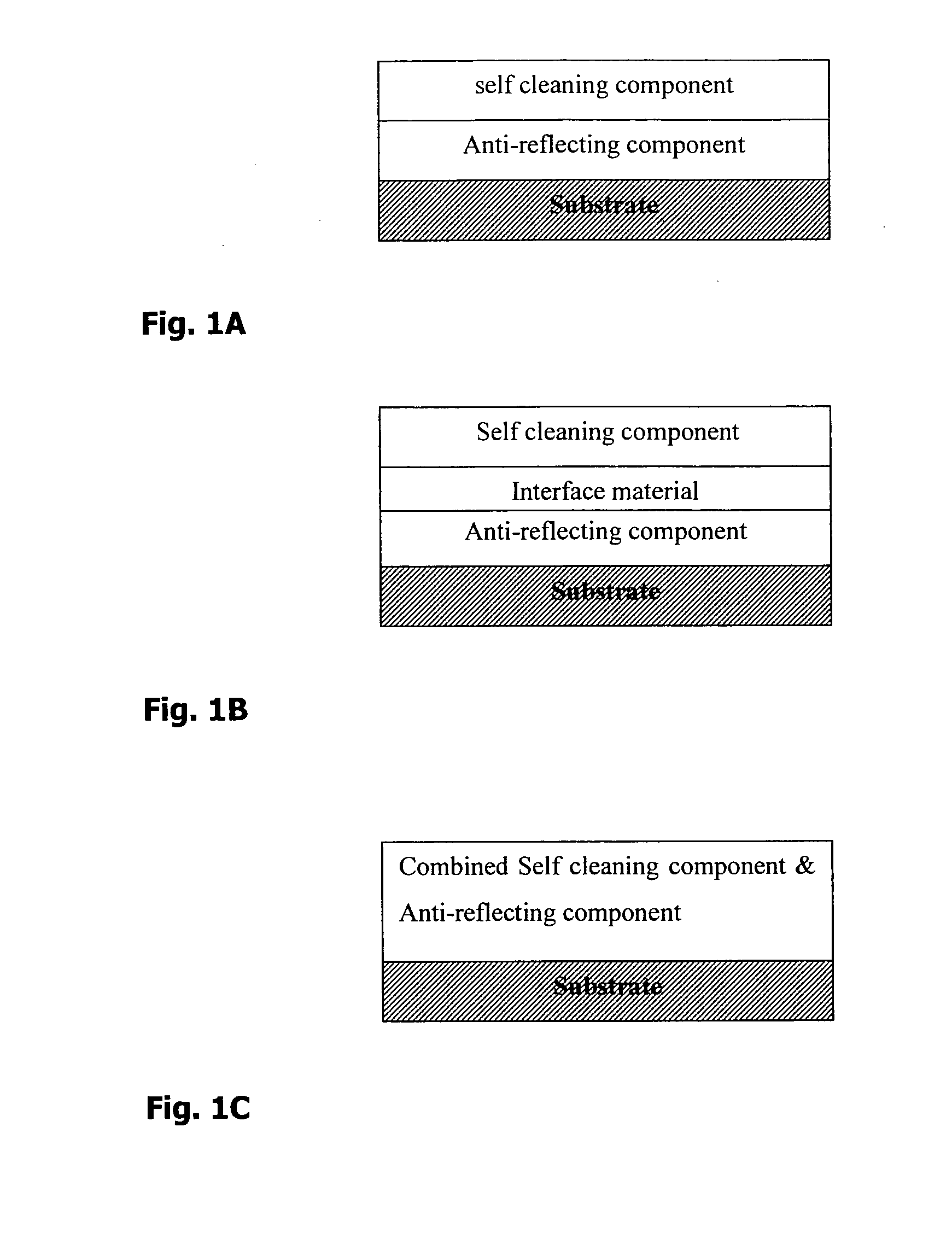

substrate having a self cleaning Anti-reflecting coating and method for its preparation

PatentInactiveUS20120009429A1

Innovation

- A dual coating system comprising an anti-reflecting (ARC) component and a self-cleaning (SCC) component, where the ARC component includes porous silica and the SCC component utilizes nano- and micro-structuring agents like fluorosilane and colloidal silica, applied in a multi-layer configuration to achieve both low reflectance and self-cleaning properties.

Environmental Impact and Sustainability Considerations

The development of self-cleaning and anti-fogging surfaces carries significant environmental implications that must be considered in their lifecycle assessment. Traditional cleaning methods often rely on chemical agents containing volatile organic compounds (VOCs), phosphates, and other environmentally harmful substances. Self-cleaning technologies can substantially reduce the consumption of these cleaning chemicals, thereby decreasing water pollution and minimizing the release of toxic substances into ecosystems.

Energy consumption represents another critical environmental factor. While some self-cleaning surfaces require energy inputs for activation (such as photocatalytic surfaces needing UV exposure), the net energy balance often favors these technologies when compared to conventional cleaning processes. Reduced maintenance frequency translates to lower energy requirements for cleaning operations, particularly in large-scale applications like building facades or solar panels.

Material sustainability constitutes a fundamental consideration in developing next-generation anti-fogging surfaces. Current approaches frequently incorporate nanomaterials such as titanium dioxide, zinc oxide, or specialized polymers. The environmental impact of these materials varies significantly depending on extraction methods, synthesis processes, and end-of-life disposal scenarios. Research indicates that some nanomaterials may persist in the environment with potential bioaccumulation concerns, necessitating careful risk assessment.

Durability directly influences the sustainability profile of self-cleaning surfaces. Technologies with extended functional lifespans distribute their initial environmental manufacturing impact across longer operational periods. Recent advancements have improved wear resistance and functional stability, though further improvements remain necessary for optimal environmental performance.

Water conservation represents a significant benefit of self-cleaning technologies. By reducing or eliminating manual cleaning requirements, these surfaces can save substantial water volumes, particularly in water-stressed regions. Quantitative studies demonstrate that buildings with self-cleaning facades can reduce water consumption for maintenance by 70-80% compared to conventional surfaces.

End-of-life considerations must be integrated into development strategies for these technologies. Designing for recyclability, biodegradability, or safe disposal pathways should be prioritized alongside performance characteristics. Some promising approaches incorporate naturally derived materials or bio-inspired designs that minimize environmental footprint while maintaining functional properties.

Carbon footprint reduction potential exists throughout the lifecycle of self-cleaning surfaces. Manufacturing processes continue to evolve toward more energy-efficient methods, while the operational benefits include reduced maintenance-related emissions and potential energy savings in climate-controlled environments where fogging is prevented.

Energy consumption represents another critical environmental factor. While some self-cleaning surfaces require energy inputs for activation (such as photocatalytic surfaces needing UV exposure), the net energy balance often favors these technologies when compared to conventional cleaning processes. Reduced maintenance frequency translates to lower energy requirements for cleaning operations, particularly in large-scale applications like building facades or solar panels.

Material sustainability constitutes a fundamental consideration in developing next-generation anti-fogging surfaces. Current approaches frequently incorporate nanomaterials such as titanium dioxide, zinc oxide, or specialized polymers. The environmental impact of these materials varies significantly depending on extraction methods, synthesis processes, and end-of-life disposal scenarios. Research indicates that some nanomaterials may persist in the environment with potential bioaccumulation concerns, necessitating careful risk assessment.

Durability directly influences the sustainability profile of self-cleaning surfaces. Technologies with extended functional lifespans distribute their initial environmental manufacturing impact across longer operational periods. Recent advancements have improved wear resistance and functional stability, though further improvements remain necessary for optimal environmental performance.

Water conservation represents a significant benefit of self-cleaning technologies. By reducing or eliminating manual cleaning requirements, these surfaces can save substantial water volumes, particularly in water-stressed regions. Quantitative studies demonstrate that buildings with self-cleaning facades can reduce water consumption for maintenance by 70-80% compared to conventional surfaces.

End-of-life considerations must be integrated into development strategies for these technologies. Designing for recyclability, biodegradability, or safe disposal pathways should be prioritized alongside performance characteristics. Some promising approaches incorporate naturally derived materials or bio-inspired designs that minimize environmental footprint while maintaining functional properties.

Carbon footprint reduction potential exists throughout the lifecycle of self-cleaning surfaces. Manufacturing processes continue to evolve toward more energy-efficient methods, while the operational benefits include reduced maintenance-related emissions and potential energy savings in climate-controlled environments where fogging is prevented.

Durability and Performance Testing Methodologies

Durability and performance testing methodologies for self-cleaning and anti-fogging surfaces represent critical evaluation frameworks that determine the practical viability of these technologies in real-world applications. Standardized testing protocols have evolved significantly over the past decade, with organizations such as ASTM International, ISO, and JIS developing specific guidelines for assessing the longevity and effectiveness of functional surface treatments.

The accelerated weathering tests form the cornerstone of durability assessment, typically employing QUV accelerated weathering testers that simulate years of outdoor exposure through controlled cycles of UV radiation, temperature fluctuations, and moisture conditions. For anti-fogging surfaces specifically, thermal cycling tests between extreme temperatures (-20°C to 80°C) are essential to evaluate performance stability under thermal stress conditions that typically induce fogging.

Chemical resistance testing has become increasingly sophisticated, involving exposure to various substances including acidic rain simulants (pH 4.0-5.0), alkaline cleaning agents, organic solvents, and salt spray. These tests are particularly relevant for automotive and architectural applications where surfaces encounter diverse chemical environments. The standardized procedures typically require 500-1000 hours of continuous exposure followed by performance reassessment.

Mechanical durability evaluations focus on abrasion resistance through linear abraser testing (ASTM D4060), pencil hardness tests (ASTM D3363), and cross-hatch adhesion assessments (ASTM D3359). Advanced methodologies now incorporate nano-indentation techniques to quantify changes in surface mechanical properties at the microscale level, providing insights into degradation mechanisms that conventional macroscopic tests might miss.

Optical performance metrics for anti-fogging surfaces include light transmission maintenance, haze development, and contact angle hysteresis measurements over time. The ISO 23232 standard specifically addresses anti-fogging performance through controlled condensation tests, measuring the time required for light transmission to decrease below 90% under standardized humidity and temperature conditions.

Field testing complements laboratory assessments by exposing samples to real-world conditions across different climate zones. Multi-site testing programs typically involve installations in tropical, arid, polar, and marine environments with quarterly performance evaluations over 2-3 year periods. This approach provides validation data that correlates with accelerated testing results and helps establish acceleration factors for predicting long-term performance.

Recent advancements include the development of combinatorial testing methodologies that simultaneously subject surfaces to multiple stressors, better simulating real-world conditions where surfaces rarely experience isolated degradation factors. These comprehensive testing protocols have significantly improved the predictive accuracy of performance evaluations and accelerated the development cycle for next-generation self-cleaning and anti-fogging technologies.

The accelerated weathering tests form the cornerstone of durability assessment, typically employing QUV accelerated weathering testers that simulate years of outdoor exposure through controlled cycles of UV radiation, temperature fluctuations, and moisture conditions. For anti-fogging surfaces specifically, thermal cycling tests between extreme temperatures (-20°C to 80°C) are essential to evaluate performance stability under thermal stress conditions that typically induce fogging.

Chemical resistance testing has become increasingly sophisticated, involving exposure to various substances including acidic rain simulants (pH 4.0-5.0), alkaline cleaning agents, organic solvents, and salt spray. These tests are particularly relevant for automotive and architectural applications where surfaces encounter diverse chemical environments. The standardized procedures typically require 500-1000 hours of continuous exposure followed by performance reassessment.

Mechanical durability evaluations focus on abrasion resistance through linear abraser testing (ASTM D4060), pencil hardness tests (ASTM D3363), and cross-hatch adhesion assessments (ASTM D3359). Advanced methodologies now incorporate nano-indentation techniques to quantify changes in surface mechanical properties at the microscale level, providing insights into degradation mechanisms that conventional macroscopic tests might miss.

Optical performance metrics for anti-fogging surfaces include light transmission maintenance, haze development, and contact angle hysteresis measurements over time. The ISO 23232 standard specifically addresses anti-fogging performance through controlled condensation tests, measuring the time required for light transmission to decrease below 90% under standardized humidity and temperature conditions.

Field testing complements laboratory assessments by exposing samples to real-world conditions across different climate zones. Multi-site testing programs typically involve installations in tropical, arid, polar, and marine environments with quarterly performance evaluations over 2-3 year periods. This approach provides validation data that correlates with accelerated testing results and helps establish acceleration factors for predicting long-term performance.

Recent advancements include the development of combinatorial testing methodologies that simultaneously subject surfaces to multiple stressors, better simulating real-world conditions where surfaces rarely experience isolated degradation factors. These comprehensive testing protocols have significantly improved the predictive accuracy of performance evaluations and accelerated the development cycle for next-generation self-cleaning and anti-fogging technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!