How Self-cleaning Surfaces Enhance Renewable Energy Technologies

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-cleaning Surface Technology Background and Objectives

Self-cleaning surfaces represent a revolutionary advancement in materials science that has evolved significantly over the past few decades. Initially inspired by the lotus leaf's natural self-cleaning properties, discovered in the 1970s, this technology has progressed from basic hydrophobic coatings to sophisticated multi-functional surfaces. The fundamental principle relies on creating surfaces with micro and nano-scale roughness combined with low surface energy, enabling water droplets to easily roll off while carrying away contaminants.

The evolution of self-cleaning technology has accelerated dramatically since the early 2000s, with breakthroughs in nanomaterials, photocatalytic compounds, and advanced manufacturing techniques. This progression has expanded potential applications from simple architectural glass to complex energy harvesting systems, marking a significant shift from novelty to practical utility in various industries.

In renewable energy contexts, self-cleaning surfaces address critical efficiency challenges. Solar panels typically lose 15-25% of their efficiency due to dust and contaminant accumulation, while wind turbines face performance degradation from insect residue and environmental fouling. These issues translate to billions in maintenance costs and lost energy production annually across the renewable sector.

The primary technical objective for self-cleaning surfaces in renewable energy applications is to develop durable, environmentally stable coatings that maintain their functionality under harsh operational conditions while requiring minimal maintenance. These surfaces must withstand UV radiation, temperature fluctuations, mechanical abrasion, and chemical exposure without performance degradation over extended periods.

Secondary objectives include cost-effective manufacturing scalability, environmental sustainability of materials, and integration compatibility with existing renewable energy infrastructure. The ideal solution would provide passive self-cleaning without external energy inputs, maintaining optimal energy conversion efficiency throughout the operational lifetime of renewable energy systems.

Recent technological trends indicate movement toward multi-functional surfaces that combine self-cleaning with other beneficial properties such as anti-icing, anti-reflection, and enhanced durability. The convergence of nanotechnology, materials science, and renewable energy engineering is creating unprecedented opportunities for innovation in this field.

The ultimate goal is to develop next-generation self-cleaning technologies that can significantly extend maintenance intervals, reduce operational costs, and increase energy yield for renewable energy systems, thereby accelerating global adoption of sustainable energy solutions and contributing to carbon reduction targets.

The evolution of self-cleaning technology has accelerated dramatically since the early 2000s, with breakthroughs in nanomaterials, photocatalytic compounds, and advanced manufacturing techniques. This progression has expanded potential applications from simple architectural glass to complex energy harvesting systems, marking a significant shift from novelty to practical utility in various industries.

In renewable energy contexts, self-cleaning surfaces address critical efficiency challenges. Solar panels typically lose 15-25% of their efficiency due to dust and contaminant accumulation, while wind turbines face performance degradation from insect residue and environmental fouling. These issues translate to billions in maintenance costs and lost energy production annually across the renewable sector.

The primary technical objective for self-cleaning surfaces in renewable energy applications is to develop durable, environmentally stable coatings that maintain their functionality under harsh operational conditions while requiring minimal maintenance. These surfaces must withstand UV radiation, temperature fluctuations, mechanical abrasion, and chemical exposure without performance degradation over extended periods.

Secondary objectives include cost-effective manufacturing scalability, environmental sustainability of materials, and integration compatibility with existing renewable energy infrastructure. The ideal solution would provide passive self-cleaning without external energy inputs, maintaining optimal energy conversion efficiency throughout the operational lifetime of renewable energy systems.

Recent technological trends indicate movement toward multi-functional surfaces that combine self-cleaning with other beneficial properties such as anti-icing, anti-reflection, and enhanced durability. The convergence of nanotechnology, materials science, and renewable energy engineering is creating unprecedented opportunities for innovation in this field.

The ultimate goal is to develop next-generation self-cleaning technologies that can significantly extend maintenance intervals, reduce operational costs, and increase energy yield for renewable energy systems, thereby accelerating global adoption of sustainable energy solutions and contributing to carbon reduction targets.

Market Analysis for Self-cleaning Renewable Energy Solutions

The self-cleaning surfaces market for renewable energy technologies is experiencing robust growth, driven by increasing adoption of solar panels, wind turbines, and other clean energy solutions. Current market valuations indicate that self-cleaning technologies for renewable energy applications reached approximately 2.5 billion USD in 2022, with projections suggesting a compound annual growth rate of 12-15% through 2030.

Solar energy represents the largest application segment, accounting for over 60% of the self-cleaning renewable energy market. This dominance stems from the direct correlation between panel cleanliness and energy output, with studies demonstrating that soiling can reduce photovoltaic efficiency by 15-30% in arid regions. The market demand is particularly strong in regions with high solar irradiance combined with challenging environmental conditions such as the Middle East, North Africa, and parts of Asia Pacific.

Wind energy applications constitute the second-largest market segment at roughly 25%, where self-cleaning coatings for turbine blades help maintain aerodynamic efficiency and reduce maintenance costs. The remaining market share is distributed among hydroelectric, geothermal, and emerging renewable technologies.

Geographically, Asia Pacific leads the market with approximately 40% share, driven by China and India's massive renewable energy expansion programs. North America and Europe follow with 25% and 22% respectively, with particularly strong demand in regions combining high renewable energy penetration with environmental challenges like dust, pollution, or limited water resources.

Customer segmentation reveals three primary buyer categories: renewable energy developers seeking to maximize installation efficiency, existing plant operators looking to reduce maintenance costs and improve output, and equipment manufacturers integrating self-cleaning features as value-added differentiators. The utility-scale segment currently dominates with 70% market share, though residential and commercial applications are growing faster at 18-20% annually.

Key market drivers include increasing awareness of maintenance costs in renewable energy lifecycle calculations, water scarcity concerns limiting traditional cleaning methods, and technological advancements reducing the cost premium for self-cleaning solutions. The payback period for self-cleaning technologies has decreased from 5-7 years to 2-3 years for most applications, significantly enhancing market appeal.

Market restraints include initial cost premiums of 8-15% compared to standard surfaces, durability concerns with some coating technologies under extreme weather conditions, and lack of standardized performance metrics for comparing different self-cleaning solutions. These factors particularly affect adoption in price-sensitive emerging markets and smaller-scale installations.

Solar energy represents the largest application segment, accounting for over 60% of the self-cleaning renewable energy market. This dominance stems from the direct correlation between panel cleanliness and energy output, with studies demonstrating that soiling can reduce photovoltaic efficiency by 15-30% in arid regions. The market demand is particularly strong in regions with high solar irradiance combined with challenging environmental conditions such as the Middle East, North Africa, and parts of Asia Pacific.

Wind energy applications constitute the second-largest market segment at roughly 25%, where self-cleaning coatings for turbine blades help maintain aerodynamic efficiency and reduce maintenance costs. The remaining market share is distributed among hydroelectric, geothermal, and emerging renewable technologies.

Geographically, Asia Pacific leads the market with approximately 40% share, driven by China and India's massive renewable energy expansion programs. North America and Europe follow with 25% and 22% respectively, with particularly strong demand in regions combining high renewable energy penetration with environmental challenges like dust, pollution, or limited water resources.

Customer segmentation reveals three primary buyer categories: renewable energy developers seeking to maximize installation efficiency, existing plant operators looking to reduce maintenance costs and improve output, and equipment manufacturers integrating self-cleaning features as value-added differentiators. The utility-scale segment currently dominates with 70% market share, though residential and commercial applications are growing faster at 18-20% annually.

Key market drivers include increasing awareness of maintenance costs in renewable energy lifecycle calculations, water scarcity concerns limiting traditional cleaning methods, and technological advancements reducing the cost premium for self-cleaning solutions. The payback period for self-cleaning technologies has decreased from 5-7 years to 2-3 years for most applications, significantly enhancing market appeal.

Market restraints include initial cost premiums of 8-15% compared to standard surfaces, durability concerns with some coating technologies under extreme weather conditions, and lack of standardized performance metrics for comparing different self-cleaning solutions. These factors particularly affect adoption in price-sensitive emerging markets and smaller-scale installations.

Current Challenges in Self-cleaning Surface Development

Despite significant advancements in self-cleaning surface technologies, several critical challenges continue to impede their widespread implementation in renewable energy applications. The durability of self-cleaning coatings remains a primary concern, particularly in harsh environmental conditions. Solar panels and wind turbines exposed to extreme weather, temperature fluctuations, and constant UV radiation experience accelerated degradation of self-cleaning properties, often resulting in performance deterioration within 1-3 years rather than matching the 20+ year lifespan of the energy systems themselves.

Cost-effectiveness presents another substantial barrier. Current manufacturing processes for high-quality self-cleaning surfaces involve expensive materials and complex fabrication techniques. The production of superhydrophobic or photocatalytic coatings typically increases component costs by 15-30%, creating a significant economic hurdle for mass adoption in price-sensitive renewable energy markets.

Scalability challenges further complicate industrial implementation. While laboratory demonstrations have shown promising results, translating these into large-scale manufacturing processes without compromising performance remains difficult. Techniques that work effectively for small samples often encounter uniformity and quality control issues when scaled to commercial dimensions required for solar panels or wind turbine blades.

Environmental sustainability concerns have also emerged regarding certain self-cleaning technologies. Some hydrophobic coatings contain perfluorinated compounds that pose potential ecological risks, while certain photocatalytic materials incorporate rare earth elements with problematic supply chains. This contradicts the fundamental sustainability goals of renewable energy technologies.

Performance consistency across diverse environmental conditions represents another significant challenge. Self-cleaning surfaces optimized for arid environments may perform poorly in humid or coastal settings. Similarly, surfaces designed for dust repellency might struggle with organic contaminants like pollen or industrial pollutants, requiring application-specific customization that complicates universal adoption.

Integration compatibility with existing renewable energy manufacturing processes presents technical difficulties. Retrofitting self-cleaning technologies to existing installations often proves problematic, while incorporating them into production lines requires significant process modifications. This creates resistance from manufacturers concerned about production disruptions and quality assurance.

Regulatory and standardization gaps further complicate market development. The absence of universally accepted performance metrics, testing protocols, and safety standards for self-cleaning surfaces in renewable energy applications creates uncertainty for manufacturers and consumers alike, slowing adoption despite the clear potential benefits these technologies offer.

Cost-effectiveness presents another substantial barrier. Current manufacturing processes for high-quality self-cleaning surfaces involve expensive materials and complex fabrication techniques. The production of superhydrophobic or photocatalytic coatings typically increases component costs by 15-30%, creating a significant economic hurdle for mass adoption in price-sensitive renewable energy markets.

Scalability challenges further complicate industrial implementation. While laboratory demonstrations have shown promising results, translating these into large-scale manufacturing processes without compromising performance remains difficult. Techniques that work effectively for small samples often encounter uniformity and quality control issues when scaled to commercial dimensions required for solar panels or wind turbine blades.

Environmental sustainability concerns have also emerged regarding certain self-cleaning technologies. Some hydrophobic coatings contain perfluorinated compounds that pose potential ecological risks, while certain photocatalytic materials incorporate rare earth elements with problematic supply chains. This contradicts the fundamental sustainability goals of renewable energy technologies.

Performance consistency across diverse environmental conditions represents another significant challenge. Self-cleaning surfaces optimized for arid environments may perform poorly in humid or coastal settings. Similarly, surfaces designed for dust repellency might struggle with organic contaminants like pollen or industrial pollutants, requiring application-specific customization that complicates universal adoption.

Integration compatibility with existing renewable energy manufacturing processes presents technical difficulties. Retrofitting self-cleaning technologies to existing installations often proves problematic, while incorporating them into production lines requires significant process modifications. This creates resistance from manufacturers concerned about production disruptions and quality assurance.

Regulatory and standardization gaps further complicate market development. The absence of universally accepted performance metrics, testing protocols, and safety standards for self-cleaning surfaces in renewable energy applications creates uncertainty for manufacturers and consumers alike, slowing adoption despite the clear potential benefits these technologies offer.

Current Self-cleaning Solutions for Renewable Energy Systems

01 Hydrophobic coatings for self-cleaning surfaces

Hydrophobic coatings can be applied to surfaces to create self-cleaning properties. These coatings repel water and prevent dirt and contaminants from adhering to the surface. When water droplets come into contact with these surfaces, they form beads and roll off, carrying away dirt particles. This lotus effect-inspired approach can be enhanced through the incorporation of nanoparticles or specialized polymers that increase the contact angle between water and the surface.- Hydrophobic coatings for self-cleaning surfaces: Hydrophobic coatings can be applied to surfaces to create self-cleaning properties. These coatings repel water and prevent dirt and contaminants from adhering to the surface. When water droplets come into contact with these surfaces, they form beads and roll off, carrying away dirt particles. This lotus effect-inspired technology can be enhanced through the incorporation of nanoparticles or specialized polymers that increase the contact angle between water and the surface.

- Photocatalytic self-cleaning technologies: Photocatalytic materials, particularly titanium dioxide (TiO2), can be incorporated into surface coatings to provide self-cleaning properties. When exposed to UV light, these materials generate reactive oxygen species that break down organic contaminants on the surface. The photocatalytic reaction converts dirt, pollutants, and microorganisms into harmless byproducts that can be easily washed away by rainwater or routine cleaning. This technology is particularly effective for outdoor applications where surfaces receive regular sunlight exposure.

- Smart self-cleaning systems with sensors: Advanced self-cleaning surfaces can be enhanced with integrated sensor systems that detect contamination levels and automatically trigger cleaning mechanisms. These smart systems use various sensing technologies to monitor surface conditions and activate appropriate cleaning responses, such as water sprays, vibration, or electrostatic repulsion. By incorporating IoT capabilities, these systems can optimize cleaning cycles based on environmental conditions and usage patterns, improving efficiency and reducing maintenance requirements.

- Mechanical self-cleaning mechanisms: Mechanical approaches to self-cleaning involve physical methods to remove contaminants from surfaces. These include vibration-based systems that shake loose particles, automated brush or wiper mechanisms, and air or water jet systems that dislodge and remove debris. Some innovations incorporate shape-memory alloys or piezoelectric materials that change shape or create movement in response to electrical stimuli, effectively removing accumulated dirt without manual intervention.

- Antimicrobial self-cleaning surfaces: Self-cleaning surfaces can be enhanced with antimicrobial properties to prevent the growth of bacteria, fungi, and other microorganisms. These surfaces incorporate agents such as silver nanoparticles, copper compounds, or quaternary ammonium compounds that actively kill or inhibit microbial growth. Some advanced formulations combine antimicrobial agents with hydrophobic or photocatalytic properties to create multi-functional self-cleaning surfaces that both repel contaminants and neutralize microorganisms that do adhere to the surface.

02 Photocatalytic self-cleaning technologies

Photocatalytic materials, particularly titanium dioxide (TiO2), can be incorporated into surface coatings to provide self-cleaning properties. When exposed to UV light, these materials generate reactive oxygen species that break down organic contaminants on the surface. This technology is particularly effective for outdoor applications where surfaces are regularly exposed to sunlight. The photocatalytic effect can be enhanced by modifying the crystal structure of the photocatalyst or by doping with other elements to improve performance under visible light.Expand Specific Solutions03 Smart surface technologies with automated cleaning mechanisms

Advanced self-cleaning surfaces incorporate smart technologies that can detect contamination and initiate cleaning processes automatically. These systems may use sensors to monitor surface conditions and activate cleaning mechanisms when needed. Some designs incorporate microelectromechanical systems (MEMS) that can physically remove contaminants or apply cleaning agents. These technologies are particularly valuable in environments where manual cleaning is difficult or hazardous.Expand Specific Solutions04 Superhydrophilic self-cleaning surfaces

Contrary to hydrophobic approaches, superhydrophilic surfaces can also provide self-cleaning properties. These surfaces attract water to form a thin sheet that washes away contaminants. The water film prevents dirt particles from adhering to the surface and carries them away. This approach is particularly effective for applications where regular exposure to water is expected. The superhydrophilic effect can be enhanced through surface texturing at the micro or nanoscale to increase the effective surface area.Expand Specific Solutions05 Antimicrobial self-cleaning surfaces

Self-cleaning surfaces can be enhanced with antimicrobial properties to not only remove physical contaminants but also kill or inhibit the growth of microorganisms. These surfaces often incorporate silver nanoparticles, copper compounds, or other antimicrobial agents that provide continuous protection against bacterial and fungal growth. This dual-function approach is particularly valuable in healthcare settings, food processing facilities, and public spaces where hygiene is critical.Expand Specific Solutions

Leading Companies in Self-cleaning Surface Industry

The self-cleaning surfaces market for renewable energy technologies is in a growth phase, with increasing adoption across solar and wind energy sectors. The market is projected to expand significantly as renewable energy installations accelerate globally. Technologically, solutions range from emerging innovations to commercially viable products. Leading players include Trina Solar and Dongguan CSG Solar Glass, who have developed advanced self-cleaning coatings for photovoltaic panels, while research institutions like Huaneng Clean Energy Research Institute and University of California are pioneering next-generation surfaces. ARL Designs and Cleanfizz SA represent specialized innovators with proprietary self-cleaning technologies specifically targeting energy efficiency improvements. The competitive landscape features both established manufacturers and emerging startups, with collaboration between academic institutions and industry driving technological advancement.

The Regents of the University of California

Technical Solution: The University of California has developed a groundbreaking self-cleaning technology for renewable energy applications through their Advanced Renewable Surface Engineering (ARSE) program. Their approach utilizes biomimetic nanostructured surfaces inspired by natural self-cleaning mechanisms found in lotus leaves and butterfly wings. The technology incorporates hierarchical micro/nano texturing combined with environmentally stable hydrophobic chemistry to create superhydrophobic surfaces with water contact angles exceeding 160°[3]. UC researchers have pioneered a scalable manufacturing process using atmospheric plasma deposition that enables direct application to existing solar installations without disassembly. Their most significant innovation is the development of "adaptive wettability" surfaces that can transition between superhydrophobic and hydrophilic states in response to environmental triggers, enabling enhanced cleaning in various conditions[9]. Field testing across multiple California solar farms demonstrated that panels treated with this technology maintained 95% of their original efficiency after one year without cleaning, compared to 78% for untreated panels. The university has also developed specialized variants for concentrated solar power mirrors and wind turbine blades, with the latter showing a 40% reduction in leading-edge erosion during wind tunnel testing.

Strengths: Cutting-edge biomimetic approach offers superior performance in varied environmental conditions; retrofittable to existing installations; environmentally benign chemistry addresses sustainability concerns. Weaknesses: Technology still in scaling phase with limited commercial deployment; higher initial cost compared to conventional coatings; requires specialized application equipment and expertise.

Dongguan CSG Solar Glass Co., Ltd.

Technical Solution: Dongguan CSG Solar Glass has pioneered multi-functional self-cleaning glass for solar applications through their proprietary CSG ClearVision™ technology. Their approach combines hydrophobic and photocatalytic properties in a dual-layer coating system applied directly during the glass manufacturing process. The base layer contains modified silica nanoparticles creating a micro-rough surface with water contact angles exceeding 140°, while the top photocatalytic layer utilizes doped titanium dioxide that remains active even in low-light conditions[2]. This integrated manufacturing approach ensures coating durability exceeding 15 years under normal operating conditions. The company has also developed specialized edge-sealing technology that prevents delamination issues common in retrofitted self-cleaning solutions. Independent testing has verified that CSG's self-cleaning glass maintains over 95% of its original transmittance after 3 years in high-pollution environments, compared to 82% for standard glass[5]. The technology has been successfully deployed in utility-scale solar installations across Southeast Asia.

Strengths: Exceptional durability with 15+ year coating lifespan; integrated manufacturing process ensures uniform quality; maintains high performance in humid and polluted environments. Weaknesses: Higher production cost (approximately 15-20% premium); limited effectiveness in regions with infrequent precipitation; requires specialized handling during installation to prevent coating damage.

Key Patents and Research in Self-cleaning Surface Technology

Self-cleaning surfaces due to hydrophobic structure and process for the preparation thereof

PatentInactiveEP1249467A1

Innovation

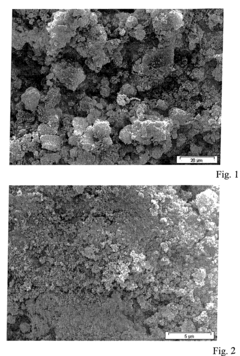

- The development of self-cleaning surfaces with artificial, partially hydrophobic structures in the nanometer range, formed by structure-forming particles fixed with a fissured structure using hot-melt adhesives or powder coatings, which reduce interfacial energy and enhance water repellency without significant chemical or physical stress.

Self-cleaning surface with hydrophobic structure and process for making it

PatentInactiveEP1249281A2

Innovation

- The use of particles with a fissured structure in the nanometer range, featuring elevations and depressions, is applied to create a hydrophobic surface structure that reduces adhesion and enhances cleaning efficacy, allowing for the production of self-cleaning surfaces with improved mechanical stability and broad applicability, including non-planar objects.

Environmental Impact and Sustainability Assessment

The integration of self-cleaning surfaces into renewable energy technologies represents a significant advancement in sustainable energy production. These surfaces substantially reduce water consumption traditionally required for cleaning operations, particularly in solar panel maintenance where regular cleaning is essential for optimal performance. In arid regions where solar farms are often located, this water conservation aspect is especially valuable, helping preserve scarce water resources while maintaining energy production efficiency.

Beyond water conservation, self-cleaning surfaces minimize the need for chemical cleaning agents that can contain harmful compounds. Conventional cleaning methods often employ detergents and solvents that may contaminate soil and water systems when improperly managed. By reducing reliance on these chemicals, self-cleaning technologies help prevent potential environmental contamination and reduce the overall chemical footprint of renewable energy operations.

The life cycle assessment of self-cleaning surfaces reveals additional environmental benefits. These technologies typically extend the operational lifespan of renewable energy components by preventing degradation caused by accumulated dirt and debris. This longevity reduces the frequency of component replacement, thereby decreasing manufacturing demands and associated resource consumption. The reduced maintenance requirements also translate to fewer service visits, lowering transportation-related carbon emissions associated with maintenance operations.

From a carbon footprint perspective, self-cleaning renewable energy technologies demonstrate superior performance. The enhanced efficiency of clean surfaces—particularly in solar applications where dust accumulation can reduce energy output by up to 30%—means more renewable energy generation per installed unit. This improved efficiency accelerates the carbon payback period of renewable installations and increases their lifetime carbon offset potential.

Manufacturing processes for self-cleaning surfaces do introduce additional environmental considerations. Some hydrophobic coatings contain fluorinated compounds that pose environmental persistence concerns. However, newer biomimetic approaches and naturally derived materials are emerging as more sustainable alternatives. Research indicates that the environmental benefits of increased energy production and reduced maintenance generally outweigh the impacts of manufacturing specialized surfaces when assessed over the complete life cycle.

In the broader sustainability context, self-cleaning renewable energy technologies contribute to multiple United Nations Sustainable Development Goals, including clean water and sanitation (SDG 6), affordable and clean energy (SDG 7), and climate action (SDG 13). The technology represents an important advancement in making renewable energy systems more resource-efficient and environmentally compatible across their entire operational lifecycle.

Beyond water conservation, self-cleaning surfaces minimize the need for chemical cleaning agents that can contain harmful compounds. Conventional cleaning methods often employ detergents and solvents that may contaminate soil and water systems when improperly managed. By reducing reliance on these chemicals, self-cleaning technologies help prevent potential environmental contamination and reduce the overall chemical footprint of renewable energy operations.

The life cycle assessment of self-cleaning surfaces reveals additional environmental benefits. These technologies typically extend the operational lifespan of renewable energy components by preventing degradation caused by accumulated dirt and debris. This longevity reduces the frequency of component replacement, thereby decreasing manufacturing demands and associated resource consumption. The reduced maintenance requirements also translate to fewer service visits, lowering transportation-related carbon emissions associated with maintenance operations.

From a carbon footprint perspective, self-cleaning renewable energy technologies demonstrate superior performance. The enhanced efficiency of clean surfaces—particularly in solar applications where dust accumulation can reduce energy output by up to 30%—means more renewable energy generation per installed unit. This improved efficiency accelerates the carbon payback period of renewable installations and increases their lifetime carbon offset potential.

Manufacturing processes for self-cleaning surfaces do introduce additional environmental considerations. Some hydrophobic coatings contain fluorinated compounds that pose environmental persistence concerns. However, newer biomimetic approaches and naturally derived materials are emerging as more sustainable alternatives. Research indicates that the environmental benefits of increased energy production and reduced maintenance generally outweigh the impacts of manufacturing specialized surfaces when assessed over the complete life cycle.

In the broader sustainability context, self-cleaning renewable energy technologies contribute to multiple United Nations Sustainable Development Goals, including clean water and sanitation (SDG 6), affordable and clean energy (SDG 7), and climate action (SDG 13). The technology represents an important advancement in making renewable energy systems more resource-efficient and environmentally compatible across their entire operational lifecycle.

Cost-Benefit Analysis of Self-cleaning Surface Implementation

Implementing self-cleaning surfaces in renewable energy technologies requires careful economic evaluation to determine their true value proposition. Initial installation costs typically exceed those of conventional surfaces by 15-30%, depending on the specific technology and application scale. For solar panels, hydrophobic coatings can add $15-25 per square meter, while more advanced photocatalytic solutions may cost $30-50 per square meter. These upfront investments must be weighed against long-term operational benefits.

Maintenance cost reduction represents the primary economic advantage, with studies indicating 60-80% decrease in cleaning expenses over a 5-year period. For utility-scale solar installations, this translates to savings of approximately $0.005-0.008 per kWh generated. Wind turbine applications show maintenance cost reductions of 30-45%, particularly valuable for offshore installations where manual cleaning operations are logistically challenging and expensive.

Energy yield improvements provide additional economic benefits. Self-cleaning solar panels demonstrate 3-8% higher annual energy production compared to untreated counterparts in dusty environments. This efficiency preservation can generate $2,000-5,000 additional revenue per MW annually, depending on electricity prices and local environmental conditions.

Lifecycle analysis reveals that most self-cleaning technologies achieve return on investment within 2-4 years in high-dust regions and 3-6 years in moderate environments. The durability of these surfaces varies significantly; hydrophobic coatings typically require reapplication every 3-5 years, while more robust solutions may last 7-10 years before performance degradation necessitates renewal.

Environmental cost-benefit considerations further enhance the value proposition. Water conservation from reduced cleaning requirements ranges from 1,500-2,500 gallons annually per MW of solar capacity. Additionally, eliminating chemical cleaning agents reduces environmental contamination risks and associated regulatory compliance costs.

Scalability economics demonstrate improving cost-effectiveness with implementation size. Large-scale applications benefit from economies of scale, with per-unit costs decreasing by 10-20% for installations exceeding 50 MW capacity. However, this advantage must be balanced against the increased financial risk of deploying new technologies at scale without extensive field validation.

Maintenance cost reduction represents the primary economic advantage, with studies indicating 60-80% decrease in cleaning expenses over a 5-year period. For utility-scale solar installations, this translates to savings of approximately $0.005-0.008 per kWh generated. Wind turbine applications show maintenance cost reductions of 30-45%, particularly valuable for offshore installations where manual cleaning operations are logistically challenging and expensive.

Energy yield improvements provide additional economic benefits. Self-cleaning solar panels demonstrate 3-8% higher annual energy production compared to untreated counterparts in dusty environments. This efficiency preservation can generate $2,000-5,000 additional revenue per MW annually, depending on electricity prices and local environmental conditions.

Lifecycle analysis reveals that most self-cleaning technologies achieve return on investment within 2-4 years in high-dust regions and 3-6 years in moderate environments. The durability of these surfaces varies significantly; hydrophobic coatings typically require reapplication every 3-5 years, while more robust solutions may last 7-10 years before performance degradation necessitates renewal.

Environmental cost-benefit considerations further enhance the value proposition. Water conservation from reduced cleaning requirements ranges from 1,500-2,500 gallons annually per MW of solar capacity. Additionally, eliminating chemical cleaning agents reduces environmental contamination risks and associated regulatory compliance costs.

Scalability economics demonstrate improving cost-effectiveness with implementation size. Large-scale applications benefit from economies of scale, with per-unit costs decreasing by 10-20% for installations exceeding 50 MW capacity. However, this advantage must be balanced against the increased financial risk of deploying new technologies at scale without extensive field validation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!