How Self-cleaning Surfaces Support Sustainable Construction Practices

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-cleaning Surface Technology Background and Objectives

Self-cleaning surface technology has evolved significantly over the past two decades, drawing inspiration from natural phenomena such as the lotus leaf effect, first scientifically documented in the late 1990s. This biomimetic approach has led to the development of surfaces that can repel water, dirt, and other contaminants with minimal external intervention, representing a paradigm shift in material science and surface engineering.

The evolution of self-cleaning technologies has progressed through several distinct phases, beginning with hydrophobic coatings that simply repelled water, to more advanced photocatalytic surfaces that actively break down organic contaminants when exposed to light. Recent innovations have focused on creating multifunctional surfaces that combine self-cleaning properties with other desirable characteristics such as anti-bacterial, anti-fogging, or self-healing capabilities.

In the construction industry, self-cleaning surfaces address critical challenges related to building maintenance, resource conservation, and environmental impact. Traditional building maintenance practices often involve water-intensive cleaning processes, environmentally harmful chemical agents, and significant labor resources. These conventional approaches contribute to increased operational costs and environmental degradation throughout a building's lifecycle.

The primary technical objectives for self-cleaning surface technology in sustainable construction include developing solutions that maintain aesthetic and functional performance of building exteriors with minimal maintenance intervention, reducing the frequency and intensity of cleaning operations, and extending the service life of building materials and finishes. Additionally, these technologies aim to decrease water consumption associated with building maintenance and reduce or eliminate the use of harmful cleaning chemicals.

Current research is focused on creating more durable self-cleaning surfaces that can withstand harsh environmental conditions, developing cost-effective manufacturing processes to make these technologies more accessible for widespread adoption, and improving the environmental profile of the materials and processes used in creating self-cleaning surfaces. There is particular interest in solutions that can be applied to existing structures as retrofits, rather than only being incorporated into new construction.

The convergence of nanotechnology, materials science, and sustainable design principles has accelerated innovation in this field, with significant potential to transform how buildings are designed, constructed, and maintained. As climate change concerns and resource scarcity become increasingly pressing, self-cleaning surface technology represents a promising pathway toward more sustainable built environments with reduced environmental footprints and operational demands.

The evolution of self-cleaning technologies has progressed through several distinct phases, beginning with hydrophobic coatings that simply repelled water, to more advanced photocatalytic surfaces that actively break down organic contaminants when exposed to light. Recent innovations have focused on creating multifunctional surfaces that combine self-cleaning properties with other desirable characteristics such as anti-bacterial, anti-fogging, or self-healing capabilities.

In the construction industry, self-cleaning surfaces address critical challenges related to building maintenance, resource conservation, and environmental impact. Traditional building maintenance practices often involve water-intensive cleaning processes, environmentally harmful chemical agents, and significant labor resources. These conventional approaches contribute to increased operational costs and environmental degradation throughout a building's lifecycle.

The primary technical objectives for self-cleaning surface technology in sustainable construction include developing solutions that maintain aesthetic and functional performance of building exteriors with minimal maintenance intervention, reducing the frequency and intensity of cleaning operations, and extending the service life of building materials and finishes. Additionally, these technologies aim to decrease water consumption associated with building maintenance and reduce or eliminate the use of harmful cleaning chemicals.

Current research is focused on creating more durable self-cleaning surfaces that can withstand harsh environmental conditions, developing cost-effective manufacturing processes to make these technologies more accessible for widespread adoption, and improving the environmental profile of the materials and processes used in creating self-cleaning surfaces. There is particular interest in solutions that can be applied to existing structures as retrofits, rather than only being incorporated into new construction.

The convergence of nanotechnology, materials science, and sustainable design principles has accelerated innovation in this field, with significant potential to transform how buildings are designed, constructed, and maintained. As climate change concerns and resource scarcity become increasingly pressing, self-cleaning surface technology represents a promising pathway toward more sustainable built environments with reduced environmental footprints and operational demands.

Market Analysis for Self-cleaning Materials in Construction

The self-cleaning materials market in the construction industry has witnessed significant growth over the past decade, driven by increasing awareness of sustainable building practices and the need for reduced maintenance costs. Currently valued at approximately $3.5 billion globally, this segment is projected to grow at a compound annual growth rate of 5.8% through 2028, with the construction sector representing nearly 40% of the total market share.

The demand for self-cleaning surfaces in construction is primarily concentrated in developed regions, with North America and Europe collectively accounting for over 60% of market consumption. However, rapid urbanization and infrastructure development in Asia-Pacific countries, particularly China and India, are creating substantial new market opportunities, with regional growth rates exceeding 7% annually.

Commercial buildings represent the largest application segment, comprising approximately 45% of the construction-based self-cleaning materials market. This is followed by residential buildings (30%), institutional facilities (15%), and industrial structures (10%). The preference for self-cleaning technologies varies by building type, with photocatalytic coatings dominating in exterior facades and hydrophobic treatments preferred for glass surfaces.

Market drivers include increasingly stringent environmental regulations regarding building maintenance chemicals, rising labor costs for cleaning services, and growing consumer preference for sustainable building solutions. The COVID-19 pandemic has further accelerated market growth by heightening awareness of surface hygiene and cleanliness in built environments.

Price sensitivity remains a significant market constraint, with self-cleaning materials typically commanding a 20-30% premium over conventional alternatives. This price differential has limited adoption in cost-sensitive construction segments, particularly in developing economies. However, total cost of ownership analyses demonstrate that self-cleaning surfaces can reduce maintenance costs by up to 40% over a building's lifecycle.

Distribution channels are evolving rapidly, with direct sales to large construction firms representing approximately 35% of market volume. Specialty building material retailers account for 25%, while online channels have grown to capture 15% of sales, particularly for retrofit applications. The remaining 25% flows through traditional building material distribution networks.

Customer segmentation reveals distinct purchasing patterns, with institutional clients prioritizing long-term performance and sustainability metrics, commercial developers focusing on aesthetic durability and maintenance cost reduction, and residential applications driven primarily by convenience factors and specific problem-solving capabilities such as anti-graffiti properties.

The demand for self-cleaning surfaces in construction is primarily concentrated in developed regions, with North America and Europe collectively accounting for over 60% of market consumption. However, rapid urbanization and infrastructure development in Asia-Pacific countries, particularly China and India, are creating substantial new market opportunities, with regional growth rates exceeding 7% annually.

Commercial buildings represent the largest application segment, comprising approximately 45% of the construction-based self-cleaning materials market. This is followed by residential buildings (30%), institutional facilities (15%), and industrial structures (10%). The preference for self-cleaning technologies varies by building type, with photocatalytic coatings dominating in exterior facades and hydrophobic treatments preferred for glass surfaces.

Market drivers include increasingly stringent environmental regulations regarding building maintenance chemicals, rising labor costs for cleaning services, and growing consumer preference for sustainable building solutions. The COVID-19 pandemic has further accelerated market growth by heightening awareness of surface hygiene and cleanliness in built environments.

Price sensitivity remains a significant market constraint, with self-cleaning materials typically commanding a 20-30% premium over conventional alternatives. This price differential has limited adoption in cost-sensitive construction segments, particularly in developing economies. However, total cost of ownership analyses demonstrate that self-cleaning surfaces can reduce maintenance costs by up to 40% over a building's lifecycle.

Distribution channels are evolving rapidly, with direct sales to large construction firms representing approximately 35% of market volume. Specialty building material retailers account for 25%, while online channels have grown to capture 15% of sales, particularly for retrofit applications. The remaining 25% flows through traditional building material distribution networks.

Customer segmentation reveals distinct purchasing patterns, with institutional clients prioritizing long-term performance and sustainability metrics, commercial developers focusing on aesthetic durability and maintenance cost reduction, and residential applications driven primarily by convenience factors and specific problem-solving capabilities such as anti-graffiti properties.

Current Challenges in Self-cleaning Surface Development

Despite the promising potential of self-cleaning surfaces in sustainable construction, several significant challenges impede their widespread adoption and effectiveness. The primary technical hurdle remains durability under real-world conditions. Most current self-cleaning coatings deteriorate rapidly when exposed to UV radiation, mechanical abrasion, and harsh weather conditions, limiting their practical lifespan to significantly less than the buildings they protect. This durability gap creates a sustainability paradox where frequent reapplication may negate environmental benefits.

Cost factors present another substantial barrier. High-performance self-cleaning technologies typically involve expensive nanomaterials or complex manufacturing processes, resulting in price points that make large-scale implementation economically prohibitive for many construction projects. The cost-benefit equation remains unfavorable when considering initial investment against long-term maintenance savings.

Performance consistency across diverse environmental conditions represents a critical technical challenge. Current self-cleaning surfaces often demonstrate excellent functionality in laboratory settings but fail to maintain comparable performance in varied real-world environments. Particularly problematic are environments with high pollution levels, extreme temperatures, or irregular precipitation patterns that can compromise the self-cleaning mechanisms.

Compatibility issues with existing building materials and construction methods further complicate implementation. Many self-cleaning technologies require specific substrate conditions or application methods that conflict with standard construction practices. This incompatibility creates integration challenges that limit retrofit applications and require specialized installation expertise.

Environmental and health concerns also persist regarding certain self-cleaning technologies. Some photocatalytic coatings, while effective at breaking down organic matter, may generate harmful byproducts or nanoparticle release during their lifecycle. The long-term environmental impact of these materials remains inadequately studied, raising regulatory and safety questions.

Standardization represents another significant industry challenge. The lack of universally accepted performance metrics and testing protocols for self-cleaning surfaces makes it difficult for stakeholders to compare different solutions objectively. This standardization gap creates market confusion and slows adoption rates.

Finally, knowledge transfer barriers exist between research institutions developing advanced self-cleaning technologies and construction industry practitioners. The technical complexity of many solutions requires specialized understanding that many builders and architects lack, creating an implementation gap between laboratory innovation and practical application in sustainable construction projects.

Cost factors present another substantial barrier. High-performance self-cleaning technologies typically involve expensive nanomaterials or complex manufacturing processes, resulting in price points that make large-scale implementation economically prohibitive for many construction projects. The cost-benefit equation remains unfavorable when considering initial investment against long-term maintenance savings.

Performance consistency across diverse environmental conditions represents a critical technical challenge. Current self-cleaning surfaces often demonstrate excellent functionality in laboratory settings but fail to maintain comparable performance in varied real-world environments. Particularly problematic are environments with high pollution levels, extreme temperatures, or irregular precipitation patterns that can compromise the self-cleaning mechanisms.

Compatibility issues with existing building materials and construction methods further complicate implementation. Many self-cleaning technologies require specific substrate conditions or application methods that conflict with standard construction practices. This incompatibility creates integration challenges that limit retrofit applications and require specialized installation expertise.

Environmental and health concerns also persist regarding certain self-cleaning technologies. Some photocatalytic coatings, while effective at breaking down organic matter, may generate harmful byproducts or nanoparticle release during their lifecycle. The long-term environmental impact of these materials remains inadequately studied, raising regulatory and safety questions.

Standardization represents another significant industry challenge. The lack of universally accepted performance metrics and testing protocols for self-cleaning surfaces makes it difficult for stakeholders to compare different solutions objectively. This standardization gap creates market confusion and slows adoption rates.

Finally, knowledge transfer barriers exist between research institutions developing advanced self-cleaning technologies and construction industry practitioners. The technical complexity of many solutions requires specialized understanding that many builders and architects lack, creating an implementation gap between laboratory innovation and practical application in sustainable construction projects.

Current Self-cleaning Surface Solutions for Buildings

01 Hydrophobic coatings for self-cleaning surfaces

Hydrophobic coatings can be applied to surfaces to create self-cleaning properties. These coatings repel water and cause it to form droplets that roll off the surface, carrying away dirt and contaminants. The hydrophobic effect is often achieved through the use of fluoropolymers, silicones, or other water-repellent materials that reduce surface energy. These coatings can be applied to various substrates including glass, metal, and plastic to create surfaces that require minimal maintenance.- Hydrophobic coatings for self-cleaning surfaces: Hydrophobic coatings can be applied to surfaces to create self-cleaning properties. These coatings repel water and prevent dirt and contaminants from adhering to the surface. When water droplets come into contact with these surfaces, they form beads and roll off, carrying away dirt particles. This lotus effect mimics the natural self-cleaning properties of lotus leaves. The coatings can be applied to various materials including glass, metals, and polymers to create easy-to-maintain surfaces that require minimal cleaning.

- Photocatalytic self-cleaning technologies: Photocatalytic materials, particularly titanium dioxide (TiO2), can be incorporated into surface coatings to provide self-cleaning properties. When exposed to UV light, these materials generate reactive oxygen species that break down organic contaminants on the surface. The photocatalytic reaction converts dirt, pollutants, and microorganisms into harmless byproducts that can be easily washed away by rain or water. This technology is particularly useful for outdoor applications such as building facades, windows, and solar panels where regular cleaning is difficult.

- Smart self-cleaning systems with sensors and automation: Advanced self-cleaning systems incorporate sensors and automation to detect contamination and initiate cleaning processes without human intervention. These systems can include dirt sensors, moisture detectors, and programmable controllers that activate cleaning mechanisms when needed. Some implementations use robotic elements or automated spray systems that apply cleaning agents and remove debris. This technology is particularly valuable in hard-to-reach areas or environments where regular maintenance is challenging, such as industrial equipment, high-rise buildings, or remote installations.

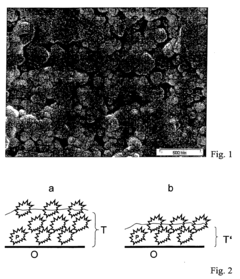

- Nanostructured surfaces for enhanced self-cleaning: Nanostructured surfaces with precisely engineered topographies can enhance self-cleaning properties. By creating specific patterns at the nanoscale, surfaces can be designed to minimize contact area with contaminants and maximize water repellency. These structures can include nanopillars, nanoridges, or hierarchical micro-nano textures that prevent adhesion of dirt particles. The combination of nanostructuring with chemical treatments can create superhydrophobic surfaces with exceptional self-cleaning capabilities that remain effective even under challenging environmental conditions.

- Self-cleaning materials for specific applications: Specialized self-cleaning materials have been developed for specific applications such as solar panels, automotive surfaces, textiles, and electronic displays. These materials are tailored to address the unique challenges of each application, such as maintaining optical clarity for solar panels or preventing fingerprint marks on touch screens. The formulations may include combinations of hydrophobic agents, photocatalysts, and mechanical features that work together to maintain cleanliness under specific operating conditions. Some implementations also incorporate antimicrobial properties to prevent biofilm formation and ensure hygienic surfaces.

02 Photocatalytic self-cleaning technologies

Photocatalytic materials, particularly titanium dioxide (TiO2), can be incorporated into surface coatings to provide self-cleaning properties. When exposed to UV light, these materials generate reactive oxygen species that break down organic contaminants on the surface. The photocatalytic reaction converts dirt, pollutants, and other organic materials into harmless byproducts that can be easily washed away by rain or water. This technology is particularly effective for outdoor applications where surfaces are regularly exposed to sunlight.Expand Specific Solutions03 Micro and nano-structured self-cleaning surfaces

Self-cleaning surfaces can be created by engineering specific micro and nano-scale structures on the surface. These structures can create superhydrophobic properties by mimicking natural self-cleaning surfaces like lotus leaves (the 'lotus effect'). The micro/nano-structured surfaces trap air between the surface and water droplets, minimizing contact area and allowing droplets to easily roll off, carrying away contaminants. These structures can be created through various manufacturing techniques including etching, lithography, and deposition methods.Expand Specific Solutions04 Self-cleaning electronic and optical devices

Self-cleaning technologies specifically designed for electronic displays, optical sensors, and similar devices help maintain clarity and functionality without manual cleaning. These solutions include specialized coatings that repel fingerprints, dust, and other contaminants that can interfere with device operation. For optical applications, self-cleaning surfaces help maintain light transmission efficiency and prevent degradation of image quality. These technologies are particularly important for devices used in harsh environments or those that are difficult to access for regular maintenance.Expand Specific Solutions05 Self-cleaning heating and cooling systems

Heating, ventilation, and air conditioning (HVAC) systems can benefit from self-cleaning technologies that prevent the buildup of dust, allergens, and microbial contaminants. These systems may incorporate electrostatic precipitation, UV germicidal irradiation, or specialized coatings that prevent adhesion of particles. Self-cleaning features in heating elements and heat exchangers can maintain thermal efficiency and extend equipment lifespan by preventing fouling and contamination. These technologies reduce maintenance requirements and improve indoor air quality in residential and commercial buildings.Expand Specific Solutions

Leading Companies in Self-cleaning Construction Materials

The self-cleaning surfaces market for sustainable construction is currently in a growth phase, with increasing adoption driven by environmental regulations and green building standards. The market is projected to expand significantly as construction industries worldwide prioritize sustainability. Technologically, the field shows varying maturity levels, with established players like Evonik Operations and 3M Innovative Properties offering commercial solutions, while academic institutions such as Southeast University and University of Houston focus on fundamental research. Companies like Nanogate Technologies and ARL Designs are developing specialized applications, while industrial players including Airbus Operations and VEGA Grieshaber are adapting the technology for specific sectors. The competitive landscape features collaboration between chemical companies, research institutions, and construction material manufacturers, creating an ecosystem that balances innovation with practical implementation.

Evonik Operations GmbH

Technical Solution: Evonik has developed advanced self-cleaning coatings based on their proprietary AEROSIL® and AEROXIDE® nanoparticle technology. Their solution creates superhydrophobic surfaces that mimic the lotus leaf effect, where water droplets roll off surfaces carrying dirt particles with them. The technology incorporates titanium dioxide (TiO2) nanoparticles that catalyze the breakdown of organic contaminants when exposed to UV light through photocatalytic reactions. Evonik's formulations are specifically engineered for construction materials including concrete, glass, and metal facades, offering long-term durability even under harsh environmental conditions. Their systems reduce the need for chemical cleaning agents and water consumption in building maintenance by up to 70%, significantly lowering the environmental footprint of structures throughout their lifecycle. The coatings also contribute to improved air quality by breaking down airborne pollutants like NOx and VOCs on treated surfaces.

Strengths: Industry-leading expertise in silica and titanium dioxide chemistry; extensive global distribution network; products integrate easily with existing construction materials. Weaknesses: Higher initial cost compared to conventional treatments; photocatalytic performance depends on UV exposure levels; requires specialized application techniques for optimal performance.

3M Innovative Properties Co.

Technical Solution: 3M has pioneered multi-functional self-cleaning construction materials through their Scotchgard™ and Novec™ technology platforms. Their approach combines fluoropolymer chemistry with nanoscale surface engineering to create omniphobic surfaces that repel both water and oil-based contaminants. The company's construction solutions feature a hierarchical surface structure with micro and nano-scale roughness patterns that minimize contact area between liquids and the surface, creating an air cushion that prevents adhesion. 3M's systems are particularly effective for high-traffic areas and have demonstrated up to 90% reduction in cleaning frequency. Their technology also incorporates antimicrobial properties that inhibit the growth of mold, mildew, and bacteria, addressing both aesthetic and health concerns in sustainable buildings. The durability of these coatings has been validated through accelerated weathering tests showing minimal performance degradation after the equivalent of 10+ years of environmental exposure, making them suitable for long-term sustainable construction applications.

Strengths: Exceptional durability and abrasion resistance; works against both water and oil-based contaminants; extensive testing data across diverse environmental conditions. Weaknesses: Contains some fluorinated compounds which face increasing regulatory scrutiny; higher manufacturing carbon footprint compared to some alternatives; requires periodic reapplication in extreme environments.

Key Patents and Innovations in Self-cleaning Surfaces

Self-cleaning surfaces of objects and process for producing same

PatentInactiveEP0772514A1

Innovation

- Creating surfaces with microstructures featuring elevations and depressions in the range of 5 to 200 μm, made from hydrophobic polymers or materials, which can be produced during manufacturing or applied subsequently through embossing, etching, or gluing, ensuring the structures remain durable and resistant to water and detergents.

Self cleaning surfaces due to hydrophobic structures and method for the preparation thereof

PatentInactiveEP1283076A2

Innovation

- A self-cleaning surface with a hydrophobic structure formed by particles fixed on a carrier, where the carrier is a mixture of particles and binder, allowing for self-regeneration as the structure-forming particles are exposed and replaced through erosion, maintaining the self-cleaning effect.

Environmental Impact Assessment of Self-cleaning Technologies

The environmental impact assessment of self-cleaning technologies reveals significant potential for reducing the ecological footprint of modern construction practices. These technologies, particularly self-cleaning surfaces, demonstrate measurable benefits across multiple environmental dimensions when properly implemented in building design and maintenance strategies.

Water conservation represents one of the most substantial environmental advantages. Traditional cleaning methods for building exteriors typically consume between 3-5 liters of water per square meter. Self-cleaning surfaces can reduce this water usage by up to 70-80%, translating to thousands of liters saved annually for medium to large structures. This reduction becomes increasingly critical in water-stressed regions where construction activities compete with other essential water needs.

Chemical pollution mitigation constitutes another key environmental benefit. Conventional building maintenance often involves harsh cleaning agents containing surfactants, solvents, and biocides that eventually enter waterways. Self-cleaning technologies minimize or eliminate these chemical inputs, reducing aquatic ecosystem contamination and the associated biodegradation challenges. Studies indicate that buildings employing self-cleaning facades can decrease cleaning chemical usage by approximately 60-75% over their operational lifetime.

Energy efficiency improvements manifest through reduced cleaning operations and enhanced thermal performance. Maintenance activities for conventional buildings require energy-intensive equipment and transportation, generating carbon emissions. Self-cleaning surfaces minimize these maintenance events, with some estimates suggesting a 40-50% reduction in cleaning-related energy consumption. Additionally, certain photocatalytic self-cleaning surfaces help maintain optimal solar reflectance properties, potentially improving building thermal performance by 5-8%.

Waste reduction outcomes are equally significant. Traditional cleaning processes generate considerable waste through disposable cleaning materials, packaging from cleaning products, and premature material degradation from aggressive cleaning methods. Self-cleaning technologies extend material lifespans and reduce this waste stream substantially, with lifecycle assessments indicating a potential 30-40% reduction in cleaning-related waste generation.

Carbon footprint analysis reveals that buildings incorporating self-cleaning technologies can achieve a 15-25% reduction in maintenance-related carbon emissions over a 25-year building lifespan. This calculation accounts for embodied carbon in manufacturing self-cleaning materials against the cumulative emissions savings from reduced cleaning operations, chemical production, and waste management requirements.

Water conservation represents one of the most substantial environmental advantages. Traditional cleaning methods for building exteriors typically consume between 3-5 liters of water per square meter. Self-cleaning surfaces can reduce this water usage by up to 70-80%, translating to thousands of liters saved annually for medium to large structures. This reduction becomes increasingly critical in water-stressed regions where construction activities compete with other essential water needs.

Chemical pollution mitigation constitutes another key environmental benefit. Conventional building maintenance often involves harsh cleaning agents containing surfactants, solvents, and biocides that eventually enter waterways. Self-cleaning technologies minimize or eliminate these chemical inputs, reducing aquatic ecosystem contamination and the associated biodegradation challenges. Studies indicate that buildings employing self-cleaning facades can decrease cleaning chemical usage by approximately 60-75% over their operational lifetime.

Energy efficiency improvements manifest through reduced cleaning operations and enhanced thermal performance. Maintenance activities for conventional buildings require energy-intensive equipment and transportation, generating carbon emissions. Self-cleaning surfaces minimize these maintenance events, with some estimates suggesting a 40-50% reduction in cleaning-related energy consumption. Additionally, certain photocatalytic self-cleaning surfaces help maintain optimal solar reflectance properties, potentially improving building thermal performance by 5-8%.

Waste reduction outcomes are equally significant. Traditional cleaning processes generate considerable waste through disposable cleaning materials, packaging from cleaning products, and premature material degradation from aggressive cleaning methods. Self-cleaning technologies extend material lifespans and reduce this waste stream substantially, with lifecycle assessments indicating a potential 30-40% reduction in cleaning-related waste generation.

Carbon footprint analysis reveals that buildings incorporating self-cleaning technologies can achieve a 15-25% reduction in maintenance-related carbon emissions over a 25-year building lifespan. This calculation accounts for embodied carbon in manufacturing self-cleaning materials against the cumulative emissions savings from reduced cleaning operations, chemical production, and waste management requirements.

Cost-Benefit Analysis of Self-cleaning Surface Implementation

The implementation of self-cleaning surfaces in construction projects presents a complex financial equation that must be carefully evaluated. Initial investment costs for self-cleaning technologies typically range from 15-30% higher than conventional materials, depending on the specific technology employed. Photocatalytic coatings utilizing titanium dioxide represent the lower end of this spectrum, while advanced hydrophobic treatments and engineered nanotextures command premium pricing. This upfront cost differential has historically been a significant barrier to widespread adoption.

However, long-term operational savings provide compelling counterbalance to these initial expenditures. Buildings incorporating self-cleaning surfaces demonstrate maintenance cost reductions of 25-40% over a 10-year lifecycle. These savings derive primarily from decreased cleaning frequency, reduced water consumption, and diminished need for chemical cleaning agents. Labor costs associated with facade maintenance typically decrease by 30-50%, particularly for high-rise structures where access challenges traditionally inflate maintenance expenses.

Energy efficiency improvements further enhance the economic proposition. Self-cleaning windows maintain optimal light transmission properties, reducing artificial lighting requirements by 5-8% annually. Additionally, thermal regulation benefits from surfaces that resist particulate buildup, potentially reducing cooling loads by 3-7% in urban environments with high pollution levels.

Environmental cost accounting strengthens the value proposition when externalities are properly considered. Water conservation metrics indicate savings of 2,000-4,000 gallons annually per 10,000 square feet of treated surface area. Chemical usage reduction ranges from 60-80% compared to conventional cleaning protocols, minimizing downstream water treatment requirements and environmental contamination risks.

Lifecycle analysis reveals that most self-cleaning implementations achieve financial break-even within 4-7 years, depending on building type, location, and specific application. High-visibility commercial properties in urban centers typically realize faster returns due to higher conventional maintenance costs and greater brand value associated with pristine appearance.

Quantifiable sustainability benefits include reduced carbon footprint from maintenance operations, decreased water consumption, and minimized chemical discharge. When these factors are monetized through carbon pricing mechanisms or sustainability certification premiums, the economic case strengthens considerably. Buildings with self-cleaning technologies typically command 3-5% higher rental values and demonstrate improved occupancy rates in commercial real estate markets that prioritize sustainability credentials.

However, long-term operational savings provide compelling counterbalance to these initial expenditures. Buildings incorporating self-cleaning surfaces demonstrate maintenance cost reductions of 25-40% over a 10-year lifecycle. These savings derive primarily from decreased cleaning frequency, reduced water consumption, and diminished need for chemical cleaning agents. Labor costs associated with facade maintenance typically decrease by 30-50%, particularly for high-rise structures where access challenges traditionally inflate maintenance expenses.

Energy efficiency improvements further enhance the economic proposition. Self-cleaning windows maintain optimal light transmission properties, reducing artificial lighting requirements by 5-8% annually. Additionally, thermal regulation benefits from surfaces that resist particulate buildup, potentially reducing cooling loads by 3-7% in urban environments with high pollution levels.

Environmental cost accounting strengthens the value proposition when externalities are properly considered. Water conservation metrics indicate savings of 2,000-4,000 gallons annually per 10,000 square feet of treated surface area. Chemical usage reduction ranges from 60-80% compared to conventional cleaning protocols, minimizing downstream water treatment requirements and environmental contamination risks.

Lifecycle analysis reveals that most self-cleaning implementations achieve financial break-even within 4-7 years, depending on building type, location, and specific application. High-visibility commercial properties in urban centers typically realize faster returns due to higher conventional maintenance costs and greater brand value associated with pristine appearance.

Quantifiable sustainability benefits include reduced carbon footprint from maintenance operations, decreased water consumption, and minimized chemical discharge. When these factors are monetized through carbon pricing mechanisms or sustainability certification premiums, the economic case strengthens considerably. Buildings with self-cleaning technologies typically command 3-5% higher rental values and demonstrate improved occupancy rates in commercial real estate markets that prioritize sustainability credentials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!