Why Self-cleaning Surfaces are Pivotal for Public Hygiene

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-cleaning Surface Technology Background and Objectives

Self-cleaning surfaces represent a revolutionary advancement in material science that has evolved significantly over the past few decades. Initially inspired by natural phenomena such as the lotus leaf effect (discovered in the 1970s), this technology has progressed from basic hydrophobic coatings to sophisticated multi-functional surfaces capable of autonomous cleaning through various mechanisms. The trajectory of development has accelerated particularly in the last decade, with breakthroughs in nanotechnology enabling more effective and durable self-cleaning properties.

The evolution of self-cleaning technology can be traced through several key phases: observation of natural self-cleaning surfaces, development of first-generation hydrophobic coatings, advancement to photocatalytic surfaces in the 1990s, and the current era of hybrid and smart self-cleaning materials. Each phase has built upon previous knowledge, gradually enhancing performance while addressing limitations of earlier approaches.

In the context of public hygiene, self-cleaning surfaces have emerged as a critical technology with potential to transform infection control strategies. The COVID-19 pandemic has dramatically heightened awareness of surface transmission risks in public spaces, creating unprecedented urgency for passive cleaning solutions that can function continuously without human intervention or chemical applications.

The primary technical objectives in this field now center on developing surfaces that combine multiple self-cleaning mechanisms (hydrophobicity, photocatalysis, and antimicrobial properties) while maintaining durability in high-traffic public environments. Researchers aim to create solutions that remain effective for extended periods, function under various environmental conditions, and can be manufactured at scale with reasonable costs.

Another critical objective involves expanding the range of base materials compatible with self-cleaning technologies. Current applications are often limited to specific substrates, whereas public hygiene demands require implementation across diverse materials including metals, plastics, ceramics, glass, and textiles found throughout public infrastructure.

The ultimate goal of current research efforts is to develop next-generation self-cleaning surfaces that can significantly reduce pathogen transmission in public spaces, decrease the resource burden of conventional cleaning protocols, and contribute to more sustainable hygiene practices. This involves not only enhancing technical performance but also addressing practical considerations such as regulatory compliance, cost-effectiveness, and seamless integration into existing infrastructure.

As public health concerns continue to drive innovation, the technology trajectory points toward increasingly sophisticated surfaces that combine passive cleaning capabilities with active sensing and response mechanisms, potentially creating truly intelligent materials that adapt to changing contamination conditions.

The evolution of self-cleaning technology can be traced through several key phases: observation of natural self-cleaning surfaces, development of first-generation hydrophobic coatings, advancement to photocatalytic surfaces in the 1990s, and the current era of hybrid and smart self-cleaning materials. Each phase has built upon previous knowledge, gradually enhancing performance while addressing limitations of earlier approaches.

In the context of public hygiene, self-cleaning surfaces have emerged as a critical technology with potential to transform infection control strategies. The COVID-19 pandemic has dramatically heightened awareness of surface transmission risks in public spaces, creating unprecedented urgency for passive cleaning solutions that can function continuously without human intervention or chemical applications.

The primary technical objectives in this field now center on developing surfaces that combine multiple self-cleaning mechanisms (hydrophobicity, photocatalysis, and antimicrobial properties) while maintaining durability in high-traffic public environments. Researchers aim to create solutions that remain effective for extended periods, function under various environmental conditions, and can be manufactured at scale with reasonable costs.

Another critical objective involves expanding the range of base materials compatible with self-cleaning technologies. Current applications are often limited to specific substrates, whereas public hygiene demands require implementation across diverse materials including metals, plastics, ceramics, glass, and textiles found throughout public infrastructure.

The ultimate goal of current research efforts is to develop next-generation self-cleaning surfaces that can significantly reduce pathogen transmission in public spaces, decrease the resource burden of conventional cleaning protocols, and contribute to more sustainable hygiene practices. This involves not only enhancing technical performance but also addressing practical considerations such as regulatory compliance, cost-effectiveness, and seamless integration into existing infrastructure.

As public health concerns continue to drive innovation, the technology trajectory points toward increasingly sophisticated surfaces that combine passive cleaning capabilities with active sensing and response mechanisms, potentially creating truly intelligent materials that adapt to changing contamination conditions.

Market Analysis for Self-cleaning Solutions in Public Spaces

The self-cleaning surfaces market for public spaces has experienced significant growth in recent years, driven by increasing health awareness and hygiene concerns, particularly accelerated by the global pandemic. The market size for self-cleaning technologies in public spaces reached approximately $3.5 billion in 2022 and is projected to grow at a compound annual growth rate of 6.8% through 2028, according to industry reports.

Public transportation hubs represent the largest segment of this market, accounting for nearly 28% of total demand. Healthcare facilities follow closely at 24%, with educational institutions, commercial buildings, and recreational facilities comprising the remaining significant portions. This distribution reflects the critical need for hygiene maintenance in high-traffic areas where pathogen transmission risks are elevated.

Regional analysis reveals North America currently leads the market with a 35% share, followed by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to witness the fastest growth rate of 8.2% annually, driven by rapid urbanization, increasing public health investments, and growing middle-class populations in countries like China and India.

Consumer behavior studies indicate a growing willingness to pay premium prices for enhanced safety features in public spaces. A recent survey found that 72% of respondents expressed increased concern about surface hygiene in public areas post-pandemic, with 64% stating they would prefer establishments that implement self-cleaning technologies.

The market is segmented by technology type, with photocatalytic coatings holding the largest share at 32%, followed by hydrophobic and hydrophilic surfaces at 28%, antimicrobial treatments at 22%, and other emerging technologies at 18%. Each technology addresses different aspects of self-cleaning requirements, from water repellency to active decomposition of organic matter.

Cost-benefit analyses demonstrate that despite higher initial implementation costs, self-cleaning surfaces offer significant long-term savings. Public facilities implementing these technologies report maintenance cost reductions of 30-40% over five years, alongside decreased absenteeism rates among staff and improved public perception scores.

Market challenges include the relatively high initial investment costs, varying durability across different technologies, and the need for standardized performance metrics. Additionally, consumer education remains crucial, as many potential adopters lack understanding of the different technologies and their specific benefits.

Future market growth will likely be driven by technological innovations reducing costs, increasing durability, and expanding application versatility. The integration of smart sensors and IoT capabilities with self-cleaning surfaces represents an emerging trend that could significantly expand market potential in the coming years.

Public transportation hubs represent the largest segment of this market, accounting for nearly 28% of total demand. Healthcare facilities follow closely at 24%, with educational institutions, commercial buildings, and recreational facilities comprising the remaining significant portions. This distribution reflects the critical need for hygiene maintenance in high-traffic areas where pathogen transmission risks are elevated.

Regional analysis reveals North America currently leads the market with a 35% share, followed by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to witness the fastest growth rate of 8.2% annually, driven by rapid urbanization, increasing public health investments, and growing middle-class populations in countries like China and India.

Consumer behavior studies indicate a growing willingness to pay premium prices for enhanced safety features in public spaces. A recent survey found that 72% of respondents expressed increased concern about surface hygiene in public areas post-pandemic, with 64% stating they would prefer establishments that implement self-cleaning technologies.

The market is segmented by technology type, with photocatalytic coatings holding the largest share at 32%, followed by hydrophobic and hydrophilic surfaces at 28%, antimicrobial treatments at 22%, and other emerging technologies at 18%. Each technology addresses different aspects of self-cleaning requirements, from water repellency to active decomposition of organic matter.

Cost-benefit analyses demonstrate that despite higher initial implementation costs, self-cleaning surfaces offer significant long-term savings. Public facilities implementing these technologies report maintenance cost reductions of 30-40% over five years, alongside decreased absenteeism rates among staff and improved public perception scores.

Market challenges include the relatively high initial investment costs, varying durability across different technologies, and the need for standardized performance metrics. Additionally, consumer education remains crucial, as many potential adopters lack understanding of the different technologies and their specific benefits.

Future market growth will likely be driven by technological innovations reducing costs, increasing durability, and expanding application versatility. The integration of smart sensors and IoT capabilities with self-cleaning surfaces represents an emerging trend that could significantly expand market potential in the coming years.

Current Self-cleaning Technologies and Implementation Challenges

Self-cleaning surfaces represent a diverse technological landscape with several established approaches currently in commercial use or advanced development stages. Hydrophobic and superhydrophobic coatings, inspired by the lotus leaf's natural self-cleaning properties, create water-repellent surfaces where water droplets roll off, carrying contaminants away. These coatings typically employ nanostructured materials with low surface energy, creating contact angles exceeding 150 degrees. Commercial applications include architectural glass, automotive windshields, and textile treatments.

Photocatalytic surfaces, particularly those utilizing titanium dioxide (TiO₂), represent another significant technology. When exposed to UV light, these surfaces generate reactive oxygen species that decompose organic contaminants and kill microorganisms. TiO₂-based coatings have found applications in exterior building materials, air purification systems, and hospital environments. Recent advancements have extended photocatalytic activity into visible light spectrum, broadening potential applications.

Antimicrobial surfaces incorporating silver nanoparticles, copper alloys, or quaternary ammonium compounds provide continuous disinfection capabilities. These materials actively kill bacteria, viruses, and fungi through various mechanisms including cell membrane disruption and metabolic interference. Healthcare facilities have increasingly adopted copper-alloy touch surfaces to reduce healthcare-associated infections.

Despite promising technologies, significant implementation challenges persist. Durability remains a primary concern, as many self-cleaning coatings deteriorate under mechanical abrasion, chemical exposure, or environmental weathering. Most commercial coatings require periodic reapplication, limiting their practical utility in high-traffic public spaces. Cost factors also present barriers, with advanced self-cleaning technologies often carrying premium prices that restrict widespread adoption.

Technical limitations further complicate implementation. Photocatalytic surfaces require sufficient light exposure to function effectively, limiting their utility in indoor or low-light environments. Hydrophobic coatings may fail under certain conditions, particularly with oil-based contaminants. Additionally, some antimicrobial technologies raise concerns about potential environmental impacts and antimicrobial resistance development.

Standardization and testing protocols represent another challenge. The self-cleaning industry lacks universally accepted performance metrics, making it difficult for end-users to compare products objectively. This regulatory uncertainty, combined with limited long-term performance data in real-world conditions, has slowed adoption in critical public hygiene applications.

Integration with existing infrastructure presents practical hurdles. Retrofitting established public facilities with self-cleaning technologies often requires significant modification or complete replacement of surfaces, creating logistical and financial barriers. These challenges collectively highlight the need for continued research and development to create more robust, cost-effective, and easily implemented self-cleaning solutions for public hygiene applications.

Photocatalytic surfaces, particularly those utilizing titanium dioxide (TiO₂), represent another significant technology. When exposed to UV light, these surfaces generate reactive oxygen species that decompose organic contaminants and kill microorganisms. TiO₂-based coatings have found applications in exterior building materials, air purification systems, and hospital environments. Recent advancements have extended photocatalytic activity into visible light spectrum, broadening potential applications.

Antimicrobial surfaces incorporating silver nanoparticles, copper alloys, or quaternary ammonium compounds provide continuous disinfection capabilities. These materials actively kill bacteria, viruses, and fungi through various mechanisms including cell membrane disruption and metabolic interference. Healthcare facilities have increasingly adopted copper-alloy touch surfaces to reduce healthcare-associated infections.

Despite promising technologies, significant implementation challenges persist. Durability remains a primary concern, as many self-cleaning coatings deteriorate under mechanical abrasion, chemical exposure, or environmental weathering. Most commercial coatings require periodic reapplication, limiting their practical utility in high-traffic public spaces. Cost factors also present barriers, with advanced self-cleaning technologies often carrying premium prices that restrict widespread adoption.

Technical limitations further complicate implementation. Photocatalytic surfaces require sufficient light exposure to function effectively, limiting their utility in indoor or low-light environments. Hydrophobic coatings may fail under certain conditions, particularly with oil-based contaminants. Additionally, some antimicrobial technologies raise concerns about potential environmental impacts and antimicrobial resistance development.

Standardization and testing protocols represent another challenge. The self-cleaning industry lacks universally accepted performance metrics, making it difficult for end-users to compare products objectively. This regulatory uncertainty, combined with limited long-term performance data in real-world conditions, has slowed adoption in critical public hygiene applications.

Integration with existing infrastructure presents practical hurdles. Retrofitting established public facilities with self-cleaning technologies often requires significant modification or complete replacement of surfaces, creating logistical and financial barriers. These challenges collectively highlight the need for continued research and development to create more robust, cost-effective, and easily implemented self-cleaning solutions for public hygiene applications.

Mainstream Self-cleaning Surface Solutions and Applications

01 Photocatalytic self-cleaning surfaces

Surfaces coated with photocatalytic materials such as titanium dioxide (TiO2) can break down organic contaminants when exposed to light. These surfaces utilize photocatalytic reactions to decompose bacteria, viruses, and other organic matter, maintaining hygiene without frequent manual cleaning. The technology is particularly effective in high-touch areas and can be applied to various materials including glass, ceramics, and plastics to create surfaces that actively combat microbial growth.- Photocatalytic self-cleaning surfaces: Surfaces coated with photocatalytic materials such as titanium dioxide (TiO2) can break down organic contaminants when exposed to light. These surfaces use photocatalytic reactions to decompose bacteria, viruses, and other organic matter, maintaining hygiene without manual cleaning. The technology is particularly useful in high-touch areas and can be applied to various materials including glass, ceramics, and plastics to create surfaces that remain clean and hygienic for longer periods.

- Hydrophobic and hydrophilic self-cleaning technologies: Self-cleaning surfaces can utilize either hydrophobic (water-repelling) or hydrophilic (water-attracting) properties. Hydrophobic surfaces, often using nanostructured coatings, cause water droplets to bead up and roll off, carrying away dirt particles. Hydrophilic surfaces allow water to spread evenly, washing away contaminants. Both technologies reduce bacterial adhesion and biofilm formation, enhancing hygiene in various environments from healthcare facilities to household surfaces.

- Antimicrobial surface treatments and coatings: Surfaces can be treated with antimicrobial agents that actively kill or inhibit the growth of microorganisms. These treatments include silver nanoparticles, copper compounds, quaternary ammonium compounds, and other biocides incorporated into coatings or directly into materials. Such surfaces continuously work to reduce microbial contamination, providing ongoing hygiene protection in healthcare settings, food preparation areas, and public spaces where infection control is critical.

- Automated cleaning systems for surfaces: Automated systems can maintain surface hygiene through programmed cleaning cycles. These include robotic cleaners, integrated spray systems, UV sterilization devices, and self-sanitizing mechanisms built into fixtures and appliances. Such systems can detect contamination and initiate cleaning protocols automatically, ensuring consistent hygiene standards without human intervention, particularly valuable in high-risk environments or areas difficult for manual cleaning.

- Smart materials with responsive cleaning properties: Advanced materials that respond to environmental triggers to initiate self-cleaning processes represent the cutting edge of hygiene technology. These include surfaces that change properties in response to temperature, pH, or specific contaminants. Some materials incorporate encapsulated cleaning agents that release when triggered by specific conditions. Others feature structural transformations that physically dislodge contaminants. These smart surfaces adapt to contamination events, providing targeted hygiene maintenance in real-time.

02 Hydrophobic and superhydrophobic coatings

These coatings create water-repellent surfaces that prevent liquid adhesion, causing water droplets to roll off while carrying away contaminants. This self-cleaning mechanism, often called the "lotus effect," minimizes bacterial attachment and biofilm formation. The coatings can be applied to various surfaces including bathroom fixtures, medical equipment, and food preparation areas, reducing the need for chemical cleaners while maintaining hygienic conditions.Expand Specific Solutions03 Automated cleaning systems for hygiene maintenance

Automated systems incorporate sensors, robotics, and programmable cleaning cycles to maintain hygienic conditions without human intervention. These systems can detect contamination levels and deploy appropriate cleaning mechanisms including UV sterilization, steam cleaning, or chemical disinfection. Applications range from self-cleaning toilets and bathroom fixtures to industrial food processing equipment and healthcare facilities, ensuring consistent hygiene standards while reducing labor costs.Expand Specific Solutions04 Antimicrobial surface materials and coatings

Surfaces incorporating antimicrobial agents such as silver nanoparticles, copper compounds, or quaternary ammonium compounds actively kill or inhibit microbial growth upon contact. These materials provide continuous disinfection without requiring external activation, making them effective for high-touch surfaces in healthcare settings, public facilities, and household applications. The antimicrobial properties can be embedded within the material itself or applied as coatings, providing long-lasting hygiene benefits.Expand Specific Solutions05 UV-C light disinfection systems

Systems utilizing ultraviolet-C (UV-C) light automatically disinfect surfaces by damaging the DNA and RNA of microorganisms. These systems can be integrated into various environments including bathrooms, kitchens, and medical facilities to provide scheduled or on-demand disinfection cycles. Advanced implementations include motion sensors to ensure safe operation only when areas are unoccupied, and reflective surfaces to maximize coverage and effectiveness in eliminating pathogens from hard-to-reach areas.Expand Specific Solutions

Leading Companies and Research Institutions in Self-cleaning Surfaces

Self-cleaning surfaces are emerging as a critical technology for public hygiene, currently transitioning from early development to commercial growth phase. The market is projected to reach $1.5-2 billion by 2025, expanding at approximately 15% CAGR. Technical maturity varies across applications, with companies demonstrating different specialization levels. Evonik Operations and Unilever IP Holdings lead in chemical coatings, while Gree Electric and Canon incorporate self-cleaning features into consumer products. Academic institutions like University of Florida and Shanghai Normal University contribute fundamental research. Healthcare-focused players including Bard Access Systems and Dr. Schumacher are advancing antimicrobial surfaces for medical settings. The technology is approaching mainstream adoption in high-touch public surfaces, though cost and durability challenges remain for mass implementation.

Evonik Operations GmbH

Technical Solution: Evonik has developed advanced self-cleaning surface technologies based on their proprietary AEROSIL® and AEROXIDE® nanoparticle systems. Their approach combines hydrophobic and photocatalytic properties to create surfaces that actively repel water, dirt, and organic contaminants. The technology incorporates titanium dioxide (TiO2) nanoparticles that, when exposed to UV light, trigger photocatalytic reactions breaking down organic matter and killing microorganisms. Evonik's coatings create a nanoscale surface roughness that traps air between water droplets and the surface, causing them to bead up and roll off, carrying contaminants away. This "lotus effect" inspired technology has been successfully applied to architectural glass, ceramic surfaces, and textiles, providing long-lasting protection against microbial growth and reducing cleaning frequency by up to 70% in high-traffic public areas.

Strengths: Evonik's solutions offer exceptional durability (3+ years in exterior applications) and versatility across multiple substrate materials. Their formulations maintain effectiveness even in low-light conditions. Weaknesses: The photocatalytic components require some UV exposure for optimal performance, potentially limiting effectiveness in interior spaces without sufficient natural light.

Airbus Operations Ltd.

Technical Solution: Airbus has pioneered self-cleaning surface technology specifically designed for aircraft interiors to enhance cabin hygiene and passenger safety. Their proprietary "CleanSky" coating system utilizes a combination of silver nanoparticles and hydrophobic polymers to create surfaces that resist bacterial adhesion and facilitate easy cleaning. The technology incorporates a multi-layered approach: a base layer bonds to various cabin materials (plastics, metals, fabrics), while the active layer contains antimicrobial agents that continuously neutralize pathogens. The topmost layer creates a nanoscale texture that reduces surface contact area for contaminants. Independent testing has shown these surfaces reduce bacterial load by over 99.9% within 2 hours of contamination and maintain effectiveness through hundreds of cleaning cycles. Airbus has implemented this technology on high-touch surfaces including tray tables, armrests, and lavatory fixtures, significantly reducing the risk of disease transmission in the confined aircraft environment where traditional cleaning methods face limitations due to quick turnaround times between flights.

Strengths: The technology maintains effectiveness through hundreds of cleaning cycles and harsh aviation-grade disinfectants, providing long-term protection. The system works passively without requiring external activation. Weaknesses: Higher initial implementation costs compared to standard surfaces, and potential for gradual degradation in antimicrobial effectiveness over extended service periods requiring periodic reapplication.

Key Patents and Scientific Breakthroughs in Self-cleaning Materials

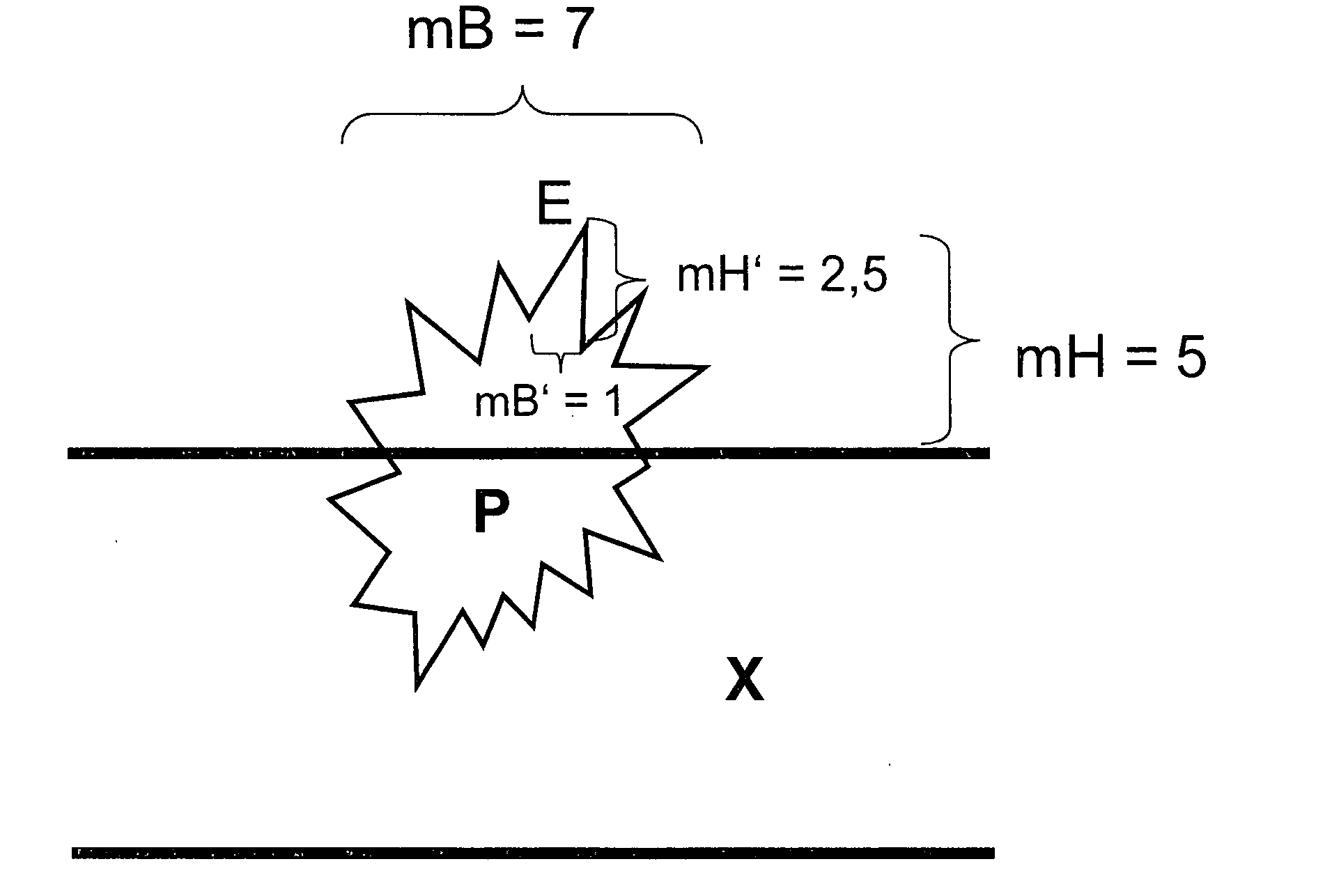

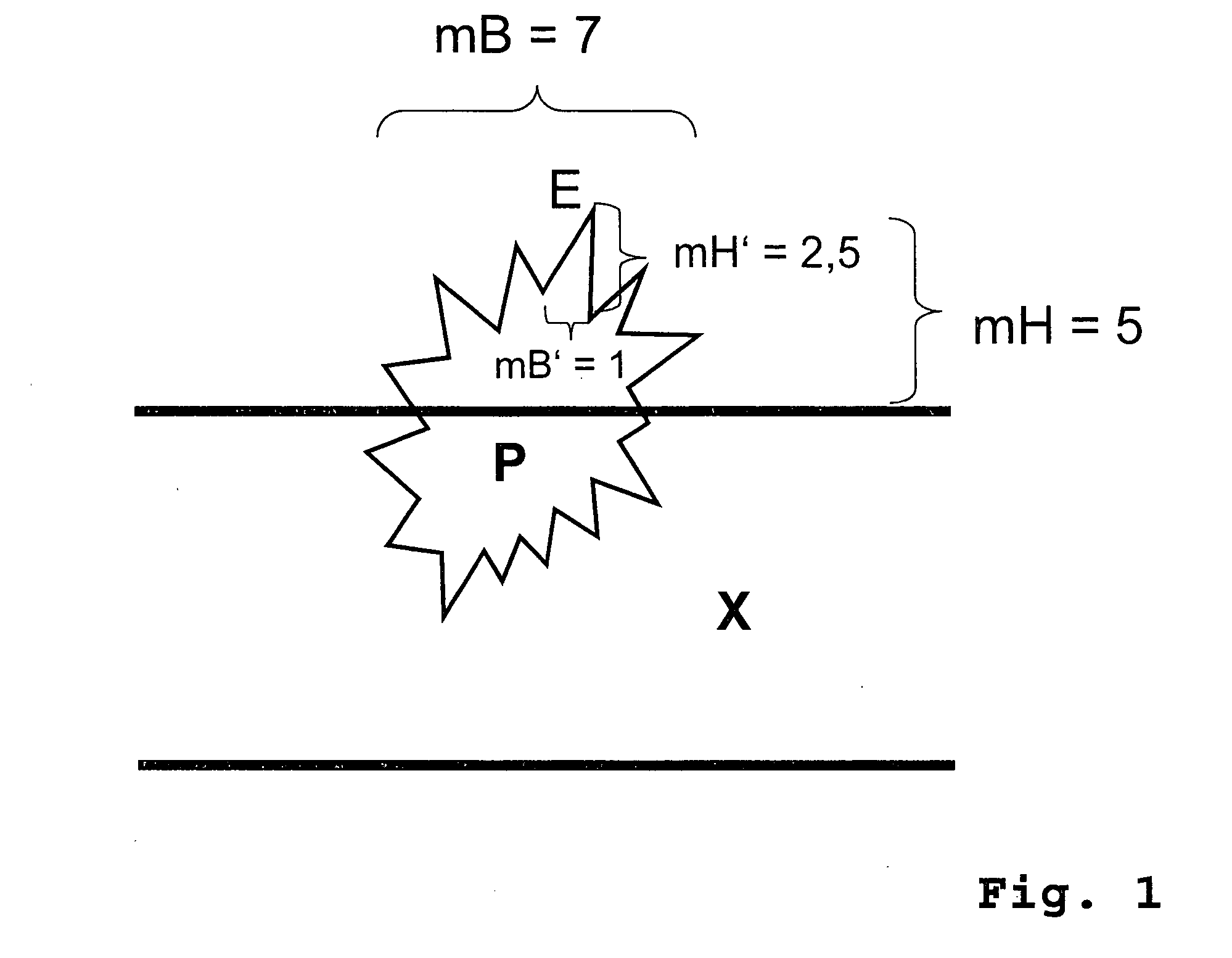

Self-cleaning surfaces comprising elevations formed by hydrophobic particles and having improved mechanical strength

PatentActiveUS20060147675A1

Innovation

- A self-cleaning surface is created using a mixture of hydrophobic metal oxide particles and wax particles, fixed to a substrate, which enhances mechanical stability by providing a supporting effect similar to fins, allowing for higher abrasion resistance without compromising the self-cleaning properties.

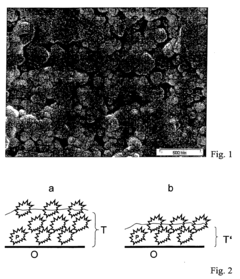

Self cleaning surfaces due to hydrophobic structures and method for the preparation thereof

PatentInactiveEP1283076A2

Innovation

- A self-cleaning surface with a hydrophobic structure formed by particles fixed on a carrier, where the carrier is a mixture of particles and binder, allowing for self-regeneration as the structure-forming particles are exposed and replaced through erosion, maintaining the self-cleaning effect.

Environmental Impact and Sustainability of Self-cleaning Technologies

The environmental footprint of traditional cleaning methods is substantial, with chemical cleaners contributing to water pollution, indoor air quality degradation, and resource depletion. Self-cleaning technologies offer a promising alternative that can significantly reduce these environmental impacts while enhancing public hygiene standards.

Self-cleaning surfaces typically employ one of several mechanisms: photocatalytic processes that break down organic matter using light energy, hydrophobic coatings that repel water and contaminants, or antimicrobial materials that actively kill pathogens. Each approach presents distinct environmental considerations throughout its lifecycle.

Lifecycle assessment studies indicate that photocatalytic self-cleaning surfaces, particularly those utilizing titanium dioxide (TiO2), can reduce water consumption by up to 70% compared to conventional cleaning regimens. This water conservation benefit is especially valuable in water-stressed regions, where public hygiene must be balanced against resource constraints.

Chemical reduction represents another significant environmental advantage. Traditional disinfection protocols often rely on harsh chemicals that pose risks to aquatic ecosystems when discharged. Self-cleaning technologies can decrease chemical cleaning agent usage by 40-60%, substantially reducing the environmental burden of cleaning runoff.

Energy efficiency considerations vary by technology type. While some self-cleaning surfaces require minimal energy inputs once installed, photocatalytic systems may incorporate UV light sources that consume electricity. However, advanced designs increasingly utilize ambient light or incorporate energy-harvesting components, moving toward net-zero energy operation.

Manufacturing sustainability remains a challenge for certain self-cleaning technologies. Nanomaterials production can be energy-intensive and may involve specialized processes with their own environmental implications. Research indicates that the environmental payback period—when benefits outweigh production impacts—ranges from 1-3 years for most applications.

End-of-life management presents both challenges and opportunities. Some self-cleaning coatings may complicate recycling processes for underlying materials, while others incorporate biodegradable components. The durability factor is crucial; longer-lasting self-cleaning surfaces reduce replacement frequency and associated waste generation.

Climate impact assessments demonstrate that widespread adoption of self-cleaning technologies in public spaces could contribute to greenhouse gas reduction targets by decreasing water heating requirements, chemical production, and transportation emissions associated with traditional cleaning operations.

Self-cleaning surfaces typically employ one of several mechanisms: photocatalytic processes that break down organic matter using light energy, hydrophobic coatings that repel water and contaminants, or antimicrobial materials that actively kill pathogens. Each approach presents distinct environmental considerations throughout its lifecycle.

Lifecycle assessment studies indicate that photocatalytic self-cleaning surfaces, particularly those utilizing titanium dioxide (TiO2), can reduce water consumption by up to 70% compared to conventional cleaning regimens. This water conservation benefit is especially valuable in water-stressed regions, where public hygiene must be balanced against resource constraints.

Chemical reduction represents another significant environmental advantage. Traditional disinfection protocols often rely on harsh chemicals that pose risks to aquatic ecosystems when discharged. Self-cleaning technologies can decrease chemical cleaning agent usage by 40-60%, substantially reducing the environmental burden of cleaning runoff.

Energy efficiency considerations vary by technology type. While some self-cleaning surfaces require minimal energy inputs once installed, photocatalytic systems may incorporate UV light sources that consume electricity. However, advanced designs increasingly utilize ambient light or incorporate energy-harvesting components, moving toward net-zero energy operation.

Manufacturing sustainability remains a challenge for certain self-cleaning technologies. Nanomaterials production can be energy-intensive and may involve specialized processes with their own environmental implications. Research indicates that the environmental payback period—when benefits outweigh production impacts—ranges from 1-3 years for most applications.

End-of-life management presents both challenges and opportunities. Some self-cleaning coatings may complicate recycling processes for underlying materials, while others incorporate biodegradable components. The durability factor is crucial; longer-lasting self-cleaning surfaces reduce replacement frequency and associated waste generation.

Climate impact assessments demonstrate that widespread adoption of self-cleaning technologies in public spaces could contribute to greenhouse gas reduction targets by decreasing water heating requirements, chemical production, and transportation emissions associated with traditional cleaning operations.

Public Health Benefits and Infection Control Applications

Self-cleaning surfaces represent a transformative approach to public health management, offering significant benefits in infection control and disease prevention. These surfaces actively reduce pathogen loads in high-touch environments, creating a continuous barrier against microbial colonization that conventional cleaning methods cannot match. Studies have demonstrated that self-cleaning surfaces can reduce bacterial counts by up to 99.9% in healthcare settings, substantially decreasing the risk of healthcare-associated infections (HAIs) which affect approximately 1 in 31 hospitalized patients annually.

The implementation of self-cleaning technologies in public spaces directly addresses the challenge of fomite transmission—the spread of pathogens via contaminated surfaces. This transmission route has been identified as significant for numerous pathogens including influenza viruses, noroviruses, and certain coronaviruses. By disrupting this transmission pathway, self-cleaning surfaces contribute to comprehensive infection control strategies beyond what hand hygiene alone can achieve.

In healthcare environments specifically, these technologies show promise in reducing the burden of antibiotic-resistant organisms. Research indicates that copper-based self-cleaning surfaces can reduce infections caused by methicillin-resistant Staphylococcus aureus (MRSA) by approximately 58% in intensive care units. This represents not only improved patient outcomes but also substantial cost savings, as each HAI adds an estimated $28,400 to $33,800 to hospitalization costs.

Beyond acute healthcare settings, self-cleaning surfaces offer significant public health benefits in schools, transportation hubs, and food service establishments. In educational institutions, where absenteeism due to infectious illness represents a substantial burden, pilot programs implementing self-cleaning surfaces on high-touch areas have demonstrated reductions in illness-related absences by up to 21%. Similarly, in mass transit systems, where surfaces may harbor pathogens for extended periods, self-cleaning technologies provide continuous protection between scheduled cleaning interventions.

The economic impact of these health benefits extends beyond direct healthcare costs. Reduced absenteeism in workplaces and schools, decreased burden on healthcare systems during seasonal illness peaks, and enhanced public confidence in shared spaces all contribute to the broader societal value of self-cleaning surface implementation. Cost-benefit analyses suggest that despite higher initial investment, the long-term public health returns make these technologies increasingly attractive as part of comprehensive hygiene strategies.

The implementation of self-cleaning technologies in public spaces directly addresses the challenge of fomite transmission—the spread of pathogens via contaminated surfaces. This transmission route has been identified as significant for numerous pathogens including influenza viruses, noroviruses, and certain coronaviruses. By disrupting this transmission pathway, self-cleaning surfaces contribute to comprehensive infection control strategies beyond what hand hygiene alone can achieve.

In healthcare environments specifically, these technologies show promise in reducing the burden of antibiotic-resistant organisms. Research indicates that copper-based self-cleaning surfaces can reduce infections caused by methicillin-resistant Staphylococcus aureus (MRSA) by approximately 58% in intensive care units. This represents not only improved patient outcomes but also substantial cost savings, as each HAI adds an estimated $28,400 to $33,800 to hospitalization costs.

Beyond acute healthcare settings, self-cleaning surfaces offer significant public health benefits in schools, transportation hubs, and food service establishments. In educational institutions, where absenteeism due to infectious illness represents a substantial burden, pilot programs implementing self-cleaning surfaces on high-touch areas have demonstrated reductions in illness-related absences by up to 21%. Similarly, in mass transit systems, where surfaces may harbor pathogens for extended periods, self-cleaning technologies provide continuous protection between scheduled cleaning interventions.

The economic impact of these health benefits extends beyond direct healthcare costs. Reduced absenteeism in workplaces and schools, decreased burden on healthcare systems during seasonal illness peaks, and enhanced public confidence in shared spaces all contribute to the broader societal value of self-cleaning surface implementation. Cost-benefit analyses suggest that despite higher initial investment, the long-term public health returns make these technologies increasingly attractive as part of comprehensive hygiene strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!