Patent Review of Self-cleaning Technologies and Their Applications

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-cleaning Technologies Background and Objectives

Self-cleaning technologies represent a revolutionary advancement in material science and surface engineering, drawing inspiration from natural phenomena such as the lotus leaf effect and gecko adhesion mechanisms. The development of these technologies has evolved significantly over the past three decades, transitioning from basic hydrophobic coatings to sophisticated multi-functional surfaces capable of autonomous cleaning in various environments.

The historical trajectory of self-cleaning technologies began in the early 1990s with the scientific documentation of the lotus effect, which demonstrated how microscopic surface structures could create superhydrophobic properties. This discovery catalyzed research into biomimetic approaches for creating artificial self-cleaning surfaces. By the early 2000s, the first commercial applications emerged in architectural glass and exterior paints, though with limited durability and effectiveness.

Current technological trends indicate a shift toward multi-mechanism self-cleaning surfaces that combine hydrophobicity, photocatalytic activity, and antimicrobial properties. The integration of nanotechnology has enabled more precise control over surface structures, while advances in polymer science have improved durability and application versatility. Emerging approaches include stimuli-responsive surfaces that can adapt their properties based on environmental conditions.

The primary objectives of contemporary self-cleaning technology research include enhancing durability under harsh environmental conditions, reducing manufacturing costs for widespread commercial adoption, and developing environmentally sustainable formulations free from harmful chemicals. Additionally, researchers aim to create omniphobic surfaces repellent to both water and oil-based contaminants, and to develop self-healing capabilities that can restore damaged self-cleaning properties.

From an application perspective, self-cleaning technologies seek to address maintenance challenges across multiple sectors including construction, automotive, consumer electronics, healthcare, and renewable energy. In particular, the solar energy sector represents a critical application area, where self-cleaning surfaces can significantly improve photovoltaic efficiency by preventing dust accumulation.

The convergence of self-cleaning technologies with other advanced materials science fields, such as smart materials and Internet of Things (IoT) sensors, presents opportunities for creating intelligent surfaces that can monitor their own condition and cleaning effectiveness. This integration aligns with broader sustainability goals by reducing water consumption, minimizing chemical cleaning agents, and extending product lifecycles.

The historical trajectory of self-cleaning technologies began in the early 1990s with the scientific documentation of the lotus effect, which demonstrated how microscopic surface structures could create superhydrophobic properties. This discovery catalyzed research into biomimetic approaches for creating artificial self-cleaning surfaces. By the early 2000s, the first commercial applications emerged in architectural glass and exterior paints, though with limited durability and effectiveness.

Current technological trends indicate a shift toward multi-mechanism self-cleaning surfaces that combine hydrophobicity, photocatalytic activity, and antimicrobial properties. The integration of nanotechnology has enabled more precise control over surface structures, while advances in polymer science have improved durability and application versatility. Emerging approaches include stimuli-responsive surfaces that can adapt their properties based on environmental conditions.

The primary objectives of contemporary self-cleaning technology research include enhancing durability under harsh environmental conditions, reducing manufacturing costs for widespread commercial adoption, and developing environmentally sustainable formulations free from harmful chemicals. Additionally, researchers aim to create omniphobic surfaces repellent to both water and oil-based contaminants, and to develop self-healing capabilities that can restore damaged self-cleaning properties.

From an application perspective, self-cleaning technologies seek to address maintenance challenges across multiple sectors including construction, automotive, consumer electronics, healthcare, and renewable energy. In particular, the solar energy sector represents a critical application area, where self-cleaning surfaces can significantly improve photovoltaic efficiency by preventing dust accumulation.

The convergence of self-cleaning technologies with other advanced materials science fields, such as smart materials and Internet of Things (IoT) sensors, presents opportunities for creating intelligent surfaces that can monitor their own condition and cleaning effectiveness. This integration aligns with broader sustainability goals by reducing water consumption, minimizing chemical cleaning agents, and extending product lifecycles.

Market Demand Analysis for Self-cleaning Solutions

The global market for self-cleaning technologies has witnessed substantial growth in recent years, driven by increasing consumer demand for low-maintenance products and heightened awareness of hygiene and cleanliness. The market value for self-cleaning surfaces reached approximately $3.5 billion in 2022 and is projected to grow at a compound annual growth rate of 7.8% through 2028, indicating robust market potential.

Consumer electronics represents one of the fastest-growing application segments, with smartphone manufacturers increasingly incorporating self-cleaning coatings on touchscreens to reduce fingerprints and bacterial growth. Market research indicates that 65% of premium smartphone users consider self-cleaning features as a significant value addition, willing to pay a premium of 8-12% for such functionality.

The architectural and construction sector demonstrates the largest market share for self-cleaning technologies, particularly in exterior glass, facades, and roofing materials. The demand is especially strong in urban areas with high pollution levels, where self-cleaning building materials can reduce maintenance costs by up to 40% over their lifetime. Commercial buildings adopting these technologies report maintenance savings averaging $1.25 per square foot annually.

Healthcare facilities represent another critical market segment with stringent cleanliness requirements. The COVID-19 pandemic has accelerated adoption, with hospital administrators reporting increased interest in antimicrobial and self-cleaning surfaces for high-touch areas. Market surveys indicate that 78% of healthcare facilities are considering implementing self-cleaning technologies within the next three years.

Automotive applications show promising growth potential, particularly for exterior coatings and interior surfaces. Premium vehicle manufacturers have begun incorporating hydrophobic windshields and self-cleaning paint technologies, with consumer willingness-to-pay studies showing positive reception among luxury vehicle buyers.

Regional analysis reveals that North America and Europe currently lead market adoption, accounting for approximately 60% of global market share. However, the Asia-Pacific region, particularly China and Japan, demonstrates the fastest growth rate at 9.3% annually, driven by rapid urbanization and increasing disposable income.

Consumer behavior studies indicate shifting preferences toward sustainable and low-maintenance products across all demographics. Particularly notable is the millennial consumer segment, which shows 72% higher preference for self-cleaning features compared to older generations, suggesting long-term market sustainability as this demographic gains purchasing power.

Consumer electronics represents one of the fastest-growing application segments, with smartphone manufacturers increasingly incorporating self-cleaning coatings on touchscreens to reduce fingerprints and bacterial growth. Market research indicates that 65% of premium smartphone users consider self-cleaning features as a significant value addition, willing to pay a premium of 8-12% for such functionality.

The architectural and construction sector demonstrates the largest market share for self-cleaning technologies, particularly in exterior glass, facades, and roofing materials. The demand is especially strong in urban areas with high pollution levels, where self-cleaning building materials can reduce maintenance costs by up to 40% over their lifetime. Commercial buildings adopting these technologies report maintenance savings averaging $1.25 per square foot annually.

Healthcare facilities represent another critical market segment with stringent cleanliness requirements. The COVID-19 pandemic has accelerated adoption, with hospital administrators reporting increased interest in antimicrobial and self-cleaning surfaces for high-touch areas. Market surveys indicate that 78% of healthcare facilities are considering implementing self-cleaning technologies within the next three years.

Automotive applications show promising growth potential, particularly for exterior coatings and interior surfaces. Premium vehicle manufacturers have begun incorporating hydrophobic windshields and self-cleaning paint technologies, with consumer willingness-to-pay studies showing positive reception among luxury vehicle buyers.

Regional analysis reveals that North America and Europe currently lead market adoption, accounting for approximately 60% of global market share. However, the Asia-Pacific region, particularly China and Japan, demonstrates the fastest growth rate at 9.3% annually, driven by rapid urbanization and increasing disposable income.

Consumer behavior studies indicate shifting preferences toward sustainable and low-maintenance products across all demographics. Particularly notable is the millennial consumer segment, which shows 72% higher preference for self-cleaning features compared to older generations, suggesting long-term market sustainability as this demographic gains purchasing power.

Current Status and Technical Challenges

Self-cleaning technologies have witnessed significant advancements globally, with research institutions and companies across North America, Europe, and Asia leading innovation efforts. Current market analysis indicates that self-cleaning technologies have reached varying levels of maturity across different application sectors. In architectural applications, self-cleaning glass and concrete have achieved commercial viability, while textile applications remain predominantly in early commercialization phases. The automotive and solar panel sectors demonstrate growing adoption rates, though widespread implementation faces economic barriers.

The global patent landscape reveals concentrated innovation clusters in Japan, Germany, the United States, and increasingly in China. Japanese companies hold dominant positions in photocatalytic coatings, while European entities lead in hydrophobic surface treatments. Recent patent filing trends show a 15% annual growth in self-cleaning technology patents over the past five years, with particular acceleration in biomimetic approaches.

Despite promising developments, several technical challenges persist across the self-cleaning technology spectrum. Durability remains a primary concern, with many solutions demonstrating performance degradation under prolonged environmental exposure. Current photocatalytic coatings typically lose 30-40% efficiency after 3-5 years of outdoor exposure. Hydrophobic coatings face similar limitations, with mechanical abrasion significantly reducing their functional lifespan.

Cost-effectiveness presents another substantial barrier, particularly for large-scale applications. Manufacturing processes for advanced self-cleaning surfaces often require specialized equipment and precise control parameters, driving production costs significantly higher than conventional alternatives. This cost differential has limited market penetration in price-sensitive sectors.

Compatibility issues across diverse substrate materials constitute another technical hurdle. Solutions optimized for glass surfaces often perform poorly on textiles or polymeric materials, necessitating application-specific formulations. This fragmentation impedes standardization efforts and economies of scale.

Environmental concerns have also emerged as regulatory frameworks evolve. Some nanoparticle-based self-cleaning technologies face scrutiny regarding potential ecological impacts, particularly regarding leaching into water systems. Additionally, certain hydrophobic treatments contain perfluorinated compounds facing increasing regulatory restrictions.

The performance gap between laboratory demonstrations and real-world applications represents a persistent challenge. Controlled testing environments rarely replicate the complex combination of contaminants, weather conditions, and mechanical stresses encountered in practical applications. This discrepancy often results in overstated performance claims and subsequent market disappointment.

The global patent landscape reveals concentrated innovation clusters in Japan, Germany, the United States, and increasingly in China. Japanese companies hold dominant positions in photocatalytic coatings, while European entities lead in hydrophobic surface treatments. Recent patent filing trends show a 15% annual growth in self-cleaning technology patents over the past five years, with particular acceleration in biomimetic approaches.

Despite promising developments, several technical challenges persist across the self-cleaning technology spectrum. Durability remains a primary concern, with many solutions demonstrating performance degradation under prolonged environmental exposure. Current photocatalytic coatings typically lose 30-40% efficiency after 3-5 years of outdoor exposure. Hydrophobic coatings face similar limitations, with mechanical abrasion significantly reducing their functional lifespan.

Cost-effectiveness presents another substantial barrier, particularly for large-scale applications. Manufacturing processes for advanced self-cleaning surfaces often require specialized equipment and precise control parameters, driving production costs significantly higher than conventional alternatives. This cost differential has limited market penetration in price-sensitive sectors.

Compatibility issues across diverse substrate materials constitute another technical hurdle. Solutions optimized for glass surfaces often perform poorly on textiles or polymeric materials, necessitating application-specific formulations. This fragmentation impedes standardization efforts and economies of scale.

Environmental concerns have also emerged as regulatory frameworks evolve. Some nanoparticle-based self-cleaning technologies face scrutiny regarding potential ecological impacts, particularly regarding leaching into water systems. Additionally, certain hydrophobic treatments contain perfluorinated compounds facing increasing regulatory restrictions.

The performance gap between laboratory demonstrations and real-world applications represents a persistent challenge. Controlled testing environments rarely replicate the complex combination of contaminants, weather conditions, and mechanical stresses encountered in practical applications. This discrepancy often results in overstated performance claims and subsequent market disappointment.

Current Self-cleaning Technical Solutions

01 Photocatalytic self-cleaning surfaces

Photocatalytic materials, particularly titanium dioxide (TiO2) coatings, can be applied to surfaces to create self-cleaning properties. When exposed to UV light, these materials trigger oxidation reactions that break down organic dirt, pollutants, and microorganisms on the surface. This technology is commonly used in building materials, glass, and exterior surfaces to maintain cleanliness with minimal maintenance requirements.- Photocatalytic self-cleaning surfaces: Photocatalytic materials, particularly titanium dioxide (TiO2) coatings, can be applied to surfaces to create self-cleaning properties. When exposed to UV light, these materials trigger chemical reactions that break down organic dirt, pollutants, and bacteria on the surface. This technology is commonly used in building materials, glass, and exterior surfaces to maintain cleanliness with minimal maintenance requirements.

- Self-cleaning ovens and cooking appliances: Self-cleaning technologies in ovens and cooking appliances utilize high-temperature pyrolytic processes to decompose food residues and grease into ash. These systems typically heat the oven cavity to extremely high temperatures (around 500°C) to carbonize organic matter, which can then be easily wiped away. Some advanced systems incorporate catalytic liners that continuously clean during normal cooking operations by breaking down splattered grease and food particles.

- Hydrophobic and superhydrophobic coatings: Hydrophobic and superhydrophobic coatings create water-repellent surfaces that facilitate self-cleaning through the lotus effect. Water droplets on these surfaces maintain a high contact angle, causing them to roll off easily while collecting dirt particles along the way. These coatings can be applied to various materials including glass, textiles, and building exteriors to reduce maintenance and cleaning requirements while maintaining surface appearance and functionality.

- Automated self-cleaning systems: Automated self-cleaning systems incorporate mechanical components, sensors, and control algorithms to perform cleaning operations without human intervention. These systems may include robotic mechanisms, water jets, brushes, or air blowers that activate according to programmed schedules or when sensors detect contamination. Applications range from self-cleaning toilets and bathroom fixtures to industrial equipment and public facilities that require regular maintenance.

- Self-cleaning filtration and membrane technologies: Self-cleaning filtration systems employ various mechanisms to prevent clogging and maintain operational efficiency without manual intervention. These technologies may use backwashing, ultrasonic vibrations, mechanical scrapers, or pulsed flow to dislodge accumulated particles from filter surfaces. Advanced membrane systems incorporate similar principles to extend service life and reduce maintenance requirements in water treatment, industrial processing, and environmental applications.

02 Hydrophobic and hydrophilic self-cleaning coatings

Self-cleaning surfaces can be engineered with either hydrophobic (water-repelling) or hydrophilic (water-attracting) properties. Hydrophobic coatings create a lotus effect where water droplets roll off surfaces carrying dirt particles away. Hydrophilic coatings spread water into thin sheets that wash away contaminants. These technologies are applied in various industries including construction, automotive, and consumer products to reduce maintenance and cleaning requirements.Expand Specific Solutions03 Self-cleaning heating systems and ovens

Self-cleaning technologies for heating appliances utilize high-temperature pyrolytic processes to decompose food residues and contaminants into ash. These systems typically operate by heating the interior to extremely high temperatures (around 500°C) to carbonize organic matter, which can then be easily wiped away. Advanced versions may incorporate catalytic converters to reduce smoke and odors during the cleaning cycle, improving efficiency and user experience.Expand Specific Solutions04 Automated self-cleaning mechanisms for electronic devices

Electronic devices can incorporate automated self-cleaning mechanisms to maintain optimal performance. These systems may include brushes, air jets, or vibration mechanisms that automatically remove dust and debris from critical components. Some implementations use sensors to detect contamination levels and trigger cleaning cycles accordingly. This technology is particularly valuable in devices operating in dusty environments or those with cooling systems that can be compromised by particulate buildup.Expand Specific Solutions05 Software-based self-cleaning systems

Software solutions implement self-cleaning functionalities to maintain system performance and security. These systems automatically identify and remove temporary files, cache data, malware, and other digital clutter that can degrade performance. Advanced implementations may use machine learning algorithms to identify patterns of unnecessary data accumulation and optimize cleaning schedules. This approach helps maintain system integrity and performance without requiring manual intervention.Expand Specific Solutions

Key Industry Players and Patent Holders

The self-cleaning technologies market is currently in a growth phase, with an expanding ecosystem of players across consumer robotics, home appliances, and industrial applications. The market is experiencing robust growth driven by increasing consumer demand for automated cleaning solutions and technological advancements in AI, sensors, and robotics. Leading companies like iRobot, Ecovacs, and Roborock have established strong positions in the consumer robotics segment with mature product offerings, while traditional appliance manufacturers such as Haier, Samsung, and Gree are integrating self-cleaning capabilities into their product lines. Industrial applications are being developed by specialized players like Avidbots and Global Plasma Solutions. The technology shows varying maturity levels across segments, with consumer robotics being most advanced, while industrial and specialized applications continue to evolve through innovations from research institutions like Industrial Technology Research Institute and universities.

Beijing Roborock Technology Co., Ltd.

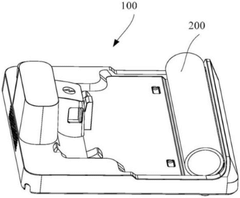

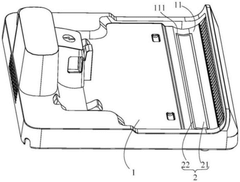

Technical Solution: Roborock has developed proprietary self-cleaning technologies centered around their VibraRise system and sonic mopping capabilities. Their patented self-cleaning dock implements a comprehensive maintenance approach that includes automatic mop washing with heated water (reaching temperatures of 60°C), scrubbing against a grooved cleaning module, and hot air drying to prevent mold and bacteria growth. The company's latest S8 Pro Ultra model features an all-in-one dock that automatically empties the dust bin, refills the water tank, cleans the mop, and performs self-maintenance without user intervention. Roborock's patents also cover their ReactiveAI Obstacle Avoidance System that prevents contamination by identifying and avoiding potential sources of stubborn debris and pet accidents, thereby reducing the frequency of required self-cleaning cycles and extending filter life.

Strengths: Advanced integration of both wet and dry self-cleaning capabilities; high-temperature mop cleaning effectively eliminates bacteria; comprehensive dock system handles multiple maintenance tasks automatically. Weaknesses: Bulky docking stations require significant space; high water consumption for self-cleaning functions; premium pricing positions products at the higher end of the market.

Haier Smart Home Co., Ltd.

Technical Solution: Haier has developed extensive self-cleaning technologies across their appliance ecosystem, with particular focus on their patented ABT (Antibacterial Technology) self-cleaning systems. In their washing machines, Haier implements steam-based self-cleaning that reaches temperatures of 70°C to eliminate 99.9% of bacteria while dissolving detergent residues. Their refrigeration systems incorporate photocatalytic technology that activates when doors are closed, breaking down odors and bacterial contaminants without manual intervention. Haier's air conditioning units feature their patented Self-Clean technology that freezes condensation on the evaporator coils before rapidly thawing it to flush away contaminants, followed by high-temperature sterilization reaching 56°C for comprehensive disinfection. Their latest patents focus on IoT-connected self-maintenance systems that analyze usage patterns and automatically schedule cleaning cycles based on actual usage rather than fixed intervals.

Strengths: Comprehensive ecosystem approach allowing coordinated self-cleaning across multiple appliances; effective high-temperature sterilization capabilities; smart scheduling optimizes cleaning frequency based on actual usage patterns. Weaknesses: Higher energy consumption during self-cleaning cycles; premium pricing strategy; some technologies require specific water quality parameters for optimal performance.

Core Patents and Technical Literature Analysis

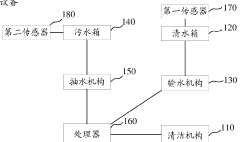

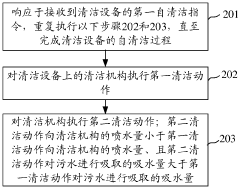

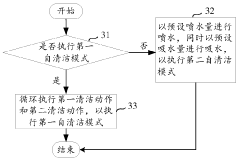

Self-cleaning method for cleaning device, cleaning apparatus, and device and storage medium

PatentWO2023138368A1

Innovation

- A self-cleaning method for cleaning equipment is provided. By repeatedly executing the first and second cleaning actions, the water spray amount of the second cleaning action is less than the first cleaning action, and the water absorption amount of the second cleaning action is greater than the first cleaning action. Combined with the predetermined Set conditions and sensor detection to ensure that the cleaning mechanism is thoroughly cleaned and water is saved.

Self-cleaning method and device

PatentPendingCN120190152A

Innovation

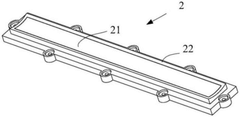

- A self-cleaning method is adopted to heat the liquid in the cleaning chamber by installing a heating assembly at the bottom of the cleaning base station, or directly heating the surface of the roller brush assembly, combining the adjustable interference between the scraper assembly and the roller brush assembly, efficient cleaning of the surface and root of the roller brush assembly is achieved.

Environmental Impact Assessment

The environmental impact of self-cleaning technologies represents a critical dimension in evaluating their overall sustainability and long-term viability. These technologies, while offering significant benefits in terms of reduced maintenance and extended product lifecycles, also present complex environmental considerations that warrant thorough assessment.

Self-cleaning surfaces typically employ one of several mechanisms: photocatalytic reactions, superhydrophobic or superhydrophilic properties, or antimicrobial agents. Each approach carries distinct environmental implications. Photocatalytic technologies, particularly those utilizing titanium dioxide (TiO₂), demonstrate promising environmental benefits through their ability to break down airborne pollutants and volatile organic compounds. Research indicates that buildings coated with photocatalytic materials can reduce nitrogen oxide levels in surrounding air by 20-45%, effectively functioning as passive air purifiers.

Water conservation represents another significant environmental advantage of self-cleaning technologies. Traditional cleaning methods for large architectural surfaces, solar panels, and industrial equipment consume substantial water resources and often involve chemical detergents. Self-cleaning surfaces can reduce water usage by 70-80% over conventional cleaning regimens, contributing meaningfully to conservation efforts in water-stressed regions.

However, these technologies are not without environmental concerns. The production and application of nanomaterials central to many self-cleaning surfaces raise questions regarding potential ecological impacts. Nanoparticle leaching into water systems remains inadequately studied, with preliminary research suggesting possible bioaccumulation in aquatic organisms. The manufacturing processes for these specialized materials also typically demand higher energy inputs than conventional surface treatments, potentially offsetting some environmental gains.

Life cycle assessment (LCA) studies reveal a nuanced environmental profile. While self-cleaning technologies generally demonstrate reduced environmental impact during operational phases, their production phase often shows increased carbon footprints. The environmental break-even point typically occurs after 2-5 years of deployment, depending on application context and cleaning frequency requirements.

Regulatory frameworks addressing these technologies remain inconsistent globally, with European standards generally more developed than those in other regions. The ISO 14000 series provides some guidance on environmental management aspects, but specific standards for self-cleaning technologies are still evolving, creating uncertainty for manufacturers and potential adopters.

Future environmental improvements will likely emerge from research focused on biodegradable self-cleaning materials and production methods with reduced energy requirements. Biomimetic approaches, which replicate natural self-cleaning mechanisms like the lotus leaf effect, show particular promise for environmentally compatible solutions.

Self-cleaning surfaces typically employ one of several mechanisms: photocatalytic reactions, superhydrophobic or superhydrophilic properties, or antimicrobial agents. Each approach carries distinct environmental implications. Photocatalytic technologies, particularly those utilizing titanium dioxide (TiO₂), demonstrate promising environmental benefits through their ability to break down airborne pollutants and volatile organic compounds. Research indicates that buildings coated with photocatalytic materials can reduce nitrogen oxide levels in surrounding air by 20-45%, effectively functioning as passive air purifiers.

Water conservation represents another significant environmental advantage of self-cleaning technologies. Traditional cleaning methods for large architectural surfaces, solar panels, and industrial equipment consume substantial water resources and often involve chemical detergents. Self-cleaning surfaces can reduce water usage by 70-80% over conventional cleaning regimens, contributing meaningfully to conservation efforts in water-stressed regions.

However, these technologies are not without environmental concerns. The production and application of nanomaterials central to many self-cleaning surfaces raise questions regarding potential ecological impacts. Nanoparticle leaching into water systems remains inadequately studied, with preliminary research suggesting possible bioaccumulation in aquatic organisms. The manufacturing processes for these specialized materials also typically demand higher energy inputs than conventional surface treatments, potentially offsetting some environmental gains.

Life cycle assessment (LCA) studies reveal a nuanced environmental profile. While self-cleaning technologies generally demonstrate reduced environmental impact during operational phases, their production phase often shows increased carbon footprints. The environmental break-even point typically occurs after 2-5 years of deployment, depending on application context and cleaning frequency requirements.

Regulatory frameworks addressing these technologies remain inconsistent globally, with European standards generally more developed than those in other regions. The ISO 14000 series provides some guidance on environmental management aspects, but specific standards for self-cleaning technologies are still evolving, creating uncertainty for manufacturers and potential adopters.

Future environmental improvements will likely emerge from research focused on biodegradable self-cleaning materials and production methods with reduced energy requirements. Biomimetic approaches, which replicate natural self-cleaning mechanisms like the lotus leaf effect, show particular promise for environmentally compatible solutions.

Cross-industry Application Potential

Self-cleaning technologies demonstrate remarkable versatility across multiple industries, extending far beyond their traditional applications in glass and construction materials. The healthcare sector represents a particularly promising frontier, where antimicrobial self-cleaning surfaces could revolutionize infection control in hospitals and medical facilities. These technologies can significantly reduce hospital-acquired infections by continuously eliminating pathogens on high-touch surfaces such as door handles, bed rails, and medical equipment.

In the automotive industry, self-cleaning coatings are being integrated into both exterior and interior components. Beyond the obvious application for windshields and body panels, these technologies show potential for maintaining sensors critical to autonomous driving systems, ensuring their consistent performance regardless of environmental conditions. The transportation sector more broadly could benefit from self-cleaning surfaces in public transit systems, reducing maintenance costs while improving hygiene standards.

The consumer electronics market presents another substantial opportunity, with self-cleaning technologies potentially extending device lifespan and improving user experience. Smartphones, tablets, and wearable devices accumulate fingerprints, oils, and bacteria through constant handling, making them ideal candidates for self-cleaning coatings that maintain both aesthetics and hygiene.

In the energy sector, self-cleaning photovoltaic panels could significantly improve efficiency and reduce maintenance costs. Solar farms in dusty or desert environments experience substantial power losses due to particulate accumulation, a problem that could be mitigated through advanced self-cleaning technologies, potentially increasing energy yield by 15-25% annually.

The textile industry is exploring self-cleaning fabrics for applications ranging from everyday clothing to specialized workwear and military uniforms. These textiles could reduce water consumption associated with laundering while extending garment lifespan, addressing both environmental and economic concerns.

Marine and offshore industries face persistent challenges with biofouling on ship hulls and underwater structures. Self-cleaning coatings that prevent organism attachment could reduce drag, improve fuel efficiency, and minimize the need for manual cleaning, offering substantial operational cost savings while reducing environmental impact from traditional antifouling compounds.

The food processing industry could benefit from self-cleaning surfaces that prevent bacterial contamination and biofilm formation, potentially reducing foodborne illness outbreaks while extending equipment operational life and reducing cleaning downtime.

In the automotive industry, self-cleaning coatings are being integrated into both exterior and interior components. Beyond the obvious application for windshields and body panels, these technologies show potential for maintaining sensors critical to autonomous driving systems, ensuring their consistent performance regardless of environmental conditions. The transportation sector more broadly could benefit from self-cleaning surfaces in public transit systems, reducing maintenance costs while improving hygiene standards.

The consumer electronics market presents another substantial opportunity, with self-cleaning technologies potentially extending device lifespan and improving user experience. Smartphones, tablets, and wearable devices accumulate fingerprints, oils, and bacteria through constant handling, making them ideal candidates for self-cleaning coatings that maintain both aesthetics and hygiene.

In the energy sector, self-cleaning photovoltaic panels could significantly improve efficiency and reduce maintenance costs. Solar farms in dusty or desert environments experience substantial power losses due to particulate accumulation, a problem that could be mitigated through advanced self-cleaning technologies, potentially increasing energy yield by 15-25% annually.

The textile industry is exploring self-cleaning fabrics for applications ranging from everyday clothing to specialized workwear and military uniforms. These textiles could reduce water consumption associated with laundering while extending garment lifespan, addressing both environmental and economic concerns.

Marine and offshore industries face persistent challenges with biofouling on ship hulls and underwater structures. Self-cleaning coatings that prevent organism attachment could reduce drag, improve fuel efficiency, and minimize the need for manual cleaning, offering substantial operational cost savings while reducing environmental impact from traditional antifouling compounds.

The food processing industry could benefit from self-cleaning surfaces that prevent bacterial contamination and biofilm formation, potentially reducing foodborne illness outbreaks while extending equipment operational life and reducing cleaning downtime.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!