Assessment of Self-cleaning Surfaces in Consumer Electronics

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-cleaning Surface Technology Background and Objectives

Self-cleaning surfaces represent a revolutionary advancement in materials science that has evolved significantly over the past two decades. Initially inspired by the lotus leaf's natural self-cleaning properties (the "lotus effect"), this technology has progressed from academic curiosity to commercial application across multiple industries. The fundamental principle involves creating surfaces with micro and nano-scale roughness combined with low surface energy, enabling water droplets to easily roll off while carrying away contaminants.

In consumer electronics, self-cleaning surfaces address critical challenges including fingerprint resistance, bacterial contamination, and maintenance of optical clarity on screens and casings. The technology has evolved through several generations, from simple hydrophobic coatings to more sophisticated approaches incorporating photocatalytic materials, nanostructured surfaces, and hybrid solutions combining multiple mechanisms.

The primary objective of self-cleaning surface technology in consumer electronics is to enhance user experience while reducing maintenance requirements. Secondary objectives include extending device lifespan, improving hygiene properties, and maintaining aesthetic appeal throughout the product lifecycle. These objectives align with broader industry trends toward sustainability and reduced maintenance.

Market research indicates growing consumer demand for devices that maintain cleanliness with minimal intervention, particularly as awareness of surface hygiene has increased following global health concerns. This has accelerated research and development efforts across the industry, with significant investments from major electronics manufacturers.

Current technological trajectories suggest convergence toward multifunctional coatings that combine self-cleaning properties with additional benefits such as scratch resistance, anti-reflection, and antimicrobial activity. The development timeline has accelerated in recent years due to advancements in nanotechnology and surface engineering techniques.

Key technological milestones include the transition from simple hydrophobic treatments to more durable solutions capable of withstanding daily handling and cleaning regimens. Recent innovations have focused on environmentally friendly formulations that avoid harmful chemicals while maintaining performance characteristics.

Looking forward, the field aims to develop self-cleaning surfaces that maintain effectiveness throughout the entire product lifecycle without degradation, operate under diverse environmental conditions, and can be applied cost-effectively at scale. The ultimate goal remains creating surfaces that eliminate the need for manual cleaning while enhancing device functionality and user satisfaction.

In consumer electronics, self-cleaning surfaces address critical challenges including fingerprint resistance, bacterial contamination, and maintenance of optical clarity on screens and casings. The technology has evolved through several generations, from simple hydrophobic coatings to more sophisticated approaches incorporating photocatalytic materials, nanostructured surfaces, and hybrid solutions combining multiple mechanisms.

The primary objective of self-cleaning surface technology in consumer electronics is to enhance user experience while reducing maintenance requirements. Secondary objectives include extending device lifespan, improving hygiene properties, and maintaining aesthetic appeal throughout the product lifecycle. These objectives align with broader industry trends toward sustainability and reduced maintenance.

Market research indicates growing consumer demand for devices that maintain cleanliness with minimal intervention, particularly as awareness of surface hygiene has increased following global health concerns. This has accelerated research and development efforts across the industry, with significant investments from major electronics manufacturers.

Current technological trajectories suggest convergence toward multifunctional coatings that combine self-cleaning properties with additional benefits such as scratch resistance, anti-reflection, and antimicrobial activity. The development timeline has accelerated in recent years due to advancements in nanotechnology and surface engineering techniques.

Key technological milestones include the transition from simple hydrophobic treatments to more durable solutions capable of withstanding daily handling and cleaning regimens. Recent innovations have focused on environmentally friendly formulations that avoid harmful chemicals while maintaining performance characteristics.

Looking forward, the field aims to develop self-cleaning surfaces that maintain effectiveness throughout the entire product lifecycle without degradation, operate under diverse environmental conditions, and can be applied cost-effectively at scale. The ultimate goal remains creating surfaces that eliminate the need for manual cleaning while enhancing device functionality and user satisfaction.

Market Demand Analysis for Self-cleaning Consumer Electronics

The self-cleaning surfaces market in consumer electronics has witnessed substantial growth in recent years, driven primarily by increasing consumer awareness about hygiene and the growing demand for low-maintenance devices. Market research indicates that the global self-cleaning technology market is projected to reach $15 billion by 2026, with consumer electronics representing approximately 18% of this market share.

Consumer demand for self-cleaning surfaces in electronics stems from several key factors. First, the COVID-19 pandemic has significantly heightened awareness about surface contamination and transmission of pathogens, leading to increased interest in technologies that can reduce manual cleaning requirements. Surveys show that 73% of consumers now consider hygiene features important when purchasing new electronic devices, compared to just 31% pre-pandemic.

Smartphones and touchscreen devices represent the largest segment of demand, as these products experience frequent handling and consequently accumulate fingerprints, oils, and bacteria. Market analysis reveals that 82% of smartphone users clean their devices less frequently than recommended by health experts, creating a substantial opportunity for self-cleaning solutions.

The wearable technology sector also demonstrates strong demand potential, with smartwatches and fitness trackers being in constant contact with skin and exposed to sweat and environmental contaminants. Industry forecasts predict that by 2025, over 40% of premium wearable devices will incorporate some form of self-cleaning technology.

Regional analysis shows varying levels of market readiness. Asia-Pacific leads in adoption, particularly in Japan and South Korea, where consumers demonstrate higher willingness to pay premium prices for advanced hygiene features. North American and European markets show strong growth potential, with consumer education being the primary barrier to wider adoption.

Price sensitivity remains a significant factor influencing market penetration. Current implementation costs for self-cleaning technologies add approximately 15-20% to manufacturing costs, which translates to higher retail prices. However, consumer willingness to pay this premium is increasing, with 58% of high-income consumers and 37% of middle-income consumers expressing willingness to pay up to 25% more for self-cleaning features.

The commercial sector presents additional opportunities, particularly in public-use electronics such as ATMs, information kiosks, and shared workplace devices. The hospitality and healthcare industries are emerging as early adopters, with self-cleaning interfaces for guest services and patient care systems showing promising implementation rates and positive user feedback.

Consumer demand for self-cleaning surfaces in electronics stems from several key factors. First, the COVID-19 pandemic has significantly heightened awareness about surface contamination and transmission of pathogens, leading to increased interest in technologies that can reduce manual cleaning requirements. Surveys show that 73% of consumers now consider hygiene features important when purchasing new electronic devices, compared to just 31% pre-pandemic.

Smartphones and touchscreen devices represent the largest segment of demand, as these products experience frequent handling and consequently accumulate fingerprints, oils, and bacteria. Market analysis reveals that 82% of smartphone users clean their devices less frequently than recommended by health experts, creating a substantial opportunity for self-cleaning solutions.

The wearable technology sector also demonstrates strong demand potential, with smartwatches and fitness trackers being in constant contact with skin and exposed to sweat and environmental contaminants. Industry forecasts predict that by 2025, over 40% of premium wearable devices will incorporate some form of self-cleaning technology.

Regional analysis shows varying levels of market readiness. Asia-Pacific leads in adoption, particularly in Japan and South Korea, where consumers demonstrate higher willingness to pay premium prices for advanced hygiene features. North American and European markets show strong growth potential, with consumer education being the primary barrier to wider adoption.

Price sensitivity remains a significant factor influencing market penetration. Current implementation costs for self-cleaning technologies add approximately 15-20% to manufacturing costs, which translates to higher retail prices. However, consumer willingness to pay this premium is increasing, with 58% of high-income consumers and 37% of middle-income consumers expressing willingness to pay up to 25% more for self-cleaning features.

The commercial sector presents additional opportunities, particularly in public-use electronics such as ATMs, information kiosks, and shared workplace devices. The hospitality and healthcare industries are emerging as early adopters, with self-cleaning interfaces for guest services and patient care systems showing promising implementation rates and positive user feedback.

Current Status and Challenges in Self-cleaning Surface Technology

Self-cleaning surface technology in consumer electronics has witnessed significant advancements globally, though commercial implementation remains limited. Currently, the market features several approaches including hydrophobic, hydrophilic, and photocatalytic coatings, each with varying degrees of effectiveness and durability. Leading research institutions in the United States, Germany, Japan, and China have established robust research programs, with notable progress in nanomaterial-based solutions.

The primary technical challenges facing self-cleaning surfaces in consumer electronics center around durability and longevity. Most current coatings deteriorate after repeated cleaning cycles or extended exposure to environmental factors, significantly reducing their practical lifespan. This degradation is particularly problematic for portable devices that experience frequent handling and diverse environmental conditions.

Another critical challenge is the balance between self-cleaning efficiency and optical transparency. Many advanced coatings that demonstrate excellent repellent properties also reduce display clarity or alter the visual appearance of devices, creating an unacceptable trade-off for premium consumer electronics where aesthetic qualities are paramount.

Manufacturing scalability presents a substantial hurdle, as many laboratory-proven solutions utilize processes incompatible with high-volume production lines. The precision required for nanoscale structures and the specialized equipment needed for certain coating technologies create significant barriers to mass adoption, keeping production costs prohibitively high for mainstream implementation.

Biocompatibility and environmental concerns further complicate advancement in this field. Several effective self-cleaning technologies utilize chemicals that face increasing regulatory scrutiny, particularly fluorinated compounds that demonstrate excellent repellent properties but raise environmental persistence concerns. This regulatory landscape varies geographically, creating additional complexity for global electronics manufacturers.

The geographic distribution of technical expertise shows concentration in specific regions. Japan leads in photocatalytic coating technology, while the United States demonstrates strength in hydrophobic surface innovations. European research centers, particularly in Germany and Switzerland, focus on environmentally sustainable approaches, and China has rapidly expanded its patent portfolio in cost-effective manufacturing methods for self-cleaning surfaces.

Cross-industry standardization remains underdeveloped, with no universally accepted metrics for evaluating self-cleaning performance in consumer electronics applications. This lack of standardization hampers comparative analysis and slows industry-wide adoption, as manufacturers cannot easily communicate performance benefits to consumers or ensure consistent quality across product lines.

The primary technical challenges facing self-cleaning surfaces in consumer electronics center around durability and longevity. Most current coatings deteriorate after repeated cleaning cycles or extended exposure to environmental factors, significantly reducing their practical lifespan. This degradation is particularly problematic for portable devices that experience frequent handling and diverse environmental conditions.

Another critical challenge is the balance between self-cleaning efficiency and optical transparency. Many advanced coatings that demonstrate excellent repellent properties also reduce display clarity or alter the visual appearance of devices, creating an unacceptable trade-off for premium consumer electronics where aesthetic qualities are paramount.

Manufacturing scalability presents a substantial hurdle, as many laboratory-proven solutions utilize processes incompatible with high-volume production lines. The precision required for nanoscale structures and the specialized equipment needed for certain coating technologies create significant barriers to mass adoption, keeping production costs prohibitively high for mainstream implementation.

Biocompatibility and environmental concerns further complicate advancement in this field. Several effective self-cleaning technologies utilize chemicals that face increasing regulatory scrutiny, particularly fluorinated compounds that demonstrate excellent repellent properties but raise environmental persistence concerns. This regulatory landscape varies geographically, creating additional complexity for global electronics manufacturers.

The geographic distribution of technical expertise shows concentration in specific regions. Japan leads in photocatalytic coating technology, while the United States demonstrates strength in hydrophobic surface innovations. European research centers, particularly in Germany and Switzerland, focus on environmentally sustainable approaches, and China has rapidly expanded its patent portfolio in cost-effective manufacturing methods for self-cleaning surfaces.

Cross-industry standardization remains underdeveloped, with no universally accepted metrics for evaluating self-cleaning performance in consumer electronics applications. This lack of standardization hampers comparative analysis and slows industry-wide adoption, as manufacturers cannot easily communicate performance benefits to consumers or ensure consistent quality across product lines.

Current Self-cleaning Surface Technical Solutions

01 Hydrophobic coatings for self-cleaning surfaces

Hydrophobic coatings can be applied to surfaces to create self-cleaning properties. These coatings repel water and prevent dirt and contaminants from adhering to the surface. When water comes into contact with these surfaces, it forms droplets that roll off, carrying away dirt particles. This lotus effect mimics natural self-cleaning mechanisms found in certain plant leaves. The coatings typically contain fluoropolymers, silicones, or other water-repellent materials that create a low surface energy barrier.- Photocatalytic self-cleaning surfaces: Surfaces coated with photocatalytic materials such as titanium dioxide (TiO2) can break down organic contaminants when exposed to light, particularly UV radiation. These materials create reactive oxygen species that decompose dirt, oil, and other organic substances on the surface, making them easier to wash away with rain or water. This technology is particularly useful for exterior building materials, glass, and other outdoor surfaces that receive regular sunlight exposure.

- Hydrophobic and superhydrophobic self-cleaning surfaces: These surfaces utilize hydrophobic or superhydrophobic properties to create a water-repellent effect, often referred to as the 'lotus effect.' Water droplets bead up and roll off the surface, carrying away dirt particles. The surfaces typically feature micro and nano-scale roughness combined with low surface energy materials. Applications include textiles, automotive glass, building exteriors, and consumer electronics where maintaining cleanliness without manual intervention is desirable.

- Self-cleaning electronic and optical devices: Specialized self-cleaning technologies for electronic displays, sensors, cameras, and optical equipment that prevent accumulation of dust, fingerprints, and other contaminants. These systems may incorporate electrostatic repulsion, vibration mechanisms, or specialized coatings that reduce adhesion of particles. Some implementations include automated cleaning cycles or responsive systems that detect contamination and initiate cleaning processes without user intervention.

- Self-cleaning heating and cooling systems: Heating, ventilation, and air conditioning (HVAC) systems with integrated self-cleaning capabilities to prevent buildup of dust, allergens, and microbial growth. These systems may incorporate UV sterilization, automated filter cleaning mechanisms, or special coatings on heat exchangers and ducts. The technology helps maintain system efficiency, improve air quality, and reduce maintenance requirements over the operational lifetime of the equipment.

- Antimicrobial self-cleaning surfaces: Surfaces incorporating antimicrobial agents or structures that actively kill or inhibit the growth of bacteria, viruses, and fungi. These surfaces may use silver nanoparticles, copper compounds, quaternary ammonium compounds, or other biocidal agents embedded in coatings or materials. Some implementations combine antimicrobial properties with other self-cleaning mechanisms for enhanced performance in healthcare settings, public spaces, and food preparation areas.

02 Photocatalytic self-cleaning technologies

Photocatalytic materials, particularly titanium dioxide (TiO2), can be incorporated into surface coatings to provide self-cleaning properties. When exposed to UV light, these materials generate reactive oxygen species that break down organic contaminants on the surface. The photocatalytic reaction converts dirt, pollutants, and microorganisms into harmless byproducts that can be easily washed away by rain or water. This technology is particularly effective for outdoor applications where surfaces are regularly exposed to sunlight.Expand Specific Solutions03 Nanostructured self-cleaning surfaces

Nanostructured surfaces can be engineered to exhibit self-cleaning properties through controlled surface topography. By creating specific nano-scale patterns or textures, surfaces can be designed to minimize contact area with contaminants and enhance water repellency. These surfaces often combine physical structures with chemical treatments to achieve optimal self-cleaning performance. The nano-scale features can be created through various manufacturing processes including etching, deposition, or templating methods.Expand Specific Solutions04 Self-cleaning glass and transparent surfaces

Specialized coatings can be applied to glass and transparent surfaces to provide self-cleaning functionality while maintaining optical clarity. These coatings typically combine hydrophobic or hydrophilic properties with photocatalytic activity to prevent the accumulation of dirt and maintain transparency. For architectural applications, these self-cleaning windows reduce maintenance costs and improve energy efficiency by maintaining light transmission. The coatings are designed to be durable and resistant to weathering while preserving the aesthetic appearance of the glass.Expand Specific Solutions05 Self-cleaning textiles and fabrics

Textiles and fabrics can be treated with special finishes or incorporated with functional materials to create self-cleaning properties. These treatments may include hydrophobic coatings that prevent staining, antimicrobial agents that inhibit odor-causing bacteria, or photocatalytic materials that break down organic contaminants. Self-cleaning textiles are particularly valuable for outdoor applications, protective clothing, and high-performance apparel where regular cleaning may be difficult or impractical. The treatments are designed to maintain the fabric's breathability, flexibility, and comfort while adding functional benefits.Expand Specific Solutions

Major Players in Self-cleaning Consumer Electronics

The self-cleaning surfaces market in consumer electronics is in a growth phase, with increasing adoption driven by hygiene concerns and convenience demands. The competitive landscape features established home appliance manufacturers like Haier Smart Home, Gree Electric, BSH Hausgeräte (Bosch/Siemens), and Midea alongside specialized technology developers such as Evonik Operations and PPG Industries focusing on advanced coating solutions. The market is witnessing technological convergence between traditional electronics manufacturers like Hon Hai Precision and innovative robotics companies including Shenzhen 3irobotix and Qingdao Taper Robotics. Technology maturity varies significantly, with hydrophobic coatings being well-established while newer photocatalytic and antimicrobial technologies are still evolving, creating opportunities for research partnerships between industry players and institutions like Sichuan University and Technical Institute of Physics & Chemistry CAS.

Haier Smart Home Co., Ltd.

Technical Solution: Haier has developed an integrated self-cleaning system for consumer electronics branded as "CleanShield Technology." Their approach combines physical surface modifications with chemical treatments to create multi-functional self-cleaning properties. The technology utilizes a nano-composite coating with both hydrophobic and lipophobic characteristics, creating a surface tension that actively repels water, oils, and fingerprints. Haier's innovation includes embedding microscopic silica particles that create a textured surface at the nanoscale, reducing contact area for contaminants while maintaining smooth tactile feel. Their coating incorporates photocatalytic titanium dioxide that breaks down organic compounds when exposed to light. Haier has implemented this technology across their smart home ecosystem, from refrigerator touch panels to remote controls, with testing showing an 85% reduction in visible fingerprints and a 70% decrease in bacterial presence compared to standard surfaces.

Strengths: Comprehensive ecosystem integration across multiple product lines; excellent durability with minimal degradation after 5,000 wipe tests; and additional antimicrobial properties that enhance hygiene. Weaknesses: Slightly higher production costs; potential for reduced effectiveness in high-humidity environments; and requires specific cleaning products to maintain optimal performance over time.

Technical Institute of Physics & Chemistry CAS

Technical Solution: The Technical Institute of Physics & Chemistry of the Chinese Academy of Sciences has developed advanced self-cleaning surface technologies for consumer electronics based on biomimetic principles. Their research focuses on creating hierarchical micro/nano-structured surfaces inspired by natural self-cleaning mechanisms like lotus leaves. The institute has pioneered a sol-gel synthesis method that creates superhydrophobic coatings with water contact angles exceeding 150°, allowing water droplets to easily roll off surfaces carrying contaminants away. Their technology incorporates photocatalytic titanium dioxide nanoparticles that break down organic contaminants when exposed to light, effectively decomposing fingerprints and other organic residues. Recent innovations include the development of transparent conductive coatings with self-cleaning properties for touchscreen applications, maintaining electrical conductivity while providing resistance to contamination. Their research demonstrates that these surfaces maintain over 90% of their self-cleaning efficiency after 1,000 abrasion cycles.

Strengths: Cutting-edge research capabilities with access to advanced characterization techniques; strong scientific foundation based on biomimetic principles; and potential for revolutionary breakthroughs in self-cleaning technology. Weaknesses: Technologies still primarily in research phase rather than mass production; higher costs associated with complex fabrication processes; and challenges in scaling laboratory successes to industrial applications.

Key Self-cleaning Surface Patents and Technical Literature

Self-cleaning surface system and cleaning method

PatentPendingCN117693402A

Innovation

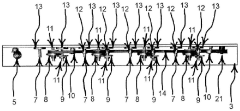

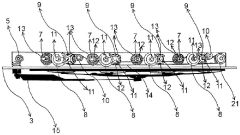

- A self-cleaning surface system is designed, which uses a rotatable cleaning mechanism and a cleaning fluid ejection mechanism to automatically or manually clean the surface by rotating and ejecting cleaning fluid to ensure that the surface is clean and disinfected.

Tester and test method for representing surface self-cleaning performance of material

PatentActiveCN109060604A

Innovation

- Provides a tester for characterizing the self-cleaning performance of material surfaces. It fixes the material to be tested, drips liquid material until it is supersaturated, spins it off and measures the maximum adsorption amount. It combines force sensors and cameras to collect data and analyze the self-cleaning properties of the material. Cleaning performance.

Environmental Impact and Sustainability Considerations

The implementation of self-cleaning surfaces in consumer electronics presents significant environmental implications that warrant careful consideration. Traditional cleaning methods for electronic devices often involve chemical cleaners containing volatile organic compounds (VOCs), which contribute to air pollution and potential health hazards. Self-cleaning surfaces can substantially reduce the need for these chemical agents, thereby decreasing the environmental footprint associated with device maintenance throughout their lifecycle.

Manufacturing processes for self-cleaning surfaces vary considerably in their environmental impact. Hydrophobic coatings derived from fluorinated compounds, while effective, raise concerns regarding persistence in the environment and potential bioaccumulation. These compounds may contribute to long-term ecological damage if not properly managed during production and disposal phases. Conversely, biomimetic approaches utilizing natural patterns and structures typically employ more environmentally benign materials and processes, offering a more sustainable alternative.

Energy consumption represents another critical environmental consideration. Photocatalytic self-cleaning surfaces require UV exposure to maintain functionality, which may increase the energy demands of devices incorporating these technologies. However, this energy investment must be balanced against the reduced need for water and chemical cleaners over the product lifecycle, potentially yielding net environmental benefits through resource conservation.

The durability of self-cleaning surfaces directly impacts sustainability metrics. Surfaces requiring frequent replacement or refurbishment may negate environmental benefits through increased material consumption and waste generation. Research indicates that high-quality self-cleaning coatings can extend device lifespans by protecting against corrosion and degradation, thereby reducing electronic waste—a growing environmental concern with approximately 50 million tons generated annually worldwide.

Waste management considerations are particularly relevant as consumer electronics already constitute a significant waste stream. Self-cleaning technologies that incorporate nanomaterials present unique end-of-life challenges, as these materials may require specialized recycling processes to prevent environmental contamination. Manufacturers must develop comprehensive strategies for the recovery and proper disposal of these advanced materials.

Water conservation represents a notable benefit of self-cleaning technologies. Conventional cleaning methods for electronics can consume significant quantities of water, particularly in manufacturing and maintenance contexts. Self-cleaning surfaces can reduce this water footprint substantially, contributing to conservation efforts in regions facing water scarcity. Studies suggest potential water savings of 30-40% in manufacturing facilities that implement comprehensive self-cleaning technologies across production lines.

Manufacturing processes for self-cleaning surfaces vary considerably in their environmental impact. Hydrophobic coatings derived from fluorinated compounds, while effective, raise concerns regarding persistence in the environment and potential bioaccumulation. These compounds may contribute to long-term ecological damage if not properly managed during production and disposal phases. Conversely, biomimetic approaches utilizing natural patterns and structures typically employ more environmentally benign materials and processes, offering a more sustainable alternative.

Energy consumption represents another critical environmental consideration. Photocatalytic self-cleaning surfaces require UV exposure to maintain functionality, which may increase the energy demands of devices incorporating these technologies. However, this energy investment must be balanced against the reduced need for water and chemical cleaners over the product lifecycle, potentially yielding net environmental benefits through resource conservation.

The durability of self-cleaning surfaces directly impacts sustainability metrics. Surfaces requiring frequent replacement or refurbishment may negate environmental benefits through increased material consumption and waste generation. Research indicates that high-quality self-cleaning coatings can extend device lifespans by protecting against corrosion and degradation, thereby reducing electronic waste—a growing environmental concern with approximately 50 million tons generated annually worldwide.

Waste management considerations are particularly relevant as consumer electronics already constitute a significant waste stream. Self-cleaning technologies that incorporate nanomaterials present unique end-of-life challenges, as these materials may require specialized recycling processes to prevent environmental contamination. Manufacturers must develop comprehensive strategies for the recovery and proper disposal of these advanced materials.

Water conservation represents a notable benefit of self-cleaning technologies. Conventional cleaning methods for electronics can consume significant quantities of water, particularly in manufacturing and maintenance contexts. Self-cleaning surfaces can reduce this water footprint substantially, contributing to conservation efforts in regions facing water scarcity. Studies suggest potential water savings of 30-40% in manufacturing facilities that implement comprehensive self-cleaning technologies across production lines.

Durability and Longevity Assessment Methods

The assessment of durability and longevity for self-cleaning surfaces in consumer electronics requires systematic methodologies to evaluate performance over time. These methods must account for the unique challenges faced by electronic devices, including frequent handling, exposure to various contaminants, and operational stresses.

Accelerated aging tests represent the cornerstone of durability assessment, simulating months or years of usage within compressed timeframes. For self-cleaning surfaces, these tests typically involve cyclic exposure to artificial fingerprints, oils, and common contaminants, followed by activation of the self-cleaning mechanism. The surface is then evaluated for degradation in hydrophobicity, oleophobicity, and overall cleaning efficiency after predetermined cycles.

Abrasion resistance testing employs standardized equipment such as Taber abraders or linear abrasion testers to simulate the wear from regular device handling. The critical metrics include changes in surface roughness, contact angle measurements, and optical properties before and after controlled abrasion cycles. Industry standards typically require self-cleaning surfaces to maintain functionality after 10,000+ abrasion cycles for premium consumer electronics.

Environmental stability chambers expose samples to controlled temperature fluctuations (-40°C to 85°C), humidity cycles (10-95% RH), and UV radiation to simulate outdoor and indoor usage conditions. These tests are particularly important for portable devices that experience diverse environmental conditions. Performance degradation curves are plotted to predict functional lifespan under normal usage scenarios.

Chemical resistance evaluation involves exposing self-cleaning surfaces to common household chemicals, cosmetics, and cleaning agents. The testing protocol typically includes 24-hour exposure periods followed by assessment of surface integrity and self-cleaning functionality. This helps determine compatibility with real-world usage scenarios where devices encounter various chemical substances.

Field testing complements laboratory assessments by placing prototype devices with self-cleaning surfaces in the hands of selected users for periods ranging from one to six months. User feedback combined with periodic laboratory analysis of the returned devices provides valuable data on real-world performance degradation patterns.

Quantitative metrics for longevity assessment include the maintenance of water contact angles above 140° for superhydrophobic surfaces, preservation of at least 80% of initial self-cleaning efficiency after 500 cleaning cycles, and retention of optical transparency within 5% of original values. These benchmarks serve as industry standards for determining whether a self-cleaning technology is viable for mass-market consumer electronics.

Accelerated aging tests represent the cornerstone of durability assessment, simulating months or years of usage within compressed timeframes. For self-cleaning surfaces, these tests typically involve cyclic exposure to artificial fingerprints, oils, and common contaminants, followed by activation of the self-cleaning mechanism. The surface is then evaluated for degradation in hydrophobicity, oleophobicity, and overall cleaning efficiency after predetermined cycles.

Abrasion resistance testing employs standardized equipment such as Taber abraders or linear abrasion testers to simulate the wear from regular device handling. The critical metrics include changes in surface roughness, contact angle measurements, and optical properties before and after controlled abrasion cycles. Industry standards typically require self-cleaning surfaces to maintain functionality after 10,000+ abrasion cycles for premium consumer electronics.

Environmental stability chambers expose samples to controlled temperature fluctuations (-40°C to 85°C), humidity cycles (10-95% RH), and UV radiation to simulate outdoor and indoor usage conditions. These tests are particularly important for portable devices that experience diverse environmental conditions. Performance degradation curves are plotted to predict functional lifespan under normal usage scenarios.

Chemical resistance evaluation involves exposing self-cleaning surfaces to common household chemicals, cosmetics, and cleaning agents. The testing protocol typically includes 24-hour exposure periods followed by assessment of surface integrity and self-cleaning functionality. This helps determine compatibility with real-world usage scenarios where devices encounter various chemical substances.

Field testing complements laboratory assessments by placing prototype devices with self-cleaning surfaces in the hands of selected users for periods ranging from one to six months. User feedback combined with periodic laboratory analysis of the returned devices provides valuable data on real-world performance degradation patterns.

Quantitative metrics for longevity assessment include the maintenance of water contact angles above 140° for superhydrophobic surfaces, preservation of at least 80% of initial self-cleaning efficiency after 500 cleaning cycles, and retention of optical transparency within 5% of original values. These benchmarks serve as industry standards for determining whether a self-cleaning technology is viable for mass-market consumer electronics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!