Why Hydrophobicity is Key in Self-cleaning Surface Design

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrophobic Self-cleaning Surface Background & Objectives

Self-cleaning surfaces have emerged as a significant area of research and development over the past few decades, drawing inspiration from natural phenomena such as the lotus leaf effect. The concept of hydrophobicity, which refers to the property of repelling water, has been central to this technological evolution. Since the formal identification of the lotus effect in the 1970s, scientists have been working to understand and replicate the micro and nano-scale structures that create natural hydrophobic surfaces.

The development trajectory of hydrophobic self-cleaning surfaces has accelerated significantly in the 21st century, with breakthroughs in nanotechnology enabling more precise control over surface properties. Initial research focused primarily on understanding the fundamental physics of water-repellent surfaces, while recent advancements have shifted toward practical applications and commercial viability.

Current technological trends indicate a move toward multifunctional surfaces that combine hydrophobicity with other desirable properties such as mechanical durability, optical transparency, and antimicrobial capabilities. This evolution reflects the growing recognition that practical self-cleaning surfaces must perform reliably under diverse and challenging real-world conditions.

The primary technical objective in this field is to develop surfaces with superhydrophobic properties (contact angles >150°) that maintain their performance over extended periods despite exposure to environmental stressors. Secondary objectives include reducing manufacturing costs, enhancing durability, and developing environmentally friendly production methods that avoid harmful chemicals.

Researchers are particularly focused on overcoming the trade-off between hydrophobicity and mechanical durability, as many highly water-repellent surfaces are susceptible to physical damage that compromises their self-cleaning properties. Another key goal is the development of scalable manufacturing techniques that can transition laboratory successes to mass production.

The scientific understanding of hydrophobicity has evolved from simple contact angle measurements to sophisticated analyses of surface energy, contact angle hysteresis, and sliding angles. This deeper comprehension has revealed that optimal self-cleaning performance requires both high static contact angles and low contact angle hysteresis, allowing water droplets to easily roll off surfaces while carrying away contaminants.

Looking forward, the field aims to develop adaptive or stimuli-responsive hydrophobic surfaces that can adjust their properties in response to environmental conditions, potentially extending their functional lifespan and application range. The ultimate goal remains creating cost-effective, durable self-cleaning surfaces that can significantly reduce maintenance requirements and resource consumption across multiple industries.

The development trajectory of hydrophobic self-cleaning surfaces has accelerated significantly in the 21st century, with breakthroughs in nanotechnology enabling more precise control over surface properties. Initial research focused primarily on understanding the fundamental physics of water-repellent surfaces, while recent advancements have shifted toward practical applications and commercial viability.

Current technological trends indicate a move toward multifunctional surfaces that combine hydrophobicity with other desirable properties such as mechanical durability, optical transparency, and antimicrobial capabilities. This evolution reflects the growing recognition that practical self-cleaning surfaces must perform reliably under diverse and challenging real-world conditions.

The primary technical objective in this field is to develop surfaces with superhydrophobic properties (contact angles >150°) that maintain their performance over extended periods despite exposure to environmental stressors. Secondary objectives include reducing manufacturing costs, enhancing durability, and developing environmentally friendly production methods that avoid harmful chemicals.

Researchers are particularly focused on overcoming the trade-off between hydrophobicity and mechanical durability, as many highly water-repellent surfaces are susceptible to physical damage that compromises their self-cleaning properties. Another key goal is the development of scalable manufacturing techniques that can transition laboratory successes to mass production.

The scientific understanding of hydrophobicity has evolved from simple contact angle measurements to sophisticated analyses of surface energy, contact angle hysteresis, and sliding angles. This deeper comprehension has revealed that optimal self-cleaning performance requires both high static contact angles and low contact angle hysteresis, allowing water droplets to easily roll off surfaces while carrying away contaminants.

Looking forward, the field aims to develop adaptive or stimuli-responsive hydrophobic surfaces that can adjust their properties in response to environmental conditions, potentially extending their functional lifespan and application range. The ultimate goal remains creating cost-effective, durable self-cleaning surfaces that can significantly reduce maintenance requirements and resource consumption across multiple industries.

Market Analysis for Self-cleaning Surface Technologies

The self-cleaning surfaces market has experienced significant growth over the past decade, driven by increasing demand across multiple sectors including construction, automotive, electronics, and healthcare. Currently valued at approximately $8 billion globally, the market is projected to reach $12 billion by 2027, representing a compound annual growth rate of 5.7%. This growth trajectory is supported by rising consumer awareness of hygiene and cleanliness, particularly accelerated by the global pandemic which heightened focus on surface contamination.

The construction sector dominates the self-cleaning surfaces market, accounting for nearly 40% of total demand. Within this sector, self-cleaning glass for windows, facades, and solar panels represents the largest application segment. The automotive industry follows as the second-largest consumer, with applications in windshields, mirrors, and exterior paint protection. Healthcare applications, though smaller in market share, are experiencing the fastest growth rate at 7.2% annually due to increasing emphasis on infection control in medical environments.

Regional analysis reveals that Europe currently leads the market with approximately 35% share, followed closely by North America at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years due to rapid urbanization, increasing construction activities, and growing automotive production in countries like China and India.

Consumer willingness to pay premium prices for self-cleaning technologies varies significantly across sectors. In high-end residential and commercial construction, consumers demonstrate up to 15-20% price premium acceptance for self-cleaning features. The automotive sector shows moderate price sensitivity with 10-15% premium acceptance, while mass-market construction applications remain highly price-sensitive.

Key market drivers include increasing labor costs for cleaning and maintenance, growing environmental concerns regarding chemical cleaning agents, and technological advancements reducing the production costs of hydrophobic materials. Regulatory trends favoring water conservation and reduced chemical usage further support market expansion. However, market challenges persist, including durability concerns of current hydrophobic coatings, inconsistent performance across varying environmental conditions, and relatively high initial implementation costs.

The competitive landscape features both established chemical companies and innovative startups. Major players include PPG Industries, Saint-Gobain, and Nippon Paint dominating with comprehensive product portfolios, while specialized companies like NBD Nano and Aculon drive innovation through advanced hydrophobic technologies.

The construction sector dominates the self-cleaning surfaces market, accounting for nearly 40% of total demand. Within this sector, self-cleaning glass for windows, facades, and solar panels represents the largest application segment. The automotive industry follows as the second-largest consumer, with applications in windshields, mirrors, and exterior paint protection. Healthcare applications, though smaller in market share, are experiencing the fastest growth rate at 7.2% annually due to increasing emphasis on infection control in medical environments.

Regional analysis reveals that Europe currently leads the market with approximately 35% share, followed closely by North America at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years due to rapid urbanization, increasing construction activities, and growing automotive production in countries like China and India.

Consumer willingness to pay premium prices for self-cleaning technologies varies significantly across sectors. In high-end residential and commercial construction, consumers demonstrate up to 15-20% price premium acceptance for self-cleaning features. The automotive sector shows moderate price sensitivity with 10-15% premium acceptance, while mass-market construction applications remain highly price-sensitive.

Key market drivers include increasing labor costs for cleaning and maintenance, growing environmental concerns regarding chemical cleaning agents, and technological advancements reducing the production costs of hydrophobic materials. Regulatory trends favoring water conservation and reduced chemical usage further support market expansion. However, market challenges persist, including durability concerns of current hydrophobic coatings, inconsistent performance across varying environmental conditions, and relatively high initial implementation costs.

The competitive landscape features both established chemical companies and innovative startups. Major players include PPG Industries, Saint-Gobain, and Nippon Paint dominating with comprehensive product portfolios, while specialized companies like NBD Nano and Aculon drive innovation through advanced hydrophobic technologies.

Current Hydrophobic Technology Landscape & Challenges

The global landscape of hydrophobic surface technologies has evolved significantly over the past decade, with major advancements in both fundamental understanding and practical applications. Currently, several key technologies dominate the field, including superhydrophobic coatings based on fluorinated compounds, silicone-based repellent treatments, and biomimetic structured surfaces inspired by natural phenomena like the lotus leaf effect.

Despite these advancements, significant challenges persist in the development and implementation of hydrophobic technologies for self-cleaning surfaces. Durability remains a primary concern, as many hydrophobic coatings deteriorate under mechanical abrasion, UV exposure, and chemical attack. Commercial applications often require surfaces to maintain their hydrophobic properties for years, yet many current solutions begin to degrade after months of environmental exposure.

Cost-effectiveness presents another substantial barrier to widespread adoption. High-performance hydrophobic treatments typically involve expensive materials or complex manufacturing processes, limiting their application to premium products or specialized industries. The scalability of production methods for structured surfaces with micro and nano-features remains particularly problematic for mass-market implementation.

Environmental considerations have also emerged as a critical challenge. Traditional fluorinated compounds that deliver excellent hydrophobicity face increasing regulatory scrutiny due to their persistence in the environment and potential toxicity. This has accelerated research into more sustainable alternatives, though these often demonstrate inferior performance or longevity compared to conventional options.

The geographical distribution of hydrophobic technology development shows concentration in several key regions. North America and Europe lead in fundamental research and patent filings, while East Asian countries, particularly Japan and South Korea, demonstrate strength in commercial applications and manufacturing innovations. China has rapidly emerged as a significant player, with substantial increases in both research output and industrial implementation over the past five years.

Technical limitations in current hydrophobic technologies include the trade-off between transparency and hydrophobicity, challenges in maintaining performance on flexible substrates, and difficulties in creating multifunctional surfaces that combine hydrophobicity with other desirable properties such as anti-icing or antimicrobial capabilities.

Recent research has focused on addressing these challenges through approaches such as hierarchical surface structures, hybrid organic-inorganic compositions, and self-healing materials that can restore hydrophobic properties after damage. However, the translation of these laboratory innovations into commercially viable products remains a significant hurdle for the industry.

Despite these advancements, significant challenges persist in the development and implementation of hydrophobic technologies for self-cleaning surfaces. Durability remains a primary concern, as many hydrophobic coatings deteriorate under mechanical abrasion, UV exposure, and chemical attack. Commercial applications often require surfaces to maintain their hydrophobic properties for years, yet many current solutions begin to degrade after months of environmental exposure.

Cost-effectiveness presents another substantial barrier to widespread adoption. High-performance hydrophobic treatments typically involve expensive materials or complex manufacturing processes, limiting their application to premium products or specialized industries. The scalability of production methods for structured surfaces with micro and nano-features remains particularly problematic for mass-market implementation.

Environmental considerations have also emerged as a critical challenge. Traditional fluorinated compounds that deliver excellent hydrophobicity face increasing regulatory scrutiny due to their persistence in the environment and potential toxicity. This has accelerated research into more sustainable alternatives, though these often demonstrate inferior performance or longevity compared to conventional options.

The geographical distribution of hydrophobic technology development shows concentration in several key regions. North America and Europe lead in fundamental research and patent filings, while East Asian countries, particularly Japan and South Korea, demonstrate strength in commercial applications and manufacturing innovations. China has rapidly emerged as a significant player, with substantial increases in both research output and industrial implementation over the past five years.

Technical limitations in current hydrophobic technologies include the trade-off between transparency and hydrophobicity, challenges in maintaining performance on flexible substrates, and difficulties in creating multifunctional surfaces that combine hydrophobicity with other desirable properties such as anti-icing or antimicrobial capabilities.

Recent research has focused on addressing these challenges through approaches such as hierarchical surface structures, hybrid organic-inorganic compositions, and self-healing materials that can restore hydrophobic properties after damage. However, the translation of these laboratory innovations into commercially viable products remains a significant hurdle for the industry.

Current Hydrophobic Self-cleaning Surface Solutions

01 Superhydrophobic coatings for self-cleaning surfaces

Superhydrophobic coatings can be applied to surfaces to create self-cleaning properties. These coatings typically have a water contact angle greater than 150° and a low sliding angle, allowing water droplets to easily roll off the surface, carrying away dirt and contaminants. The coatings often combine micro and nano-scale roughness with low surface energy materials to achieve the lotus effect, where water beads up and rolls off instead of spreading on the surface.- Superhydrophobic coatings for self-cleaning surfaces: Superhydrophobic coatings can be applied to surfaces to create self-cleaning properties. These coatings typically have a water contact angle greater than 150° and low sliding angle, allowing water droplets to easily roll off the surface, carrying away dirt and contaminants. The coatings often combine micro and nano-scale roughness with low surface energy materials to achieve the lotus effect, where water beads up and rolls off instead of spreading on the surface.

- Nanostructured surfaces for enhanced hydrophobicity: Nanostructured surfaces can significantly enhance hydrophobic properties for self-cleaning applications. By creating nanoscale patterns or textures on surfaces, the actual contact area between water droplets and the surface is minimized, increasing the water contact angle. These nanostructures can be fabricated using various methods including lithography, etching, deposition, or self-assembly techniques. The resulting surfaces exhibit excellent water repellency and self-cleaning capabilities.

- Biomimetic approaches to self-cleaning surfaces: Biomimetic approaches involve mimicking natural self-cleaning surfaces such as lotus leaves, butterfly wings, and gecko feet to develop synthetic self-cleaning materials. These natural surfaces have evolved unique micro and nano-scale structures that create superhydrophobic properties. By understanding and replicating these biological designs, researchers can develop artificial self-cleaning surfaces with optimized hydrophobicity for various applications including building facades, solar panels, and textiles.

- Chemical modifications for hydrophobic self-cleaning surfaces: Chemical modifications can be applied to surfaces to enhance their hydrophobicity and self-cleaning properties. These modifications typically involve applying low surface energy compounds such as fluorinated polymers, silanes, or silicones that reduce the surface energy and increase water contact angles. Chemical treatments can be combined with physical surface texturing to create durable self-cleaning surfaces that maintain their hydrophobic properties over extended periods of use and exposure to environmental conditions.

- Smart self-cleaning surfaces with switchable hydrophobicity: Smart self-cleaning surfaces feature switchable hydrophobicity that can be controlled by external stimuli such as temperature, pH, light, or electric fields. These surfaces can transition between hydrophobic and hydrophilic states on demand, allowing for adaptive self-cleaning functionality. The ability to switch surface properties enables more versatile applications where both water-repellent and water-attracting behaviors might be beneficial under different conditions or for different purposes.

02 Nanostructured surfaces for enhanced hydrophobicity

Nanostructured surfaces can significantly enhance hydrophobic properties for self-cleaning applications. By creating nanoscale patterns or textures on surfaces, the contact area between water droplets and the surface is minimized, increasing the water contact angle. These nanostructures can be fabricated using various methods including lithography, etching, deposition, or self-assembly techniques. The resulting surfaces exhibit excellent water repellency and self-cleaning capabilities.Expand Specific Solutions03 Biomimetic approaches to self-cleaning surfaces

Biomimetic approaches involve mimicking natural hydrophobic surfaces such as lotus leaves, butterfly wings, or shark skin to create artificial self-cleaning surfaces. These natural surfaces have evolved specific micro and nano-structures that provide exceptional water repellency. By understanding and replicating these biological structures, researchers can develop synthetic self-cleaning surfaces with similar properties. These biomimetic surfaces often combine hierarchical structures with chemical modifications to achieve optimal hydrophobicity.Expand Specific Solutions04 Polymer-based hydrophobic coatings

Polymer-based hydrophobic coatings offer versatile solutions for creating self-cleaning surfaces. These coatings typically incorporate fluoropolymers, silicones, or other hydrophobic polymers that lower the surface energy. The polymers can be modified with additives or structured to enhance their water-repellent properties. These coatings are often easy to apply, durable, and can be tailored for specific applications ranging from textiles to building materials, providing long-lasting self-cleaning functionality.Expand Specific Solutions05 Self-cleaning surfaces for specific applications

Self-cleaning hydrophobic surfaces are designed for specific applications such as solar panels, windows, automotive surfaces, and electronic devices. These specialized surfaces address unique challenges related to their operating environments. For example, self-cleaning coatings for solar panels must maintain transparency while repelling dust and water to maintain energy efficiency. Similarly, automotive applications require durability against weathering and mechanical stress while maintaining water repellency for visibility and cleanliness.Expand Specific Solutions

Leading Companies in Hydrophobic Surface Industry

The hydrophobic self-cleaning surface design market is currently in a growth phase, with increasing applications across automotive, construction, and consumer goods sectors. The global market size for self-cleaning coatings is projected to reach approximately $3.5 billion by 2025, driven by growing demand for maintenance-free surfaces. Technologically, the field is advancing from basic hydrophobic coatings to more sophisticated multi-functional surfaces. Leading companies demonstrate varying levels of technical maturity: 3M and Evonik have established commercial product lines with advanced hydrophobic technologies, while research institutions like Industrial Technology Research Institute and Georgia Tech Research Corp are developing next-generation solutions. Companies like Fraunhofer-Gesellschaft and Beneq are pioneering atomic layer deposition techniques for superior hydrophobic performance, while automotive manufacturers such as Hyundai are integrating these technologies into vehicle surfaces for enhanced durability and aesthetics.

Evonik Operations GmbH

Technical Solution: Evonik has developed advanced hydrophobic coating technologies based on silica nanoparticles and fluorinated polymers that create hierarchical surface structures mimicking the lotus leaf effect. Their AEROSIL® and AEROXIDE® nanoparticle systems create nano-roughness that, when combined with hydrophobic chemical treatments, achieve water contact angles exceeding 150° for superhydrophobicity. Evonik's approach involves creating dual-scale roughness (micro and nano) on surfaces, then applying specialized silanes and fluorosilanes that lower surface energy to below 20 mN/m. Their TEGOTOP® series specifically targets self-cleaning applications by maintaining air pockets between water droplets and the solid surface, enabling the easy rolling of droplets that collect contaminants. The company has also pioneered durable hydrophobic coatings that maintain functionality after 10,000+ abrasion cycles through chemical bonding of the hydrophobic agents to substrate materials.

Strengths: Superior durability through chemical bonding technology; comprehensive product portfolio spanning industrial to consumer applications; proprietary nanoparticle technology enabling precise control of surface roughness. Weaknesses: Higher cost compared to conventional treatments; some formulations contain fluorinated compounds facing increasing regulatory scrutiny; application process requires careful control of environmental conditions for optimal performance.

3M Innovative Properties Co.

Technical Solution: 3M has pioneered hydrophobic surface technologies through their Scotchgard™ and Novec™ product lines, focusing on fluorochemical-based treatments that create low surface energy barriers. Their approach combines fluoropolymer chemistry with engineered surface texturing to achieve water contact angles of 110-150°. 3M's technology creates hierarchical surface structures where microscale roughness is overlaid with nanoscale features, then treated with proprietary fluorochemical compounds that reduce surface energy to approximately 10-15 mN/m. Their Easy Clean Coating technology specifically leverages the relationship between hydrophobicity and self-cleaning by creating surfaces where the adhesion force between water droplets and contaminants exceeds the adhesion between droplets and the surface. 3M has also developed spray-applicable hydrophobic treatments that can be applied to existing surfaces, forming transparent layers that maintain optical clarity while providing water and oil repellency, with demonstrated durability of 1-3 years in outdoor applications.

Strengths: Extensive expertise in fluorochemical technology providing excellent oil and water repellency; broad application versatility across multiple industries; established manufacturing infrastructure enabling consistent quality and global distribution. Weaknesses: Environmental concerns regarding some fluorinated compounds; relatively high cost compared to conventional treatments; performance degradation under high-abrasion conditions requiring periodic reapplication.

Key Hydrophobic Mechanisms & Scientific Principles

Self-cleaning surfaces with hydrophobic structures and process for making them

PatentInactiveEP1249280A3

Innovation

- A self-cleaning surface with a hydrophobic structure in the nanometer range is created by fixing particles with jagged elevations and depressions onto a surface using a carrier, which reduces mechanical stress and allows for easy cleaning without damaging scratch-sensitive surfaces, and can be applied to various shapes and materials.

Self cleaning surfaces having a surface structure made up of hydrophobic structural particles and wax particles

PatentInactiveEP1674535A1

Innovation

- A self-cleaning surface is created using a mixture of hydrophobic metal oxide particles and wax particles fixed to a surface with a carrier, which enhances mechanical stability while maintaining the fine structure and self-cleaning properties, with the wax particles providing support and protection against mechanical load.

Environmental Impact & Sustainability Considerations

The adoption of hydrophobic self-cleaning surfaces represents a significant advancement in sustainable technology, offering substantial environmental benefits across multiple sectors. These surfaces drastically reduce the need for chemical cleaning agents, many of which contain harmful compounds that contaminate water systems and soil when discharged. By minimizing reliance on these chemicals, hydrophobic surfaces help prevent the introduction of persistent pollutants into ecosystems, protecting aquatic life and maintaining biodiversity.

Water conservation constitutes another critical environmental advantage of hydrophobic self-cleaning surfaces. Traditional cleaning methods typically consume large volumes of water, particularly in industrial and commercial applications. Self-cleaning surfaces can reduce water usage by up to 70% in certain applications, contributing significantly to conservation efforts in water-stressed regions and reducing the energy footprint associated with water treatment and distribution.

The longevity of hydrophobic surfaces further enhances their sustainability profile. By resisting degradation from environmental factors and maintaining functionality over extended periods, these surfaces reduce the frequency of replacement and refurbishment. This durability translates directly into reduced resource consumption and waste generation throughout the product lifecycle, aligning with circular economy principles.

Energy efficiency represents another dimension of environmental impact. Buildings equipped with self-cleaning hydrophobic facades require less maintenance and cleaning, reducing the energy consumption associated with access equipment and cleaning operations. In solar applications, hydrophobic coatings on photovoltaic panels prevent dust accumulation, maintaining optimal energy generation efficiency without frequent water-intensive cleaning.

Manufacturing processes for hydrophobic surfaces present both challenges and opportunities from a sustainability perspective. While some production methods involve energy-intensive processes or potentially harmful chemicals, significant advancements in green chemistry approaches are emerging. Bio-inspired hydrophobic materials derived from renewable resources offer promising alternatives to conventional synthetic compounds, potentially reducing the carbon footprint of production.

End-of-life considerations must also factor into sustainability assessments. Research into biodegradable hydrophobic coatings and recyclable substrate materials is advancing, though challenges remain in separating composite materials for effective recycling. Life cycle assessment studies indicate that despite potential manufacturing impacts, the net environmental benefit of hydrophobic self-cleaning surfaces is positive when considering reduced cleaning chemical use, water conservation, and extended service life.

Water conservation constitutes another critical environmental advantage of hydrophobic self-cleaning surfaces. Traditional cleaning methods typically consume large volumes of water, particularly in industrial and commercial applications. Self-cleaning surfaces can reduce water usage by up to 70% in certain applications, contributing significantly to conservation efforts in water-stressed regions and reducing the energy footprint associated with water treatment and distribution.

The longevity of hydrophobic surfaces further enhances their sustainability profile. By resisting degradation from environmental factors and maintaining functionality over extended periods, these surfaces reduce the frequency of replacement and refurbishment. This durability translates directly into reduced resource consumption and waste generation throughout the product lifecycle, aligning with circular economy principles.

Energy efficiency represents another dimension of environmental impact. Buildings equipped with self-cleaning hydrophobic facades require less maintenance and cleaning, reducing the energy consumption associated with access equipment and cleaning operations. In solar applications, hydrophobic coatings on photovoltaic panels prevent dust accumulation, maintaining optimal energy generation efficiency without frequent water-intensive cleaning.

Manufacturing processes for hydrophobic surfaces present both challenges and opportunities from a sustainability perspective. While some production methods involve energy-intensive processes or potentially harmful chemicals, significant advancements in green chemistry approaches are emerging. Bio-inspired hydrophobic materials derived from renewable resources offer promising alternatives to conventional synthetic compounds, potentially reducing the carbon footprint of production.

End-of-life considerations must also factor into sustainability assessments. Research into biodegradable hydrophobic coatings and recyclable substrate materials is advancing, though challenges remain in separating composite materials for effective recycling. Life cycle assessment studies indicate that despite potential manufacturing impacts, the net environmental benefit of hydrophobic self-cleaning surfaces is positive when considering reduced cleaning chemical use, water conservation, and extended service life.

Durability & Performance Testing Methodologies

Testing the durability and performance of hydrophobic self-cleaning surfaces requires rigorous methodologies to ensure their effectiveness in real-world applications. Standard testing protocols typically include accelerated weathering tests that simulate extended exposure to UV radiation, temperature fluctuations, and moisture cycles. These tests often utilize equipment such as QUV accelerated weathering testers or xenon arc chambers to replicate years of environmental exposure in a compressed timeframe.

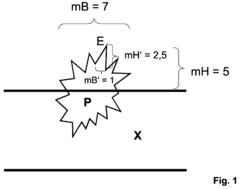

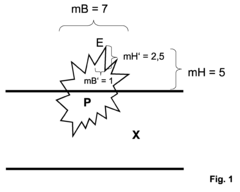

Contact angle measurement serves as a fundamental quantitative assessment for hydrophobic surfaces. The static water contact angle should ideally exceed 150° for superhydrophobic surfaces, while sliding angle measurements (the tilting angle at which a water droplet begins to move) should be below 10° to demonstrate effective self-cleaning properties. These measurements must be conducted before and after durability testing to evaluate performance degradation.

Abrasion resistance testing is critical for surfaces expected to withstand physical contact. Linear abrasion testers applying standardized forces with defined abrasive materials (typically following ASTM D4060 or ISO 11998 protocols) can quantify coating durability through weight loss measurements and hydrophobicity retention after specified cycles. For more severe applications, sand erosion tests or scratch resistance evaluations may be implemented.

Chemical resistance evaluation involves exposing surfaces to various substances including acidic and alkaline solutions, organic solvents, and cleaning agents. Surfaces are typically immersed or subjected to chemical droplets for predetermined periods, after which hydrophobicity, appearance, and structural integrity are reassessed.

Self-cleaning efficacy testing employs standardized contaminants (often carbon black, silica dust, or organic particulates) applied to surfaces at specified concentrations. Water droplets are then introduced to assess removal efficiency, typically quantified through optical measurements of surface cleanliness before and after water contact.

Adhesion testing following ASTM D3359 (tape test) or ASTM D4541 (pull-off test) evaluates the bonding strength between hydrophobic coatings and substrates. This is particularly important for applications where thermal cycling or mechanical stress might compromise coating adhesion.

Long-term performance monitoring in actual deployment environments provides the most valuable data, though it requires significant time investment. Field testing stations that expose samples to natural conditions while allowing periodic performance assessment represent the gold standard for validating laboratory predictions and ensuring real-world applicability of hydrophobic self-cleaning surfaces.

Contact angle measurement serves as a fundamental quantitative assessment for hydrophobic surfaces. The static water contact angle should ideally exceed 150° for superhydrophobic surfaces, while sliding angle measurements (the tilting angle at which a water droplet begins to move) should be below 10° to demonstrate effective self-cleaning properties. These measurements must be conducted before and after durability testing to evaluate performance degradation.

Abrasion resistance testing is critical for surfaces expected to withstand physical contact. Linear abrasion testers applying standardized forces with defined abrasive materials (typically following ASTM D4060 or ISO 11998 protocols) can quantify coating durability through weight loss measurements and hydrophobicity retention after specified cycles. For more severe applications, sand erosion tests or scratch resistance evaluations may be implemented.

Chemical resistance evaluation involves exposing surfaces to various substances including acidic and alkaline solutions, organic solvents, and cleaning agents. Surfaces are typically immersed or subjected to chemical droplets for predetermined periods, after which hydrophobicity, appearance, and structural integrity are reassessed.

Self-cleaning efficacy testing employs standardized contaminants (often carbon black, silica dust, or organic particulates) applied to surfaces at specified concentrations. Water droplets are then introduced to assess removal efficiency, typically quantified through optical measurements of surface cleanliness before and after water contact.

Adhesion testing following ASTM D3359 (tape test) or ASTM D4541 (pull-off test) evaluates the bonding strength between hydrophobic coatings and substrates. This is particularly important for applications where thermal cycling or mechanical stress might compromise coating adhesion.

Long-term performance monitoring in actual deployment environments provides the most valuable data, though it requires significant time investment. Field testing stations that expose samples to natural conditions while allowing periodic performance assessment represent the gold standard for validating laboratory predictions and ensuring real-world applicability of hydrophobic self-cleaning surfaces.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!