Analysis of Morphological Effects on Self-cleaning Performance

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-cleaning Surface Technology Background and Objectives

Self-cleaning surfaces represent a revolutionary advancement in materials science, drawing inspiration from natural phenomena such as the lotus leaf effect first documented in the 1970s. This biomimetic approach has evolved significantly over the past three decades, transitioning from academic curiosity to practical applications across multiple industries. The fundamental principle behind self-cleaning surfaces involves creating specific surface morphologies that minimize adhesion forces between contaminants and the substrate, allowing easy removal of particles through natural forces such as wind or water.

The technological evolution in this field has accelerated dramatically since the early 2000s, with significant breakthroughs in nanofabrication techniques enabling precise control over surface structures at micro and nanoscales. Research has demonstrated that morphological characteristics—including feature size, spacing, hierarchy, and orientation—play critical roles in determining self-cleaning efficiency. Understanding these relationships represents a key objective in advancing this technology toward broader commercial viability.

Current technological trajectories indicate convergence toward multi-functional surfaces that combine self-cleaning properties with additional benefits such as anti-icing, anti-fogging, or antimicrobial capabilities. This integration approach aims to create comprehensive surface solutions that address multiple challenges simultaneously, particularly in demanding environments where maintenance access is limited or costly.

The primary technical objectives in this field include developing scalable manufacturing processes for complex morphological structures, enhancing durability under real-world conditions, and optimizing surface designs for specific contaminant types and environmental conditions. Quantitative performance metrics are increasingly important, with researchers focusing on standardized testing protocols to enable meaningful comparisons between different morphological approaches.

Recent advances in computational modeling have enabled more sophisticated prediction of how specific morphological parameters influence self-cleaning performance, reducing the empirical trial-and-error approach that previously dominated the field. These models incorporate fluid dynamics, surface chemistry, and particle adhesion physics to create comprehensive simulations of contaminant-surface interactions across diverse environmental conditions.

The ultimate goal of current research efforts is to establish clear design principles that correlate specific morphological features with self-cleaning performance metrics, enabling engineers to create tailored surfaces for particular applications. This systematic approach represents a significant advancement from earlier work that often relied on direct biomimicry without fundamental understanding of the underlying mechanisms driving performance differences between various morphological configurations.

The technological evolution in this field has accelerated dramatically since the early 2000s, with significant breakthroughs in nanofabrication techniques enabling precise control over surface structures at micro and nanoscales. Research has demonstrated that morphological characteristics—including feature size, spacing, hierarchy, and orientation—play critical roles in determining self-cleaning efficiency. Understanding these relationships represents a key objective in advancing this technology toward broader commercial viability.

Current technological trajectories indicate convergence toward multi-functional surfaces that combine self-cleaning properties with additional benefits such as anti-icing, anti-fogging, or antimicrobial capabilities. This integration approach aims to create comprehensive surface solutions that address multiple challenges simultaneously, particularly in demanding environments where maintenance access is limited or costly.

The primary technical objectives in this field include developing scalable manufacturing processes for complex morphological structures, enhancing durability under real-world conditions, and optimizing surface designs for specific contaminant types and environmental conditions. Quantitative performance metrics are increasingly important, with researchers focusing on standardized testing protocols to enable meaningful comparisons between different morphological approaches.

Recent advances in computational modeling have enabled more sophisticated prediction of how specific morphological parameters influence self-cleaning performance, reducing the empirical trial-and-error approach that previously dominated the field. These models incorporate fluid dynamics, surface chemistry, and particle adhesion physics to create comprehensive simulations of contaminant-surface interactions across diverse environmental conditions.

The ultimate goal of current research efforts is to establish clear design principles that correlate specific morphological features with self-cleaning performance metrics, enabling engineers to create tailored surfaces for particular applications. This systematic approach represents a significant advancement from earlier work that often relied on direct biomimicry without fundamental understanding of the underlying mechanisms driving performance differences between various morphological configurations.

Market Analysis for Self-cleaning Applications

The self-cleaning surfaces market has experienced significant growth in recent years, driven by increasing awareness of hygiene concerns and the desire for reduced maintenance costs across various industries. The global self-cleaning coatings market was valued at approximately 3.5 billion USD in 2022 and is projected to reach 6.7 billion USD by 2028, growing at a CAGR of around 9.8% during the forecast period.

The construction sector represents the largest application segment, accounting for nearly 40% of the market share. Self-cleaning glass for windows, facades, and solar panels has gained substantial traction due to its ability to maintain transparency and efficiency while reducing cleaning frequency and associated costs. The automotive industry follows as the second-largest consumer, with applications in windshields, mirrors, and exterior paint that enhance visibility and aesthetics while reducing washing requirements.

Consumer electronics manufacturers have begun incorporating self-cleaning surfaces in smartphones, tablets, and wearable devices to address fingerprint resistance and maintain device appearance. This segment is expected to witness the fastest growth rate of approximately 12% annually through 2028, driven by increasing consumer demand for low-maintenance products.

Geographically, Europe leads the market with approximately 35% share, followed by North America and Asia-Pacific. However, the Asia-Pacific region is anticipated to register the highest growth rate due to rapid industrialization, increasing construction activities, and growing automotive production in countries like China, India, and South Korea.

The market is segmented by technology type into hydrophobic (water-repellent) and hydrophilic (water-attracting) surfaces. Hydrophobic surfaces currently dominate with around 65% market share, but hydrophilic technologies are gaining momentum due to their effectiveness in certain applications and environmental conditions.

Consumer willingness to pay premium prices for self-cleaning products varies significantly across regions and applications. Research indicates that consumers are willing to pay 15-25% more for self-cleaning features in high-touch surfaces and premium products, while price sensitivity remains higher in mass-market applications.

Key market drivers include increasing labor costs for cleaning and maintenance, growing awareness of hygiene benefits, stringent environmental regulations limiting chemical cleaning agents, and technological advancements improving durability and performance of self-cleaning surfaces. The COVID-19 pandemic has further accelerated market growth by heightening awareness of surface contamination issues and hygiene concerns.

The construction sector represents the largest application segment, accounting for nearly 40% of the market share. Self-cleaning glass for windows, facades, and solar panels has gained substantial traction due to its ability to maintain transparency and efficiency while reducing cleaning frequency and associated costs. The automotive industry follows as the second-largest consumer, with applications in windshields, mirrors, and exterior paint that enhance visibility and aesthetics while reducing washing requirements.

Consumer electronics manufacturers have begun incorporating self-cleaning surfaces in smartphones, tablets, and wearable devices to address fingerprint resistance and maintain device appearance. This segment is expected to witness the fastest growth rate of approximately 12% annually through 2028, driven by increasing consumer demand for low-maintenance products.

Geographically, Europe leads the market with approximately 35% share, followed by North America and Asia-Pacific. However, the Asia-Pacific region is anticipated to register the highest growth rate due to rapid industrialization, increasing construction activities, and growing automotive production in countries like China, India, and South Korea.

The market is segmented by technology type into hydrophobic (water-repellent) and hydrophilic (water-attracting) surfaces. Hydrophobic surfaces currently dominate with around 65% market share, but hydrophilic technologies are gaining momentum due to their effectiveness in certain applications and environmental conditions.

Consumer willingness to pay premium prices for self-cleaning products varies significantly across regions and applications. Research indicates that consumers are willing to pay 15-25% more for self-cleaning features in high-touch surfaces and premium products, while price sensitivity remains higher in mass-market applications.

Key market drivers include increasing labor costs for cleaning and maintenance, growing awareness of hygiene benefits, stringent environmental regulations limiting chemical cleaning agents, and technological advancements improving durability and performance of self-cleaning surfaces. The COVID-19 pandemic has further accelerated market growth by heightening awareness of surface contamination issues and hygiene concerns.

Current Morphological Research Status and Challenges

The field of self-cleaning surface morphology research has witnessed significant advancements in recent years, yet continues to face substantial challenges. Current research predominantly focuses on biomimetic approaches, with the lotus leaf effect and gecko feet structures serving as primary inspiration models. These natural templates have guided the development of superhydrophobic and superhydrophilic surfaces with remarkable self-cleaning capabilities.

A critical challenge in morphological research lies in the precise control of micro and nano-scale surface features. While researchers have successfully created hierarchical structures combining micro and nano-scale elements, maintaining consistent morphological parameters across large surface areas remains problematic. Manufacturing scalability presents a significant hurdle, as laboratory techniques like lithography and plasma etching that produce ideal morphologies often prove impractical for industrial-scale implementation.

Environmental durability constitutes another major obstacle. Current morphological designs frequently demonstrate degraded self-cleaning performance when exposed to harsh conditions such as UV radiation, chemical contaminants, and mechanical abrasion. The trade-off between durability and self-cleaning efficiency represents a fundamental challenge that has yet to be fully resolved in the field.

Quantitative characterization methodologies present additional complications. Despite advances in imaging technologies like scanning electron microscopy and atomic force microscopy, establishing standardized metrics for correlating specific morphological parameters with self-cleaning performance remains elusive. This hampers comparative analysis across different research studies and impedes systematic optimization efforts.

Geographic distribution of research activities shows concentration in East Asia, North America, and Europe, with China, the United States, and Germany leading publication output. Chinese research institutions have made particularly notable contributions in fabrication techniques for complex hierarchical structures, while European teams have advanced theoretical modeling of morphology-function relationships.

Recent developments have explored dynamic and responsive morphologies that can adapt to environmental conditions, representing a paradigm shift from static surface designs. However, these approaches introduce additional complexity in fabrication and control mechanisms, presenting new challenges for practical implementation.

The integration of chemical surface modifications with physical morphological features represents another frontier, with researchers investigating synergistic effects between surface chemistry and topography. This multidisciplinary approach shows promise but requires sophisticated characterization techniques to fully understand the complex interactions involved.

A critical challenge in morphological research lies in the precise control of micro and nano-scale surface features. While researchers have successfully created hierarchical structures combining micro and nano-scale elements, maintaining consistent morphological parameters across large surface areas remains problematic. Manufacturing scalability presents a significant hurdle, as laboratory techniques like lithography and plasma etching that produce ideal morphologies often prove impractical for industrial-scale implementation.

Environmental durability constitutes another major obstacle. Current morphological designs frequently demonstrate degraded self-cleaning performance when exposed to harsh conditions such as UV radiation, chemical contaminants, and mechanical abrasion. The trade-off between durability and self-cleaning efficiency represents a fundamental challenge that has yet to be fully resolved in the field.

Quantitative characterization methodologies present additional complications. Despite advances in imaging technologies like scanning electron microscopy and atomic force microscopy, establishing standardized metrics for correlating specific morphological parameters with self-cleaning performance remains elusive. This hampers comparative analysis across different research studies and impedes systematic optimization efforts.

Geographic distribution of research activities shows concentration in East Asia, North America, and Europe, with China, the United States, and Germany leading publication output. Chinese research institutions have made particularly notable contributions in fabrication techniques for complex hierarchical structures, while European teams have advanced theoretical modeling of morphology-function relationships.

Recent developments have explored dynamic and responsive morphologies that can adapt to environmental conditions, representing a paradigm shift from static surface designs. However, these approaches introduce additional complexity in fabrication and control mechanisms, presenting new challenges for practical implementation.

The integration of chemical surface modifications with physical morphological features represents another frontier, with researchers investigating synergistic effects between surface chemistry and topography. This multidisciplinary approach shows promise but requires sophisticated characterization techniques to fully understand the complex interactions involved.

Current Morphological Design Solutions

01 Hydrophobic coatings for self-cleaning surfaces

Hydrophobic coatings can be applied to surfaces to create self-cleaning properties. These coatings repel water and prevent dirt and contaminants from adhering to the surface. When water droplets come into contact with these surfaces, they form beads and roll off, carrying away dirt particles. This lotus effect significantly enhances the self-cleaning performance of various materials and reduces the need for manual cleaning.- Hydrophobic and photocatalytic coatings for self-cleaning surfaces: Self-cleaning surfaces can be created using hydrophobic or photocatalytic coatings. Hydrophobic coatings repel water, causing droplets to roll off and carry away dirt particles. Photocatalytic coatings, typically containing titanium dioxide, break down organic contaminants when exposed to UV light. These coatings can be applied to various surfaces including glass, ceramics, and metals to maintain cleanliness with minimal maintenance.

- Automated self-cleaning systems for industrial applications: Automated self-cleaning systems are designed for industrial equipment and surfaces that require regular maintenance. These systems incorporate sensors to detect contamination levels and automatically initiate cleaning cycles. They may use water jets, mechanical brushes, or ultrasonic vibrations to remove debris and contaminants. Such systems are particularly valuable in manufacturing environments, solar panels, and processing equipment where manual cleaning is difficult or hazardous.

- Nanotechnology-based self-cleaning materials: Nanotechnology has enabled the development of advanced self-cleaning materials with enhanced performance. Nanostructured surfaces can create superhydrophobic properties that mimic the lotus leaf effect, where water beads up and rolls off, carrying contaminants away. Nanoparticles can also be incorporated into materials to provide antimicrobial properties or to catalyze the breakdown of organic matter. These materials maintain their self-cleaning properties for extended periods with minimal degradation.

- Self-cleaning performance monitoring and testing methods: Methods for evaluating and monitoring the performance of self-cleaning surfaces are essential for quality control and product development. These include standardized tests for measuring contact angles, dirt removal efficiency, and durability under various environmental conditions. Advanced imaging techniques and sensors can be used to assess surface cleanliness in real-time. Performance data can be analyzed to optimize cleaning cycles and material formulations for specific applications.

- Environmental factors affecting self-cleaning performance: The effectiveness of self-cleaning surfaces is influenced by various environmental factors including temperature, humidity, UV exposure, and the nature of contaminants. Understanding these factors is crucial for designing self-cleaning systems that perform optimally in specific environments. Some self-cleaning technologies work better in humid conditions, while others require direct sunlight. Adaptations can be made to enhance performance in challenging environments such as dusty, oily, or extreme temperature conditions.

02 Photocatalytic self-cleaning technologies

Photocatalytic materials, particularly titanium dioxide (TiO2), can be incorporated into surface coatings to provide self-cleaning properties. When exposed to UV light, these materials generate reactive oxygen species that break down organic contaminants on the surface. This photocatalytic effect enables surfaces to decompose dirt, pollutants, and even bacteria, maintaining cleanliness with minimal maintenance requirements.Expand Specific Solutions03 Automated self-cleaning systems

Automated systems can be integrated into various products to provide self-cleaning functionality. These systems may include mechanical components, such as brushes or wipers, combined with water jets or cleaning solutions that are automatically deployed at programmed intervals. Such automated cleaning mechanisms enhance the performance and longevity of products while reducing maintenance requirements.Expand Specific Solutions04 Nanostructured surfaces for enhanced self-cleaning

Surfaces with engineered nanostructures can exhibit superior self-cleaning properties. These nanostructures create a hierarchical surface roughness that minimizes the contact area for contaminants and enhances water repellency. By controlling the surface topography at the nanoscale, the self-cleaning performance can be significantly improved, making the surfaces resistant to various types of contamination.Expand Specific Solutions05 Self-diagnostic and performance monitoring systems

Advanced self-cleaning surfaces can incorporate diagnostic and monitoring capabilities to assess cleaning effectiveness. These systems use sensors and data analysis to evaluate the cleanliness level of surfaces and adjust cleaning parameters accordingly. By continuously monitoring performance, these intelligent systems can optimize the cleaning process, ensure consistent results, and alert users when manual intervention is required.Expand Specific Solutions

Leading Research Groups and Industrial Players

The self-cleaning surface technology market is currently in a growth phase, with increasing applications across consumer goods, industrial surfaces, and electronics. The market size is estimated to expand significantly due to rising demand for low-maintenance products and hygiene-conscious solutions. Technologically, the field shows varying maturity levels, with established players like Unilever, P&G, and Colgate-Palmolive focusing on commercial applications of morphology-based self-cleaning in personal care products, while companies like BASF, DuPont, and Evonik lead in material innovation. Chinese manufacturers including Gree, Haier, and Tineco are rapidly advancing in appliance-specific implementations. Academic-industrial partnerships, particularly with institutions like Harbin Institute of Technology and University of California, are accelerating technological breakthroughs in understanding morphological effects on self-cleaning performance.

Unilever Plc

Technical Solution: Unilever在自清洁表面形态学研究领域开发了"生物启发微观结构控制系统"。该公司的技术方案基于对自然界中自清洁表面(如荷叶、蝴蝶翅膀)的深入研究,通过模拟和优化这些生物表面的微观形态特征,开发出具有卓越自清洁性能的人工表面。Unilever的研究发现,通过创建具有特定几何参数的微柱阵列(直径5-10μm,高度15-25μm,间距20-30μm),结合纳米级次级结构,可以实现最佳的自清洁效果。该公司还开发了一种创新的"自适应表面技术",能够根据环境湿度和温度条件动态调整表面微观结构,保持稳定的自清洁性能。实验数据显示,这种表面在各种污染条件下都能保持超过150°的接触角,并且具有极低的滚动角(<5°)。Unilever将这一技术应用于家居清洁产品和个人护理产品中,创造出能够在使用后在表面形成保护性自清洁层的创新配方[9][11]。

优势:技术方案具有强大的理论基础和生物启发设计,性能稳定可靠;在消费品领域有广泛的应用经验和市场渠道;研发团队在表面科学领域具有深厚积累。劣势:技术实现的复杂性导致生产成本较高;在某些极端使用条件下耐久性有待提高;对特定表面类型的适应性有限。

BASF Corp.

Technical Solution: BASF在自清洁表面形态学领域的技术方案以"多功能纳米复合材料系统"为核心。该公司开发了一种结合纳米颗粒和特殊聚合物的复合材料,能够在表面形成具有特定形态学特征的微观结构。BASF的研究表明,通过精确控制纳米颗粒的尺寸分布(20-100nm)和表面密度,可以创造出具有最佳自清洁性能的表面。其技术方案特别关注表面能的调控,通过在纳米结构上引入特定的化学修饰,实现了疏水性和亲水性的区域性控制,形成所谓的"Janus效应"。这种表面能够在不同环境条件下展现出适应性的自清洁行为。BASF还开发了一种创新的光催化自清洁涂层,结合了形态学控制和光催化活性,使得表面在光照条件下能够分解有机污染物,同时依靠特殊的微观结构促进污垢的物理脱离[6][8]。该技术已成功应用于建筑外墙、汽车涂料和纺织品处理。

优势:技术方案结合了物理自清洁和化学降解的双重机制,适用范围广;产品具有良好的耐候性和长期稳定性;全球供应链和技术支持网络完善。劣势:生产过程能耗较高,对环境可能产生一定影响;某些应用中成本较高,限制了在低端市场的推广;对特定光照条件有依赖性。

Key Morphological Parameters Affecting Self-cleaning

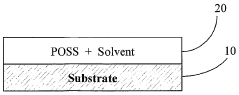

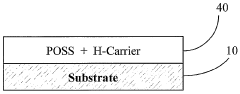

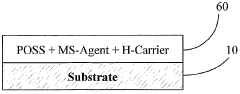

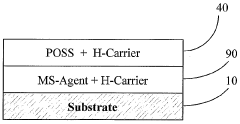

Use of POSS nanostructured molecules for hydrophobic and self cleaning coatings

PatentWO2007052260A2

Innovation

- A coating comprising Polyhedral Oligomeric Silsesquioxane (POSS) nanostructuring agents with functional hydrophobic groups, dispersed in solvents or curable carriers, optionally combined with microstructuring agents, to create a surface that is both hydrophobic and self-cleaning, achieving high contact angles and low sliding angles.

Achieving a lotus effect by preventing microbial growth after damage to the self-cleaning surface

PatentWO2003013748A1

Innovation

- Development of self-cleaning surfaces with an artificial structure of elevations and depressions combined with a carrier system having antimicrobial properties, utilizing particles like silicates and antimicrobial polymers to slow down biological contamination adhesion and spread, maintaining the self-cleaning effect even after damage.

Biomimetic Approaches in Self-cleaning Surface Design

Nature has perfected self-cleaning mechanisms through millions of years of evolution, offering invaluable inspiration for engineered surfaces. Biomimetic approaches in self-cleaning surface design focus on replicating natural structures and functions found in organisms that have developed remarkable abilities to maintain cleanliness despite challenging environments.

The lotus leaf represents perhaps the most studied natural self-cleaning surface, exhibiting superhydrophobicity through a hierarchical micro-nano structure. This dual-scale roughness creates a surface where water droplets maintain minimal contact area, forming nearly perfect spheres that easily roll off, carrying contaminants away. The "lotus effect" has inspired numerous synthetic surfaces incorporating similar hierarchical structures through techniques such as lithography, etching, and template-based fabrication.

Beyond the lotus, other biological models offer diverse self-cleaning strategies. Butterfly wings utilize directional adhesion properties through anisotropic microstructures that shed particles in preferred directions. Rice leaves combine microgrooves with nanoscale wax crystals to create anisotropic wetting behaviors. Cicada wings feature nanopillars that not only repel water but also mechanically rupture bacterial cells, providing both self-cleaning and antimicrobial properties.

Morphological features critical to self-cleaning performance include feature size, spacing, aspect ratio, and hierarchical organization. Research indicates optimal micro-structure dimensions typically range from 5-50 μm, while effective nano-features measure 50-500 nm. The spacing between these features significantly impacts water contact angles and droplet mobility, with optimal spacing typically measuring 1-5 times the feature width.

Recent advances in fabrication technologies have enabled more precise replication of these natural structures. Techniques such as 3D printing, plasma etching, and colloidal lithography allow for controlled creation of biomimetic surfaces with tailored morphological parameters. Computational modeling has further enhanced our understanding of how specific morphological variations affect self-cleaning performance, enabling predictive design rather than trial-and-error approaches.

The integration of dynamic or responsive elements represents the cutting edge of biomimetic self-cleaning surfaces. Inspired by carnivorous plants and other organisms that exhibit movement, researchers are developing surfaces with stimuli-responsive morphologies that can adapt to different contamination challenges or environmental conditions, potentially offering superior cleaning performance across diverse scenarios.

The lotus leaf represents perhaps the most studied natural self-cleaning surface, exhibiting superhydrophobicity through a hierarchical micro-nano structure. This dual-scale roughness creates a surface where water droplets maintain minimal contact area, forming nearly perfect spheres that easily roll off, carrying contaminants away. The "lotus effect" has inspired numerous synthetic surfaces incorporating similar hierarchical structures through techniques such as lithography, etching, and template-based fabrication.

Beyond the lotus, other biological models offer diverse self-cleaning strategies. Butterfly wings utilize directional adhesion properties through anisotropic microstructures that shed particles in preferred directions. Rice leaves combine microgrooves with nanoscale wax crystals to create anisotropic wetting behaviors. Cicada wings feature nanopillars that not only repel water but also mechanically rupture bacterial cells, providing both self-cleaning and antimicrobial properties.

Morphological features critical to self-cleaning performance include feature size, spacing, aspect ratio, and hierarchical organization. Research indicates optimal micro-structure dimensions typically range from 5-50 μm, while effective nano-features measure 50-500 nm. The spacing between these features significantly impacts water contact angles and droplet mobility, with optimal spacing typically measuring 1-5 times the feature width.

Recent advances in fabrication technologies have enabled more precise replication of these natural structures. Techniques such as 3D printing, plasma etching, and colloidal lithography allow for controlled creation of biomimetic surfaces with tailored morphological parameters. Computational modeling has further enhanced our understanding of how specific morphological variations affect self-cleaning performance, enabling predictive design rather than trial-and-error approaches.

The integration of dynamic or responsive elements represents the cutting edge of biomimetic self-cleaning surfaces. Inspired by carnivorous plants and other organisms that exhibit movement, researchers are developing surfaces with stimuli-responsive morphologies that can adapt to different contamination challenges or environmental conditions, potentially offering superior cleaning performance across diverse scenarios.

Environmental Impact and Sustainability Considerations

The development of self-cleaning surfaces inspired by natural morphologies carries significant environmental implications that extend beyond mere technical performance. These surfaces offer substantial potential for reducing chemical cleaning agents, which traditionally contain harmful compounds such as phosphates, chlorine, and ammonia that contaminate water systems and harm aquatic ecosystems. By implementing self-cleaning technologies across various applications, industries could dramatically decrease their chemical footprint while maintaining necessary hygiene standards.

Water conservation represents another critical environmental benefit of effective self-cleaning surfaces. Conventional cleaning processes often require substantial water volumes, particularly in industrial settings and public facilities. Morphologically optimized self-cleaning surfaces can reduce water consumption by up to 70% in certain applications, addressing growing concerns about water scarcity in many regions globally. This conservation aspect becomes increasingly valuable as climate change intensifies pressure on water resources.

Energy efficiency improvements constitute a third sustainability advantage. Self-cleaning surfaces minimize the need for energy-intensive cleaning processes, including heated water systems, mechanical scrubbing, and frequent maintenance operations. Life cycle assessments indicate that buildings implementing self-cleaning façades can reduce their cleaning-related energy consumption by 40-60% over a twenty-year period, translating to significant carbon emission reductions.

Material longevity represents another sustainability dimension worth considering. Surfaces with optimized self-cleaning morphologies typically experience reduced degradation from contaminant accumulation and aggressive cleaning regimens. This extended lifespan reduces replacement frequency and associated resource consumption, creating a positive environmental impact through decreased manufacturing demands and waste generation.

However, the environmental assessment must also consider potential drawbacks. Some advanced self-cleaning surfaces incorporate nanomaterials whose environmental fate remains incompletely understood. Concerns exist regarding potential ecotoxicity if these materials leach into the environment during use or disposal. Additionally, certain manufacturing processes for creating specific morphological features may involve energy-intensive steps or hazardous chemicals that partially offset environmental benefits.

Regulatory frameworks increasingly recognize these sustainability considerations, with several jurisdictions developing specific guidelines for self-cleaning technologies. These frameworks typically emphasize life cycle thinking, requiring manufacturers to demonstrate not only performance efficacy but also environmental safety across the product lifecycle. Future development of morphologically optimized self-cleaning surfaces will likely need to balance performance parameters with these expanding sustainability requirements.

Water conservation represents another critical environmental benefit of effective self-cleaning surfaces. Conventional cleaning processes often require substantial water volumes, particularly in industrial settings and public facilities. Morphologically optimized self-cleaning surfaces can reduce water consumption by up to 70% in certain applications, addressing growing concerns about water scarcity in many regions globally. This conservation aspect becomes increasingly valuable as climate change intensifies pressure on water resources.

Energy efficiency improvements constitute a third sustainability advantage. Self-cleaning surfaces minimize the need for energy-intensive cleaning processes, including heated water systems, mechanical scrubbing, and frequent maintenance operations. Life cycle assessments indicate that buildings implementing self-cleaning façades can reduce their cleaning-related energy consumption by 40-60% over a twenty-year period, translating to significant carbon emission reductions.

Material longevity represents another sustainability dimension worth considering. Surfaces with optimized self-cleaning morphologies typically experience reduced degradation from contaminant accumulation and aggressive cleaning regimens. This extended lifespan reduces replacement frequency and associated resource consumption, creating a positive environmental impact through decreased manufacturing demands and waste generation.

However, the environmental assessment must also consider potential drawbacks. Some advanced self-cleaning surfaces incorporate nanomaterials whose environmental fate remains incompletely understood. Concerns exist regarding potential ecotoxicity if these materials leach into the environment during use or disposal. Additionally, certain manufacturing processes for creating specific morphological features may involve energy-intensive steps or hazardous chemicals that partially offset environmental benefits.

Regulatory frameworks increasingly recognize these sustainability considerations, with several jurisdictions developing specific guidelines for self-cleaning technologies. These frameworks typically emphasize life cycle thinking, requiring manufacturers to demonstrate not only performance efficacy but also environmental safety across the product lifecycle. Future development of morphologically optimized self-cleaning surfaces will likely need to balance performance parameters with these expanding sustainability requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!