Analysis of Self-cleaning Surfaces in the Context of LEED Standards

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-cleaning Surface Technology Background and Objectives

Self-cleaning surfaces represent a significant advancement in material science and sustainable building technology, with roots dating back to the 1970s when researchers first observed the "lotus effect" - the natural self-cleaning property of lotus leaves. This biomimetic discovery led to decades of research and development aimed at creating synthetic surfaces with similar properties. The evolution of self-cleaning technology has progressed from simple hydrophobic coatings to sophisticated photocatalytic materials and advanced nanostructured surfaces that can repel water, dirt, and even kill bacteria.

The technological trajectory has been marked by several key innovations, including the development of titanium dioxide (TiO2) photocatalytic coatings in the 1990s, the commercialization of hydrophobic glass for architectural applications in the early 2000s, and more recently, the integration of nanotechnology to create multifunctional self-cleaning surfaces. These advancements have significantly expanded the potential applications beyond windows to include building facades, solar panels, and interior surfaces.

In the context of Leadership in Energy and Environmental Design (LEED) standards, self-cleaning surfaces align with multiple sustainability objectives. LEED, developed by the U.S. Green Building Council, has increasingly recognized innovative materials that reduce maintenance requirements, extend product lifecycles, and minimize the use of cleaning chemicals. The 2019 LEED v4.1 update specifically acknowledges materials that contribute to improved indoor environmental quality and reduced operational impacts.

The primary technical objectives for self-cleaning surfaces in the LEED context include: developing durable solutions that maintain efficacy throughout a building's lifecycle; creating formulations that eliminate or significantly reduce the need for chemical cleaners; designing surfaces that contribute to energy efficiency through better light transmission or thermal regulation; and ensuring these technologies are cost-effective enough for widespread adoption in green building projects.

Current research is focused on addressing several challenges, including improving durability under real-world conditions, reducing manufacturing costs, eliminating potentially harmful nanoparticles, and quantifying the long-term environmental benefits. The intersection of self-cleaning technology with LEED certification represents a promising frontier for sustainable building practices, with potential to transform maintenance protocols, reduce chemical usage, and extend material lifespans across the built environment.

The technological trajectory has been marked by several key innovations, including the development of titanium dioxide (TiO2) photocatalytic coatings in the 1990s, the commercialization of hydrophobic glass for architectural applications in the early 2000s, and more recently, the integration of nanotechnology to create multifunctional self-cleaning surfaces. These advancements have significantly expanded the potential applications beyond windows to include building facades, solar panels, and interior surfaces.

In the context of Leadership in Energy and Environmental Design (LEED) standards, self-cleaning surfaces align with multiple sustainability objectives. LEED, developed by the U.S. Green Building Council, has increasingly recognized innovative materials that reduce maintenance requirements, extend product lifecycles, and minimize the use of cleaning chemicals. The 2019 LEED v4.1 update specifically acknowledges materials that contribute to improved indoor environmental quality and reduced operational impacts.

The primary technical objectives for self-cleaning surfaces in the LEED context include: developing durable solutions that maintain efficacy throughout a building's lifecycle; creating formulations that eliminate or significantly reduce the need for chemical cleaners; designing surfaces that contribute to energy efficiency through better light transmission or thermal regulation; and ensuring these technologies are cost-effective enough for widespread adoption in green building projects.

Current research is focused on addressing several challenges, including improving durability under real-world conditions, reducing manufacturing costs, eliminating potentially harmful nanoparticles, and quantifying the long-term environmental benefits. The intersection of self-cleaning technology with LEED certification represents a promising frontier for sustainable building practices, with potential to transform maintenance protocols, reduce chemical usage, and extend material lifespans across the built environment.

Market Demand Analysis for LEED-Compliant Self-cleaning Surfaces

The market for self-cleaning surfaces that comply with Leadership in Energy and Environmental Design (LEED) standards has shown significant growth in recent years, driven by increasing awareness of sustainable building practices and stricter environmental regulations. The global green building materials market, which includes self-cleaning surfaces, was valued at approximately $256 billion in 2020 and is projected to reach $377 billion by 2027, representing a compound annual growth rate of 8.6%.

Self-cleaning surfaces offer substantial benefits that align with LEED certification requirements, particularly in the categories of Materials & Resources, Indoor Environmental Quality, and Innovation. Building owners and developers increasingly seek these solutions to achieve higher LEED ratings, which can result in premium property values, reduced maintenance costs, and enhanced corporate sustainability profiles.

Commercial buildings represent the largest market segment for LEED-compliant self-cleaning surfaces, accounting for nearly 45% of the total demand. This is followed by healthcare facilities (22%), educational institutions (18%), and residential buildings (15%). The healthcare sector shows particularly strong growth potential due to heightened hygiene concerns and infection control requirements.

Regional analysis indicates North America leads the market with approximately 38% share, followed by Europe (32%) and Asia-Pacific (24%). The United States, Germany, and Japan are the top three individual markets. Developing economies, particularly China and India, are experiencing the fastest growth rates as they implement more stringent building codes and sustainability requirements.

Consumer demand is increasingly driven by the dual benefits of operational cost savings and environmental performance. Studies indicate that buildings utilizing self-cleaning surfaces can reduce maintenance costs by 15-30% over a five-year period, while simultaneously reducing the use of chemical cleaning agents by up to 40%. These quantifiable benefits strengthen the value proposition for building owners seeking LEED certification.

Market research shows that 78% of commercial building owners consider sustainability features important in their purchasing decisions, with 64% specifically mentioning easy-to-maintain surfaces as a priority. Furthermore, 82% of corporate tenants express preference for buildings with green certifications, creating market pull for LEED-compliant building materials including self-cleaning surfaces.

The COVID-19 pandemic has accelerated market growth, with heightened awareness of surface hygiene driving a 27% increase in inquiries about self-cleaning technologies in 2020-2021. This trend is expected to continue, with market forecasts suggesting sustained annual growth of 12-15% for LEED-compliant self-cleaning surfaces through 2025, outpacing the broader green building materials market.

Self-cleaning surfaces offer substantial benefits that align with LEED certification requirements, particularly in the categories of Materials & Resources, Indoor Environmental Quality, and Innovation. Building owners and developers increasingly seek these solutions to achieve higher LEED ratings, which can result in premium property values, reduced maintenance costs, and enhanced corporate sustainability profiles.

Commercial buildings represent the largest market segment for LEED-compliant self-cleaning surfaces, accounting for nearly 45% of the total demand. This is followed by healthcare facilities (22%), educational institutions (18%), and residential buildings (15%). The healthcare sector shows particularly strong growth potential due to heightened hygiene concerns and infection control requirements.

Regional analysis indicates North America leads the market with approximately 38% share, followed by Europe (32%) and Asia-Pacific (24%). The United States, Germany, and Japan are the top three individual markets. Developing economies, particularly China and India, are experiencing the fastest growth rates as they implement more stringent building codes and sustainability requirements.

Consumer demand is increasingly driven by the dual benefits of operational cost savings and environmental performance. Studies indicate that buildings utilizing self-cleaning surfaces can reduce maintenance costs by 15-30% over a five-year period, while simultaneously reducing the use of chemical cleaning agents by up to 40%. These quantifiable benefits strengthen the value proposition for building owners seeking LEED certification.

Market research shows that 78% of commercial building owners consider sustainability features important in their purchasing decisions, with 64% specifically mentioning easy-to-maintain surfaces as a priority. Furthermore, 82% of corporate tenants express preference for buildings with green certifications, creating market pull for LEED-compliant building materials including self-cleaning surfaces.

The COVID-19 pandemic has accelerated market growth, with heightened awareness of surface hygiene driving a 27% increase in inquiries about self-cleaning technologies in 2020-2021. This trend is expected to continue, with market forecasts suggesting sustained annual growth of 12-15% for LEED-compliant self-cleaning surfaces through 2025, outpacing the broader green building materials market.

Current State and Challenges in Self-cleaning Surface Technology

Self-cleaning surface technology has witnessed significant advancements globally, with varying degrees of development across different regions. In North America and Europe, research institutions and companies have made substantial progress in developing hydrophobic and photocatalytic self-cleaning surfaces that align with LEED (Leadership in Energy and Environmental Design) standards. Asia, particularly Japan and China, has also emerged as a hub for self-cleaning technology innovation, focusing on cost-effective manufacturing processes.

Currently, the most prevalent self-cleaning technologies include hydrophobic/superhydrophobic surfaces, photocatalytic surfaces, and hybrid systems combining multiple mechanisms. Hydrophobic surfaces repel water and contaminants through micro and nano-structured topographies, while photocatalytic surfaces utilize materials like titanium dioxide (TiO₂) that break down organic matter when exposed to UV light. These technologies have found applications in building facades, windows, solar panels, and automotive surfaces.

Despite these advancements, several technical challenges persist in the widespread adoption of self-cleaning surfaces within LEED-certified buildings. Durability remains a primary concern, as many self-cleaning coatings deteriorate under prolonged environmental exposure, UV radiation, and mechanical abrasion. The performance degradation over time significantly impacts their long-term sustainability benefits, a critical factor in LEED certification calculations.

Another major challenge is the limited functionality under diverse environmental conditions. Most photocatalytic surfaces require UV light exposure to function effectively, reducing their efficiency in indoor applications or regions with limited sunlight. Similarly, hydrophobic surfaces may lose their self-cleaning properties in extremely dusty or polluted environments, requiring additional maintenance that contradicts their intended purpose.

The integration of self-cleaning technologies with other building materials and systems presents compatibility issues. Many existing coatings may affect the aesthetic properties of architectural surfaces or interfere with other functional requirements such as thermal insulation or fire resistance, creating barriers to implementation in comprehensive green building designs.

Cost-effectiveness remains a significant constraint, particularly for large-scale applications required in commercial buildings seeking LEED certification. The manufacturing processes for advanced self-cleaning surfaces often involve expensive materials and complex procedures, resulting in prohibitive implementation costs that challenge the economic feasibility of these solutions in mainstream construction projects.

Regulatory and standardization challenges further complicate the landscape. The lack of unified testing protocols and performance metrics specifically addressing self-cleaning surfaces within green building standards creates uncertainty for manufacturers and building designers. This regulatory gap hinders the proper evaluation of these technologies' contributions to sustainability goals outlined in LEED certification criteria.

Currently, the most prevalent self-cleaning technologies include hydrophobic/superhydrophobic surfaces, photocatalytic surfaces, and hybrid systems combining multiple mechanisms. Hydrophobic surfaces repel water and contaminants through micro and nano-structured topographies, while photocatalytic surfaces utilize materials like titanium dioxide (TiO₂) that break down organic matter when exposed to UV light. These technologies have found applications in building facades, windows, solar panels, and automotive surfaces.

Despite these advancements, several technical challenges persist in the widespread adoption of self-cleaning surfaces within LEED-certified buildings. Durability remains a primary concern, as many self-cleaning coatings deteriorate under prolonged environmental exposure, UV radiation, and mechanical abrasion. The performance degradation over time significantly impacts their long-term sustainability benefits, a critical factor in LEED certification calculations.

Another major challenge is the limited functionality under diverse environmental conditions. Most photocatalytic surfaces require UV light exposure to function effectively, reducing their efficiency in indoor applications or regions with limited sunlight. Similarly, hydrophobic surfaces may lose their self-cleaning properties in extremely dusty or polluted environments, requiring additional maintenance that contradicts their intended purpose.

The integration of self-cleaning technologies with other building materials and systems presents compatibility issues. Many existing coatings may affect the aesthetic properties of architectural surfaces or interfere with other functional requirements such as thermal insulation or fire resistance, creating barriers to implementation in comprehensive green building designs.

Cost-effectiveness remains a significant constraint, particularly for large-scale applications required in commercial buildings seeking LEED certification. The manufacturing processes for advanced self-cleaning surfaces often involve expensive materials and complex procedures, resulting in prohibitive implementation costs that challenge the economic feasibility of these solutions in mainstream construction projects.

Regulatory and standardization challenges further complicate the landscape. The lack of unified testing protocols and performance metrics specifically addressing self-cleaning surfaces within green building standards creates uncertainty for manufacturers and building designers. This regulatory gap hinders the proper evaluation of these technologies' contributions to sustainability goals outlined in LEED certification criteria.

Current Technical Solutions for Self-cleaning Surfaces

01 Hydrophobic coatings for self-cleaning surfaces

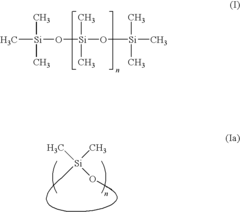

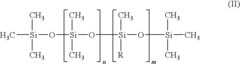

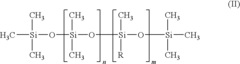

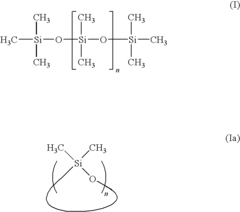

Hydrophobic coatings can be applied to surfaces to create self-cleaning properties. These coatings repel water and prevent dirt and contaminants from adhering to the surface. When water droplets come into contact with these surfaces, they form beads and roll off, carrying away dirt particles. This lotus effect mimics the natural self-cleaning properties of lotus leaves. The coatings can be applied to various materials including glass, metals, and polymers to create easy-to-maintain surfaces that require minimal cleaning.- Hydrophobic coatings for self-cleaning surfaces: Hydrophobic coatings can be applied to surfaces to create self-cleaning properties. These coatings repel water and cause it to bead up and roll off the surface, carrying away dirt and contaminants. The hydrophobic effect is often achieved through the use of fluoropolymers, silicones, or other water-repellent materials that create a low surface energy. These coatings can be applied to various substrates including glass, metal, and plastic to create surfaces that require minimal maintenance.

- Photocatalytic self-cleaning surfaces: Photocatalytic materials, particularly titanium dioxide (TiO2), can be incorporated into surface coatings to create self-cleaning properties. When exposed to UV light, these materials generate reactive oxygen species that break down organic contaminants on the surface. The photocatalytic reaction converts dirt, pollutants, and other organic materials into water-soluble compounds that can be easily washed away by rain or water. This technology is particularly useful for outdoor applications such as building facades, windows, and solar panels.

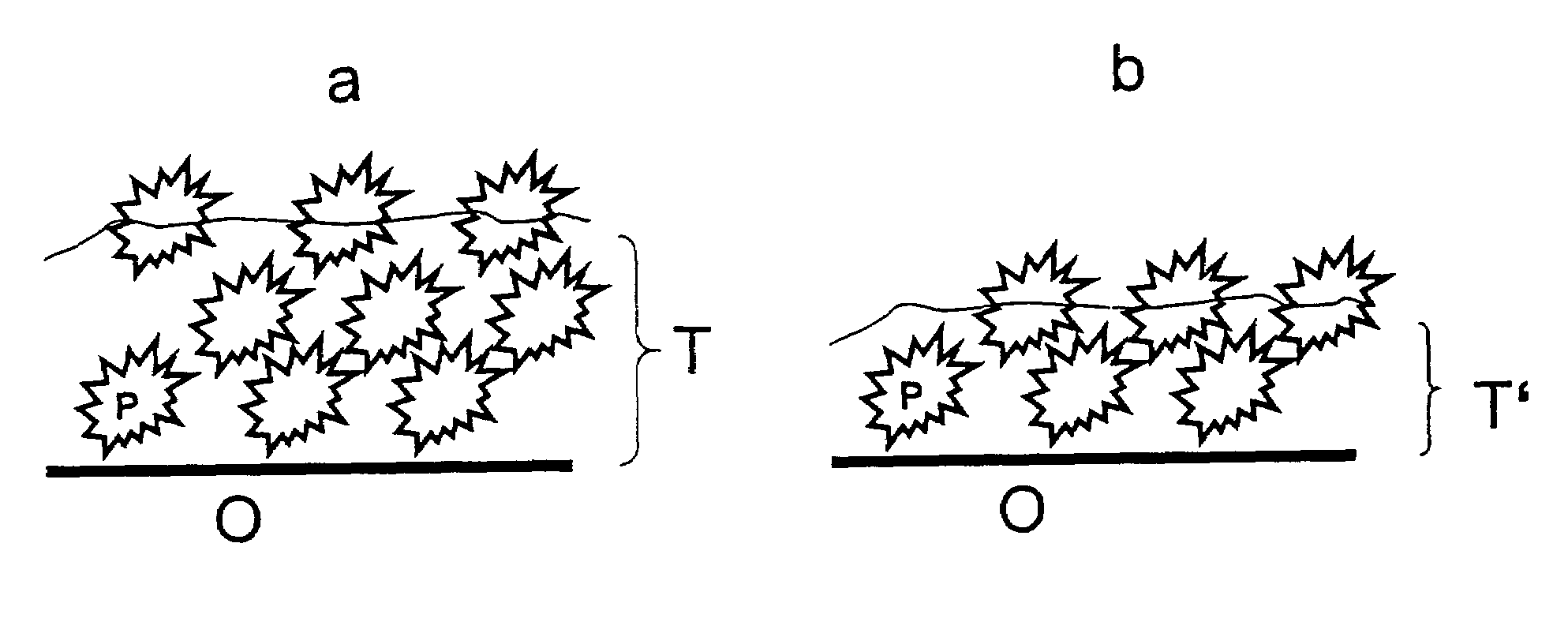

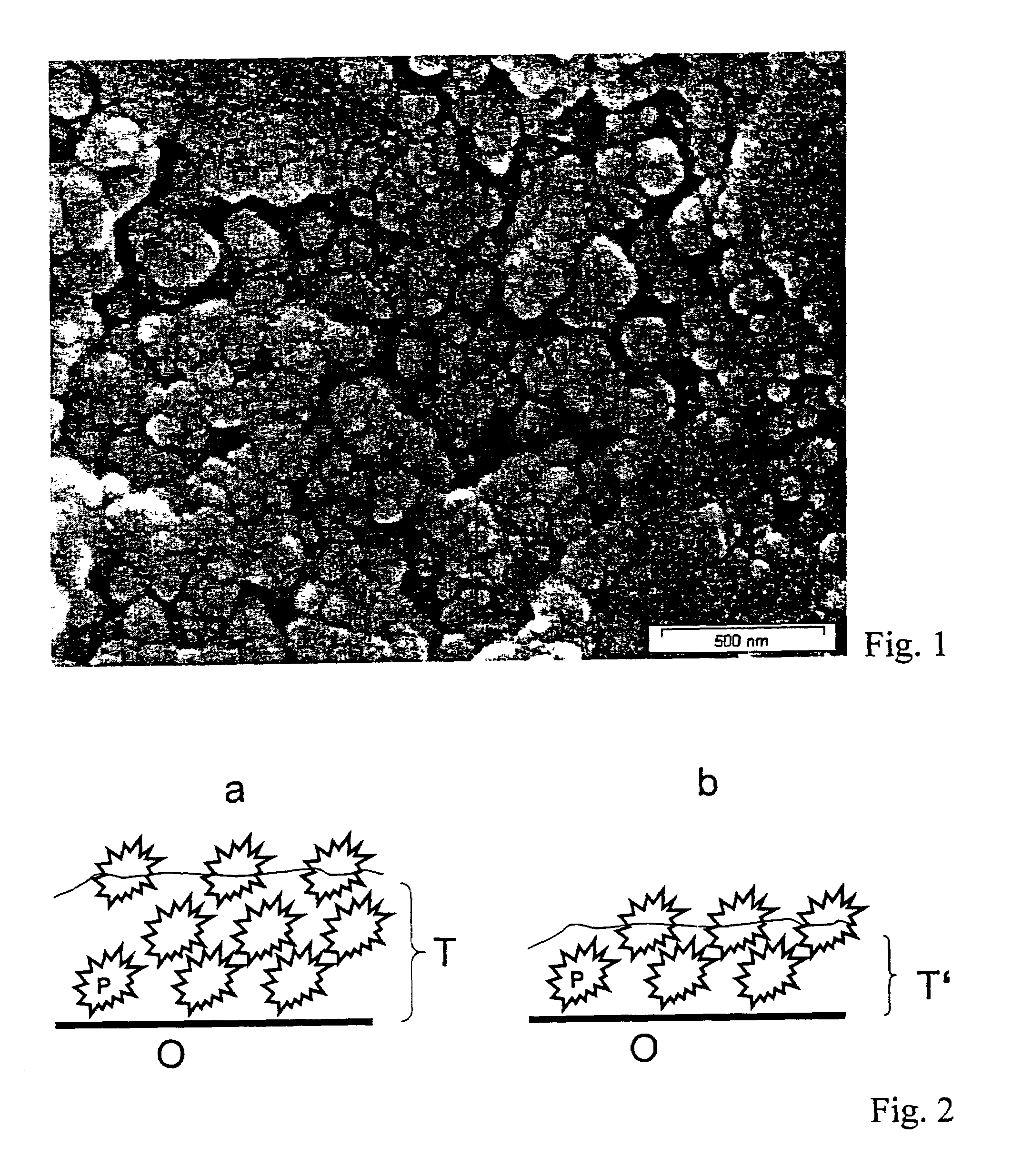

- Micro and nano-structured self-cleaning surfaces: Self-cleaning surfaces can be created by engineering specific micro and nano-scale surface structures that mimic natural self-cleaning surfaces like lotus leaves. These structures create a combination of roughness and hydrophobicity that minimizes the contact area between water droplets and the surface, allowing them to easily roll off carrying contaminants with them. The hierarchical surface structures can be created through various manufacturing techniques including etching, lithography, and deposition methods to achieve the desired self-cleaning properties.

- Self-cleaning electronic and optical devices: Electronic and optical devices can incorporate self-cleaning technologies to maintain optimal performance. These include touchscreens, displays, sensors, cameras, and optical lenses that utilize various self-cleaning mechanisms to prevent the accumulation of fingerprints, dust, and other contaminants. The self-cleaning properties can be achieved through hydrophobic coatings, electrostatic repulsion, or automated cleaning systems integrated into the device. This technology is particularly important for maintaining the functionality of devices in environments where regular manual cleaning is impractical.

- Active self-cleaning systems: Active self-cleaning systems utilize mechanical, electrical, or other energy inputs to remove contaminants from surfaces. These systems may include automated wipers, air jets, vibration mechanisms, or electrostatic fields that actively dislodge and remove particles from surfaces. Unlike passive self-cleaning surfaces that rely solely on material properties, active systems can provide on-demand cleaning when triggered manually or automatically in response to detected contamination. These systems are particularly useful in applications where high levels of cleanliness are required or where passive methods alone are insufficient.

02 Photocatalytic self-cleaning technologies

Photocatalytic materials, particularly titanium dioxide (TiO2), can be incorporated into surface coatings to provide self-cleaning properties. When exposed to UV light, these materials generate reactive oxygen species that break down organic contaminants on the surface. The photocatalytic reaction converts dirt, pollutants, and microorganisms into harmless byproducts that can be easily washed away by rain or water. This technology is particularly useful for outdoor applications such as building facades, windows, and solar panels where regular cleaning is difficult.Expand Specific Solutions03 Smart self-cleaning systems with sensors

Advanced self-cleaning systems incorporate sensors and automated mechanisms to detect contamination and initiate cleaning processes. These smart systems can monitor surface conditions and activate cleaning functions only when necessary, optimizing resource usage. The systems may include integrated water sprayers, mechanical wipers, or electrostatic dust repulsion mechanisms that work together to maintain clean surfaces. This technology is particularly valuable in hard-to-reach areas or environments where regular manual cleaning is impractical or dangerous.Expand Specific Solutions04 Self-cleaning textiles and fabrics

Specialized treatments can be applied to textiles and fabrics to create self-cleaning properties. These treatments may include nanoparticle coatings, chemical modifications of fiber surfaces, or incorporation of functional groups that repel stains and contaminants. Some self-cleaning fabrics utilize structural features that minimize contact between the fabric surface and contaminants. These technologies are particularly useful for clothing, upholstery, and industrial textiles that are exposed to dirt, stains, or biological contaminants.Expand Specific Solutions05 Thermal and mechanical self-cleaning mechanisms

Some self-cleaning surfaces utilize thermal or mechanical principles to remove contaminants. These may include surfaces that change properties with temperature variations, causing contaminants to detach, or surfaces with micro-textures that minimize adhesion forces. Mechanical self-cleaning can involve vibration, rotation, or other movements that dislodge particles from surfaces. These approaches are particularly useful in industrial settings where chemical or water-based cleaning methods may not be practical, such as in manufacturing equipment, heating elements, or specialized instruments.Expand Specific Solutions

Key Industry Players in Self-cleaning Surface Market

The self-cleaning surfaces market is currently in a growth phase, with increasing adoption driven by LEED certification requirements for sustainable building practices. The market is expected to reach $13-15 billion by 2026, growing at 5-7% CAGR. Leading players represent diverse technological approaches: established chemical companies (Evonik, 3M) focus on specialty coatings; appliance manufacturers (BSH Hausgeräte, Kärcher, Dyson) integrate self-cleaning technologies into consumer products; while academic institutions (University of Liverpool, Rensselaer Polytechnic) drive fundamental innovation. The technology maturity varies significantly across applications, with hydrophobic coatings being most commercially advanced, while photocatalytic and biomimetic solutions are emerging. Companies like S.C. Johnson and Haier are increasingly positioning self-cleaning technologies as essential components of green building certification strategies.

Evonik Operations GmbH

Technical Solution: Evonik has pioneered PROTECTOSIL® SC CONCENTRATE, a specialized self-cleaning surface treatment designed specifically to meet sustainable building standards including LEED. This silicon-based technology creates superhydrophobic surfaces that effectively shed water and contaminants through the "lotus effect," where water beads up and rolls off surfaces, carrying dirt particles with it[2]. The treatment forms nano-scale surface structures that minimize contact area between contaminants and the treated surface. Unlike conventional coatings, Evonik's solution chemically bonds with mineral substrates, providing long-term durability without peeling or flaking. The technology contributes to LEED credits by reducing water consumption for cleaning by up to 70%, extending maintenance cycles, and eliminating the need for harsh cleaning chemicals[4]. Additionally, Evonik has developed photocatalytic additives that can be incorporated into building materials, which use sunlight to break down organic pollutants and contribute to improved air quality around buildings. Their solutions are particularly effective for exterior facades, concrete, natural stone, and other porous building materials.

Strengths: Chemical bonding technology provides exceptional durability (10+ years) compared to conventional coatings, and the solutions are water-based with minimal VOC content, directly supporting LEED indoor air quality requirements. Weaknesses: Application requires specific environmental conditions and professional installation to achieve optimal performance, and the technology is less effective on horizontal surfaces where water pooling occurs, limiting its application range in comprehensive building projects.

3M Innovative Properties Co.

Technical Solution: 3M has developed advanced self-cleaning surface technologies that align with LEED standards through their Scotchgard™ and Novec™ product lines. Their approach combines hydrophobic and oleophobic coatings that repel water, oil, and dirt particles, creating surfaces that require minimal cleaning agents and water. The technology incorporates fluoropolymer chemistry that forms an invisible molecular barrier on surfaces, preventing contaminants from adhering while maintaining transparency and original surface appearance[1]. 3M's self-cleaning solutions are particularly focused on building materials and glass treatments that contribute to LEED credits in water efficiency, indoor environmental quality, and materials & resources categories. Their products are formulated with low VOC emissions and reduced chemical content, helping buildings achieve LEED points for healthier indoor environments[3]. The company has also developed photocatalytic coatings that use light energy to break down organic contaminants, further enhancing self-cleaning capabilities while improving air quality.

Strengths: Extensive R&D capabilities and established market presence allow for comprehensive testing and validation of self-cleaning technologies. Their solutions integrate seamlessly with existing building materials, facilitating adoption in LEED projects. Weaknesses: Some formulations still contain fluorochemicals which face increasing regulatory scrutiny, and the initial application cost can be higher than conventional treatments, potentially limiting widespread adoption in cost-sensitive projects.

Core Patents and Innovations in Self-cleaning Surface Technology

Process for producing detachable dirt- and water-repellent surface coatings

PatentInactiveUS7531598B2

Innovation

- A process involving suspending hydrophobic particles in a solution of silicone wax and a highly volatile siloxane, applied to the article and then removing the siloxane, creating a detachable, durable, and water-repellent surface structure that can be easily removed using mechanical means.

Surfaces rendered self-cleaning by hydrophobic structures and a process for their production

PatentInactiveUS7211313B2

Innovation

- A self-cleaning surface with a hydrophobic, structured surface formed by particles secured to a carrier mixture of particles and binder, where the carrier system allows for the release of new structure-forming particles during erosion, maintaining the self-cleaning effect through self-regeneration.

Environmental Impact Assessment of Self-cleaning Surface Technologies

The environmental impact assessment of self-cleaning surface technologies reveals significant implications for sustainability in building design and maintenance. These innovative surfaces, which include photocatalytic coatings, hydrophobic treatments, and nanostructured materials, demonstrate varying degrees of environmental performance throughout their lifecycle.

Primary environmental benefits include substantial reductions in water consumption for cleaning operations, with studies indicating potential savings of 70-80% compared to conventional cleaning methods. This water conservation aspect aligns directly with LEED Water Efficiency credits, particularly in water-stressed regions where building maintenance represents a significant portion of operational water usage.

Chemical usage reduction constitutes another major environmental advantage, as self-cleaning surfaces minimize the need for detergents, solvents, and other cleaning agents that often contain volatile organic compounds (VOCs) and other environmentally harmful substances. Quantitative analyses suggest a 50-65% reduction in cleaning chemical usage over building lifespans, contributing to improved indoor air quality and reduced environmental contamination.

Energy efficiency improvements manifest through multiple pathways. Photocatalytic surfaces can reduce cooling loads by mitigating heat island effects, while certain hydrophobic coatings enhance thermal performance by preventing moisture accumulation. Research indicates potential energy savings of 5-12% depending on building type, climate zone, and specific technology implementation.

However, manufacturing processes for these advanced materials present environmental concerns. Production of nanoparticles and specialized coatings often requires energy-intensive processes and potentially hazardous precursor chemicals. Life cycle assessments reveal that the embodied energy of some self-cleaning technologies may offset operational benefits if manufacturing methods are not optimized for sustainability.

End-of-life considerations remain problematic for certain self-cleaning technologies. Nanoparticle-based coatings pose potential ecological risks if improperly disposed of, while some treatments may complicate material recycling efforts. The durability factor—with lifespans ranging from 3-15 years depending on technology type and exposure conditions—significantly influences overall environmental performance calculations.

When evaluated against LEED criteria, self-cleaning surfaces contribute positively to several credit categories beyond water efficiency, including Materials & Resources (reduced maintenance materials), Indoor Environmental Quality (reduced cleaning chemical exposure), and Innovation credits. However, the environmental trade-offs must be carefully weighed in specific project contexts to ensure net positive sustainability outcomes.

Primary environmental benefits include substantial reductions in water consumption for cleaning operations, with studies indicating potential savings of 70-80% compared to conventional cleaning methods. This water conservation aspect aligns directly with LEED Water Efficiency credits, particularly in water-stressed regions where building maintenance represents a significant portion of operational water usage.

Chemical usage reduction constitutes another major environmental advantage, as self-cleaning surfaces minimize the need for detergents, solvents, and other cleaning agents that often contain volatile organic compounds (VOCs) and other environmentally harmful substances. Quantitative analyses suggest a 50-65% reduction in cleaning chemical usage over building lifespans, contributing to improved indoor air quality and reduced environmental contamination.

Energy efficiency improvements manifest through multiple pathways. Photocatalytic surfaces can reduce cooling loads by mitigating heat island effects, while certain hydrophobic coatings enhance thermal performance by preventing moisture accumulation. Research indicates potential energy savings of 5-12% depending on building type, climate zone, and specific technology implementation.

However, manufacturing processes for these advanced materials present environmental concerns. Production of nanoparticles and specialized coatings often requires energy-intensive processes and potentially hazardous precursor chemicals. Life cycle assessments reveal that the embodied energy of some self-cleaning technologies may offset operational benefits if manufacturing methods are not optimized for sustainability.

End-of-life considerations remain problematic for certain self-cleaning technologies. Nanoparticle-based coatings pose potential ecological risks if improperly disposed of, while some treatments may complicate material recycling efforts. The durability factor—with lifespans ranging from 3-15 years depending on technology type and exposure conditions—significantly influences overall environmental performance calculations.

When evaluated against LEED criteria, self-cleaning surfaces contribute positively to several credit categories beyond water efficiency, including Materials & Resources (reduced maintenance materials), Indoor Environmental Quality (reduced cleaning chemical exposure), and Innovation credits. However, the environmental trade-offs must be carefully weighed in specific project contexts to ensure net positive sustainability outcomes.

LEED Certification Integration Strategies for Self-cleaning Surfaces

Integrating self-cleaning surfaces into building design represents a significant opportunity for achieving LEED (Leadership in Energy and Environmental Design) certification points across multiple categories. The strategic implementation of these surfaces can contribute to Indoor Environmental Quality credits by reducing the need for chemical cleaning agents that may release volatile organic compounds (VOCs). Buildings utilizing self-cleaning technologies on exterior facades, windows, and interior surfaces can maintain cleaner environments with fewer chemical interventions, directly supporting LEED's emphasis on occupant health and wellbeing.

Materials and Resources credits can be addressed through self-cleaning surfaces that demonstrate durability and longevity, reducing replacement frequency and associated waste. Photocatalytic coatings, for example, can extend the service life of building materials by preventing degradation from organic contaminants and pollution. Documentation of these extended life cycles and reduced maintenance requirements provides quantifiable evidence for LEED submission packages.

Energy and Atmosphere credits benefit from self-cleaning technologies applied to solar panels and glazing systems. By maintaining optimal light transmission through windows and maximizing photovoltaic efficiency, these surfaces contribute to overall building energy performance. Studies indicate that self-cleaning glass can maintain up to 90% of its original light transmission capabilities over time, compared to significant degradation in untreated surfaces.

Water Efficiency credits can be pursued through hydrophobic self-cleaning surfaces that reduce water consumption during maintenance operations. Buildings implementing comprehensive self-cleaning strategies have documented water savings of 30-40% in exterior cleaning operations, providing measurable data for LEED documentation.

Innovation credits offer perhaps the most straightforward path for self-cleaning technologies within the LEED framework. Project teams can develop specific innovation strategies that demonstrate quantifiable environmental benefits from these surfaces, particularly when combined with other sustainable design elements or when applied in novel contexts that address multiple sustainability challenges simultaneously.

For successful LEED integration, project teams should develop comprehensive documentation strategies that track performance metrics before and after implementation. This includes monitoring cleaning frequency, water and chemical usage, energy performance, and indoor air quality parameters. Early engagement with LEED consultants during the design phase ensures proper alignment of self-cleaning surface specifications with targeted credits.

Cross-disciplinary collaboration between architects, engineers, sustainability consultants, and manufacturers is essential for maximizing LEED potential. This collaborative approach ensures that self-cleaning technologies are not implemented in isolation but as part of a holistic sustainable building strategy that leverages their full environmental and health benefits within the LEED certification framework.

Materials and Resources credits can be addressed through self-cleaning surfaces that demonstrate durability and longevity, reducing replacement frequency and associated waste. Photocatalytic coatings, for example, can extend the service life of building materials by preventing degradation from organic contaminants and pollution. Documentation of these extended life cycles and reduced maintenance requirements provides quantifiable evidence for LEED submission packages.

Energy and Atmosphere credits benefit from self-cleaning technologies applied to solar panels and glazing systems. By maintaining optimal light transmission through windows and maximizing photovoltaic efficiency, these surfaces contribute to overall building energy performance. Studies indicate that self-cleaning glass can maintain up to 90% of its original light transmission capabilities over time, compared to significant degradation in untreated surfaces.

Water Efficiency credits can be pursued through hydrophobic self-cleaning surfaces that reduce water consumption during maintenance operations. Buildings implementing comprehensive self-cleaning strategies have documented water savings of 30-40% in exterior cleaning operations, providing measurable data for LEED documentation.

Innovation credits offer perhaps the most straightforward path for self-cleaning technologies within the LEED framework. Project teams can develop specific innovation strategies that demonstrate quantifiable environmental benefits from these surfaces, particularly when combined with other sustainable design elements or when applied in novel contexts that address multiple sustainability challenges simultaneously.

For successful LEED integration, project teams should develop comprehensive documentation strategies that track performance metrics before and after implementation. This includes monitoring cleaning frequency, water and chemical usage, energy performance, and indoor air quality parameters. Early engagement with LEED consultants during the design phase ensures proper alignment of self-cleaning surface specifications with targeted credits.

Cross-disciplinary collaboration between architects, engineers, sustainability consultants, and manufacturers is essential for maximizing LEED potential. This collaborative approach ensures that self-cleaning technologies are not implemented in isolation but as part of a holistic sustainable building strategy that leverages their full environmental and health benefits within the LEED certification framework.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!