How Self-cleaning Surfaces Can Contribute to Zero Waste Goals

OCT 14, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-cleaning Surface Technology Background and Objectives

Self-cleaning surfaces represent a revolutionary advancement in materials science that has evolved significantly over the past two decades. Initially inspired by the lotus leaf's natural ability to repel water and contaminants, this technology has progressed from basic hydrophobic coatings to sophisticated multi-functional surfaces with autonomous cleaning capabilities. The evolution trajectory shows a clear shift from passive self-cleaning mechanisms toward active systems that can respond to environmental triggers without external intervention.

The fundamental principle behind self-cleaning surfaces involves creating micro and nano-structured topographies combined with specific chemical compositions that minimize adhesion forces between contaminants and the surface. This enables water droplets to easily roll off, carrying away dirt particles—a phenomenon known as the "lotus effect." More advanced iterations incorporate photocatalytic materials that break down organic contaminants when exposed to light, particularly titanium dioxide (TiO₂) which has become a cornerstone material in this field.

In the context of zero waste initiatives, self-cleaning surfaces present a compelling technological solution with multifaceted benefits. The primary objective of integrating these surfaces into zero waste strategies is to significantly reduce cleaning resource consumption—including water, chemical detergents, and energy—while extending product lifecycles and minimizing maintenance waste. By eliminating or drastically reducing the need for conventional cleaning processes, these surfaces directly address several waste streams simultaneously.

Current technological objectives focus on developing more durable self-cleaning coatings that maintain functionality over extended periods, even in harsh environmental conditions. Research aims to create omniphobic surfaces that repel not only water but also oils, organic solvents, and biological materials. Additionally, there is growing interest in developing self-healing properties that can restore damaged surface structures autonomously, further extending functional lifespans.

The convergence of nanotechnology, materials science, and sustainable engineering has accelerated innovation in this field, with particular emphasis on environmentally benign manufacturing processes and non-toxic formulations. Recent advancements have expanded potential applications beyond traditional architectural surfaces to include textiles, electronics, transportation, and medical devices—all sectors with significant waste footprints that could benefit from reduced cleaning and maintenance requirements.

As global sustainability initiatives gain momentum, self-cleaning surface technology is increasingly recognized as a strategic enabler for circular economy models by minimizing resource inputs and waste outputs throughout product lifecycles. The technology's evolution continues to be driven by both environmental imperatives and economic incentives, with projections suggesting substantial growth as implementation barriers decrease and performance capabilities expand.

The fundamental principle behind self-cleaning surfaces involves creating micro and nano-structured topographies combined with specific chemical compositions that minimize adhesion forces between contaminants and the surface. This enables water droplets to easily roll off, carrying away dirt particles—a phenomenon known as the "lotus effect." More advanced iterations incorporate photocatalytic materials that break down organic contaminants when exposed to light, particularly titanium dioxide (TiO₂) which has become a cornerstone material in this field.

In the context of zero waste initiatives, self-cleaning surfaces present a compelling technological solution with multifaceted benefits. The primary objective of integrating these surfaces into zero waste strategies is to significantly reduce cleaning resource consumption—including water, chemical detergents, and energy—while extending product lifecycles and minimizing maintenance waste. By eliminating or drastically reducing the need for conventional cleaning processes, these surfaces directly address several waste streams simultaneously.

Current technological objectives focus on developing more durable self-cleaning coatings that maintain functionality over extended periods, even in harsh environmental conditions. Research aims to create omniphobic surfaces that repel not only water but also oils, organic solvents, and biological materials. Additionally, there is growing interest in developing self-healing properties that can restore damaged surface structures autonomously, further extending functional lifespans.

The convergence of nanotechnology, materials science, and sustainable engineering has accelerated innovation in this field, with particular emphasis on environmentally benign manufacturing processes and non-toxic formulations. Recent advancements have expanded potential applications beyond traditional architectural surfaces to include textiles, electronics, transportation, and medical devices—all sectors with significant waste footprints that could benefit from reduced cleaning and maintenance requirements.

As global sustainability initiatives gain momentum, self-cleaning surface technology is increasingly recognized as a strategic enabler for circular economy models by minimizing resource inputs and waste outputs throughout product lifecycles. The technology's evolution continues to be driven by both environmental imperatives and economic incentives, with projections suggesting substantial growth as implementation barriers decrease and performance capabilities expand.

Market Demand Analysis for Waste Reduction Solutions

The global market for waste reduction solutions has witnessed significant growth in recent years, driven by increasing environmental concerns, regulatory pressures, and consumer awareness. Self-cleaning surfaces represent an innovative approach within this market, offering potential to substantially reduce cleaning-related waste generation. Current market analysis indicates that the global self-cleaning coatings market was valued at approximately $3.5 billion in 2022 and is projected to grow at a compound annual growth rate of 7.8% through 2030.

The demand for waste reduction technologies is particularly strong in urban centers and developed economies where waste management costs are high. Municipal governments worldwide spend over $200 billion annually on waste management, creating substantial incentive for preventative solutions. Self-cleaning surfaces directly address this need by minimizing the use of cleaning agents, reducing water consumption, and extending the lifespan of treated materials.

Healthcare facilities represent a primary market segment, where self-cleaning surfaces can reduce biohazard waste and minimize the use of harsh disinfectants. Hospitals typically generate 5-7 kg of waste per bed per day, with cleaning materials constituting a significant portion. The COVID-19 pandemic has accelerated demand in this sector, with heightened awareness of surface contamination driving a 34% increase in antimicrobial surface solution inquiries.

The commercial building sector presents another substantial market opportunity. Commercial buildings in the United States alone spend approximately $8.3 billion annually on cleaning services. Self-cleaning technologies can reduce these costs by 15-30% while simultaneously decreasing cleaning waste generation. Major commercial real estate developers have begun incorporating self-cleaning surfaces into new construction specifications, indicating growing market acceptance.

Consumer markets also show promising growth potential. Household cleaning products generate significant plastic waste, with over 1 billion plastic cleaning bottles discarded annually in the United States. Market research indicates that 67% of consumers would pay a premium for products that reduce household waste generation, creating a receptive market for self-cleaning consumer goods.

Transportation sectors, particularly aviation and public transit, represent emerging markets with substantial growth potential. These industries face intensive cleaning requirements and strict sanitation standards, making them ideal candidates for self-cleaning surface applications. The aviation industry alone spends approximately $3.8 billion annually on aircraft cleaning, with waste disposal representing a significant operational challenge.

Regional analysis shows the highest current adoption rates in Europe and North America, with Asia-Pacific representing the fastest-growing market. Regulatory frameworks supporting zero waste initiatives, particularly in the European Union, are creating favorable market conditions for self-cleaning technologies as part of broader waste reduction strategies.

The demand for waste reduction technologies is particularly strong in urban centers and developed economies where waste management costs are high. Municipal governments worldwide spend over $200 billion annually on waste management, creating substantial incentive for preventative solutions. Self-cleaning surfaces directly address this need by minimizing the use of cleaning agents, reducing water consumption, and extending the lifespan of treated materials.

Healthcare facilities represent a primary market segment, where self-cleaning surfaces can reduce biohazard waste and minimize the use of harsh disinfectants. Hospitals typically generate 5-7 kg of waste per bed per day, with cleaning materials constituting a significant portion. The COVID-19 pandemic has accelerated demand in this sector, with heightened awareness of surface contamination driving a 34% increase in antimicrobial surface solution inquiries.

The commercial building sector presents another substantial market opportunity. Commercial buildings in the United States alone spend approximately $8.3 billion annually on cleaning services. Self-cleaning technologies can reduce these costs by 15-30% while simultaneously decreasing cleaning waste generation. Major commercial real estate developers have begun incorporating self-cleaning surfaces into new construction specifications, indicating growing market acceptance.

Consumer markets also show promising growth potential. Household cleaning products generate significant plastic waste, with over 1 billion plastic cleaning bottles discarded annually in the United States. Market research indicates that 67% of consumers would pay a premium for products that reduce household waste generation, creating a receptive market for self-cleaning consumer goods.

Transportation sectors, particularly aviation and public transit, represent emerging markets with substantial growth potential. These industries face intensive cleaning requirements and strict sanitation standards, making them ideal candidates for self-cleaning surface applications. The aviation industry alone spends approximately $3.8 billion annually on aircraft cleaning, with waste disposal representing a significant operational challenge.

Regional analysis shows the highest current adoption rates in Europe and North America, with Asia-Pacific representing the fastest-growing market. Regulatory frameworks supporting zero waste initiatives, particularly in the European Union, are creating favorable market conditions for self-cleaning technologies as part of broader waste reduction strategies.

Current State and Challenges in Self-cleaning Technologies

Self-cleaning surface technologies have made significant strides globally, with varying levels of development across different regions. In North America and Europe, research institutions and companies have established advanced capabilities in developing hydrophobic and photocatalytic surfaces. Asia, particularly Japan and China, has emerged as a powerhouse in commercializing these technologies, with numerous patents filed annually for industrial applications.

The current technological landscape encompasses several distinct approaches. Superhydrophobic surfaces, inspired by the lotus leaf effect, utilize micro and nano-structured surfaces to repel water and contaminants effectively. Photocatalytic surfaces, primarily using titanium dioxide (TiO2), break down organic matter when exposed to UV light. More recent innovations include slippery liquid-infused porous surfaces (SLIPS) that maintain a lubricating layer to prevent adhesion of contaminants.

Despite these advancements, significant challenges persist in scaling self-cleaning technologies for widespread adoption in waste reduction strategies. Durability remains a primary concern, as many self-cleaning coatings deteriorate under mechanical abrasion, chemical exposure, or prolonged environmental conditions. Most current solutions require periodic maintenance or reapplication, limiting their long-term sustainability benefits.

Cost-effectiveness presents another substantial barrier. Manufacturing processes for creating micro and nanostructured surfaces often involve complex, energy-intensive methods that contradict zero waste principles. The economic viability gap between laboratory prototypes and mass-market products continues to impede widespread implementation.

Performance limitations also exist across different environmental conditions. Many photocatalytic materials require specific light wavelengths and intensities to function optimally, while superhydrophobic surfaces may lose effectiveness in high-humidity environments or when exposed to oils and organic solvents.

Toxicity concerns surround certain nanomaterials used in self-cleaning formulations, particularly regarding their potential environmental impact throughout their lifecycle. The release of nanoparticles during weathering or degradation raises questions about bioaccumulation and ecological effects, creating tension with zero waste objectives.

Standardization represents another challenge, as the industry lacks unified metrics for evaluating self-cleaning performance across different applications and environments. This hampers comparative assessment and slows adoption in regulated industries where performance guarantees are essential.

Integration challenges exist when incorporating self-cleaning properties into existing manufacturing processes and material systems without compromising other functional requirements or increasing waste generation during production. The balance between optimizing self-cleaning properties and maintaining structural integrity, appearance, and other performance characteristics remains difficult to achieve at scale.

The current technological landscape encompasses several distinct approaches. Superhydrophobic surfaces, inspired by the lotus leaf effect, utilize micro and nano-structured surfaces to repel water and contaminants effectively. Photocatalytic surfaces, primarily using titanium dioxide (TiO2), break down organic matter when exposed to UV light. More recent innovations include slippery liquid-infused porous surfaces (SLIPS) that maintain a lubricating layer to prevent adhesion of contaminants.

Despite these advancements, significant challenges persist in scaling self-cleaning technologies for widespread adoption in waste reduction strategies. Durability remains a primary concern, as many self-cleaning coatings deteriorate under mechanical abrasion, chemical exposure, or prolonged environmental conditions. Most current solutions require periodic maintenance or reapplication, limiting their long-term sustainability benefits.

Cost-effectiveness presents another substantial barrier. Manufacturing processes for creating micro and nanostructured surfaces often involve complex, energy-intensive methods that contradict zero waste principles. The economic viability gap between laboratory prototypes and mass-market products continues to impede widespread implementation.

Performance limitations also exist across different environmental conditions. Many photocatalytic materials require specific light wavelengths and intensities to function optimally, while superhydrophobic surfaces may lose effectiveness in high-humidity environments or when exposed to oils and organic solvents.

Toxicity concerns surround certain nanomaterials used in self-cleaning formulations, particularly regarding their potential environmental impact throughout their lifecycle. The release of nanoparticles during weathering or degradation raises questions about bioaccumulation and ecological effects, creating tension with zero waste objectives.

Standardization represents another challenge, as the industry lacks unified metrics for evaluating self-cleaning performance across different applications and environments. This hampers comparative assessment and slows adoption in regulated industries where performance guarantees are essential.

Integration challenges exist when incorporating self-cleaning properties into existing manufacturing processes and material systems without compromising other functional requirements or increasing waste generation during production. The balance between optimizing self-cleaning properties and maintaining structural integrity, appearance, and other performance characteristics remains difficult to achieve at scale.

Current Technical Solutions for Self-cleaning Surfaces

01 Hydrophobic self-cleaning surface technologies

Hydrophobic coatings create water-repellent surfaces that enable self-cleaning properties. These surfaces cause water droplets to bead up and roll off, carrying away dirt and contaminants. This technology reduces the need for chemical cleaners and water consumption in maintenance processes, contributing significantly to waste reduction. Applications include building exteriors, solar panels, and automotive surfaces where maintaining cleanliness without frequent manual cleaning is beneficial.- Hydrophobic self-cleaning surface technologies: Hydrophobic coatings and materials that repel water and contaminants, creating self-cleaning surfaces that reduce the need for chemical cleaners and water. These surfaces minimize waste by preventing dirt adhesion and reducing cleaning frequency. The technology often involves nanostructured materials or special polymers that create a lotus leaf effect, where water droplets roll off surfaces carrying away dirt particles.

- Photocatalytic self-cleaning materials: Materials incorporating photocatalysts like titanium dioxide that break down organic contaminants when exposed to light. These surfaces decompose pollutants and dirt into harmless byproducts, reducing the need for chemical cleaners and maintenance. The photocatalytic reaction converts harmful substances into water and carbon dioxide, effectively reducing waste and environmental impact while maintaining cleanliness.

- Waste reduction through automated cleaning systems: Automated and robotic cleaning systems that optimize the use of cleaning agents and water, significantly reducing waste compared to manual cleaning methods. These systems can precisely control the amount of cleaning resources used, target specific areas that need cleaning, and operate during off-hours to maximize efficiency. The technology includes sensors to detect dirt levels and adjust cleaning intensity accordingly.

- Sustainable waste management in cleaning processes: Innovative approaches to manage and reduce waste generated during cleaning processes, including water recycling systems, biodegradable cleaning agents, and waste separation technologies. These methods focus on minimizing environmental impact by reducing the volume of cleaning waste and ensuring proper disposal or recycling of unavoidable waste products.

- Smart surface materials with self-regenerating properties: Advanced materials with self-healing or self-regenerating properties that maintain their self-cleaning capabilities over extended periods, reducing replacement frequency and associated waste. These surfaces can repair minor damage through various mechanisms, including embedded microcapsules with healing agents or materials that respond to environmental triggers to restore functionality. The longevity of these materials significantly reduces waste from frequent replacement of conventional surfaces.

02 Photocatalytic self-cleaning materials

Photocatalytic materials, primarily based on titanium dioxide (TiO2), break down organic contaminants when exposed to light. These surfaces actively decompose pollutants, bacteria, and dirt through oxidation reactions triggered by UV radiation. The technology minimizes the need for chemical cleaning agents and extends maintenance intervals, resulting in reduced waste generation. These materials can be incorporated into building materials, glass, and various consumer products to provide continuous self-cleaning functionality.Expand Specific Solutions03 Automated waste reduction cleaning systems

Intelligent cleaning systems utilize sensors and automated mechanisms to optimize cleaning processes and reduce waste. These systems can detect the level of contamination and apply precise amounts of cleaning agents only where needed, minimizing overconsumption of resources. Features include water recycling capabilities, targeted cleaning mechanisms, and programmable cleaning cycles that adapt to actual usage patterns rather than fixed schedules, significantly reducing water, energy, and chemical waste.Expand Specific Solutions04 Biomimetic self-cleaning surface designs

Inspired by natural self-cleaning mechanisms like lotus leaves and butterfly wings, biomimetic surfaces incorporate micro and nano-structured patterns that minimize adhesion of contaminants. These surfaces reduce the need for cleaning agents and water by preventing dirt accumulation in the first place. The specialized surface topographies create superhydrophobic or superhydrophilic properties that either repel contaminants or spread water into thin sheets that efficiently carry away dirt, resulting in significant reductions in maintenance waste.Expand Specific Solutions05 Waste-reducing filtration and separation technologies

Advanced filtration and separation systems incorporate self-cleaning mechanisms to extend operational lifespans and reduce waste generation. These technologies include backwashing filters, vibration-assisted cleaning, and membrane systems with built-in cleaning capabilities. By maintaining efficiency without frequent replacement or manual cleaning, these systems minimize waste from discarded filter media and cleaning agents. Applications range from industrial water treatment to household appliances where continuous operation with minimal maintenance is desired.Expand Specific Solutions

Key Industry Players in Self-cleaning Surface Development

The self-cleaning surfaces market is currently in a growth phase, with increasing adoption across multiple industries as organizations pursue zero waste initiatives. The global market is estimated to reach $15 billion by 2028, driven by sustainability regulations and consumer demand for maintenance-free products. Technologically, the field shows varying maturity levels, with established players like Pilkington Group and Evonik Operations offering commercial solutions using hydrophobic and photocatalytic technologies, while research institutions such as Industrial Technology Research Institute and University of Liverpool are developing next-generation biomimetic approaches. Companies like ARL Designs and CSG Holding are bridging research-to-market gaps with specialized applications in solar energy and building materials, creating a competitive landscape balanced between established chemical companies and innovative materials science startups.

Evonik Operations GmbH

Technical Solution: Evonik has developed advanced self-cleaning coatings based on their proprietary silica nanoparticle technology. Their AEROSIL® and AEROXIDE® product lines create superhydrophobic surfaces that repel water and contaminants through the "lotus effect." These coatings incorporate titanium dioxide (TiO2) photocatalysts that break down organic matter when exposed to UV light. Evonik's technology creates hierarchical surface structures at micro and nano scales, allowing water droplets to roll off surfaces carrying away dirt particles. Their solutions are particularly effective for architectural glass, solar panels, and automotive applications, reducing the need for chemical cleaners and water consumption in maintenance processes. Recent innovations include incorporating antimicrobial properties into their coatings, further enhancing sustainability by reducing biofouling and extending product lifecycles.

Strengths: Industry-leading expertise in specialty chemicals and nanomaterials; extensive R&D capabilities; global manufacturing infrastructure. Weaknesses: Higher cost compared to conventional coatings; some formulations require specific application conditions; photocatalytic versions require UV exposure to function optimally.

Pilkington Group Ltd.

Technical Solution: Pilkington Group has pioneered self-cleaning glass technology with their Pilkington Activ™ product line, which utilizes a dual-action process to maintain clean surfaces. The technology employs a thin transparent coating of titanium dioxide that creates a photocatalytic effect when exposed to UV radiation, breaking down organic dirt particles. Additionally, the coating creates a hydrophilic surface where rainwater spreads evenly rather than forming droplets, washing away loosened dirt particles. This technology significantly reduces the need for manual cleaning, chemical detergents, and water consumption. Pilkington has expanded this technology to various glass applications including windows, facades, conservatories, and solar panels. Their latest innovations include enhanced durability coatings that maintain self-cleaning properties for over 25 years, contributing substantially to building lifecycle sustainability and waste reduction.

Strengths: Market leader in self-cleaning glass; established manufacturing and distribution networks; proven technology with decades of real-world performance data. Weaknesses: Limited to glass substrates; requires some rainfall for optimal cleaning action; higher initial cost compared to standard glass products.

Core Innovations in Self-cleaning Material Science

Self-cleaning surface with hydrophobic structure and process for making it

PatentInactiveEP1249281A3

Innovation

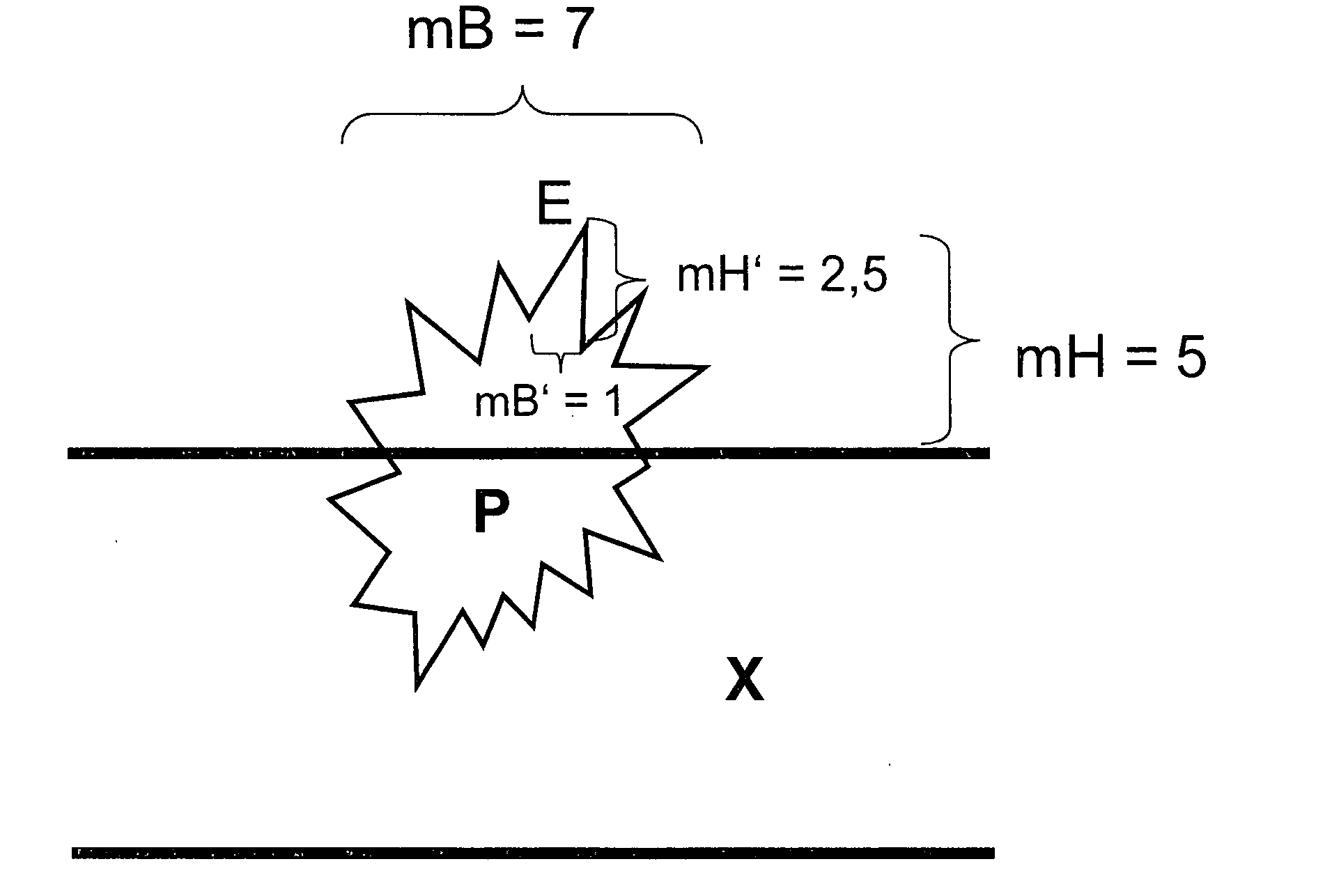

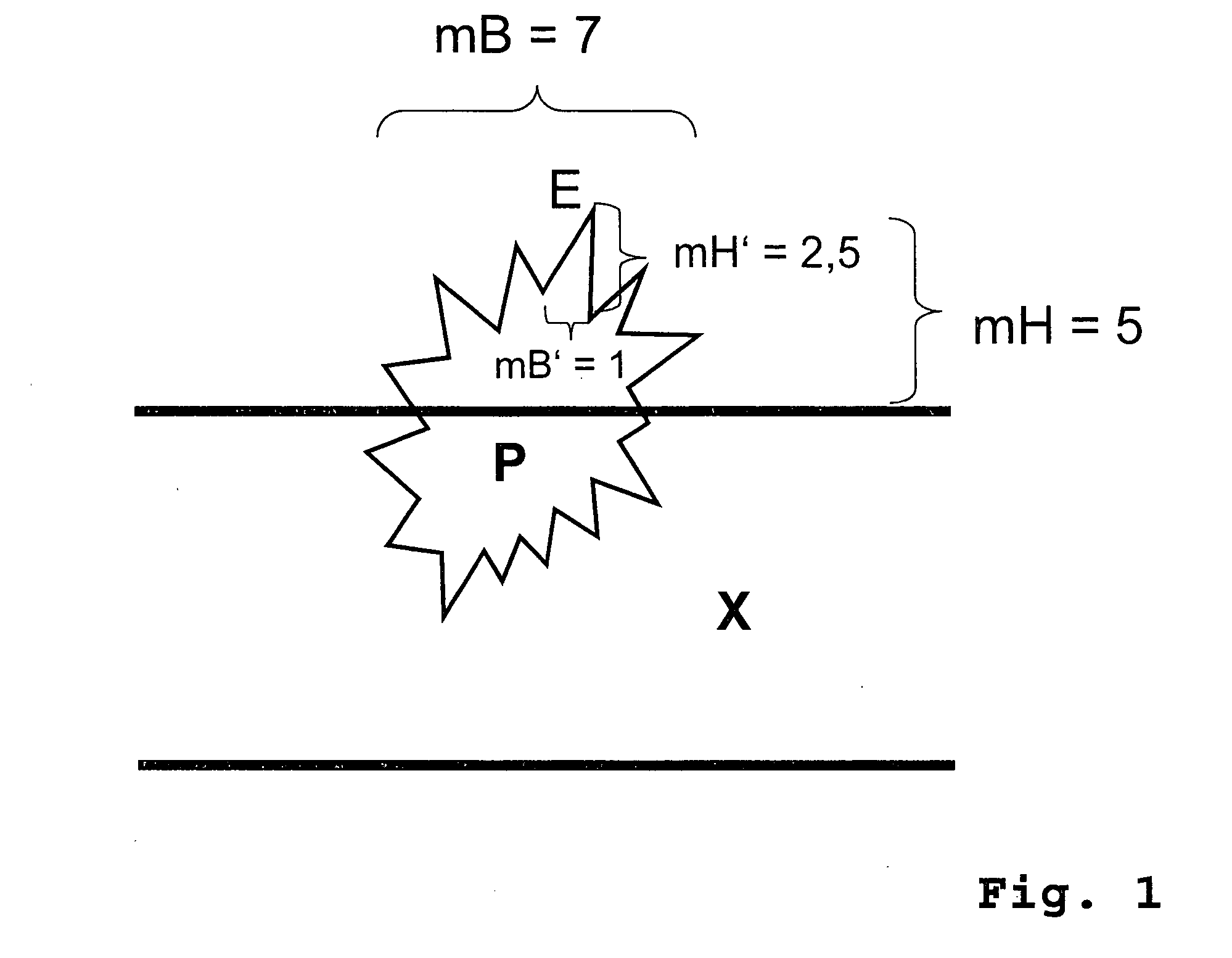

- The use of particles with a jagged, nanoscale structure and hydrophobic properties, fixed onto a surface to create a self-cleaning surface with elevations and depressions in the nanometer range, which reduces adhesion and enhances the rolling of water droplets, allowing for efficient dirt removal and improved mechanical stability.

Self-cleaning surfaces comprising elevations formed by hydrophobic particles and having improved mechanical strength

PatentActiveUS20060147675A1

Innovation

- A self-cleaning surface is created using a mixture of hydrophobic metal oxide particles and wax particles, fixed to a substrate, which enhances mechanical stability by providing a supporting effect similar to fins, allowing for higher abrasion resistance without compromising the self-cleaning properties.

Environmental Impact Assessment of Self-cleaning Solutions

The environmental impact of self-cleaning surfaces extends far beyond their immediate functionality, representing a significant advancement in sustainable technology. When properly implemented, these surfaces can substantially reduce water consumption compared to traditional cleaning methods. Conventional cleaning processes often require large volumes of water, particularly in industrial settings or for large-scale applications such as building facades and solar panels. Self-cleaning surfaces can achieve the same or better cleanliness levels with minimal or no water input, potentially saving billions of gallons annually if widely adopted.

Chemical usage reduction represents another critical environmental benefit. Traditional cleaning typically involves detergents, solvents, and other cleaning agents that contain potentially harmful chemicals. These substances eventually enter water systems, contributing to pollution and affecting aquatic ecosystems. Self-cleaning technologies, particularly those utilizing photocatalytic processes or superhydrophobic properties, minimize or eliminate the need for these chemicals, reducing the overall chemical burden on the environment.

Energy conservation emerges as a third significant environmental advantage. The maintenance of clean surfaces, especially in solar panels and windows, directly impacts energy efficiency. Self-cleaning solar panels maintain optimal energy generation capacity without manual intervention, while self-cleaning windows in buildings can improve thermal regulation and reduce heating and cooling demands. This translates to lower energy consumption and reduced carbon emissions across multiple sectors.

Life cycle assessment (LCA) studies indicate that despite the resources required for manufacturing self-cleaning surfaces, their long-term environmental benefits generally outweigh the initial environmental costs. The extended functional lifespan of treated surfaces reduces replacement frequency and associated waste generation. However, certain self-cleaning technologies, particularly those incorporating nanomaterials, raise potential environmental concerns regarding particle release and bioaccumulation that require ongoing monitoring and research.

Waste stream reduction occurs through multiple pathways when self-cleaning technologies are implemented. By eliminating or reducing cleaning product packaging, decreasing maintenance-related waste, and extending product lifespans, these surfaces contribute directly to zero waste initiatives. Additionally, the reduction in cleaning-related labor and resources creates cascading environmental benefits throughout supply chains and service industries.

Climate impact considerations reveal that widespread adoption of self-cleaning technologies could contribute meaningfully to climate change mitigation strategies through reduced water pumping energy requirements, decreased chemical manufacturing demands, and improved energy efficiency in buildings and renewable energy systems.

Chemical usage reduction represents another critical environmental benefit. Traditional cleaning typically involves detergents, solvents, and other cleaning agents that contain potentially harmful chemicals. These substances eventually enter water systems, contributing to pollution and affecting aquatic ecosystems. Self-cleaning technologies, particularly those utilizing photocatalytic processes or superhydrophobic properties, minimize or eliminate the need for these chemicals, reducing the overall chemical burden on the environment.

Energy conservation emerges as a third significant environmental advantage. The maintenance of clean surfaces, especially in solar panels and windows, directly impacts energy efficiency. Self-cleaning solar panels maintain optimal energy generation capacity without manual intervention, while self-cleaning windows in buildings can improve thermal regulation and reduce heating and cooling demands. This translates to lower energy consumption and reduced carbon emissions across multiple sectors.

Life cycle assessment (LCA) studies indicate that despite the resources required for manufacturing self-cleaning surfaces, their long-term environmental benefits generally outweigh the initial environmental costs. The extended functional lifespan of treated surfaces reduces replacement frequency and associated waste generation. However, certain self-cleaning technologies, particularly those incorporating nanomaterials, raise potential environmental concerns regarding particle release and bioaccumulation that require ongoing monitoring and research.

Waste stream reduction occurs through multiple pathways when self-cleaning technologies are implemented. By eliminating or reducing cleaning product packaging, decreasing maintenance-related waste, and extending product lifespans, these surfaces contribute directly to zero waste initiatives. Additionally, the reduction in cleaning-related labor and resources creates cascading environmental benefits throughout supply chains and service industries.

Climate impact considerations reveal that widespread adoption of self-cleaning technologies could contribute meaningfully to climate change mitigation strategies through reduced water pumping energy requirements, decreased chemical manufacturing demands, and improved energy efficiency in buildings and renewable energy systems.

Circular Economy Integration Strategies

Integrating self-cleaning surfaces into circular economy frameworks represents a strategic approach to achieving zero waste goals. These surfaces can be designed to align with circular principles by utilizing biodegradable or recyclable materials in their construction. For instance, bio-based hydrophobic coatings derived from agricultural waste can replace traditional petroleum-based alternatives, creating a closed-loop system where materials continuously cycle through the economy.

Self-cleaning technologies can extend product lifecycles significantly, reducing the need for frequent replacement and minimizing waste generation. By incorporating these surfaces into durable goods, manufacturers can design products that maintain functionality and aesthetic appeal for longer periods, supporting the circular economy principle of keeping products in use. This approach shifts business models from linear "take-make-dispose" patterns to circular systems where value is preserved.

Resource efficiency is enhanced through strategic implementation of self-cleaning surfaces in water management systems. These surfaces can reduce water consumption for cleaning by up to 80% in certain applications, contributing to conservation of this vital resource. Additionally, the reduction in cleaning chemical usage decreases environmental pollution and supports closed material loops, as fewer harmful substances enter ecosystems.

Manufacturing processes for self-cleaning surfaces can be redesigned to eliminate waste through advanced production techniques. Digital fabrication methods enable precise application of self-cleaning coatings, minimizing material waste. Furthermore, modular design approaches allow for easier disassembly and recovery of materials at end-of-life, supporting circular material flows and resource recovery.

Cross-industry collaboration accelerates circular integration of self-cleaning technologies. Partnerships between material scientists, product designers, and waste management specialists can develop holistic solutions that consider the entire lifecycle of self-cleaning products. These collaborative ecosystems foster innovation in material recovery techniques specific to advanced surface technologies.

Policy frameworks play a crucial role in supporting the integration of self-cleaning surfaces into circular economy strategies. Extended producer responsibility regulations can incentivize manufacturers to design self-cleaning products with end-of-life recovery in mind. Meanwhile, green public procurement policies can create market demand for products incorporating sustainable self-cleaning technologies, driving industry-wide adoption of circular principles.

Self-cleaning technologies can extend product lifecycles significantly, reducing the need for frequent replacement and minimizing waste generation. By incorporating these surfaces into durable goods, manufacturers can design products that maintain functionality and aesthetic appeal for longer periods, supporting the circular economy principle of keeping products in use. This approach shifts business models from linear "take-make-dispose" patterns to circular systems where value is preserved.

Resource efficiency is enhanced through strategic implementation of self-cleaning surfaces in water management systems. These surfaces can reduce water consumption for cleaning by up to 80% in certain applications, contributing to conservation of this vital resource. Additionally, the reduction in cleaning chemical usage decreases environmental pollution and supports closed material loops, as fewer harmful substances enter ecosystems.

Manufacturing processes for self-cleaning surfaces can be redesigned to eliminate waste through advanced production techniques. Digital fabrication methods enable precise application of self-cleaning coatings, minimizing material waste. Furthermore, modular design approaches allow for easier disassembly and recovery of materials at end-of-life, supporting circular material flows and resource recovery.

Cross-industry collaboration accelerates circular integration of self-cleaning technologies. Partnerships between material scientists, product designers, and waste management specialists can develop holistic solutions that consider the entire lifecycle of self-cleaning products. These collaborative ecosystems foster innovation in material recovery techniques specific to advanced surface technologies.

Policy frameworks play a crucial role in supporting the integration of self-cleaning surfaces into circular economy strategies. Extended producer responsibility regulations can incentivize manufacturers to design self-cleaning products with end-of-life recovery in mind. Meanwhile, green public procurement policies can create market demand for products incorporating sustainable self-cleaning technologies, driving industry-wide adoption of circular principles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!