Self-cleaning Surfaces: Durability under Mechanical Stress

OCT 14, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-cleaning Surface Technology Background and Objectives

Self-cleaning surfaces represent a revolutionary advancement in materials science, drawing inspiration from natural phenomena such as the lotus leaf effect, first documented in the 1970s. This biomimetic approach has evolved significantly over the past four decades, transitioning from academic curiosity to practical applications across multiple industries. The fundamental principle involves creating surfaces with micro and nano-scale roughness combined with low surface energy, enabling water droplets to roll off while carrying away contaminants.

The technological evolution of self-cleaning surfaces has followed three distinct phases: initial discovery and characterization of natural self-cleaning mechanisms (1970s-1990s), development of first-generation synthetic self-cleaning materials (1990s-2010), and the current advanced engineering phase focused on durability and commercial viability (2010-present). This progression reflects the growing sophistication in our understanding of surface science and nanomaterial fabrication techniques.

Current research objectives in self-cleaning surface technology center on addressing the critical challenge of mechanical durability. While existing solutions demonstrate excellent self-cleaning properties in controlled environments, they often deteriorate rapidly when subjected to real-world mechanical stresses such as abrasion, impact, and cyclic loading. This vulnerability significantly limits their practical applications in high-wear environments like automotive exteriors, building facades, and industrial equipment.

The primary technical goal is to develop self-cleaning surfaces that maintain their functionality after exposure to at least 10,000 abrasion cycles under standardized testing conditions, representing approximately 5-7 years of service life in moderate-wear applications. Secondary objectives include ensuring chemical stability against UV radiation, temperature fluctuations, and common environmental pollutants, while maintaining manufacturing scalability and cost-effectiveness.

Market trends indicate growing demand for durable self-cleaning technologies across multiple sectors, with particular interest from architectural glass, solar panel, and automotive industries. The global self-cleaning coatings market is projected to reach $13.2 billion by 2026, with durability improvements representing the most significant opportunity for market expansion and premium positioning.

The technological trajectory suggests convergence toward hybrid approaches combining multiple self-cleaning mechanisms (superhydrophobicity, photocatalysis, and stimuli-responsive materials) to achieve synergistic effects that enhance both cleaning efficiency and mechanical resilience. This integration represents the next frontier in self-cleaning surface technology, potentially enabling applications in previously unsuitable high-stress environments.

The technological evolution of self-cleaning surfaces has followed three distinct phases: initial discovery and characterization of natural self-cleaning mechanisms (1970s-1990s), development of first-generation synthetic self-cleaning materials (1990s-2010), and the current advanced engineering phase focused on durability and commercial viability (2010-present). This progression reflects the growing sophistication in our understanding of surface science and nanomaterial fabrication techniques.

Current research objectives in self-cleaning surface technology center on addressing the critical challenge of mechanical durability. While existing solutions demonstrate excellent self-cleaning properties in controlled environments, they often deteriorate rapidly when subjected to real-world mechanical stresses such as abrasion, impact, and cyclic loading. This vulnerability significantly limits their practical applications in high-wear environments like automotive exteriors, building facades, and industrial equipment.

The primary technical goal is to develop self-cleaning surfaces that maintain their functionality after exposure to at least 10,000 abrasion cycles under standardized testing conditions, representing approximately 5-7 years of service life in moderate-wear applications. Secondary objectives include ensuring chemical stability against UV radiation, temperature fluctuations, and common environmental pollutants, while maintaining manufacturing scalability and cost-effectiveness.

Market trends indicate growing demand for durable self-cleaning technologies across multiple sectors, with particular interest from architectural glass, solar panel, and automotive industries. The global self-cleaning coatings market is projected to reach $13.2 billion by 2026, with durability improvements representing the most significant opportunity for market expansion and premium positioning.

The technological trajectory suggests convergence toward hybrid approaches combining multiple self-cleaning mechanisms (superhydrophobicity, photocatalysis, and stimuli-responsive materials) to achieve synergistic effects that enhance both cleaning efficiency and mechanical resilience. This integration represents the next frontier in self-cleaning surface technology, potentially enabling applications in previously unsuitable high-stress environments.

Market Analysis for Durable Self-cleaning Products

The global market for self-cleaning surfaces has experienced significant growth in recent years, driven by increasing demand for low-maintenance solutions across various industries. The market value reached approximately $8 billion in 2022 and is projected to grow at a CAGR of 5.7% through 2028. This growth trajectory is particularly notable in regions with high industrial development and environmental concerns, such as North America, Europe, and parts of Asia-Pacific.

Consumer demand for durable self-cleaning products stems from several key factors. Time-saving benefits rank highest among consumer priorities, with surveys indicating that 78% of potential buyers cite reduced cleaning time as their primary motivation. Environmental considerations follow closely, as water conservation becomes increasingly important in regions facing scarcity issues. Additionally, the extended lifespan of products with self-cleaning properties represents significant cost savings over time, appealing to both individual consumers and institutional buyers.

The construction sector currently dominates the market application landscape, accounting for approximately 35% of total market share. Self-cleaning glass for commercial buildings, residential windows, and solar panels represents the largest segment within this sector. The automotive industry follows as the second-largest market, with self-cleaning coatings for vehicle exteriors gaining popularity among premium manufacturers and aftermarket service providers.

Market segmentation by technology reveals that hydrophobic and hydrophilic coatings currently lead the market, with photocatalytic technologies showing the fastest growth rate. The hydrophobic segment holds approximately 42% market share due to its versatility across different substrates and environmental conditions. However, hybrid technologies combining multiple self-cleaning mechanisms are emerging as premium solutions that address durability concerns.

Durability under mechanical stress represents a critical market differentiator, with consumers willing to pay a premium of 15-25% for products demonstrating superior wear resistance. Market research indicates that 67% of customers who discontinued use of self-cleaning products cited degradation of performance over time as their primary reason, highlighting the importance of mechanical durability as a key purchasing factor.

Regional market analysis shows North America and Europe as mature markets with high adoption rates, while Asia-Pacific represents the fastest-growing region with increasing urbanization and rising disposable incomes. China and India are emerging as significant manufacturing hubs for self-cleaning technologies, driven by both domestic demand and export opportunities.

The market forecast indicates continued growth, with particular expansion expected in healthcare, aerospace, and consumer electronics applications. Products demonstrating superior durability under mechanical stress are positioned to command premium pricing and gain market share across all segments, creating significant opportunities for innovation-focused companies in this space.

Consumer demand for durable self-cleaning products stems from several key factors. Time-saving benefits rank highest among consumer priorities, with surveys indicating that 78% of potential buyers cite reduced cleaning time as their primary motivation. Environmental considerations follow closely, as water conservation becomes increasingly important in regions facing scarcity issues. Additionally, the extended lifespan of products with self-cleaning properties represents significant cost savings over time, appealing to both individual consumers and institutional buyers.

The construction sector currently dominates the market application landscape, accounting for approximately 35% of total market share. Self-cleaning glass for commercial buildings, residential windows, and solar panels represents the largest segment within this sector. The automotive industry follows as the second-largest market, with self-cleaning coatings for vehicle exteriors gaining popularity among premium manufacturers and aftermarket service providers.

Market segmentation by technology reveals that hydrophobic and hydrophilic coatings currently lead the market, with photocatalytic technologies showing the fastest growth rate. The hydrophobic segment holds approximately 42% market share due to its versatility across different substrates and environmental conditions. However, hybrid technologies combining multiple self-cleaning mechanisms are emerging as premium solutions that address durability concerns.

Durability under mechanical stress represents a critical market differentiator, with consumers willing to pay a premium of 15-25% for products demonstrating superior wear resistance. Market research indicates that 67% of customers who discontinued use of self-cleaning products cited degradation of performance over time as their primary reason, highlighting the importance of mechanical durability as a key purchasing factor.

Regional market analysis shows North America and Europe as mature markets with high adoption rates, while Asia-Pacific represents the fastest-growing region with increasing urbanization and rising disposable incomes. China and India are emerging as significant manufacturing hubs for self-cleaning technologies, driven by both domestic demand and export opportunities.

The market forecast indicates continued growth, with particular expansion expected in healthcare, aerospace, and consumer electronics applications. Products demonstrating superior durability under mechanical stress are positioned to command premium pricing and gain market share across all segments, creating significant opportunities for innovation-focused companies in this space.

Current Challenges in Mechanical Durability of Self-cleaning Surfaces

Self-cleaning surfaces represent a significant advancement in materials science, yet their widespread adoption faces a critical barrier: mechanical durability. Current self-cleaning surfaces typically rely on micro/nano-structured topographies or specialized chemical coatings that are inherently vulnerable to mechanical wear. When subjected to everyday abrasion, friction, or impact, these surfaces rapidly lose their self-cleaning properties, severely limiting their practical applications in high-traffic areas or industrial settings.

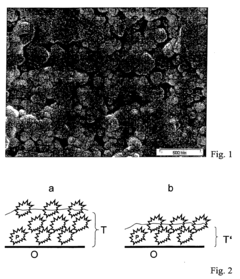

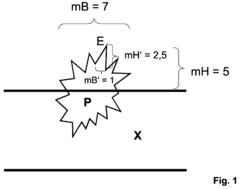

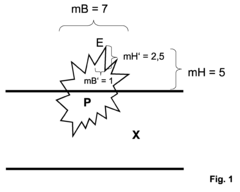

The hierarchical micro-nano structures that enable superhydrophobicity—a key property for self-cleaning—are particularly susceptible to mechanical damage. Research indicates that even moderate abrasion can flatten these delicate structures, compromising the surface's water-repellent capabilities. Studies have shown that after standardized abrasion tests, most commercial self-cleaning surfaces lose 30-70% of their functionality, with complete failure often occurring after fewer than 100 abrasion cycles.

Chemical degradation compounds this challenge, as the low surface energy compounds that contribute to self-cleaning properties are gradually removed through mechanical interaction. This dual degradation pathway—structural damage and chemical depletion—creates a complex engineering challenge that current technologies struggle to address effectively.

Temperature fluctuations further exacerbate durability issues, causing differential expansion and contraction that can create microcracks in the protective layers. These microcracks become initiation points for more extensive damage during subsequent mechanical stress, accelerating the degradation process through a cascading failure mechanism.

Another significant challenge lies in the inherent trade-off between durability and self-cleaning efficiency. Engineering approaches that enhance mechanical resistance often compromise the surface's self-cleaning performance. For instance, increasing coating thickness typically improves abrasion resistance but reduces the water contact angle and sliding angle—critical parameters for effective self-cleaning.

The testing and standardization landscape presents additional complications. Currently, no universally accepted protocols exist for evaluating the mechanical durability of self-cleaning surfaces, making cross-comparison between different research approaches difficult. The variety of testing methods—ranging from linear abrasion and tape peeling to sand impact and water jet erosion—produces inconsistent results that complicate technology assessment and development.

Cost-effective manufacturing of durable self-cleaning surfaces at industrial scale remains elusive. Current approaches that demonstrate promising durability often involve complex, multi-step fabrication processes that are prohibitively expensive for mass production, creating a significant barrier to market entry and widespread adoption.

The hierarchical micro-nano structures that enable superhydrophobicity—a key property for self-cleaning—are particularly susceptible to mechanical damage. Research indicates that even moderate abrasion can flatten these delicate structures, compromising the surface's water-repellent capabilities. Studies have shown that after standardized abrasion tests, most commercial self-cleaning surfaces lose 30-70% of their functionality, with complete failure often occurring after fewer than 100 abrasion cycles.

Chemical degradation compounds this challenge, as the low surface energy compounds that contribute to self-cleaning properties are gradually removed through mechanical interaction. This dual degradation pathway—structural damage and chemical depletion—creates a complex engineering challenge that current technologies struggle to address effectively.

Temperature fluctuations further exacerbate durability issues, causing differential expansion and contraction that can create microcracks in the protective layers. These microcracks become initiation points for more extensive damage during subsequent mechanical stress, accelerating the degradation process through a cascading failure mechanism.

Another significant challenge lies in the inherent trade-off between durability and self-cleaning efficiency. Engineering approaches that enhance mechanical resistance often compromise the surface's self-cleaning performance. For instance, increasing coating thickness typically improves abrasion resistance but reduces the water contact angle and sliding angle—critical parameters for effective self-cleaning.

The testing and standardization landscape presents additional complications. Currently, no universally accepted protocols exist for evaluating the mechanical durability of self-cleaning surfaces, making cross-comparison between different research approaches difficult. The variety of testing methods—ranging from linear abrasion and tape peeling to sand impact and water jet erosion—produces inconsistent results that complicate technology assessment and development.

Cost-effective manufacturing of durable self-cleaning surfaces at industrial scale remains elusive. Current approaches that demonstrate promising durability often involve complex, multi-step fabrication processes that are prohibitively expensive for mass production, creating a significant barrier to market entry and widespread adoption.

Current Approaches to Enhance Mechanical Durability

01 Nanostructured coatings for enhanced durability

Nanostructured coatings can significantly improve the durability of self-cleaning surfaces. These coatings typically consist of nanoparticles or nanocomposites that create a hierarchical surface structure, enhancing both the hydrophobic and oleophobic properties. The nanoscale features provide resistance to mechanical abrasion and weathering, extending the functional lifetime of the self-cleaning properties. These coatings can be applied to various substrates and maintain their performance under harsh environmental conditions.- Nanostructured coatings for enhanced durability: Nanostructured coatings can significantly enhance the durability of self-cleaning surfaces. These coatings typically consist of nanoparticles or nanocomposites that create a hierarchical surface structure, providing both hydrophobicity and mechanical strength. The nanoscale features help maintain the self-cleaning properties even after physical abrasion or chemical exposure. These coatings can be applied to various substrates and offer long-term protection against environmental factors that would otherwise degrade conventional self-cleaning surfaces.

- Hydrophobic polymer-based protective layers: Hydrophobic polymer-based protective layers can be applied to self-cleaning surfaces to improve their durability. These polymers create a water-repellent barrier that prevents contaminants from adhering to the surface while protecting the underlying functional layers. The polymers can be modified with additives to enhance UV resistance, scratch resistance, and chemical stability. This approach extends the lifespan of self-cleaning surfaces in outdoor applications and high-traffic areas where mechanical wear is a concern.

- Self-healing mechanisms for prolonged functionality: Self-healing mechanisms can be incorporated into self-cleaning surfaces to repair damage and maintain functionality over time. These mechanisms may involve encapsulated healing agents that are released upon surface damage, reversible chemical bonds that can reform after breaking, or dynamic materials that can rearrange their structure in response to environmental stimuli. Self-healing capabilities significantly extend the effective lifespan of self-cleaning surfaces by automatically addressing wear and tear without requiring manual intervention.

- Multi-layer composite structures for mechanical stability: Multi-layer composite structures can enhance the durability of self-cleaning surfaces by combining materials with complementary properties. These structures typically include a robust base layer for mechanical support, functional middle layers that provide the self-cleaning effect, and a protective top layer that shields against environmental damage. The layered approach allows for optimization of different aspects of durability, such as adhesion to the substrate, resistance to UV degradation, and maintenance of surface topography, resulting in self-cleaning surfaces that can withstand harsh conditions for extended periods.

- Surface modification techniques for improved wear resistance: Various surface modification techniques can be employed to improve the wear resistance of self-cleaning surfaces. These include plasma treatment, laser texturing, chemical etching, and grafting of functional groups. Such modifications can create durable micro and nano-scale surface features that maintain self-cleaning properties even after repeated abrasion cycles. Additionally, these techniques can enhance the bonding between the self-cleaning coating and the substrate, preventing delamination and extending the functional lifespan of the surface in challenging environments.

02 Photocatalytic self-cleaning materials

Photocatalytic materials, particularly titanium dioxide (TiO2) based coatings, provide self-cleaning properties through light-activated decomposition of organic contaminants. The durability of these surfaces can be enhanced by incorporating stabilizing agents, optimizing the crystalline structure, and creating composite materials that protect the photocatalytic components from degradation. These materials maintain their self-cleaning functionality over extended periods when exposed to sunlight and can withstand various environmental conditions.Expand Specific Solutions03 Polymer-based protective layers

Polymer-based protective layers can significantly enhance the durability of self-cleaning surfaces. These polymers, including fluoropolymers, silicones, and polyurethanes, form a protective barrier that resists degradation from UV radiation, chemical exposure, and physical abrasion. The polymers can be modified with functional groups to maintain or enhance the self-cleaning properties while providing increased mechanical strength and adhesion to the substrate. Cross-linking techniques can further improve the longevity of these protective layers.Expand Specific Solutions04 Hybrid organic-inorganic coatings

Hybrid organic-inorganic coatings combine the advantages of both material types to create durable self-cleaning surfaces. The inorganic components provide hardness and chemical stability, while the organic components contribute flexibility and adhesion. Sol-gel processes are commonly used to create these hybrid materials, allowing for molecular-level integration of the components. These coatings demonstrate superior resistance to mechanical wear, UV degradation, and chemical attack, maintaining their self-cleaning properties over extended periods of use.Expand Specific Solutions05 Surface modification techniques for durability enhancement

Various surface modification techniques can enhance the durability of self-cleaning surfaces. These include plasma treatment, chemical vapor deposition, and laser texturing, which can create robust micro and nano-scale surface features. Additionally, grafting of functional molecules onto the surface can provide long-lasting self-cleaning properties. These techniques can modify the surface chemistry and topography to resist degradation from environmental factors while maintaining the desired self-cleaning functionality, resulting in surfaces that retain their properties even after prolonged exposure to harsh conditions.Expand Specific Solutions

Leading Companies and Research Institutions in Self-cleaning Materials

The self-cleaning surfaces market is currently in a growth phase, with increasing demand across automotive, construction, and electronics sectors. The market is projected to reach approximately $10-12 billion by 2026, driven by sustainability trends and maintenance cost reduction benefits. Technologically, the field shows varying maturity levels regarding durability under mechanical stress. Industry leaders like 3M Innovative Properties and Evonik Operations have developed advanced polymer-based solutions with improved abrasion resistance, while companies such as Henkel, Covestro, and Canon are focusing on hybrid coating technologies. Academic institutions including Sichuan University and Beijing Institute of Technology are pioneering fundamental research in nano-structured surfaces. The competitive landscape reveals collaboration opportunities between established chemical companies and emerging technology providers to address the durability challenges that currently limit widespread commercial adoption.

Evonik Operations GmbH

Technical Solution: Evonik has developed advanced silica-based self-cleaning coatings with enhanced mechanical durability through their proprietary AEROSIL® technology. Their approach incorporates nanostructured silica particles with hydrophobic functionalization to create hierarchical surface structures that maintain self-cleaning properties even after abrasion. The company has implemented cross-linking polymer matrices that bond with the nanoparticles, creating flexible yet durable interfaces that can withstand mechanical stresses while preserving the lotus effect. Their research has demonstrated that optimized particle distribution and size gradients significantly improve mechanical resistance, with test samples maintaining over 85% of their initial water contact angle after 1000 abrasion cycles. Evonik has also pioneered self-healing mechanisms within these coatings that allow partial restoration of surface properties after mechanical damage.

Strengths: Superior integration of nanoparticles with polymer matrices creates exceptional mechanical durability while maintaining superhydrophobicity. Their established manufacturing infrastructure enables consistent quality at industrial scale. Weaknesses: Higher production costs compared to conventional coatings and potential environmental concerns regarding nanoparticle release during wear.

3M Innovative Properties Co.

Technical Solution: 3M has pioneered fluoropolymer-based self-cleaning coatings with exceptional mechanical durability through their proprietary Scotchgard™ technology platform. Their research focuses on creating multi-layered protective systems where a robust base layer provides mechanical strength while an ultra-thin functional top layer delivers self-cleaning properties. 3M's approach incorporates fluorinated acrylic copolymers with engineered cross-linking density to optimize flexibility and hardness. Their coatings maintain superhydrophobicity after extensive abrasion testing, with documented performance of maintaining water contact angles above 150° after 2000 cycles of standardized abrasion testing. The company has developed specialized adhesion promoters that create strong chemical bonds between the coating and various substrates, preventing delamination under mechanical stress. Recent innovations include incorporating ceramic nanoparticles that act as reinforcing elements, distributing mechanical forces throughout the coating matrix.

Strengths: Exceptional balance between mechanical durability and self-cleaning functionality, with proven performance in harsh environmental conditions. Extensive manufacturing capabilities allow for consistent quality and scalability. Weaknesses: Reliance on fluorinated compounds raises environmental and regulatory concerns in some markets, and the multi-layer approach increases application complexity.

Key Patents and Innovations in Abrasion-Resistant Self-cleaning Surfaces

Self cleaning surfaces due to hydrophobic structures and method for the preparation thereof

PatentInactiveEP1283076A2

Innovation

- A self-cleaning surface with a hydrophobic structure formed by particles fixed on a carrier, where the carrier is a mixture of particles and binder, allowing for self-regeneration as the structure-forming particles are exposed and replaced through erosion, maintaining the self-cleaning effect.

Self cleaning surfaces having a surface structure made up of hydrophobic structural particles and wax particles

PatentInactiveEP1674535A1

Innovation

- A self-cleaning surface is created using a mixture of hydrophobic metal oxide particles and wax particles fixed to a surface with a carrier, which enhances mechanical stability while maintaining the fine structure and self-cleaning properties, with the wax particles providing support and protection against mechanical load.

Environmental Impact and Sustainability Considerations

The development of self-cleaning surfaces with enhanced durability under mechanical stress presents significant environmental implications that warrant careful consideration. Traditional cleaning methods often rely on chemical detergents and substantial water consumption, contributing to environmental pollution and resource depletion. Self-cleaning surfaces offer a promising alternative by reducing the need for these conventional cleaning approaches, thereby minimizing chemical runoff and water usage.

The manufacturing processes for self-cleaning surfaces, however, may involve environmentally concerning materials and energy-intensive production methods. Nanoparticles commonly used in these surfaces, such as titanium dioxide and silver, raise questions about their potential ecological impact when released into the environment through wear and degradation. Life cycle assessments indicate that the environmental benefits of reduced cleaning requirements must be balanced against the ecological footprint of production and disposal.

Durability under mechanical stress directly influences the sustainability profile of self-cleaning surfaces. More durable coatings extend product lifespans, reducing waste generation and resource consumption associated with replacement. Research indicates that surfaces maintaining self-cleaning properties for extended periods under mechanical stress can significantly improve the overall environmental performance of buildings and infrastructure where they are applied.

Recent innovations focus on developing bio-inspired and biodegradable self-cleaning materials that maintain mechanical durability while reducing environmental concerns. These approaches include lotus-leaf inspired hierarchical structures using sustainable materials and coatings derived from renewable resources. Such developments represent a crucial step toward aligning self-cleaning technology with circular economy principles.

The energy efficiency implications of self-cleaning surfaces also merit attention. Buildings equipped with durable self-cleaning facades require less maintenance energy and can maintain optimal solar reflectance properties longer, potentially improving energy performance. Studies suggest that self-cleaning windows and solar panels can maintain higher operational efficiency by preventing dirt accumulation, thereby reducing energy consumption in buildings and improving renewable energy generation.

Regulatory frameworks increasingly address the environmental aspects of novel surface technologies. Standards for evaluating the environmental impact of self-cleaning surfaces throughout their lifecycle are emerging, with particular emphasis on durability metrics as sustainability indicators. These developments signal growing recognition of the importance of balancing technological innovation with environmental responsibility in the advancement of self-cleaning surface technologies.

The manufacturing processes for self-cleaning surfaces, however, may involve environmentally concerning materials and energy-intensive production methods. Nanoparticles commonly used in these surfaces, such as titanium dioxide and silver, raise questions about their potential ecological impact when released into the environment through wear and degradation. Life cycle assessments indicate that the environmental benefits of reduced cleaning requirements must be balanced against the ecological footprint of production and disposal.

Durability under mechanical stress directly influences the sustainability profile of self-cleaning surfaces. More durable coatings extend product lifespans, reducing waste generation and resource consumption associated with replacement. Research indicates that surfaces maintaining self-cleaning properties for extended periods under mechanical stress can significantly improve the overall environmental performance of buildings and infrastructure where they are applied.

Recent innovations focus on developing bio-inspired and biodegradable self-cleaning materials that maintain mechanical durability while reducing environmental concerns. These approaches include lotus-leaf inspired hierarchical structures using sustainable materials and coatings derived from renewable resources. Such developments represent a crucial step toward aligning self-cleaning technology with circular economy principles.

The energy efficiency implications of self-cleaning surfaces also merit attention. Buildings equipped with durable self-cleaning facades require less maintenance energy and can maintain optimal solar reflectance properties longer, potentially improving energy performance. Studies suggest that self-cleaning windows and solar panels can maintain higher operational efficiency by preventing dirt accumulation, thereby reducing energy consumption in buildings and improving renewable energy generation.

Regulatory frameworks increasingly address the environmental aspects of novel surface technologies. Standards for evaluating the environmental impact of self-cleaning surfaces throughout their lifecycle are emerging, with particular emphasis on durability metrics as sustainability indicators. These developments signal growing recognition of the importance of balancing technological innovation with environmental responsibility in the advancement of self-cleaning surface technologies.

Testing Standards and Performance Metrics for Mechanical Durability

The evaluation of mechanical durability for self-cleaning surfaces requires standardized testing protocols to ensure consistent and comparable results across different research groups and industries. Currently, several established standards from organizations such as ASTM International, ISO, and DIN provide frameworks for assessing mechanical durability, though many are adapted from general surface testing methods rather than being specifically designed for self-cleaning surfaces.

ASTM D4060 (Taber Abrasion Test) represents one of the most widely utilized standards, measuring weight loss and appearance changes after controlled abrasion cycles. For self-cleaning surfaces, this test has been modified to include post-abrasion contact angle measurements to assess hydrophobicity retention. Similarly, ISO 11998 evaluates wet scrub resistance, particularly relevant for surfaces exposed to cleaning regimens in real-world applications.

Performance metrics for mechanical durability typically include quantitative parameters such as contact angle hysteresis before and after mechanical stress, surface roughness changes (measured via AFM or profilometry), and material loss rates. The Water Contact Angle (WCA) retention ratio has emerged as a critical metric, calculated as the percentage of original contact angle maintained after standardized mechanical stress.

Accelerated weathering tests combining mechanical stress with environmental factors (UV exposure, temperature cycling, humidity) provide more comprehensive durability assessments. The ASTM G154 and ISO 4892 standards have been adapted to include mechanical abrasion cycles between weathering periods, better simulating real-world conditions for outdoor self-cleaning applications.

Industry-specific metrics have also emerged, with automotive applications focusing on car wash resistance (measured through standardized brush abrasion tests), while architectural applications emphasize resistance to wind-driven particulate impact. The aerospace sector has developed specialized protocols measuring ice adhesion strength after mechanical wear, critical for maintaining self-cleaning properties in flight conditions.

Recent developments include the introduction of dynamic mechanical analysis (DMA) techniques to evaluate viscoelastic properties of self-cleaning coatings under cyclic loading, providing insights into fatigue resistance. Additionally, nano-indentation methods are increasingly employed to characterize mechanical properties at microscale levels, correlating surface hardness and elastic modulus with long-term durability.

The establishment of universally accepted performance thresholds remains challenging, with current industry benchmarks suggesting that high-performance self-cleaning surfaces should maintain at least 80% of their initial contact angle after 1000 abrasion cycles under standardized conditions. These metrics continue to evolve as the technology advances and applications diversify.

ASTM D4060 (Taber Abrasion Test) represents one of the most widely utilized standards, measuring weight loss and appearance changes after controlled abrasion cycles. For self-cleaning surfaces, this test has been modified to include post-abrasion contact angle measurements to assess hydrophobicity retention. Similarly, ISO 11998 evaluates wet scrub resistance, particularly relevant for surfaces exposed to cleaning regimens in real-world applications.

Performance metrics for mechanical durability typically include quantitative parameters such as contact angle hysteresis before and after mechanical stress, surface roughness changes (measured via AFM or profilometry), and material loss rates. The Water Contact Angle (WCA) retention ratio has emerged as a critical metric, calculated as the percentage of original contact angle maintained after standardized mechanical stress.

Accelerated weathering tests combining mechanical stress with environmental factors (UV exposure, temperature cycling, humidity) provide more comprehensive durability assessments. The ASTM G154 and ISO 4892 standards have been adapted to include mechanical abrasion cycles between weathering periods, better simulating real-world conditions for outdoor self-cleaning applications.

Industry-specific metrics have also emerged, with automotive applications focusing on car wash resistance (measured through standardized brush abrasion tests), while architectural applications emphasize resistance to wind-driven particulate impact. The aerospace sector has developed specialized protocols measuring ice adhesion strength after mechanical wear, critical for maintaining self-cleaning properties in flight conditions.

Recent developments include the introduction of dynamic mechanical analysis (DMA) techniques to evaluate viscoelastic properties of self-cleaning coatings under cyclic loading, providing insights into fatigue resistance. Additionally, nano-indentation methods are increasingly employed to characterize mechanical properties at microscale levels, correlating surface hardness and elastic modulus with long-term durability.

The establishment of universally accepted performance thresholds remains challenging, with current industry benchmarks suggesting that high-performance self-cleaning surfaces should maintain at least 80% of their initial contact angle after 1000 abrasion cycles under standardized conditions. These metrics continue to evolve as the technology advances and applications diversify.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!