Self-cleaning Surfaces: Compliance with Environmental Health Regulations

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-cleaning Surface Technology Background and Objectives

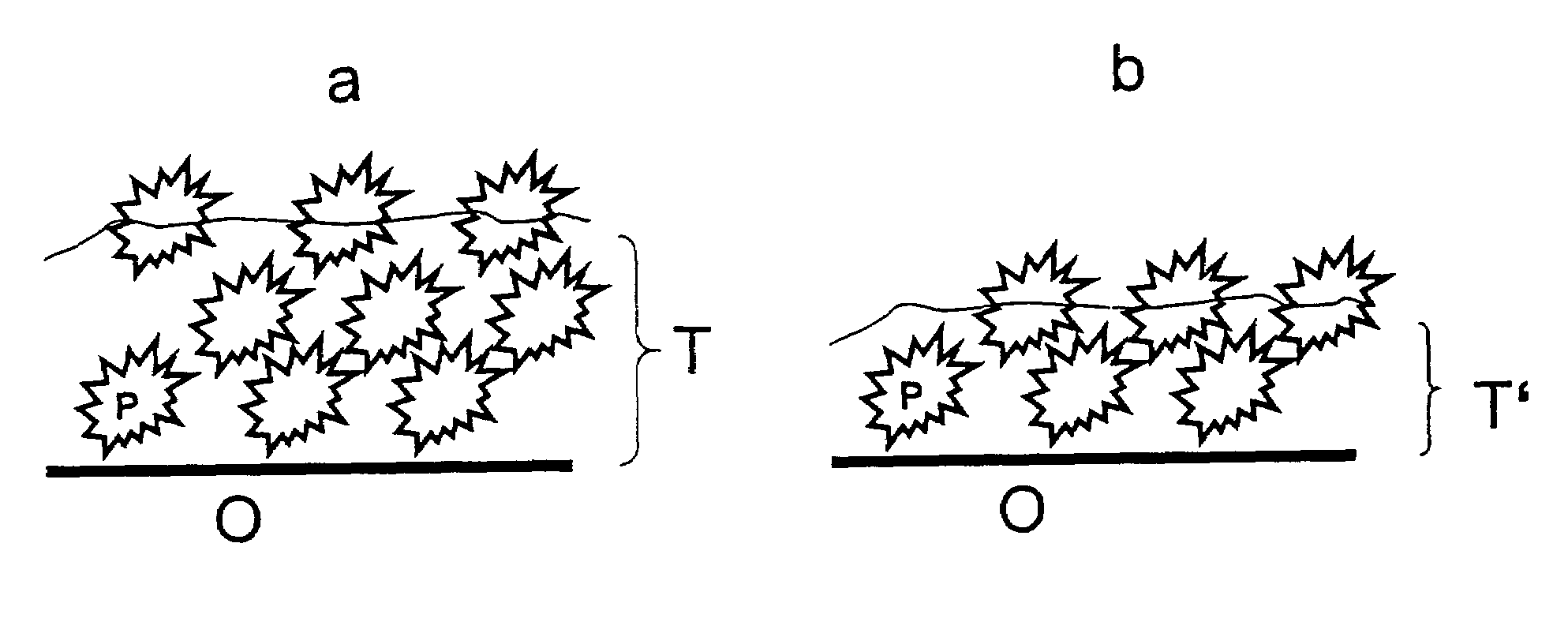

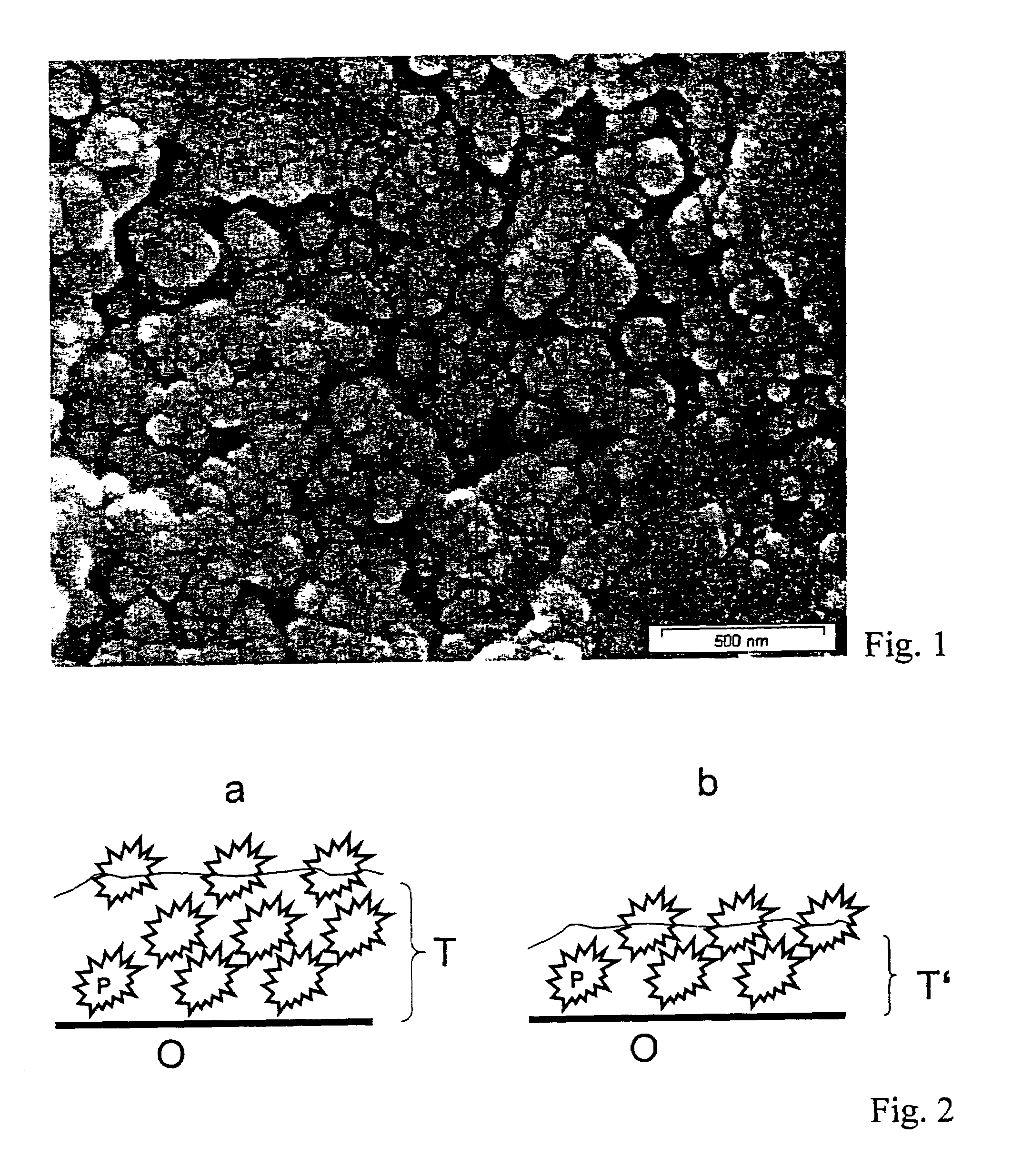

Self-cleaning surfaces represent a revolutionary advancement in material science that has evolved significantly over the past three decades. Initially inspired by the lotus leaf's natural self-cleaning properties, discovered in the early 1970s, this technology has progressed from basic hydrophobic coatings to sophisticated multi-functional surfaces. The fundamental principle relies on creating surfaces with micro and nano-scale roughness combined with low surface energy, enabling water droplets to easily roll off while carrying away contaminants.

The evolution of self-cleaning technology has followed several distinct phases. The first generation focused primarily on hydrophobic and superhydrophobic surfaces mimicking natural models. The second generation incorporated photocatalytic properties, particularly using titanium dioxide (TiO2), which breaks down organic contaminants when exposed to UV light. The current third generation integrates multiple functionalities, including antimicrobial properties, durability enhancements, and environmental adaptability.

The primary objective of modern self-cleaning surface technology is to develop solutions that maintain cleanliness while simultaneously meeting increasingly stringent environmental health regulations. This includes reducing or eliminating toxic chemicals traditionally used in cleaning processes, minimizing water consumption, and ensuring that the materials themselves do not leach harmful substances into the environment.

Recent technological goals have expanded to include compliance with specific regulatory frameworks such as REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) in Europe, EPA standards in the United States, and similar regulations in other regions. These frameworks increasingly emphasize the importance of sustainable chemistry and reduced environmental impact throughout the product lifecycle.

Another critical objective is to develop self-cleaning surfaces that maintain efficacy under real-world conditions while meeting health safety standards. This includes ensuring stability under various temperature and humidity conditions, resistance to mechanical wear, and long-term durability without performance degradation or environmental contamination.

The technology aims to address growing concerns about chemical exposure in indoor environments, particularly in healthcare facilities, food processing plants, and public spaces where traditional cleaning chemicals may contribute to air quality issues or create harmful residues. Self-cleaning surfaces offer the potential to significantly reduce these risks while maintaining or improving hygiene standards.

Looking forward, the field is moving toward developing customizable self-cleaning solutions for specific applications, with particular emphasis on environmental compatibility, energy efficiency, and integration with smart building systems for monitoring and maintenance optimization. The ultimate goal remains creating surfaces that reduce maintenance costs and environmental impact while enhancing public health protection.

The evolution of self-cleaning technology has followed several distinct phases. The first generation focused primarily on hydrophobic and superhydrophobic surfaces mimicking natural models. The second generation incorporated photocatalytic properties, particularly using titanium dioxide (TiO2), which breaks down organic contaminants when exposed to UV light. The current third generation integrates multiple functionalities, including antimicrobial properties, durability enhancements, and environmental adaptability.

The primary objective of modern self-cleaning surface technology is to develop solutions that maintain cleanliness while simultaneously meeting increasingly stringent environmental health regulations. This includes reducing or eliminating toxic chemicals traditionally used in cleaning processes, minimizing water consumption, and ensuring that the materials themselves do not leach harmful substances into the environment.

Recent technological goals have expanded to include compliance with specific regulatory frameworks such as REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) in Europe, EPA standards in the United States, and similar regulations in other regions. These frameworks increasingly emphasize the importance of sustainable chemistry and reduced environmental impact throughout the product lifecycle.

Another critical objective is to develop self-cleaning surfaces that maintain efficacy under real-world conditions while meeting health safety standards. This includes ensuring stability under various temperature and humidity conditions, resistance to mechanical wear, and long-term durability without performance degradation or environmental contamination.

The technology aims to address growing concerns about chemical exposure in indoor environments, particularly in healthcare facilities, food processing plants, and public spaces where traditional cleaning chemicals may contribute to air quality issues or create harmful residues. Self-cleaning surfaces offer the potential to significantly reduce these risks while maintaining or improving hygiene standards.

Looking forward, the field is moving toward developing customizable self-cleaning solutions for specific applications, with particular emphasis on environmental compatibility, energy efficiency, and integration with smart building systems for monitoring and maintenance optimization. The ultimate goal remains creating surfaces that reduce maintenance costs and environmental impact while enhancing public health protection.

Market Analysis for Self-cleaning Surface Applications

The self-cleaning surfaces market has experienced significant growth over the past decade, driven by increasing awareness of hygiene concerns and environmental regulations. Currently valued at approximately $8 billion globally, this market is projected to reach $12 billion by 2027, representing a compound annual growth rate of 5.8%. The COVID-19 pandemic has further accelerated this growth trajectory, as businesses and consumers alike have placed greater emphasis on cleanliness and infection prevention.

Healthcare facilities represent the largest application segment, accounting for roughly 32% of the total market share. Hospitals and medical centers are increasingly adopting self-cleaning surfaces to reduce healthcare-associated infections and comply with stringent sanitation regulations. The food processing industry follows closely behind at 24% market share, where self-cleaning surfaces help maintain hygiene standards and meet food safety compliance requirements.

Construction and architectural applications constitute another significant segment at 18% of the market. This includes self-cleaning windows, facades, and interior surfaces that reduce maintenance costs while supporting green building certifications. The automotive and transportation sector represents 15% of the market, with applications in vehicle interiors and public transportation surfaces gaining traction due to heightened passenger safety concerns.

Regional analysis reveals North America as the dominant market with 38% share, followed by Europe (32%), Asia-Pacific (22%), and the rest of the world (8%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 7.2% annually, driven by rapid urbanization, increasing healthcare infrastructure, and growing environmental awareness in countries like China and India.

Consumer preferences are shifting toward environmentally friendly self-cleaning solutions that minimize the use of harsh chemicals. This trend aligns with increasingly stringent environmental health regulations worldwide, particularly in the European Union where the REACH regulation restricts certain chemical substances in consumer products. Consequently, manufacturers are investing in developing bio-based and non-toxic self-cleaning technologies to ensure regulatory compliance.

Market challenges include the higher initial cost of self-cleaning surfaces compared to conventional alternatives, with premium pricing ranging from 30-150% higher depending on the application. Additionally, there is a need for standardized testing protocols to verify environmental compliance and performance claims, as regulatory frameworks continue to evolve across different regions.

Healthcare facilities represent the largest application segment, accounting for roughly 32% of the total market share. Hospitals and medical centers are increasingly adopting self-cleaning surfaces to reduce healthcare-associated infections and comply with stringent sanitation regulations. The food processing industry follows closely behind at 24% market share, where self-cleaning surfaces help maintain hygiene standards and meet food safety compliance requirements.

Construction and architectural applications constitute another significant segment at 18% of the market. This includes self-cleaning windows, facades, and interior surfaces that reduce maintenance costs while supporting green building certifications. The automotive and transportation sector represents 15% of the market, with applications in vehicle interiors and public transportation surfaces gaining traction due to heightened passenger safety concerns.

Regional analysis reveals North America as the dominant market with 38% share, followed by Europe (32%), Asia-Pacific (22%), and the rest of the world (8%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 7.2% annually, driven by rapid urbanization, increasing healthcare infrastructure, and growing environmental awareness in countries like China and India.

Consumer preferences are shifting toward environmentally friendly self-cleaning solutions that minimize the use of harsh chemicals. This trend aligns with increasingly stringent environmental health regulations worldwide, particularly in the European Union where the REACH regulation restricts certain chemical substances in consumer products. Consequently, manufacturers are investing in developing bio-based and non-toxic self-cleaning technologies to ensure regulatory compliance.

Market challenges include the higher initial cost of self-cleaning surfaces compared to conventional alternatives, with premium pricing ranging from 30-150% higher depending on the application. Additionally, there is a need for standardized testing protocols to verify environmental compliance and performance claims, as regulatory frameworks continue to evolve across different regions.

Technical Challenges and Regulatory Constraints

Self-cleaning surfaces face significant technical challenges that must be addressed to ensure widespread adoption. The durability of these surfaces remains a primary concern, as many current solutions deteriorate rapidly under normal use conditions. Hydrophobic and superhydrophobic coatings often lose their effectiveness after physical abrasion, UV exposure, or chemical contact, limiting their practical applications in high-traffic environments. This degradation not only reduces functionality but also potentially releases nanoparticles or chemicals into the environment.

Material compatibility presents another substantial hurdle. Self-cleaning technologies must adhere to diverse substrates including glass, metals, polymers, and textiles, each requiring specific formulation adjustments. The adhesion mechanisms between the self-cleaning coating and these varied substrates often involve complex chemical interactions that can be disrupted by environmental factors, leading to delamination or performance loss.

From a regulatory perspective, self-cleaning surfaces face stringent oversight across multiple jurisdictions. In the United States, the EPA regulates these technologies under FIFRA when antimicrobial claims are made, requiring extensive efficacy and safety testing. The FDA imposes additional requirements for surfaces intended for food contact or medical applications, necessitating biocompatibility assessments and leaching studies.

The European Union's REACH regulation presents particularly demanding compliance challenges, requiring comprehensive chemical registration and safety documentation. The Biocidal Products Regulation (BPR) further governs surfaces with antimicrobial properties, mandating extensive testing protocols and risk assessments. These regulatory frameworks often involve lengthy approval processes that can significantly delay market entry.

Toxicological concerns represent perhaps the most critical constraint. Many self-cleaning technologies incorporate nanomaterials like titanium dioxide, silver nanoparticles, or fluorinated compounds that raise significant health and environmental questions. Regulatory bodies increasingly require comprehensive ecotoxicological data, including aquatic toxicity, bioaccumulation potential, and environmental persistence assessments.

Indoor air quality regulations add another layer of complexity, particularly for photocatalytic surfaces that may generate volatile organic compounds (VOCs) or reactive oxygen species as byproducts. Building certification systems like LEED and WELL have established strict emission limits that self-cleaning technologies must meet to be specified in green building projects.

The global regulatory landscape's fragmentation creates additional challenges, as manufacturers must navigate different requirements across markets. This regulatory heterogeneity significantly increases compliance costs and complicates global product deployment strategies, often necessitating market-specific formulations and testing protocols.

Material compatibility presents another substantial hurdle. Self-cleaning technologies must adhere to diverse substrates including glass, metals, polymers, and textiles, each requiring specific formulation adjustments. The adhesion mechanisms between the self-cleaning coating and these varied substrates often involve complex chemical interactions that can be disrupted by environmental factors, leading to delamination or performance loss.

From a regulatory perspective, self-cleaning surfaces face stringent oversight across multiple jurisdictions. In the United States, the EPA regulates these technologies under FIFRA when antimicrobial claims are made, requiring extensive efficacy and safety testing. The FDA imposes additional requirements for surfaces intended for food contact or medical applications, necessitating biocompatibility assessments and leaching studies.

The European Union's REACH regulation presents particularly demanding compliance challenges, requiring comprehensive chemical registration and safety documentation. The Biocidal Products Regulation (BPR) further governs surfaces with antimicrobial properties, mandating extensive testing protocols and risk assessments. These regulatory frameworks often involve lengthy approval processes that can significantly delay market entry.

Toxicological concerns represent perhaps the most critical constraint. Many self-cleaning technologies incorporate nanomaterials like titanium dioxide, silver nanoparticles, or fluorinated compounds that raise significant health and environmental questions. Regulatory bodies increasingly require comprehensive ecotoxicological data, including aquatic toxicity, bioaccumulation potential, and environmental persistence assessments.

Indoor air quality regulations add another layer of complexity, particularly for photocatalytic surfaces that may generate volatile organic compounds (VOCs) or reactive oxygen species as byproducts. Building certification systems like LEED and WELL have established strict emission limits that self-cleaning technologies must meet to be specified in green building projects.

The global regulatory landscape's fragmentation creates additional challenges, as manufacturers must navigate different requirements across markets. This regulatory heterogeneity significantly increases compliance costs and complicates global product deployment strategies, often necessitating market-specific formulations and testing protocols.

Current Self-cleaning Surface Solutions

01 Regulatory compliance systems for self-cleaning surfaces

Systems and methods for ensuring regulatory compliance of self-cleaning surfaces through automated monitoring and reporting. These systems track compliance with environmental regulations, safety standards, and industry-specific requirements related to self-cleaning technologies. They include features for documentation management, audit trails, and real-time compliance status monitoring to help organizations meet legal obligations while implementing self-cleaning surface technologies.- Regulatory compliance systems for self-cleaning surfaces: Systems and methods for ensuring regulatory compliance of self-cleaning surfaces through automated monitoring and reporting. These systems track compliance with environmental regulations, safety standards, and industry-specific requirements related to self-cleaning technologies. They include features for documentation management, audit trails, and real-time compliance status monitoring to help organizations meet legal obligations while implementing self-cleaning surface technologies.

- Self-cleaning surface verification and certification: Methods and systems for verifying and certifying the effectiveness and compliance of self-cleaning surfaces. These include testing protocols to validate the self-cleaning properties, durability, and safety of surfaces in various environments. Certification processes ensure that self-cleaning surfaces meet industry standards and regulatory requirements, providing documentation and evidence of compliance that can be used for auditing purposes.

- Smart monitoring systems for self-cleaning surfaces: Intelligent monitoring systems that use sensors, IoT technology, and data analytics to track the performance and compliance of self-cleaning surfaces. These systems collect real-time data on surface conditions, cleaning effectiveness, and environmental factors to ensure ongoing compliance with standards. They can automatically detect non-compliance issues, trigger maintenance alerts, and generate compliance reports for regulatory purposes.

- Risk management for self-cleaning surface implementation: Frameworks and methodologies for identifying, assessing, and mitigating risks associated with self-cleaning surface technologies. These approaches help organizations manage compliance risks related to environmental impact, chemical usage, waste disposal, and human health concerns. They include risk assessment tools, contingency planning, and compliance strategies specifically designed for facilities using self-cleaning surface technologies.

- Technical standards for self-cleaning surface materials: Technical specifications and standards for materials used in self-cleaning surfaces to ensure compliance with safety and environmental regulations. These standards cover the chemical composition, durability, degradation patterns, and environmental impact of self-cleaning materials. They provide guidelines for manufacturers and implementers to develop compliant self-cleaning surface solutions that meet regulatory requirements while delivering effective cleaning performance.

02 Self-cleaning surface verification and certification

Methods and systems for verifying and certifying the performance and compliance of self-cleaning surfaces. These include testing protocols to validate the efficacy of self-cleaning properties, certification processes to ensure surfaces meet industry standards, and documentation systems that provide evidence of compliance. The verification systems may include sensor-based monitoring of surface conditions and automated reporting mechanisms to maintain certification status.Expand Specific Solutions03 Smart monitoring systems for self-cleaning surfaces

Intelligent monitoring systems that track the performance and compliance of self-cleaning surfaces in real-time. These systems utilize sensors, IoT technology, and data analytics to monitor surface conditions, cleaning effectiveness, and environmental factors. They can automatically detect non-compliance issues, trigger maintenance alerts, and generate performance reports to ensure ongoing compliance with relevant standards and regulations.Expand Specific Solutions04 Compliance management for photocatalytic self-cleaning surfaces

Specialized compliance management approaches for photocatalytic self-cleaning surfaces that use light-activated materials to break down contaminants. These systems address the unique regulatory requirements for titanium dioxide and other photocatalytic materials, including their environmental impact, durability standards, and performance metrics. The management systems include testing protocols specific to photocatalytic activity and documentation of cleaning efficiency under various light conditions.Expand Specific Solutions05 Blockchain-based compliance tracking for self-cleaning technologies

Implementation of blockchain technology to create immutable records of self-cleaning surface compliance data. These systems provide transparent, tamper-proof documentation of testing, certification, maintenance, and performance metrics. The blockchain approach ensures data integrity throughout the compliance lifecycle, facilitates secure sharing of compliance information among stakeholders, and creates auditable trails for regulatory inspections and quality assurance purposes.Expand Specific Solutions

Leading Companies and Research Institutions

The self-cleaning surfaces market is currently in a growth phase, with increasing adoption across industries driven by environmental health regulations compliance requirements. The market is projected to expand significantly, reaching approximately $15-20 billion by 2030, fueled by applications in construction, automotive, and healthcare sectors. Technologically, the field shows varying maturity levels, with companies at different development stages. Industry leaders like 3M Innovative Properties and Evonik Operations have established commercial solutions, while research institutions such as Georgia Tech Research Corp. and Sichuan University are advancing fundamental technologies. Companies including Samsung Electronics, Dyson Technology, and Ecovacs Robotics are integrating self-cleaning capabilities into consumer products, while specialized firms like Creavis and Wacker Chemie focus on developing novel chemical coatings that meet increasingly stringent environmental health standards.

Evonik Operations GmbH

Technical Solution: Evonik has developed advanced self-cleaning surface technologies based on their proprietary silica nanoparticle formulations. Their approach combines hydrophobic and oleophobic properties to create surfaces that repel both water and oil-based contaminants. The technology utilizes modified silica particles with functional groups that create a micro-rough surface texture, enabling the Lotus Effect where water droplets roll off surfaces carrying away dirt particles. Evonik's solutions incorporate biodegradable surfactants and environmentally friendly catalysts that break down organic contaminants through photocatalytic reactions when exposed to light. Their formulations have been engineered to comply with EU REACH regulations and US EPA guidelines, with VOC emissions well below regulatory thresholds. The company has also implemented life cycle assessment protocols to ensure their products maintain environmental compliance throughout their entire usage period.

Strengths: Superior durability with coatings lasting 3-5 years in outdoor applications; formulations contain no restricted substances under major global regulations; comprehensive environmental impact assessment throughout product lifecycle. Weaknesses: Higher initial cost compared to conventional coatings; requires specific application conditions for optimal performance; some formulations may need periodic reactivation in low-light environments.

The Georgia Tech Research Corp.

Technical Solution: Georgia Tech Research Corporation has developed a groundbreaking self-cleaning surface technology based on biomimetic principles that addresses environmental health compliance challenges. Their approach utilizes hierarchical surface structures inspired by natural self-cleaning surfaces like lotus leaves and butterfly wings. The technology incorporates a dual-scale texture with micro and nano features that minimize contact area with contaminants while maximizing water repellency. Their surfaces achieve superhydrophobicity with contact angles exceeding 160° and extremely low roll-off angles below 5°. Georgia Tech's formulations use environmentally benign materials including modified silica, zinc oxide, and titanium dioxide nanoparticles that have been extensively tested for environmental fate and transport. The technology incorporates photocatalytic components that actively break down organic pollutants and airborne contaminants when exposed to both UV and visible light, addressing indoor air quality regulations. Their manufacturing processes have been optimized to eliminate hazardous solvents, using water-based systems and solvent recovery techniques that comply with Clean Air Act requirements and OSHA workplace exposure limits. The research team has developed comprehensive lifecycle assessment protocols to evaluate environmental impacts from raw material extraction through disposal.

Strengths: Exceptional scientific foundation with multiple peer-reviewed publications validating performance; highly adaptable technology platform that can be customized for specific regulatory environments; comprehensive toxicological testing data available for regulatory submissions. Weaknesses: Technology still in transition from research to commercial scale; higher initial implementation costs compared to conventional solutions; requires specialized application equipment for optimal performance.

Key Patents and Scientific Breakthroughs

Surfaces rendered self-cleaning by hydrophobic structures and a process for their production

PatentInactiveUS7211313B2

Innovation

- A self-cleaning surface with a hydrophobic, structured surface formed by particles secured to a carrier mixture of particles and binder, where the carrier system allows for the release of new structure-forming particles during erosion, maintaining the self-cleaning effect through self-regeneration.

Achieving a lotus effect by preventing microbial growth after damage to the self-cleaning surface

PatentWO2003013748A1

Innovation

- Development of self-cleaning surfaces with an artificial structure of elevations and depressions combined with a carrier system having antimicrobial properties, utilizing particles like silicates and antimicrobial polymers to slow down biological contamination adhesion and spread, maintaining the self-cleaning effect even after damage.

Environmental Impact Assessment

The environmental impact assessment of self-cleaning surfaces reveals significant implications for both ecosystem health and human safety. These innovative surfaces, designed to reduce maintenance and cleaning requirements, utilize various technologies including photocatalytic materials, hydrophobic coatings, and antimicrobial agents that warrant careful evaluation regarding their environmental footprint.

Primary concerns center on the potential release of nanoparticles, particularly titanium dioxide (TiO2) and silver nanoparticles, which are common components in photocatalytic self-cleaning surfaces. Research indicates these particles may leach into water systems during rainfall or cleaning processes, potentially affecting aquatic organisms through bioaccumulation and disruption of microbial communities essential for ecosystem functioning.

Chemical runoff presents another substantial concern, especially from hydrophobic coatings containing perfluorinated compounds (PFCs) and other persistent organic pollutants. These substances demonstrate remarkable environmental persistence, with degradation timeframes extending to decades or centuries. Monitoring studies have detected these compounds in groundwater and surface water adjacent to buildings with extensive self-cleaning surface applications.

Energy consumption analysis reveals contrasting environmental impacts. While self-cleaning surfaces reduce the need for frequent cleaning operations—thereby decreasing water usage and cleaning agent consumption—their manufacturing processes often require significant energy inputs. Life cycle assessments indicate that environmental benefits typically manifest only after several years of deployment, depending on application context and local environmental conditions.

Biodiversity effects warrant particular attention, as antimicrobial properties in self-cleaning surfaces may inadvertently impact beneficial microorganisms when these materials interface with soil or water systems. This disruption could potentially cascade through ecological networks, affecting higher trophic levels in sensitive environments.

Waste management challenges emerge at product end-of-life, as many self-cleaning surfaces incorporate composite materials that resist conventional recycling processes. The potential for releasing harmful substances during disposal or incineration necessitates specialized handling protocols that many waste management systems are not currently equipped to implement.

Regulatory frameworks increasingly recognize these environmental considerations, with the European Chemicals Agency (ECHA) and the U.S. Environmental Protection Agency (EPA) developing specific guidelines for nanomaterial-containing products. Compliance often requires manufacturers to conduct ecotoxicological testing and environmental fate modeling prior to market authorization.

Primary concerns center on the potential release of nanoparticles, particularly titanium dioxide (TiO2) and silver nanoparticles, which are common components in photocatalytic self-cleaning surfaces. Research indicates these particles may leach into water systems during rainfall or cleaning processes, potentially affecting aquatic organisms through bioaccumulation and disruption of microbial communities essential for ecosystem functioning.

Chemical runoff presents another substantial concern, especially from hydrophobic coatings containing perfluorinated compounds (PFCs) and other persistent organic pollutants. These substances demonstrate remarkable environmental persistence, with degradation timeframes extending to decades or centuries. Monitoring studies have detected these compounds in groundwater and surface water adjacent to buildings with extensive self-cleaning surface applications.

Energy consumption analysis reveals contrasting environmental impacts. While self-cleaning surfaces reduce the need for frequent cleaning operations—thereby decreasing water usage and cleaning agent consumption—their manufacturing processes often require significant energy inputs. Life cycle assessments indicate that environmental benefits typically manifest only after several years of deployment, depending on application context and local environmental conditions.

Biodiversity effects warrant particular attention, as antimicrobial properties in self-cleaning surfaces may inadvertently impact beneficial microorganisms when these materials interface with soil or water systems. This disruption could potentially cascade through ecological networks, affecting higher trophic levels in sensitive environments.

Waste management challenges emerge at product end-of-life, as many self-cleaning surfaces incorporate composite materials that resist conventional recycling processes. The potential for releasing harmful substances during disposal or incineration necessitates specialized handling protocols that many waste management systems are not currently equipped to implement.

Regulatory frameworks increasingly recognize these environmental considerations, with the European Chemicals Agency (ECHA) and the U.S. Environmental Protection Agency (EPA) developing specific guidelines for nanomaterial-containing products. Compliance often requires manufacturers to conduct ecotoxicological testing and environmental fate modeling prior to market authorization.

Health Safety Compliance Framework

The Health Safety Compliance Framework for self-cleaning surfaces encompasses comprehensive regulatory standards designed to ensure these innovative materials meet stringent environmental health requirements. This framework integrates multiple regulatory bodies' guidelines, including the Environmental Protection Agency (EPA), Occupational Safety and Health Administration (OSHA), and Food and Drug Administration (FDA) standards where applicable.

At its core, the framework establishes clear parameters for chemical composition assessment, requiring manufacturers to disclose all substances used in self-cleaning formulations. These disclosures must adhere to the Toxic Substances Control Act (TSCA) inventory requirements and REACH regulations in European markets. Particularly important is the limitation on volatile organic compounds (VOCs) and persistent bioaccumulative toxins that could pose long-term environmental hazards.

Risk assessment protocols constitute another critical component, mandating systematic evaluation of potential exposure scenarios across the product lifecycle. This includes manufacturing processes, application methods, normal use conditions, and end-of-life disposal considerations. Manufacturers must demonstrate through standardized testing that their self-cleaning surfaces do not leach harmful substances at levels exceeding regulatory thresholds under various environmental conditions.

The framework also establishes performance verification standards, requiring independent laboratory validation of self-cleaning efficacy claims. These tests must follow ISO 27447 and JIS Z 2801 protocols for antimicrobial activity assessment and ISO 10678 for photocatalytic activity measurement where applicable. Documentation of these test results must be maintained for regulatory inspection and product certification purposes.

Environmental impact assessment requirements form a substantial portion of the compliance framework, necessitating lifecycle analysis from raw material extraction through disposal. Particular attention is given to biodegradability, aquatic toxicity, and potential for bioaccumulation of any compounds that might be released during the product's functional lifetime.

Worker safety provisions within the framework address occupational exposure during manufacturing and application processes. These include specific ventilation requirements, personal protective equipment specifications, and handling protocols for nanomaterials commonly used in advanced self-cleaning formulations.

Consumer safety measures complete the framework, establishing clear guidelines for product labeling, usage instructions, and hazard communications. These requirements ensure end-users receive adequate information about proper application, maintenance limitations, and potential health considerations, particularly for surfaces that might contact food or be used in sensitive environments like healthcare facilities or schools.

At its core, the framework establishes clear parameters for chemical composition assessment, requiring manufacturers to disclose all substances used in self-cleaning formulations. These disclosures must adhere to the Toxic Substances Control Act (TSCA) inventory requirements and REACH regulations in European markets. Particularly important is the limitation on volatile organic compounds (VOCs) and persistent bioaccumulative toxins that could pose long-term environmental hazards.

Risk assessment protocols constitute another critical component, mandating systematic evaluation of potential exposure scenarios across the product lifecycle. This includes manufacturing processes, application methods, normal use conditions, and end-of-life disposal considerations. Manufacturers must demonstrate through standardized testing that their self-cleaning surfaces do not leach harmful substances at levels exceeding regulatory thresholds under various environmental conditions.

The framework also establishes performance verification standards, requiring independent laboratory validation of self-cleaning efficacy claims. These tests must follow ISO 27447 and JIS Z 2801 protocols for antimicrobial activity assessment and ISO 10678 for photocatalytic activity measurement where applicable. Documentation of these test results must be maintained for regulatory inspection and product certification purposes.

Environmental impact assessment requirements form a substantial portion of the compliance framework, necessitating lifecycle analysis from raw material extraction through disposal. Particular attention is given to biodegradability, aquatic toxicity, and potential for bioaccumulation of any compounds that might be released during the product's functional lifetime.

Worker safety provisions within the framework address occupational exposure during manufacturing and application processes. These include specific ventilation requirements, personal protective equipment specifications, and handling protocols for nanomaterials commonly used in advanced self-cleaning formulations.

Consumer safety measures complete the framework, establishing clear guidelines for product labeling, usage instructions, and hazard communications. These requirements ensure end-users receive adequate information about proper application, maintenance limitations, and potential health considerations, particularly for surfaces that might contact food or be used in sensitive environments like healthcare facilities or schools.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!