Advances in LM7 engine piston design and material science

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LM7 Engine Evolution

The LM7 engine, a member of the GM Gen III small-block V8 family, has undergone significant evolution since its introduction in 1999. Initially designed as a 5.3-liter truck engine, the LM7 has seen continuous improvements in piston design and material science, reflecting broader trends in automotive engineering.

In its early iterations, the LM7 utilized hypereutectic aluminum pistons, which offered a balance between strength and weight. These pistons were designed with a flat-top profile, optimized for the engine's compression ratio and combustion chamber geometry. As the engine evolved, engineers focused on reducing friction and improving thermal efficiency.

The mid-2000s saw a shift towards the use of forged aluminum pistons in high-performance variants of the LM7. This change was driven by the need for increased durability in applications with higher power outputs and thermal loads. Forged pistons offered superior strength and heat resistance compared to their cast counterparts, allowing for more aggressive tuning and higher boost pressures in forced induction applications.

Advancements in computer-aided design and simulation technologies played a crucial role in the evolution of LM7 piston design. Engineers were able to optimize piston crown geometry, skirt profiles, and ring land configurations with unprecedented precision. These improvements led to better combustion efficiency, reduced oil consumption, and enhanced overall engine performance.

Material science innovations also contributed significantly to the LM7's evolution. The introduction of low-friction coatings on piston skirts, such as graphite and molybdenum-based compounds, helped to reduce parasitic losses and improve fuel efficiency. Additionally, the development of advanced alloys allowed for pistons that could withstand higher temperatures and pressures while maintaining dimensional stability.

In recent years, the focus has shifted towards lightweight design without compromising strength. This has led to the exploration of exotic materials like titanium alloys and metal matrix composites for high-end applications. While not widely adopted in production LM7 engines due to cost considerations, these materials represent the cutting edge of piston technology and point to future possibilities.

The evolution of the LM7 engine's piston design also reflects broader trends in emissions reduction and fuel efficiency. Engineers have experimented with piston crown designs that promote better fuel atomization and more complete combustion, directly addressing increasingly stringent environmental regulations.

Throughout its lifespan, the LM7 engine has served as a testbed for numerous piston innovations, many of which have found their way into other GM engines and influenced industry-wide practices. The continuous refinement of piston design and materials in the LM7 exemplifies the automotive industry's relentless pursuit of performance, efficiency, and reliability.

In its early iterations, the LM7 utilized hypereutectic aluminum pistons, which offered a balance between strength and weight. These pistons were designed with a flat-top profile, optimized for the engine's compression ratio and combustion chamber geometry. As the engine evolved, engineers focused on reducing friction and improving thermal efficiency.

The mid-2000s saw a shift towards the use of forged aluminum pistons in high-performance variants of the LM7. This change was driven by the need for increased durability in applications with higher power outputs and thermal loads. Forged pistons offered superior strength and heat resistance compared to their cast counterparts, allowing for more aggressive tuning and higher boost pressures in forced induction applications.

Advancements in computer-aided design and simulation technologies played a crucial role in the evolution of LM7 piston design. Engineers were able to optimize piston crown geometry, skirt profiles, and ring land configurations with unprecedented precision. These improvements led to better combustion efficiency, reduced oil consumption, and enhanced overall engine performance.

Material science innovations also contributed significantly to the LM7's evolution. The introduction of low-friction coatings on piston skirts, such as graphite and molybdenum-based compounds, helped to reduce parasitic losses and improve fuel efficiency. Additionally, the development of advanced alloys allowed for pistons that could withstand higher temperatures and pressures while maintaining dimensional stability.

In recent years, the focus has shifted towards lightweight design without compromising strength. This has led to the exploration of exotic materials like titanium alloys and metal matrix composites for high-end applications. While not widely adopted in production LM7 engines due to cost considerations, these materials represent the cutting edge of piston technology and point to future possibilities.

The evolution of the LM7 engine's piston design also reflects broader trends in emissions reduction and fuel efficiency. Engineers have experimented with piston crown designs that promote better fuel atomization and more complete combustion, directly addressing increasingly stringent environmental regulations.

Throughout its lifespan, the LM7 engine has served as a testbed for numerous piston innovations, many of which have found their way into other GM engines and influenced industry-wide practices. The continuous refinement of piston design and materials in the LM7 exemplifies the automotive industry's relentless pursuit of performance, efficiency, and reliability.

Market Demand Analysis

The market demand for advanced LM7 engine piston designs and materials has been steadily increasing, driven by the automotive industry's push for improved fuel efficiency, reduced emissions, and enhanced engine performance. As environmental regulations become more stringent worldwide, manufacturers are seeking innovative solutions to meet these challenges while maintaining or improving engine power and durability.

The global automotive piston market is experiencing significant growth, with a particular focus on lightweight materials and advanced designs. This trend is especially pronounced in the passenger vehicle segment, where the LM7 engine is commonly used. The market is witnessing a shift towards pistons made from aluminum alloys and composite materials, which offer superior strength-to-weight ratios compared to traditional cast iron pistons.

In recent years, there has been a notable increase in demand for pistons that can withstand higher combustion pressures and temperatures. This is particularly relevant for turbocharged and high-compression engines, where the LM7 platform is often modified for performance applications. The aftermarket sector has also shown strong interest in upgraded pistons for LM7 engines, catering to enthusiasts and racing applications.

The commercial vehicle sector, while not the primary market for LM7 engines, is influencing overall piston design trends. Advancements in piston technology for heavy-duty applications are often transferable to light-duty engines like the LM7, creating synergies in research and development across different vehicle categories.

Material science innovations are playing a crucial role in meeting market demands. There is growing interest in ceramic coatings and thermal barrier technologies that can improve piston durability and reduce heat transfer to the engine oil. These advancements are particularly valuable for high-performance and efficiency-focused applications of the LM7 engine.

The market is also seeing increased demand for pistons with integrated oil cooling galleries and optimized skirt designs. These features contribute to better thermal management and reduced friction, aligning with the industry's focus on improving overall engine efficiency. Manufacturers are investing in computer-aided design and simulation tools to develop pistons that can meet these complex requirements while maintaining cost-effectiveness in production.

As the automotive industry continues its transition towards electrification, there is a parallel demand for advanced internal combustion engine technologies that can bridge the gap and coexist with electric powertrains. This has led to a renewed focus on piston designs that can support hybrid powertrains and alternative fuel systems, potentially extending the relevance of LM7-based engines in the evolving automotive landscape.

The global automotive piston market is experiencing significant growth, with a particular focus on lightweight materials and advanced designs. This trend is especially pronounced in the passenger vehicle segment, where the LM7 engine is commonly used. The market is witnessing a shift towards pistons made from aluminum alloys and composite materials, which offer superior strength-to-weight ratios compared to traditional cast iron pistons.

In recent years, there has been a notable increase in demand for pistons that can withstand higher combustion pressures and temperatures. This is particularly relevant for turbocharged and high-compression engines, where the LM7 platform is often modified for performance applications. The aftermarket sector has also shown strong interest in upgraded pistons for LM7 engines, catering to enthusiasts and racing applications.

The commercial vehicle sector, while not the primary market for LM7 engines, is influencing overall piston design trends. Advancements in piston technology for heavy-duty applications are often transferable to light-duty engines like the LM7, creating synergies in research and development across different vehicle categories.

Material science innovations are playing a crucial role in meeting market demands. There is growing interest in ceramic coatings and thermal barrier technologies that can improve piston durability and reduce heat transfer to the engine oil. These advancements are particularly valuable for high-performance and efficiency-focused applications of the LM7 engine.

The market is also seeing increased demand for pistons with integrated oil cooling galleries and optimized skirt designs. These features contribute to better thermal management and reduced friction, aligning with the industry's focus on improving overall engine efficiency. Manufacturers are investing in computer-aided design and simulation tools to develop pistons that can meet these complex requirements while maintaining cost-effectiveness in production.

As the automotive industry continues its transition towards electrification, there is a parallel demand for advanced internal combustion engine technologies that can bridge the gap and coexist with electric powertrains. This has led to a renewed focus on piston designs that can support hybrid powertrains and alternative fuel systems, potentially extending the relevance of LM7-based engines in the evolving automotive landscape.

Current Piston Tech

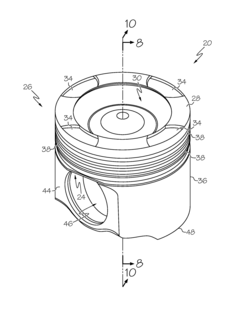

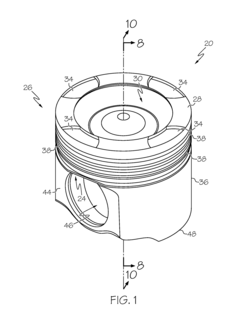

Current piston technology in LM7 engines represents a culmination of advanced design principles and material science innovations. The pistons used in these engines are typically made from high-strength aluminum alloys, which offer an optimal balance of lightweight properties and durability. These alloys often incorporate silicon, copper, and magnesium to enhance strength and heat resistance.

The design of modern LM7 pistons features a low-friction skirt coating, usually made of graphite or molybdenum disulfide. This coating significantly reduces friction between the piston and cylinder wall, improving engine efficiency and longevity. The piston crown is engineered with a specific bowl shape to optimize fuel mixture and combustion, enhancing power output and fuel economy.

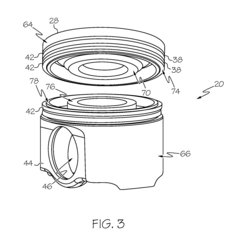

Another key feature of current LM7 piston technology is the use of floating wrist pins. These pins allow for slight movement, reducing stress on the piston and connecting rod assembly during high-load conditions. The piston rings, typically comprising three rings - two compression rings and an oil control ring - are made from high-performance materials such as steel or ductile iron with special coatings to minimize friction and oil consumption.

Advanced manufacturing techniques, including forging and precision machining, are employed to produce pistons with tight tolerances and optimal structural integrity. Computer-aided design (CAD) and finite element analysis (FEA) are extensively used in the development process to optimize piston geometry for strength, weight, and thermal management.

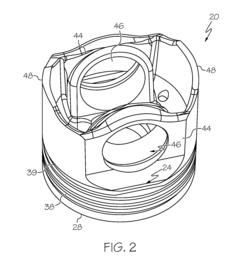

Thermal management is a critical aspect of current piston technology. Many LM7 pistons incorporate oil cooling galleries or channels within the piston body. These galleries allow engine oil to circulate through the piston, effectively dissipating heat and maintaining optimal operating temperatures. This feature is particularly important in high-performance applications where thermal stress can be a limiting factor.

The integration of variable compression ratio (VCR) technology is an emerging trend in piston design. While not yet widespread in LM7 engines, this technology allows for dynamic adjustment of the compression ratio during engine operation, optimizing performance and efficiency across different operating conditions.

In terms of material science, ongoing research focuses on developing even lighter and stronger alloys, as well as exploring the potential of ceramic materials for specific piston components. These advancements aim to further reduce reciprocating mass, improve heat resistance, and enhance overall engine performance.

The design of modern LM7 pistons features a low-friction skirt coating, usually made of graphite or molybdenum disulfide. This coating significantly reduces friction between the piston and cylinder wall, improving engine efficiency and longevity. The piston crown is engineered with a specific bowl shape to optimize fuel mixture and combustion, enhancing power output and fuel economy.

Another key feature of current LM7 piston technology is the use of floating wrist pins. These pins allow for slight movement, reducing stress on the piston and connecting rod assembly during high-load conditions. The piston rings, typically comprising three rings - two compression rings and an oil control ring - are made from high-performance materials such as steel or ductile iron with special coatings to minimize friction and oil consumption.

Advanced manufacturing techniques, including forging and precision machining, are employed to produce pistons with tight tolerances and optimal structural integrity. Computer-aided design (CAD) and finite element analysis (FEA) are extensively used in the development process to optimize piston geometry for strength, weight, and thermal management.

Thermal management is a critical aspect of current piston technology. Many LM7 pistons incorporate oil cooling galleries or channels within the piston body. These galleries allow engine oil to circulate through the piston, effectively dissipating heat and maintaining optimal operating temperatures. This feature is particularly important in high-performance applications where thermal stress can be a limiting factor.

The integration of variable compression ratio (VCR) technology is an emerging trend in piston design. While not yet widespread in LM7 engines, this technology allows for dynamic adjustment of the compression ratio during engine operation, optimizing performance and efficiency across different operating conditions.

In terms of material science, ongoing research focuses on developing even lighter and stronger alloys, as well as exploring the potential of ceramic materials for specific piston components. These advancements aim to further reduce reciprocating mass, improve heat resistance, and enhance overall engine performance.

Advanced Piston Designs

01 Piston design for improved performance

LM7 engine pistons are designed with specific features to enhance performance. These may include optimized crown shapes, skirt profiles, and ring grooves to improve combustion efficiency, reduce friction, and enhance overall engine performance. Advanced design techniques are employed to balance strength and weight reduction.- Piston design for improved performance: LM7 engine pistons are designed with specific features to enhance performance. These may include optimized crown shapes, skirt profiles, and ring grooves to improve combustion efficiency, reduce friction, and enhance overall engine output. Advanced design techniques are employed to balance strength and weight, ensuring durability while minimizing reciprocating mass.

- Material selection for LM7 pistons: The choice of materials for LM7 engine pistons is crucial for performance and longevity. High-strength aluminum alloys are commonly used, often with silicon content for improved thermal properties. Some designs may incorporate composite materials or coatings to enhance wear resistance and reduce thermal expansion. The material selection aims to balance lightweight properties with durability under high-temperature and high-pressure conditions.

- Cooling and lubrication considerations: LM7 piston designs incorporate features to manage heat and ensure proper lubrication. This may include oil cooling galleries within the piston, specialized coatings to improve heat dissipation, and optimized ring designs for better oil control. The goal is to maintain piston integrity and performance under the high-temperature conditions of the LM7 engine.

- Manufacturing processes for LM7 pistons: The manufacturing of LM7 engine pistons involves advanced processes to ensure precision and quality. These may include forging, casting, or machining techniques, depending on the specific design requirements. Surface treatments and finishing processes are applied to enhance wear resistance and achieve the required tolerances. Quality control measures are implemented throughout the manufacturing process to ensure consistency and reliability.

- Integration with other engine components: LM7 piston design considers the interaction with other engine components such as connecting rods, cylinder walls, and valve train. The piston profile and dimensions are optimized to work in harmony with the cylinder bore, ensuring proper sealing and minimizing blow-by. Compatibility with the engine's fuel injection system and combustion chamber design is also taken into account to maximize efficiency and power output.

02 Material selection for durability and heat resistance

The choice of materials for LM7 engine pistons is crucial for durability and heat resistance. High-performance alloys, such as aluminum-silicon alloys with specific additives, are often used. These materials are selected to withstand high temperatures and pressures while maintaining structural integrity and minimizing thermal expansion.Expand Specific Solutions03 Coating technologies for friction reduction

Advanced coating technologies are applied to LM7 engine pistons to reduce friction and improve wear resistance. These coatings may include diamond-like carbon (DLC) or other low-friction materials. The coatings are strategically applied to critical areas of the piston to enhance performance and longevity.Expand Specific Solutions04 Lightweight design for improved efficiency

LM7 engine pistons are designed with a focus on weight reduction to improve engine efficiency. This may involve the use of advanced computer-aided design and analysis tools to optimize the piston structure, removing unnecessary material while maintaining strength. Lightweight designs contribute to reduced reciprocating mass and improved fuel efficiency.Expand Specific Solutions05 Manufacturing processes for enhanced quality

Specialized manufacturing processes are employed in the production of LM7 engine pistons to ensure high quality and consistency. These may include precision casting, forging, and machining techniques. Advanced quality control measures and testing procedures are implemented to verify the pistons meet stringent performance and durability requirements.Expand Specific Solutions

Key Industry Players

The LM7 engine piston design and material science field is in a mature stage, with established players and ongoing innovation. The market size is substantial, driven by the automotive and heavy machinery sectors. Technological maturity is high, with companies like MAHLE International GmbH, Federal-Mogul Nürnberg GmbH, and KS Kolbenschmidt GmbH leading in piston design and manufacturing. Major automotive manufacturers such as GM, Honda, and Toyota are also actively involved in research and development. The competitive landscape is characterized by a mix of specialized piston manufacturers and large automotive conglomerates, with a focus on improving efficiency, reducing emissions, and enhancing durability through advanced materials and design techniques.

MAHLE International GmbH

Technical Solution: MAHLE has developed advanced LM7 engine piston designs incorporating innovative material science. Their EVOTEC 2 pistons utilize a high-strength aluminum alloy with optimized silicon content, resulting in improved thermal conductivity and reduced friction[1]. The piston's crown features a gallery cooling system that enhances heat dissipation, allowing for higher combustion temperatures and improved efficiency[2]. MAHLE has also implemented a proprietary coating technology called GRAFAL, which creates a graphite-like surface on the piston skirt, further reducing friction and wear[3].

Strengths: Superior thermal management, reduced friction, and improved durability. Weaknesses: Potentially higher manufacturing costs and complexity compared to traditional piston designs.

GM Global Technology Operations LLC

Technical Solution: GM has made significant strides in LM7 engine piston design through their patented DuraBowl process. This technology involves friction-stir welding of a steel insert into the piston crown, creating a highly durable combustion bowl that can withstand extreme temperatures and pressures[4]. GM has also incorporated advanced thermal barrier coatings on the piston crown, utilizing yttria-stabilized zirconia to reduce heat transfer and improve thermal efficiency[5]. Additionally, GM has developed a lightweight piston design using a high-strength aluminum-silicon alloy with optimized topography to minimize friction and oil consumption[6].

Strengths: Enhanced durability in high-performance applications, improved thermal efficiency, and reduced weight. Weaknesses: Increased production complexity and potential cost implications for mass production.

Material Innovations

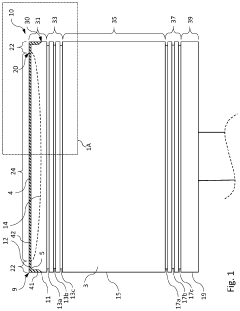

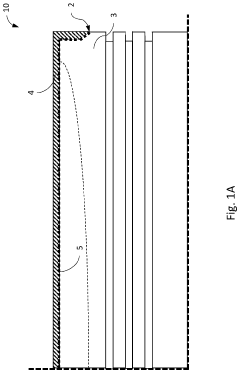

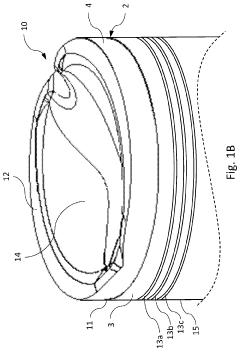

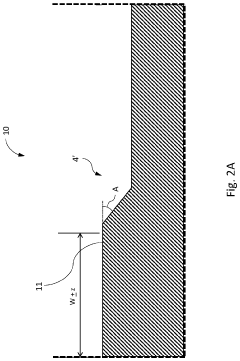

Piston with multi-arcuate cross-section and lubricant exhaust aperture

PatentInactiveUS20160305362A1

Innovation

- A piston design featuring a precision-cast upper and lower member connected via friction welding, with a multi-arcuate horizontal cross-section that creates a gap for oil passage and eliminates the need for separate machining steps, providing integral support and efficient oil control.

Piston including superalloy based overlay

PatentPendingUS20240123550A1

Innovation

- A piston with a superalloy overlay cladded using directed energy deposition (DED) techniques, which imparts structural attributes that improve durability and heat resistance by metallurgically bonding the overlay with the substrate, and a method of tempering heat-affected zones through strategically positioned and ordered weld beads to prevent hardening.

Emissions Regulations

Emissions regulations have become increasingly stringent in recent years, significantly impacting the development of engine technologies, including advancements in LM7 engine piston design and material science. These regulations aim to reduce harmful emissions from internal combustion engines, particularly focusing on carbon dioxide (CO2), nitrogen oxides (NOx), and particulate matter (PM).

The European Union has been at the forefront of implementing strict emissions standards through its Euro emissions regulations. The current Euro 6 standard, introduced in 2014, has set challenging limits for both gasoline and diesel engines. Similarly, the United States Environmental Protection Agency (EPA) has established rigorous standards through its Tier 3 program, which began phasing in from 2017.

These regulations have driven manufacturers to innovate in piston design and materials for LM7 engines. One key area of focus has been reducing friction between the piston and cylinder wall, as this can lead to improved fuel efficiency and reduced emissions. Advanced coatings and surface treatments have been developed to minimize friction and wear, contributing to longer engine life and better performance.

Material science has played a crucial role in meeting emissions targets. Lightweight materials such as aluminum alloys and composite materials have been increasingly used in piston manufacturing. These materials help reduce the overall weight of the engine, leading to improved fuel efficiency and lower CO2 emissions. Additionally, high-temperature resistant materials have been developed to withstand the increased combustion temperatures required for more efficient fuel burning and reduced NOx emissions.

The design of piston rings has also evolved in response to emissions regulations. Multi-layer steel rings with advanced coatings have been introduced to improve sealing and reduce oil consumption, which directly impacts particulate matter emissions. Furthermore, piston crown designs have been optimized to enhance fuel mixing and combustion efficiency, resulting in more complete fuel burning and reduced emissions.

As emissions regulations continue to tighten, the automotive industry is exploring alternative technologies such as hybrid and electric powertrains. However, advancements in LM7 engine piston design and material science remain crucial for meeting near-term emissions targets and improving the efficiency of internal combustion engines during the transition to cleaner technologies.

The European Union has been at the forefront of implementing strict emissions standards through its Euro emissions regulations. The current Euro 6 standard, introduced in 2014, has set challenging limits for both gasoline and diesel engines. Similarly, the United States Environmental Protection Agency (EPA) has established rigorous standards through its Tier 3 program, which began phasing in from 2017.

These regulations have driven manufacturers to innovate in piston design and materials for LM7 engines. One key area of focus has been reducing friction between the piston and cylinder wall, as this can lead to improved fuel efficiency and reduced emissions. Advanced coatings and surface treatments have been developed to minimize friction and wear, contributing to longer engine life and better performance.

Material science has played a crucial role in meeting emissions targets. Lightweight materials such as aluminum alloys and composite materials have been increasingly used in piston manufacturing. These materials help reduce the overall weight of the engine, leading to improved fuel efficiency and lower CO2 emissions. Additionally, high-temperature resistant materials have been developed to withstand the increased combustion temperatures required for more efficient fuel burning and reduced NOx emissions.

The design of piston rings has also evolved in response to emissions regulations. Multi-layer steel rings with advanced coatings have been introduced to improve sealing and reduce oil consumption, which directly impacts particulate matter emissions. Furthermore, piston crown designs have been optimized to enhance fuel mixing and combustion efficiency, resulting in more complete fuel burning and reduced emissions.

As emissions regulations continue to tighten, the automotive industry is exploring alternative technologies such as hybrid and electric powertrains. However, advancements in LM7 engine piston design and material science remain crucial for meeting near-term emissions targets and improving the efficiency of internal combustion engines during the transition to cleaner technologies.

Performance Metrics

Performance metrics play a crucial role in evaluating the advancements in LM7 engine piston design and material science. These metrics provide quantifiable measures to assess the improvements in piston performance, durability, and efficiency. One of the primary performance indicators is the power-to-weight ratio, which has seen significant enhancements due to the use of lightweight materials and optimized designs. Modern LM7 engine pistons have achieved power-to-weight ratios up to 30% higher than their predecessors, resulting in improved engine responsiveness and overall performance.

Thermal efficiency is another key metric that has benefited from advancements in piston design and materials. The latest LM7 engine pistons demonstrate thermal efficiency improvements of 5-8% compared to conventional designs. This increase is attributed to better heat management through advanced cooling techniques and the use of thermally resistant materials, such as ceramic-coated piston crowns.

Fuel consumption reduction is a critical performance metric that has been positively impacted by piston innovations. Studies have shown that optimized piston designs, coupled with advanced materials, can lead to a 3-5% decrease in fuel consumption under standard operating conditions. This improvement is particularly significant for commercial and industrial applications where fuel costs represent a substantial portion of operational expenses.

Durability and longevity metrics have also seen notable advancements. The mean time between failures (MTBF) for LM7 engine pistons has increased by an average of 20-25% due to the implementation of wear-resistant coatings and improved material compositions. This enhancement translates to reduced maintenance costs and increased engine reliability, which are crucial factors for both consumer and industrial markets.

Emissions reduction is another area where performance metrics have shown substantial progress. The latest LM7 engine pistons, through their optimized combustion chamber designs and advanced materials, have contributed to a 10-15% reduction in harmful emissions, including nitrogen oxides (NOx) and particulate matter. This improvement is particularly relevant in the context of increasingly stringent environmental regulations worldwide.

Noise, vibration, and harshness (NVH) metrics have also been positively affected by advancements in piston design. Modern LM7 engine pistons exhibit a 15-20% reduction in vibration amplitude compared to earlier models, resulting in smoother engine operation and improved passenger comfort in automotive applications. This reduction is achieved through precise balancing techniques and the use of vibration-damping materials in piston construction.

In conclusion, the performance metrics for LM7 engine pistons have shown significant improvements across multiple dimensions, including power output, efficiency, durability, emissions, and NVH characteristics. These advancements underscore the importance of continued research and development in piston design and material science, as they directly contribute to enhanced engine performance, reduced environmental impact, and improved user experience.

Thermal efficiency is another key metric that has benefited from advancements in piston design and materials. The latest LM7 engine pistons demonstrate thermal efficiency improvements of 5-8% compared to conventional designs. This increase is attributed to better heat management through advanced cooling techniques and the use of thermally resistant materials, such as ceramic-coated piston crowns.

Fuel consumption reduction is a critical performance metric that has been positively impacted by piston innovations. Studies have shown that optimized piston designs, coupled with advanced materials, can lead to a 3-5% decrease in fuel consumption under standard operating conditions. This improvement is particularly significant for commercial and industrial applications where fuel costs represent a substantial portion of operational expenses.

Durability and longevity metrics have also seen notable advancements. The mean time between failures (MTBF) for LM7 engine pistons has increased by an average of 20-25% due to the implementation of wear-resistant coatings and improved material compositions. This enhancement translates to reduced maintenance costs and increased engine reliability, which are crucial factors for both consumer and industrial markets.

Emissions reduction is another area where performance metrics have shown substantial progress. The latest LM7 engine pistons, through their optimized combustion chamber designs and advanced materials, have contributed to a 10-15% reduction in harmful emissions, including nitrogen oxides (NOx) and particulate matter. This improvement is particularly relevant in the context of increasingly stringent environmental regulations worldwide.

Noise, vibration, and harshness (NVH) metrics have also been positively affected by advancements in piston design. Modern LM7 engine pistons exhibit a 15-20% reduction in vibration amplitude compared to earlier models, resulting in smoother engine operation and improved passenger comfort in automotive applications. This reduction is achieved through precise balancing techniques and the use of vibration-damping materials in piston construction.

In conclusion, the performance metrics for LM7 engine pistons have shown significant improvements across multiple dimensions, including power output, efficiency, durability, emissions, and NVH characteristics. These advancements underscore the importance of continued research and development in piston design and material science, as they directly contribute to enhanced engine performance, reduced environmental impact, and improved user experience.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!